Home / Electrodes

Back

Reading time: 2 min

0

1592

The electrodes that will be discussed can easily be found in many retail outlets. Sellers prefer SSSI among all similar products.

There is more than one type of this brand; there are separate versions specialized for different metals.

What is the difference between these varieties? How to store them? We will answer these questions.

- general information

- Varieties

- Storage

- Results and conclusions

GOST 9466-75, certificates, passport

Technical requirements for all consumables are indicated in GOST 9466-75 . In addition to the above regulatory document, SSSI types must comply with: GOST 9467-75 (used for welding structural and heat-resistant steels), GOST 10051-75 (used for surfacing surfaces), GOST 10052-75 (used in welding technology for steels with special qualities and high degree of doping).

Additional protection of the Russian domestic market for welding materials is product certification . This document is issued for a certain time, and confirms the compliance of the parameters of the electrodes for work in certain industrial sectors (shipbuilding, oil and gas, energy and others).

The main coating of consumables contributes to the presence of harmful traces of fluorine in welding gases. Therefore, the registration certificate of the Ministry of Health, which is called an electrode passport , must indicate the level of the minimum permissible concentration of harmful impurities.

Features of SSSI calcination

It is important to heat the oven to 250-280 degrees, and also to ensure uniform calcination of the electrodes. This is achieved using special containers. It is forbidden to keep the electrodes in the oven for more than 4 hours, or to calcinate them more than three times. After calcination, the electrodes should be used within 8 hours

After this time, the event should be repeated.

If everything is done correctly and clearly, without violating technology, the quality of the seams will be at the highest level. The welder will receive a stable arc without the electrode sticking to the surface of the parts being welded.

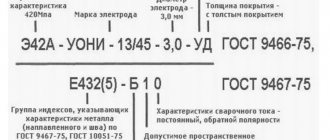

Decoding what the marking means

The abbreviation “UONI 13” stands for “universal coating of scientific institute number 13” (in Soviet times, many enterprises were assigned names in the form of a digital set for reasons of secrecy).

Addition from youtube.com user Angler 1:

Due to the saving of materials for coating, the second letter was lost... They were invented by Konstantin Vaclovich Petran, and not by a group of engineers, and in the original version they were much better, since the composition of the coating was cooler, and the fact that they are on sale now is not the same. Thanks to these electrodes, repairing equipment during World War II was carried out much easier and faster. Regarding fluorine, it is needed for the reaction of reducing hydrogen in the deposited metal with the formation of silicon fluoride 4.

The variety is indicated by the number after the fraction, for example, UONI 13/55, UONI 13/65, etc. Here “55” and “65” indicate the strength characteristics of the welding seam of a specific UONI electrode.

The packaging with consumables UONI 13/45 has the following inscription:

E42A – UONI – 13/45 – 2.0 – UD/E412(4) – B20.

Explanation of most designations can be found in GOST 9466-75.

The symbols E412(4) refer to the characteristics of the weld metal. Detailed explanation in GOST 9467-75.

Calcination before use

The electrode coating has a porous structure. In a damp room, it absorbs moisture and the consumable becomes unusable. Its coating crumbles and burns worse; the molten metal does not receive the necessary protection from oxidation.

For this reason, before cooking, the electrodes are subjected to the so-called. calcination.

This is heating in a special oven with controlled temperature and duration. Consumables are placed in forms that ensure a comprehensive and uniform supply of heat.

The manufacturer indicates the procedure parameters on the packaging and in the product description on the official website.

For SSSI electrodes they are:

- temperature: +250…+300˚С;

- time: 4 hours;

- multiplicity: no more than 3 times.

The heated electrodes are placed in a special sealed case with heat-insulated walls. You can make it yourself from a medium-diameter plastic pipe.

UONI coating does not contain organic components, so the temperature during calcination can be increased to 400˚C.

Outside the pencil case, the electrode remains dry for 8 hours. If it is not used up during this time, the procedure should be repeated, but no more than 3 times. Otherwise, the coating will crack and fall off.

We recommend reading Calculation of electrode consumption during welding

Advantages and disadvantages of the brand

The welding seam, made by a UONI consumable and a qualified specialist, has good strength characteristics , has excellent plasticity and has high impact strength. This is facilitated by the properties of the slag of the main coating.

The coating of the UUNI electrodes does not form large amounts of slag , so they can be used to make ceiling welds without any problems.

When welding alloyed materials, the necessary elements can be added to the main coating of UUI consumables to obtain special properties (corrosion resistance, thermal stability, heat resistance, cold resistance, and others). UONI surfacing electrodes create a surface with high wear resistance and protection from aggressive environments.

The ability of a weld to maintain strength characteristics at low temperatures creates conditions for use in the harsh climate of northern latitudes , for example in the Arctic.

Metal spatter during the welding process is below average compared to other brands of electrodes, which creates economic advantages.

Arc burning is not highly stable . The composition of the main coating contributes to its high ionization. Therefore, you should keep a short arc on a direct current of reverse polarity.

A high-quality seam is obtained on welding edges that are free of rust . The need to prepare the surfaces to be welded increases the labor intensity of the work.

Reviews

Reviews are left by welders of different qualification categories. Beginners, whose experience and skills do not allow them to evaluate the capabilities of SSSI brand electrodes, create negative content that is present in reviews. Some of them simply cannot form a normal welding seam with these consumables.

Qualified welders who are able to hold a stable arc when performing various welding jobs can objectively evaluate the advantages and disadvantages of the UONI brand electrodes described above. The main advantage is the ability to obtain a high-quality “strong” seam on critical structures. Of the disadvantages , the greatest inconvenience is the difficulty in performing such sometimes necessary tacks.

Why SSSI electrodes are most in demand

A distinctive feature of electrodes of this brand is that they can be used at low temperatures. The main problems arise when the seam cools, and when it cools quickly, cracks, shrinkage cavities and other defects may appear. Subsequently, they will lead to the fact that the welded parts will simply separate from each other.

High quality, as well as the absence of defects during hardening, is due to the fact that the chemical composition of the resulting seam assumes sufficiently high ductility and impact strength. This will extend the life of this connection in the future, especially if the welded parts are intended to be used in harsh and frosty climates.

It is precisely on the basis of these useful properties and qualities that SSNI electrodes have gained such high popularity among users.

It is worth noting that this connecting material is considered more professional than, for example, ANO. Therefore, it will be quite difficult for an ordinary person to work using this brand.

Kinds

Various UONI consumables are used for manual arc welding of metals and surfacing of surfaces to impart special mechanical properties.

The line of coated consumables for manual arc welding covers a wide range of materials : low carbon, carbon, low alloy, high alloy steels.

Surfacing consumables are used for surfacing cutting dies, wearing parts of machines, and sealing surfaces of metal structures.

Technical characteristics of welding electrodes UONI 13/55

Uoni 13 55 electrodes are ideal for the arc welding process and important parts made of carbon-containing and low-alloy metals, in particular those used in low-temperature areas. This type of product has proven itself to be excellent when connecting serious metal structures, where it is necessary for the weld to have a high level of ductility and impact toughness.

Popular brands: 13/55, 13/55A, 13-NZh, 13/75, 1350 and others

Let us immediately warn you that the “1350” brand indicated in the subtitle does not exist. However, in queries on the Internet, some users remove the fraction sign from the SSSI brand designation and operate with a continuous set of numbers. Such a request will not provide any necessary information. You are also unlikely to encounter SSSI 13/75. The need for its use is covered by the welding parameters of the electrodes 13/65 and 13/85.

UONI 13/45 electrodes are used for welding steel, castings and forgings; the resulting welds are distinguished by acceptable impact strength and ductility. Unlike other electrodes, they contain nickel and molybdenum.

The UONI 13/55 electrode is used for arc welding of T- and butt welds, surfaces made of high-carbon and low-alloy steel grades. They can be used in any plane , with the exception of the top-down direction when operating with direct current of reverse polarity. These electrodes have a base coating consisting of manganese, silicon, sulfur, phosphorus and carbon. The weld seam is formed with excellent resistance to crystallization cracking and low hydrogen content.

Electrode UONI 13/55A in terms of welding and technical characteristics is practically no different from the above brand . The peculiarity lies in high-quality welding at low temperatures, which is what actually causes its use in cold climates.

UONI 13/65 electrodes also have a base coating and are used for welding work on structures with increased requirements. This type of electrode can be used in almost any position in space using direct current of reverse polarity. The quality of the weld seam is practically no different from other types of SSSI electrodes.

UONI 13/85 electrodes are widely used in welding of structures made of high-strength and high-strength alloy steels. They can be used in any spatial position.

Electrode brand UONI 13-NZh, in addition to welding high-alloy steels, is used as a surfacing material for corrosion-resistant surfaces.

SSSI marking and explanation of the main parameters

To distinguish electrodes of even the same brand from each other, they came up with additional markings that determine their purpose. For example, what could the marking e50a or simply e55 mean? Having a special table at hand, you can easily determine what is what and how these names differ.

So, the letter “e” means that this is an electrode designed for manual arc welding. The number 50 is the limit of strength of the connection obtained when used correctly. The letter "A" is used to represent a seam. She says that the seam will be plastic and can easily withstand high impact loads.

This is followed by the name of the SSNI electrodes themselves, after which additional markings are placed, for example, 13-55 or 13-85. After this, the diameter of the steel core is indicated. It is worth noting that it is indicated with an accuracy of tenths of a millimeter. That is, if it’s a 5, then it’s 5.0, if it’s a 4, it’s 4.0, and so on.

At the very end there is a letter “U”, which indicates that this type of electrode is used for welding carbon steels.

What are they needed for, what are they welded, purpose, areas of application: for pipes and so on

The purpose is determined by the properties of the coating , which corresponds to the main coating. The composition of the coating gives the welding seam plasticity, high impact strength , and does not allow the formation of hot cracks. These qualities make it possible to use UONI electrodes for welding pipelines under pressure, welding metals with thick walls, structures experiencing fatigue stress, correcting casting defects, welding heat-resistant, corrosion-resistant, heat-resistant steels.

Description and scope of application

The consumable type is a steel rod with a protective coating. Under the influence of high temperature, the coating burns out and turns into a gas, separating the molten metal from the oxygen of the atmospheric air.

Most electrodes of this type are used for the manufacture of:

- lightly loaded structures;

- thin-walled pipes and low-pressure tanks.

It is allowed to carry out surfacing repairs with their help.

The scope of application depends on the brand of E42 electrodes. They are available in different designs, differing in diameter and composition of the protective coating.

Improved SSSI E42A

The only variety with basic coating.

It contains phosphorus compounds and carbides, prevents the appearance of hot cracks and gives the weld the following properties:

- plastic;

- impact strength.

These features are indicated by the index “A” in the marking.

They allow the use of E42A type electrodes for the manufacture of structures:

- placing high demands on reliability, including those experiencing alternating loads;

- operated at low temperatures.

UONI E42A electrodes contain phosphorus compounds and carbides.

Consumables are produced in the UONI 13/45 category and have the following distinctive features:

- They work only with direct current of reverse polarity (electrode-positive).

- They require cleaning the joined workpieces from rust, oil stains, dirt and water.

- Not suitable for welding in high humidity conditions.

- They are used economically due to the presence of iron powder in the coating, which compensates for the loss of metal due to evaporation and splashes.

They are capricious, so the welder requires experience and dexterity. Inverter-type welding machines are used; rectifiers are not capable of ensuring stable arc burning. The current should not be increased, as this has a bad effect on the quality of the seam.

Types of coating and diameters

In addition to the main coating, the following is used:

Sour. It contains oxides of iron, silicon and manganese

Such electrodes are used to weld with caution due to the high probability of so-called formation in the seam. hot microcracks (intergranular fractures). Rutile

Rutile is a mineral with large amounts of titanium dioxide. The consumables coated with it form a plastic seam, the level of deoxidation corresponding to semi-quiet steel. They tolerate high current well and do not allow the appearance of hot microcracks.

Acidic electrodes contain oxides of iron, silicon and manganese.

Acid and rutile electrodes of the E42 type are produced under many brands, for example OMA-2, VSTs-4 and 4M, Ogonyok, OZS-23, ANO-6, 6M, 17, etc. They cook well not only permanently, but also AC powered and suitable for beginners.

The diameter of E42 consumables is 2-12 mm. It is selected in accordance with the thickness of the smaller workpiece. This parameter determines the current strength. Thus, to weld corner No. 5 according to GOST 8509-93 with a flange thickness of 6 mm, an electrode of size 4 (mm) is required. The amperage is 120-200 A.

Explanation of markings

The letter “E” means “electrode for manual arc welding”, the number 42 is the temporary tensile strength, which is 42 kgf/sq. mm.

The full electrode marking also contains other data, for example E42A-UONI-13/45 SM-4.0-UD GOST 9467-60.

Explanation of product markings:

- SM-4.0 - made of welding wire with a diameter of 4 mm.

- U - intended for welding carbon steel.

- D - has a thick coating. Other options: S - medium, M - thin.

The product meets the requirements of GOST 9467-60.

Decoding the names of electrodes.

Technical characteristics, properties

Individual items from the UONI line of electrodes have their own special characteristics necessary to perform welding work in this specific area of application. However, the basic composition of the coating, which is the same for all types, determines the general basic properties :

- consumption for surfacing 1 kg of welding seam - 1.6 kg - 1.7 kg;

- deposition coefficient - 9.0 -9.5 g/A*hour;

- power supply requirement: DC, with reverse polarity;

- tensile strength - from 45 kgf/sq.mm to 85 kgf/sq.mm (depending on the brand).

Coating, composition

The protective layer of slag is formed by minerals from the coating composition of SSSI consumables: calcium and magnesium carbonates (marble, dolomite, magnesite), fluoride compounds (fluorspar). Otherwise, the base coating is called calcium fluoride. Some brands of UONI electrodes use a base coating with the addition of iron powder.

Appearance of electrodes UONI-13/55

Higher melting power allows for increased efficiency compared to electrodes with a standard base coating composition. However, application is limited to welding in the downward and horizontal position.

Types: E46, E46A and others

Various brands of electrodes are classified according to types, which indicate whether the consumable is used for manual arc welding (“E”) and differ in the strength characteristics of the deposited metal (numbers after the letter “E”). Several brands may belong to the same type.

For example, electrodes of the UONI 13/45 brand belong to type E46, brand UONI 13/55 to type E50A (“A” indicates increased requirements for ductility and impact strength), UONI 13/65 to type E60, UONI 13/85 to type E85A .

Diameters

Standard diameter sizes of produced UONI consumables: 2.0, 2.5, 3.0, 4.0 and 5.0 mm.

What current, polarity and more

The strength of the welding current is selected depending on the thickness of the workpieces , the corresponding diameter of the electrode rod and the spatial position of the seam.

It is important to weld with UUNI consumables in reverse polarity. If you use a straight line, the electrode rod will melt while the coating body remains intact, which will lead to arc breakage.

Video experiment with polarity

Chemical composition of weld metal

The composition of the deposited metal should correspond as closely as possible to the base metal . Therefore, there is a difference in the chemical composition of the UONI 13/55 and 13/85 electrodes used for welding different materials: the most significant difference is the absence of molybdenum in the deposited metal after welding UONI 13/55; it is present in the weld formed by the UONI 13/85 electrode .

Usage

Technological features for use differ from other types of welding consumables.

The main coating of the rod involves setting the DC mode with reverse polarity (minus to the holder cable, plus to ground). Using UONI electrodes, it is advisable to pre-heat them in an induction furnace with a temperature of 250-300 degrees.

Before the welding process, the edges of the workpieces and surfaces must be well prepared and cleaned of any types of contamination (corrosion, scale or machine oil).

Joints of rails or reinforcement must be welded in a horizontal position. However, if such an arrangement is not possible, a connection in any location of the seam (vertical or ceiling) is allowed.

To obtain a high-quality connection and to avoid unwelded areas in the body of the seam, you need to set the appropriate current strength. The table shows the main indicators of current strength, which it is advisable to set depending on the spatial position of the seams.

What can you add to the material in this article? Share your experience of using UONI welding consumables in your home workshop, how effective are they? Leave your comments in the discussion block. In construction and in the home workshop, such electrodes are perfect for creating various types of connections. However, in domestic conditions it is somewhat difficult to use UONI 13/55 consumables, since it is very difficult to organize their calcination at the required temperatures. In other cases, their use is indispensable, the welds are of high quality, they can be applied when repairing tanks, various sealed containers or pipelines.

Manufacturers: LEZ and others

The SSSI brand is widely distributed in Russia and neighboring countries. Most of the enterprises producing welding materials in these territories have consumables of the UONI brand in their assortment.

We list only a small part of them : LEZ (Losinoostrovsky Electrode Plant), SpetsElektrod (Moscow, St. Petersburg, Yekaterinburg), SZSM (Sudislavsky Welding Materials Plant, Kostroma), Oliver (Belarus), PlazmaTek (Ukraine ) and many others.

Manufacturers

Manufacturing technology and chemical composition may vary slightly, depending on the manufacturer, among which are the following large companies that guarantee high-quality materials:

Attention! When purchasing, be sure to request a certificate of compliance of electrodes with regulatory requirements, in particular GOST 9466-75, or a certificate of certification of welding materials in accordance with RD 03-613-03. They are issued by the Federal Agency for Technical Regulation, or certified by the National Welding Control Agency.

The difference, how they differ from other popular brands

Differences from ANO

At first glance, the possibility of welding with ANO brand electrodes using both alternating and direct current sources, in contrast to UONI, which welds only with direct current, is a significant technological disadvantage of the latter.

However, the tendency for increased slag formation by ANO consumables creates difficulties in forming a weld seam and requires great effort for cleaning. Welding with UONI electrodes does not leave much slag and you can safely finish the seam without stopping.

Differences from OZS

The difference in the composition of the coating (OZS - rutile, UUSI - basic) creates differences in the parameters of the welding process .

Versatility in choosing a current source (variable or constant), stable arc holding, the ability to weld through tacks, the ability to perform high-quality welding for a beginner - these main qualities inherent in the OZS electrode provide an advantage in manufacturability over UONI consumables.

However, the need to obtain a high-quality seam in critical structures forces us to choose SSSI consumables, despite the difficulties in use.

Calcination of electrodes

Each package must contain a quality certificate and instructions detailing the calcination procedure. If the instructions are not followed, both the quality of the welded products and the quality characteristics of the resulting seam will deteriorate. The calcination procedure must be carried out before using such devices. If they have not been used for 8 hours, then the calcination is repeated again. The same electrode must be processed no more than 3 times, and the total amount of time should not exceed 4 hours.

For high-quality calcination, such devices must first be placed in special boxes and only then in an oven. The operating temperature range of calcination furnaces is from 200 to 300 degrees. Only compliance with the specified conditions will make it possible to make the welding products work for a long time and prevent the formation of various defects during calcination.

We reviewed electrodes UONI 13/55

An important feature of their use is calcination. This will allow the welding electrode to work for quite a long time and avoid problems with various defects.

When purchasing such devices, it is necessary to have certificates indicating compliance with standards and technical specifications. Take good care of the electrodes and they will last a long time. Good luck with your purchase of welding devices!

Analogues: imported and Russian

Russian analogues that are closest to SSSI in terms of welding characteristics: ANO-TM; OZS-18; OZS-25; MTG-01K; MTG-02; TsU-5; TsU-5M; SE 08-00; TMU-21U; TMU-50; E138/50N.

Imported analogues: ESAB OK 48.00 and OK 48.04; FOX EV 50 (Austria); Phoenix K50 R (Austria); GARANT (Germany); LB-52U (Japan) and others.

Decoding the abbreviation Uoni

First, let's look at the name and find out where the name comes from. The decryption looks like this:

- U – Universal;

- O - Coating;

- N – Scientific;

- And - Institute.

- 13- №13

Those. this is a domestic development of a welding research institute, the name and number of which are fixed in the designation. The designation UONII is also found - the presence of an additional letter “I” indicates the Research Institute.

By the way! In the technical documentation, the correct designation is UONII; the requirements for this rule are specified in GOST 9466-75, but the name on the pack of electrodes may be UONI 13/55.

How to cook correctly, features of the welding process, theory and practice

Before welding with UUI electrodes, beginners should gain practical experience , for example, weld more often with electrodes coated with rutile coating.

Otherwise, apart from problems with arc ignition and sticking of the electrode, nothing good will happen when forming a seam. The skills of igniting an arc by lightly hitting the end of the electrode on the surface of the metal being welded or by striking the end, like igniting a match, are also acquired through practice. Important. A good seam can be obtained after calcining the electrodes (at a temperature of about 350°C for an hour) and on a surface free of rust.

Is it possible to cook on an inverter, grades for inverter welding

SSSI consumables are in perfect harmony with inverter technology . It is better to use inverter devices with a high no-load voltage ; there will be fewer problems with arc ignition at increased current strength.

Manual welding of a vertical seam

Welding a vertical seam is difficult because the molten mass, under the influence of gravity, tends to flow down . The welder's job is to prevent this from happening. A welder who has the skills to work with UONI brand electrodes will fulfill the main condition : he will keep a stable arc at a minimum distance from the end of the rod to the mirror of the weld pool.

Some technological features must

- you should choose the optimal ratio between the speed of movement of the electrode and the current load;

- The diameter of the consumable should fit into the width of the welding seam with a small gap. This will allow the consumable to move from side to side to reduce the possibility of melt drainage.

Are they suitable for cast iron?

We have practical experience in repairing cast iron parts (machinery vices, small cases and others) using electrodes of the UONI 13/55 brand. Welding of parts should be done in a heated state, and cooling after the end of the process should be as slow as possible.

Important. Heating should be maintained at around 300°C; the temperature cannot be raised any further; structural transformations occur in the cast iron, leading to cracks.

Why do they stick?

The following main causes of electrode sticking are identified:

- Using “raw” ones in the work (with a high percentage of moisture in the coating).

- The welding current is incorrectly selected. At a low value, the electrode does not ignite well, it needs to be increased.

- Human factor. Practical experience plays a decisive role here, which does not recommend installing the electrode vertically at right angles to the surface. An inclination of about 45° should be maintained and the degree of heating of the metal of the electrode rod and the weld pool itself should be taken into account.

Features of application

Each of the melting elements has its own niche of application; USI electrodes are used with the following parameters:

- The welding process occurs using reverse polarity current; the process is required by GOST.

- The seam eliminates the presence of gases and excess impurities by using a special coating of fluoride formations and various carbonates.

- The metal of the rod is used from low carbon steel compounds, which contributes to the reliability of the weld.

- Thanks to organic compounds, welding electrodes UONI 13/55 have low susceptibility to moisture.

- The design, made of low-alloy materials, avoids cracks and irregularities during the welding process.

Welding using UONI electrodes

The seam is not subject to aging or loss of fastening properties when exposed to temperature. Welding with UUNI electrodes should exclude the use of poorly cleaned materials, as they may be subject to corrosion in the future. The process occurs with a short arc, which avoids loss of connection quality. The main advantage over competitors is the result with the required hydrogen concentration, a connection resistant to the appearance of microcracks.

The chemical composition of materials and technology of use may vary depending on the manufacturer. Before purchasing, you need to inquire about compliance with the requirements and standards according to GOST, or the availability of a certificate of certification of welding materials.

Application of electrode welding in construction

Calcination procedure for welding electrodes UONI 13/55

To reduce the concentration of moisture and other unnecessary compounds in the coating - calcination by keeping it in an induction furnace. Each manufacturer of UONI 13/55 electrodes includes instructions for use and calcination of materials in the packaging. Neglecting the instructions is strictly prohibited, as this will result in a poor-quality connection.

Electrode welding principle

In situations where the instructions are not included or are damaged, it is necessary to follow the basic sequence of steps for calcination:

- The procedure is carried out immediately before use in the welding process. These actions are necessary for a high-quality result, a reliable seam and a stable burning of the welding arc.

- The maximum effect of calcination is 8 hours; if, after a specified period, the materials have not been used, the procedure is repeated again.

- The calcination time should not exceed four hours, and the permissible number of calcinations of the same UUSNI electrode is 3 times.

- The process uses a furnace heated to 250-280 degrees; for a uniform result, special molds are used, only then the melting elements are effectively calcined.

Storage conditions

Obtaining a high-quality result depends on the duration and storage conditions of the materials. Storage takes place in rooms with relative humidity up to 50%, without interacting with direct sunlight, air temperature of at least 12 degrees. Subject to all rules, standards and storage conditions of GOST 9466-75, the shelf life of materials can be unlimited.

Download GOST 9466-75

Electrode storage

Storage conditions

It should be stored in rooms where the relative air humidity does not exceed 50%, with a temperature of at least 12°C, and direct sunlight is not allowed.

Electrode storage container

Ensuring the above conditions will allow the use of SSSI consumables in work without indicating an expiration date.

Purpose of electrodes UONI 13 55

Welding electrodes UONI 13 55 are suitable for manual welding using an arc. Welding can be done in overhead, horizontal, lower, inclined positions, as well as in a vertical position from top to bottom. As mentioned above, they can weld low-alloy and carbon-containing metals. The welding seam is wear-resistant and protected from corrosion. Carbonates and fluoride compounds that make up the coating of the UONI electrode prevent the formation of hot cracks and give the weld plasticity and high impact strength. Therefore, this consumable is used when welding thick metal, correcting casting defects, and manufacturing parts that can withstand high pressure, low temperatures and long-term loads.

Electrodes Monolit UONI are widely used in shipbuilding.