The quality requirements for a submersible pump for a well are an order of magnitude higher than for a surface pump, because such a unit is located directly in the water, which is used as drinking water.

Everyone knows that high-quality equipment is quite expensive, but as it turns out, there is an exception to this rule.

The “black sheep” turned out to be the Aquarius deep pump: the technical characteristics of this device, as well as its quality, deserve the highest praise, and the cost is quite affordable.

Areas of application of the Aquarius downhole electric pump

Aquarius well pumps are designed for domestic use and can be used for the following purposes:

- for water intake from wells or wells when organizing individual water supply for houses;

- for lifting clean water from various types of reservoirs - swimming pools, ponds, lakes or rivers;

- when carrying out drainage work in case of flooding of basement rooms in houses (underground garages, cellars, basements);

- for watering plots of land with gardens and vegetable gardens, filling barrels and various types of containers with water.

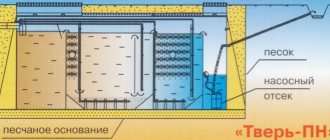

Rice. 2 Submersible pump for Aquarius well - design

Surface devices "Aquarius"

Surface pumps are those pumps that are used at a depth of only 10 m. Basically, these types of pumps are needed for watering the vegetable garden and front garden.

Convenient if there is a small body of water nearby. This pump cannot be immersed in water, because its internal systems are afraid of moisture, and if liquid gets inside the device, it will immediately fail.

Two main models that can most often be found outside the city:

The Aquarius model BCPE 1.2 has a productivity of 1.2 m3 per 1 second. The head of the water column is 80 m. It has several subtypes, and the weight of the product will depend on their choice: from 7 to 24 kg.

Device "Aquarius" BTsPE 1.6 with a performance indicator of 1.6 m3 per 1 second. The water pressure is stable at a height of 40 m. The weight of the device will also depend on the specific variety.

Operating principle and design of the Aquarius electric pump

The electric pump is classified as a centrifugal model, in which water is drawn through an inlet located in the center of the impeller axis. The liquid entering inside is thrown by curved blades to the edge of the working chamber, and due to centrifugal force is pushed out through the outlet pipe in the side of the housing.

The pump operates due to the rotation of an electric motor and is structurally made of two parts: electric and pumping. The first has an asynchronous electric motor and an external control unit attached to a cord with a plug.

The electric motor includes a stator and a rotor mounted on end bearings and in a bath of environmentally friendly oil.

The pumping part includes a strainer in the middle part of the device, a stage block with centrifugal impellers, cylindrical rings and petal outlets driven by the electric motor shaft, and an outlet pipe.

Rice. 3 BPCE 0.32, BPCE 0.5 deep pump for well Aquarius characteristics

Device and mechanism of action

The Aquarius well pump is a practical, productive and at the same time quite simple to install and maintain unit, characterized by reliability and durability in operation.

Its design includes the following elements:

— pumping part of a multistage type;

- single-phase electric motor.

Under the device body there is a drive shaft with blades, impellers and drive-type rings. All parts are fixed using a cap with internal threads.

When the pump starts, the impellers begin to move, creating a centrifugal force that pumps water to fill the inside of the unit.

The motor part of the pump includes a stator, a rotor and two ball bearings that move in an oily environment. The engine operation is controlled by the Thermik system, which protects it from overheating when operating under critical load conditions.

The unit is supplied with a submersible cord for fastening

The material of the unit body is stainless steel, the impeller is noryl. There is a capacitor box on the power cord.

Design features of electric pumps Aquarius

The Aquarius submersible pump for water intake has the following design features:

- The unit consists of modules: a unit with an electric motor in the lower part and a block of impellers in the upper half; a mesh filter is installed in the middle of the housing.

- The body of the electric pump is made of stainless steel; a brass cover with a 1-inch thread inside and two side lugs for attaching a suspension cable is installed at the top.

- The unit has an external capacitor module with a power cable and a plug with a grounding contact (electrical protection class I); to protect against overheating, a German Thermik thermal relay is built into the electric pump winding.

- There is no built-in check valve in the pump body; when connecting the pipeline, it is installed in the adapter coupling at the outlet of the unit.

Rice. 4 Pressure parameters BPCE 0.32, BPCE 0.5

Downhole tools "Vodoley"

Borehole pumps are of submersible and surface type . The submersible device differs in that it is installed directly in the well itself. The submersible device is located there the entire time it is being used. If you need repairs or need to update the pump, you will have to remove it from the well.

Surface models are much more convenient to use. Their repair and maintenance are quite easy, since they are always available for inspection. However, with many positive characteristics, they also have a number of disadvantages in technical terms. The convenience of borehole pumps is that you can install and operate them in real time with your own hands.

Downhole devices include such models as:

- devices "Aquarius" 1 "BTsPE";

- products "Aquarius" 3;

- devices "Aquarius" 16.

Characteristics of the models:

The Aquarius device BTsPE 0.32 has an operating capacity of 0.32 m3 per second, in 1 hour this is as much as 3.6 m3 of water. The water pressure is constant at a height of 40 m.

The product “Aquarius” BTsPE 032-32U will weigh only 10.5 kg, and includes a single-phase electric motor. In addition to supplying high-quality drinking water, it can easily cope with watering a summer cottage. The liquid pressure height will reach 32 meters, and the working productivity per hour will be 1.2 m3.

The “Aquarius” BTsPE 0.5 device is most often used in wells with a diameter of 12 cm or more. It has a fairly powerful engine that will provide water pressure to a given height.

The most popular model is the “Aquarius” product BCPE U 05-32. Selected for a well with a diameter of less than 11 cm. Constant water pressure is up to 48 m. Operating capacity is 3.6 liters per hour.

Water pump “Aquarius” BTsPE 0.32-63 . It has a fairly powerful motor that will provide water pressure up to 63 m.

Pump “Aquarius” 3 is the easiest to use . It has a system for automatically shutting down the device in any possible emergency situation. Can only be used with clean water. It weighs 4 kg, has a plastic body and a rubber piston. Treated with a compound, which means that the equipment becomes completely waterproof. Suitable for not very deep wells or shallow reservoirs. The manufacturer offers a remote control to control the device.

Deep pumps Aquarius for wells technical characteristics

Aquarius deep pumps, designed for water supply to country houses, have the following operational and technical parameters:

- Single-phase supply voltage is 220 V for all models; the device remains operational in the range from 198 to 242 V.

- The pumps are designed for pumping clean water with a temperature of no more than 35 C., mineralization should not exceed 1500 g/m. cube

- The nominal supply volume, depending on the model, ranges from 1.2 to 5.8 m3/h.

- The rated motor power of different brands ranges from 440 to 2820 W.

- The depth of immersion of the unit under water is up to 10 m.

- The pressure of electric pumps at nominal flow is 14 - 140 meters.

- The outer diameter of the pump is 96 mm, BPTsE can operate in wells larger than 120 mm, BPTsE models are designed for operation in wells or installation in wells from 100 mm.

A quick guide to choosing an electric pump

Before choosing an Aquarius submersible electric pump, you must have a well and know its characteristics, in addition, for reliable and durable operation of the pump, the following conditions are necessary:

— the flow rate of the well must be greater than the productivity of the selected pump, since the well silts up over time and its flow rate may decrease; — the electrical network must provide normal voltage at the pump plug; it is advisable to immediately lay a power cable (extension cord) with a cross-section of 2.5 mm2; — the well casing pipe must have an internal diameter of 120 mm or more for BTsPE series pumps and at least 100 mm for BTsPEU series pumps, in addition, the casing pipe must not have bends or internal seams that would prevent the pump from passing through it. — the Aquarius electric pump must be completely immersed in water before switching on, according to the attached instructions. In other words, for uninterrupted water supply, there must be enough water in the well, a normal voltage of 220V must be supplied to the well, the electric pump must pass freely into the casing and be guaranteed to be submerged under water.

Types of Aquarius pumps

The Ukrainian manufacturer produces pumping equipment for water intake from depths of several categories; household submersible electric pumps have the following letter marking:

- BTsPE - household centrifugal submersible electric pumps, consist of 4 series of different capacities with a designated nominal flow volume: BTsPE 0.32, BTsPE 0.5, BTsPE 1.2, BTsPE 1.6.

- NVP is a screw submersible pump, the manufacturer supplies to the market only one model of the NVP series - NVP 0.32;

- BV are household vibrating electric pumps with two check valves, well known to consumers under the brand names Alpheus, Orion and Poseidon.

The original Ukrainian Aquarius vibration electric pumps, which are visually different from their analogues by their two-valve design, should not be confused with the Russian Aquarius-3, produced in Kirov at the Lepse plant.

Rice. 6 Electric pumps BPCE 1.2, BPCE 1.6 – technical characteristics

Marking of electric pumps Aquarius

Household centrifugal submersible electric pumps BCPE are marked with the following symbols:

- The first digit indicates the nominal volume of fluid supplied by the device in cubic meters per second divided by 1000. To convert this designation to the more common cubic meters per hour, the figure is multiplied by 36.

- The second digital designation corresponds to the pressure on the pressure characteristics graph at the specified nominal flow rate.

- Some modifications of electric pumps have the symbol U at the end - in this case, BCPEU means an improved model with a power cable built into the housing, coming out from the top (in older models it was located on the side in a recess in the housing and was covered with a protective cover).

Rice. 7 BPCE 1.6, BPCE 1.2 – pressure characteristics

The lineup

Household pumps Aquarius are available in several varieties.

They can be identified by their markings:

- BC: surface pumps;

- BCPE: submersible pumps for clean water;

- BCPD: submersible drainage pumps.

The most popular models are:

Series BCPE 0.5 (Euro-1)

The performance of the youngest model in the line, weighing 7.7 kg, is 0.5 l/s or 1.8 cubic meters. m/h. The motor of such a pump has a power of 0.4 kW. The most productive representative of the series, with a power of 1.9 kW, is capable of pumping up to 3.6 cubic meters. m/h (1 l/s). Its weight is 25 kg.

The maximum pressure for different models varies from 12 to 100 m.v.st.

Installation in wells with a diameter of 110 mm is allowed.

In this group there is a model BCPEU 0.5 (Euro-1), which is distinguished by a top cable connection (for other models it is connected from the side). This design allows the unit to be placed in wells with a diameter of 100 mm. The pump weighs 17.8 kg, power consumption is 1.2 kW.

BCPE 1.2 (Euro-3)

They are used to supply autonomous water supply systems with high flow rates, for example, in networks of small neighborhoods.

The performance of the 0.75 kW model is 4.3 cubic meters. m/h (1.2 l/s); with a power of 2.85 kW, productivity increases to 9.6 cubic meters. m/h (2.66 l/s).

The weight of models within the line varies from 9 to 24.3 kg.

The maximum pressure varies from 16 to 100 m.w.st.

BCPE 0.32

Devices of this series are suitable for owners of wells with low flow rate, in which there is no point in installing a powerful and, accordingly, expensive pump. The units are quite light (weight no more than 9 kg), but the minimum well diameter is still 110 mm.

The model with the lowest power (0.4 kW) is capable of pumping 1.2 cubic meters. m of liquid per hour (0.32 l/s); the maximum productivity is 3 cubic meters. m/h or 0.85 l/s.

The maximum pressure ranges from 25 to 36 m.w.st.

The cost of Aquarius pumps of the most popular series - BTsPE 0.5 (Euro-1) varies from 7.1 to 16.2 thousand rubles.

Installation and connection of Aquarius pumps

Like all submersible borehole electric pumps for individual water supply, BCPE is designed to operate as part of a water supply installation complete with the main components of standard pumping stations: a hydraulic accumulator, a dry-running and pressure relay, a pressure gauge, and a filter.

Before putting the unit into operation, perform the following steps:

- connect the pump using a socket to the electrical network, making sure that the power cable is intact;

- connect the outlet pipe of the electric pump to the pressure pipeline using adapter couplings, the pipe should have a diameter of 1 inch;

- tie the cable to the ears of the top cover of the unit, using insulating tape or plastic clamps, connect the water pipe, cable and electrical cable together in increments of 1 - 2 meters, avoiding tension on the latter;

- lower the electric pump into the well, securing the cable and pipe to the head, while the depth of its immersion under water should not exceed 10 meters with a distance to the bottom of 40 cm.

During operation, it is necessary to ensure that the electric pump is completely lowered into the water and that the power cable is unwound.

Installation Rules

The Aquarius pump for wells and boreholes of the BTsPE brand has certain installation rules. And they must be strictly adhered to. You need to start on the surface.

Preparation

First, a pipe is attached to the device. If the device itself will be used only for watering, then a hose must be attached to it.

As for the diameter of the pipe, it must correspond to the diameter of the outlet pipe. It is not recommended to use less, because narrowing the pipeline means reducing the technical characteristics of the unit.

Attention! There is no built-in check valve in the pump design, so it is purchased as a separate unit and installed in the supply pipeline. Installation location: 1 m up from the pump. It is optimal if the check valve design has a brass seat.

Pump assembly rules

All pipe connections must be made using a threaded coupling. This applies to both the connection to the pump and the connection to the well head. It is best to attach the power supply cable to the pipe with plastic clamps. This will not only prevent damage to the cable from mechanical stress during the installation process, but will also facilitate the process of immersing the pump in a well or well. You should also know that you cannot lower or lift the device by the cable.

Now the nylon torso, which comes complete with the equipment, is attached to the eyes of the Aquarius well pump. In principle, it can be replaced with a stainless steel cable with a diameter of 3 mm, if there is doubt that the first will withstand the weight of the device.

Installation features

So, if all preparations on the surface are completed, you can proceed to the dive. It is necessary to carefully lower the pump into the well, holding it by the cable, which is tied to the head with its free end. The descent itself is carried out evenly, that is, both the cable with the pipe and the cable are carried out simultaneously.

As for the installation depth, the manufacturer recommends not lowering the unit below 0.4 m to the bottom. True, this is a recommendation value, because there are different wells: new and old. For example, in old wells the bottom is heavily silted, so it is better not to lower the pump below 1 m to the bottom, because there is always a possibility that silt deposits will get into the pumping device itself.

Pumping station Aquarius

And one last thing. This applies to the Aquarius pumping station. It should be noted that the manufacturer today offers ready-made pumping stations equipped with a pump, hydraulic accumulator, check valve and coarse filter. The complete set must include shut-off valves and an automation unit. That is, this is a ready-made local water supply network with water intake from a well or well. It is clear that the kit will also have to purchase a pipe that will connect all the elements of the water supply system.

Of course, the choice here will also be based on the Aquarius pump. It will be the heart of the station. And all other elements of the system will be selected for it. Therefore, it is very important to correctly select the unit itself for the conditions of its future operation.

Maintenance and storage of the Aquarius deep pump

Electric pumps do not require special maintenance and can operate for a long time if the operating rules are followed. Before storage, the unit is removed from the well, the remaining water is drained from the pump unit and dried; this baby should be in a dry and clean room with a temperature of 5 - 35 C. at a distance of at least 1 meter from the heating radiators. It is not allowed to be in direct sunlight, in a room with aggressive gases or vapors of acids and alkalis.

Rice. 8 Screw pump NVP - parameters

Device depending on the type of pump

The submersible device looks like an oblong capsule with a small diameter - only 10-16 cm. Other models from the Aquarius 0.32 line may have a smaller diameter.

A submersible pump will work by rotating or by forcing water inside the housing. The water is then pumped up the pipe and into the system. They produce products from stainless steel, thermoplastic and other alloys.

It is completely normal for a submersible species to remain in the well for many months. These devices can pump out up to 5 liters of water per second and produce a water pressure of up to 50-100 m.

Submersible models are divided into a number of subtypes. Based on the principle of operation, they are divided into centrifugal and vortex models, screw and vibration products. The first 3 types are very similar to each other. They differ only in the way they raise the liquid:

- Centrifugal devices “Aquarius” use centrifugal forces of rotation of a number of small rotors at once. The rotors pump water, then launch it into the pipes in the form of a spiral and actively inject it into the hose. This is the most popular variety of this type of product.

- A vortex submersible device creates a regular vortex in the chamber, which helps raise the liquid to a certain level. In terms of pressure they are often equal to or slightly inferior to centrifugal devices, but in terms of pressure they are much ahead.

- Screw devices use powerful but primitive-looking screws that pump liquid and deliver it to the top.

A vibration device is a model of a completely different type. Even the vibration product looks different than other designs. Its body is larger and not elongated. It works due to the rotation of a special tool engine inside the device - this causes multi-frequency vibration. The effect of vibration in the chamber will be transmitted to the water and stimulate its flow. This way it is possible to raise the water to all the required levels without using augers, impellers, screws or anything like that.

The vibration product is inferior to the first three varieties in terms of efficiency, but it is much cheaper, more unpretentious in operation and will not break when in contact with dirty liquid.

By type of immersion, devices are divided into:

- standard;

- deep.

Conventional models dive to a level of up to 50 m. Well, the deep versions of “Aquarius” can operate at levels from 60-80 m depth or slightly lower.

Surface models do not have many subtypes and are used only for servicing small wells. The problem is that with a pressure of 25-30 m, they can pump liquid from a depth of up to 10 m. But not every well can have such a high level. Consumer reviews indicate that the surface-type pump is extremely reliable and easy to use, but its technical characteristics and serious operating noise are negative qualities.

It is ideal for servicing a country house or a small cottage with an excellent level of aquifers.

Source: stroy-podskazka.ru

Possible breakdowns and nuances of repair of Aquarius pumps

The main reasons for the failure of the BCPE electric pump are improper installation in the well, operation of the unit in contaminated water and physical wear of parts over time. Also, during long-term operation, the unit requires periodic cleaning; the operation of the pump should be regularly checked to ensure compliance with technical specifications.

To carry out work on replacing worn parts, disassemble the pump with your own hands using the following sequence of actions:

- Disconnects the device from the electrical network, removes it from the well and disconnects the pressure pipe and cable.

- Remove the mesh filter in the middle part and unscrew the four hex head bolts with a 10 mm wrench connecting the electrical and pump parts of the device.

- The block with impellers is fixed in the housing with a locking ring; to remove it, a part of the pump is compressed from above and below using a jack or a press, after which the locking ring is removed and the stages with impellers, guide rings and washers are removed. They can be cleaned or replaced with new parts purchased from a service center.

- To disassemble the block with the electric motor, unscrew the screws at the bottom of the pump, remove the cover and drain the oil, after which the electric motor can be removed to replace the end bearings.

Start-up and maintenance

After the pump is in the well, the first start is made:

- it is necessary to close the valve on the pipeline,

- supply power to the pump (1 phase, 220 V, 50 Hz),

- Slowly open the valve.

If the water from the pressure pipeline comes out clean, then it is advisable to leave the pump running for a while and then turn it off. Then you need to connect the pump to the existing water supply system of the house.

If the pump begins to supply cloudy or silted water, the following measures must be taken:

- leaving it on, close the valve and leave the pump running for a while;

- wait for clean water.

Otherwise, all the mechanical impurities that remain in the pressure pipe and the pump structure may jam the hydraulic part or check valve.

If it is necessary to remove the pump from the well and send it for long-term storage, it is recommended to rinse it with water and then dry it thoroughly. At the time of the secondary immersion, the pump should be left in the well for some time, and then started according to the above scheme.

Cleaning and repairing minor faults

If the deep-well pump begins to work unsatisfactorily and its hydraulic part does not rotate, it means that the impellers or the internal mesh of the pump are clogged with fine sand or silt.

There is no internal dirt filter included with the pump!

To clean the wheels or screen, you need to disassemble the pump:

- Remove the protective mesh. On newer models, pry the clamp with a screwdriver and press on its middle; on older models, unscrew the screw connections.

- Remove the cable sleeve.

- Using a wrench, unscrew the bolted connections and detach the motor from the hydraulic part of the pump.

- Remove the couplings.

- Turn the shaft with a wrench and rinse the pump part, removing mechanical impurities.

If the shaft begins to turn easily, it is necessary to reassemble the pump in the reverse order.

If the impellers are jammed or damaged, it is necessary to disassemble the pump part. But only specialists from an authorized service center can perform such work while maintaining the warranty.

Procedure for repairing minor faults:

- clamp the pump housing from above and below, rest against the brass part;

- remove the stopper ring;

- remove the impellers;

- remove the stop cover with the bearing;

- try to remove the jam;

- Reassemble in reverse order.

However, service centers use a press machine when assembling/disassembling the pump, so repairing the pump yourself can be difficult.

How to choose the right pump for a well Aquarius

The selection and installation of an Aquarius borehole pump must take into account the characteristics of the well (its flow rate must ensure the required volume of water intake) and the distance to the source of water consumption; we will consider the selection of a device with the required parameters using the following example.

It is necessary to provide water to a family of 3 people, the distance to the house is 30 m, the maximum distance to the water surface in the well (dynamic water level, determined when the electric pump is running) is 20 m.

When deciding how to determine water consumption for a family of three, you can use average data; in most cases it is 1.8 cubic meters per hour.

To determine the water pressure, it is necessary to sum up the length of the vertical and horizontal sections, taking into account losses, as well as the operating pressure in the system, converted to meters. If the pressure pipeline has a diameter of 1 inch, a meter of vertical water column is equal to 10 m of horizontal section, the total losses in the line are taken equal to 20% (when calculating, the pressure in the pipes is multiplied by 1.2). The electric pump is lowered 2 meters below the dynamic level; for the correct operation of the automation in the control system, it is necessary to create a maximum pressure of about 3 bar in the line, which corresponds to 30 meters of a vertical water column. As a result, we obtain the following formula for calculating the total head H in vertical column meters:

H = (22 + 30/10) x 1.2 + 30 = 60 meters.

To select the appropriate electric pump model, graphs of pressure characteristics are used, from which it can be seen that the indicated flow is 1.8 m3/h. and a nominal head of 60 m corresponds to the model BTsPE 0.5 63U.

Rice. 10 Electric pump Aquarius as part of a water supply installation

Installation of pumps in a well - nuances of the process

First you need to decide on the type of pressure pipeline of the autonomous water supply system and carry out the basic preparatory work at the top:

- A flexible watering hose is suitable only for domestic purposes: watering the garden and filling water storage containers, while you can easily and often remove the pump;

- A plastic (HDPE) or metal pipeline is suitable for permanent stationary operation, in which the pump will be constantly lowered into the well.

The diameter of the pipeline must be selected based on the calculated flow rate of the pump, and a prerequisite is the selection according to the internal diameter of the pipe, and not the outer one.

For domestic purposes, a 32 mm HDPE pipe with an internal diameter of about 25 mm is usually used, which is convenient to connect to 0.5 series pumps, which have an outlet pressure pipe of also 25 mm.

A brass check valve must be installed on the pump pressure connection. If the pump is installed at a shallow depth (up to three meters from the surface of the earth), then the valve can be located on the pressure pipeline.

The well pump must be connected to the pipeline using a crimp or brass coupling of the appropriate diameter. Depending on the models used and the diameter of the pipeline, the coupling cross-section can be from 1 inch to 1 ¼.

The head must be similarly connected to the upper end of the pipe.

The power supply cable must be secured to the pipe using special clamps. This will greatly facilitate lifting the pump from the well and protect the cable from damage. The main thing to remember is that you cannot lift the pump by the cable, so it must be mounted on the pipe with slight slack to reduce the load.

A safety stainless cable with a cross-section of 3 mm must be attached to the eye of the pumping part and connected to the well head. It is acceptable, but not advisable, to use a nylon cable.

After this work, it is necessary to cut the pipe and connect its end to the head using transition fittings. Attach the head to the casing pipe.

Advantages of Aquarius brand pumps

Aquarius electric pumps have earned positive reviews from many consumers, having the following advantages and features:

- The electric pump is made of high-quality parts (stainless steel, brass, high-strength plastic), ensuring a long service life.

- The unit has high maintainability and can be easily disassembled with your own hands using simple household tools.

- Electric pumps are unpretentious to operating conditions and can operate for a long time with slightly contaminated water.

- The pumps have an internal winding with thermal protection against overheating and a long built-in cable with a remote capacitor unit - these factors significantly increase the reliability of the electrical part.

- The Aquarius deep pump has an optimal balance of price and quality, its cost depends on the modification and amounts to 100 - 300 USD, which is several times lower than expensive foreign analogues (Grundfos, Pedrollo, Speroni) and comparable in price to Russian and Chinese models.

- The manufacturer indicates a high service life of BCPE electric pumps, reaching up to 10 years with a minimum time to failure of 10,000 hours; the warranty period established for the electric pump is 1.5 years.

Rice. 11 Deep submersible pump for the Aquarius well - installation in a water source

Ukrainian-made Aquarius electric pumps at the same cost, unlike their Russian and Chinese counterparts, are considered higher quality devices that can last at least 10 years without repair. The units have good maintainability; you can easily clean the electric pump with your own hands, repair minor breakdowns and replace the most frequently failing parts (bearings, impellers).

Pros of the Aquarius line

Among the advantages of the Aquarius line of devices are:

- economical energy consumption;

- high productivity;

- low noise figure;

- wear resistance of parts made of stainless steel, brass and food-safe plastic;

- possibility of warranty or self-repair;

- light weight and dimensions corresponding to the diameter of the well;

- complete set allowing you to begin installation immediately.

Don’t forget about IEC 335-1 (international safety standard), warranty service for one and a half years and the ability to purchase spare parts from the manufacturer if repairs are necessary.

In terms of technical characteristics, the modifications are comparable to foreign analogues PEDROLLO and GRUNDFOS. Cost depending on the model – from 1800 rubles. up to 27,400 rub.

Features of the deep-well pump device

All downhole submersible models Aquarius have a similar structure.

The main parts are:

- multi-stage pumping sector;

- electric motor separated by a filter;

- capacitor box located outside.

Hidden under the body is a pumping unit - a monolithic box with rotating impellers and a drive.

It is the dimensions of the impeller that are responsible for one of the main characteristics of the unit - productivity. The larger its diameter, the larger the portion of water supplied over a certain period of time.

All parts are securely fastened with a screw-threaded lid. It is also the place where the cable is fixed, one of the pump mounting elements inside the well.

The motor, using a rotor-stator combination and bearings, drives the apparatus. It is filled with oil. The capacitors and electrical cable are enclosed in a condensation box.

To ensure that the equipment does not fail under force majeure circumstances, for example, during rapid drying, automatic protection made in Germany is provided.

Operation monitoring and control is carried out using a remote device. Knowledge of the structure of the Aquarius pump will help with its repair.

Vibration pumps

Most summer residents and village residents choose vibration-type devices to collect water from wells, boreholes, tanks, and surface reservoirs. They have two significant advantages over devices with a different operating principle: low price and low electricity consumption.

The two-valve pump “Aquarius” BV-0.14-63-U5 with vibration has the following technical characteristics:

- submersible type device with a two-valve liquid intake system;

- the height of the water column reaches 63 m;

- used for operation in wells and wells at a depth of no more than 5 m;

- operated in a vertical position;

- The diameter of the well should be from 9 cm.

Model "Poseidon" pump "Aquarius":

- the equipment itself weighs 3.8 kg and is quite compact in size;

- no need to initially fill with water;

- made from quality materials;

- unpretentious at work.

The vibration device “Aquarius Poseidon” (BV-0.16-63-U5) with a water intake system of four valves is suitable for wells and various types of wells if their diameter starts from 12 cm and their depth reaches 100 meters.

Characteristics:

- this model is considered the best for supplying water for drinking and for watering the garden;

- refers to centrifugal well products, the use of which will not lead to erosion of the well;

- equipped with a water cooling system;

- small size, which is extremely important for a surface-type pump;

- does not depend on air temperature;

- The pump has an automatic complete shutdown system in case of an accident.

Source: stroy-podskazka.ru

How to operate and install

Both types of pump are mounted in the well using a safety cable or rope (suspension). One end of the insurance is threaded into a special eyelet on the body, and the second is securely attached to the well head.

Any owner can easily install the unit. Installation includes several successive steps:

Using a rope with a sinker, the depth of the well is measured and the height of the pump is determined. The device is located 0.5-1 meter from the bottom to avoid silting of the pump chamber or clogging of the impeller.

Installation begins by tying a safety rope around the eyes located at the top of the unit.

A non-return valve is screwed into the pump nozzle to prevent accidental drainage of water from the system.

Then the water supply is connected. For this, a three-quarter size hose made of polymer or a metal-plastic pipe is used. A flexible garden hose can be used for watering. But providing year-round water supply requires the installation of a metal-plastic pipe. The pipe is attached with a coupling to a check valve already installed on the unit pipe.

The length of the pipe or hose is determined by the specific use. The irrigation hose can be of any length at the owner's request. The pipeline is laid to the point where the adapter is attached, which ensures the connection of the well to the main pipeline.

Using special plastic clips or insulating tape, the power cable is securely attached to the pipe or hose.

The unit is lowered using a safety rope. Do not hold on to the cable! Violation of this rule usually leads to a violation of the waterproofing of the wire or its breakage. For convenience, a small tripod with a block is installed above the head, through which the cable is gradually pulled down. It is recommended to mark the desired diving depth in advance using a marker.

Power Connection and Testing

Remember that the operation of the Aquarius pump is possible only if the voltage parameters are observed - 220 V. With other indicators, normal operation of the equipment is not guaranteed. If the network characteristics do not meet the manufacturer's requirements, connect a voltage stabilizer.

After immersing the pump in the well, make sure that its body is completely submerged in water. The power cord should not be taut like a string. Only after checking the fulfilled conditions, proceed to connecting the Aquarius pump to the power source.

If the device began pumping water and turned off only when the automation was triggered, everything was done correctly.

To ensure uninterrupted operation of the equipment, preventive disassembly is carried out. If deficiencies are noticed after inspection, they must be eliminated. For example, you can replace the bearings (if the running is tight), change the oil, check the motor winding.

Source: sovet-ingenera.com

Very useful tips

High purity vaseline oil is used as a lubricant in Aquarius pumps.

This composition is used in pharmacology for the manufacture of ointments. In this case, the manufacturer hides the name of the company supplying this product.

In total, the Aquarius pump engine contains about half a liter of Vaseline oil. But to restore the lubrication, it is better to contact the manufacturer to avoid contamination of the well with technical oils. Authorized service centers usually provide this service without any problems.

If the Aquarius pump is intended to be used in an automated water supply system, a check valve must be installed. The device is not equipped with this element; it will have to be purchased separately.

It is recommended to give preference to a valve equipped with a brass flapper. Such devices are characterized by increased wear resistance and a longer service life.

If the pump will only be used for irrigation, there is no need to purchase and install a check valve. In this case, you can block the flow of water into the hose. In this case, the pump will operate at idle speed; the device is designed for such loads.

If there is a need to replace the capacitor, it will be useful to consider the following information. “Aquarius” pumps use devices with a capacity of 14-80 uF, designed for 400 V. This is a bipolar dry capacitor made in the Czech Republic, the dielectric component of the device is polypropylene.

Depending on the model or time of manufacture of the pump, a capacitor from TESLA, AEG, Gidra, etc. may be installed in it. Models with both wired contacts and petal contacts were used.

All this allows us to conclude that similar models from any manufacturer are suitable for Aquarius pumps if their characteristics meet the specified technical requirements.

Water pipes in a self-contained water supply system usually use either half-inch or three-quarters of an inch. But the pump or pipe that connects to the pump outlet must be at least one inch in diameter.

These sections of the water supply can be connected using an adapter. When using a pipe with a smaller diameter, a slight decrease in pump performance may be observed.

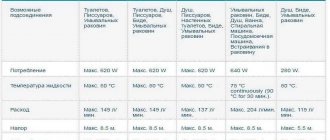

This diagram clearly shows the characteristics of various models of Aquarius pumps for a well. This data will help you choose the right pump for your specific situation.

Some amateur craftsmen tried to reduce the performance of an overly powerful pump by removing part of the working rings. Such actions can be fatal to the device. It is best to initially select equipment with the required performance.

Causes of pump failure in Aquarius

Despite their functionality and performance, Aquarius pumps have a simple design. This allows you to repair 60% of the device’s components.

The pump is constantly in water. This causes the device to operate under load. The content of abrasive materials, silt, too high a water temperature, or incorrect connection affect the operation of the device. But, despite the negative nature of the impact, these factors lead to gradual wear and tear of the mechanisms. As a result, damage can be identified at an early stage, which simplifies repairs.

Clogged internal part of the deep well pump

Negative factors affecting the operation and condition of the pumping device are:

- operation of the device in idle mode without pumping water;

- the concentration of sand and other abrasive materials in water is over 50%;

- working with liquid whose temperature exceeds 40 degrees;

- sudden and frequent voltage drops in the operating network;

- improper fastening of the cable ends at the top of the well;

- improper fixation of the device cable;

- incorrect connection of the submersible electric pump cable under water.

Factors that can lead to breakdown and make it necessary to repair the Aquarius pump include frequent removal of the device from the well and lack of grounding. Lack of grounding leads to problematic breakdowns, as it increases the rate of corrosion of metal parts. In addition, the absence of a filter on the inlet parts of the pump leads to increased load on the unit and, as a result, its malfunction.