You can currently find many types of electrodes on the market, which differ in the materials used for their manufacture and their sizes. Such welding rods for joining metals can be produced in various sizes. When choosing certain varieties of such surfacing materials, it is necessary to take into account their diameter, length, basic composition and type of coating. We will tell you in more detail how to choose the right length and diameter of the electrodes used.

Choosing the right diameter

The diameter of the rods, along with the composition of their alloy, is one of the most important parameters, therefore, when choosing one or another variety, you need to correctly determine the size you need, which will be the key to high-quality welding work. The thickness of the rod directly depends on the size of the base material. So, for example, if you need to weld metal sheets several millimeters thick, then you should choose electrodes that are small in size. If you are connecting metal parts with a thickness of several centimeters, and the depth of the seam will approach ten millimeters, then it is necessary to appropriately use thick surfacing rods for this work, which will ensure the strength of the connection. This characteristic is also influenced by the power indicator of the welding transformer. Different metals can differ significantly in their melting point, so it is necessary to correctly select the sizes of the surfacing materials used.

With the right choice, the melting temperature of the base surfacing material will be the same, which will allow both the electrodes and the base material to melt simultaneously

. Consequently, the connecting seam will be uniform, high quality and durable. At the same time, you must understand that powerful transformers at high operating currents can instantly melt electrodes whose diameter is 2-3 millimeters.

If the diameter is chosen incorrectly, this can lead to a significant deterioration in the quality of the connection. If melting requires high power and high temperature, this can lead to the appearance of through holes in thin metal sheets. That is why it is necessary to correlate the thickness of the surfacing rods used with the characteristics of the base metals and their sizes.

Selecting the length of the electrodes

The length of the electrodes is not such a significant parameter for welding, however, in certain situations, the wrong choice can lead to a significant deterioration in the quality of the welding work performed. The length of the electrode depends on its thickness and the characteristics of the elements being welded. It is necessary to understand that during the welding process, any interruption in the temperature treatment of the joint invariably leads to significant deterioration of the weld.

. Therefore, it will be necessary to select sizes of surfacing materials that will minimize or completely eliminate such welding interruptions, which will improve the quality of the work performed.

Short electrodes can be used in cases where long seams are not required. In this case, rods of 10 centimeters will be sufficient. But if you need to weld parts 30 centimeters or more in size, you need to choose electrodes that are appropriate in size, which will allow you to complete this work without interrupting welding. Please note that you should not purchase excessively long electrodes if you need to make short connections. In this case, if the length of the rods is chosen incorrectly, there is a risk of their breaking, which in turn leads to shedding of the coating, and without it the quality of the connection deteriorates significantly.

Currently, electrodes of various sizes can be found on sale. These can be either standard rods 10-15 centimeters long, or special varieties 30-40 centimeters or more long. It must be remembered that not all brands of electrodes are manufactured with a full range of sizes, which leads to some difficulties when choosing such a surfacing material.

Diameter and length of common varieties

- LB-52U. The manufacturer produces these brands with a diameter of 2.6 to 5 millimeters and a length of up to 35-40 centimeters.

- ANO-21. The length can be a maximum of 0.25-0.4 meters, with a diameter of 1.6-5 millimeters.

- MP3. This is a common type of surfacing rod and is available in a wide range. The diameter ranges from 2 to 5 millimeters, while their length reaches 45 centimeters.

- ANO-6. Buyers are offered three standard sizes, ranging from 3 to 5 millimeters. For electrodes with a diameter of 3 millimeters, the maximum length can be 35 centimeters. A five-millimeter surfacing rod has a maximum length of 45 centimeters.

Reusable monopolar electrodes ERBE

| vendor code | Description |

| 21191-172 | Knife electrode, straight, 3.4 x 18 mm, length 40 mm, rod ø 2.4 mm |

| 21191-072 | Knife electrode, straight, 3.4 x 18 mm, length 40 mm, rod ø 4 mm |

| 21191-101 | Knife electrode, straight, 1.5 x 17 mm, length 40 mm, rod ø 2.4 mm |

| 21191-001 | Knife electrode, straight, 1.5 x 17 mm, length 40 mm, rod ø 4 mm |

| 21191-100 | Knife electrode, straight, 3.4 x 24 mm, length 45 mm, rod ø 2.4 mm |

| 21191-000 | Knife electrode, straight, 3.4 x 24 mm, length 45 mm, rod ø 4 mm |

| 21191-102 | Spatula electrode, straight, 3 x 24 mm, length 45 mm, shaft ø 2.4 mm |

| 21191-002 | Spatula electrode, straight, 3 x 24 mm, length 45 mm, shaft ø 4 mm |

| 21191-159 | Spatula electrode, straight, 2.3 x 19 mm, length 45 mm, shaft ø 2.4 mm |

| 21191-059 | Spatula electrode, straight, 2.3 x 19 mm, length 45 mm, shaft ø 4 mm |

| 21191-161 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 45 mm, shaft ø 2.4 mm |

| 21191-061 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 45 mm, shaft ø 4 mm |

| 21191-107 | Spatula electrode, straight, flexible, 2 x 6 mm, length 45 mm, shaft ø 2.4 mm (e.g. for coronary artery bypass grafting) |

| 21191-007 | Spatula electrode, straight, flexible, 2 x 6 mm, length 45 mm, shaft ø 4 mm (e.g. for coronary artery bypass grafting) |

| 21191-106 | Spatula electrode, straight, flexible, 2 x 18 mm, length 45 mm, shaft ø 2.4 mm (e.g. for coronary artery bypass grafting) |

| 21191-006 | Spatula electrode, straight, flexible, 2 x 18 mm, length 45 mm, shaft ø 4 mm (e.g. for coronary artery bypass grafting) |

| 21191-105 | Spatula electrode, straight, flexible, 1.7 x 6 mm, length 50 mm, shaft ø 2.4 mm (e.g. for coronary artery bypass grafting) |

| 21191-005 | Spatula electrode, straight, flexible, 1.7 x 6 mm, length 50 mm, shaft ø 4 mm (e.g. for coronary artery bypass grafting) |

| 21191-103 | Spatula electrode, straight, flexible, 3 x 24 mm, length 60 mm, shaft ø 2.4 mm (e.g. for coronary artery bypass grafting) |

| 21191-003 | Spatula electrode, straight, flexible, 3 x 24 mm, length 60 mm, shaft ø 4 mm (e.g. for coronary artery bypass grafting) |

| 21191-104 | Spatula electrode, straight, flexible, 2 x 18 mm, length 80 mm, shaft ø 2.4 mm (e.g. for coronary artery bypass grafting) |

| 21191-004 | Spatula electrode, straight, flexible, 2 x 18 mm, length 80 mm, shaft ø 4 mm (e.g. for coronary artery bypass grafting) |

| 21191-153 | Spatula electrode, straight, 2.3 x 19 mm, length 120 mm, shaft ø 2.4 mm |

| 21191-053 | Spatula electrode, straight, 2.3 x 19 mm, length 120 mm, shaft ø 4 mm |

| 21191-155 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 120 mm, shaft ø 2.4 mm |

| 21191-055 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 120 mm, shaft ø 4 mm |

| 21191-110 | Knife electrode, straight, w 2.4 x 12 mm, length 120 mm, rod ø 2.4 mm |

| 21191-010 | Knife electrode, straight, w 2.4 x 12 mm, length 120 mm, rod ø 4 mm |

| 21191-156 | Spatula electrode, straight, 2.4 x 12 mm, length 120 mm, shaft ø 2.4 mm |

| 21191-056 | Spatula electrode, straight, 2.4 x 12 mm, length 120 mm, shaft ø 4 mm |

| 21191-157 | Spatula electrode, straight, 2.3 x 19 mm, length 180 mm, shaft ø 2.4 mm |

| 21191-057 | Spatula electrode, straight, 2.3 x 19 mm, length 180 mm, shaft ø 4 mm |

| 21191-158 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 180 mm, shaft ø 2.4 mm |

| 21191-058 | Spatula electrode, straight, insulated, 2.3 x 19 mm, length 180 mm, shaft ø 4 mm |

| 21191-108 | Knife electrode, curved, 1.5 x 17 mm, length 30 mm, rod ø 2.4 mm |

| 21191-008 | Knife electrode, curved, 1.5 x 17 mm, length 30 mm, rod ø 4 mm |

| 21191-160 | Knife electrode, curved, 2.3 x 19 mm, length 40 mm, rod ø 2.4 mm |

| 21191-060 | Knife electrode, curved, 2.3 x 19 mm, length 40 mm, rod ø 4 mm |

| 21191-162 | Spatula electrode, curved, insulated, 2.3 x 19 mm, length 40 mm, shaft ø 2.4 mm |

| 21191-062 | Spatula electrode, curved, insulated, 2.3 x 19 mm, length 40 mm, shaft ø 4 mm |

| 21191-109 | Spatula electrode, curved, 3 x 24 mm, length 40 mm, shaft ø 2.4 mm |

| 21191-009 | Spatula electrode, curved, 3 x 24 mm, length 40 mm, shaft ø 4 mm |

| 21191-154 | Spatula electrode, curved, 2.3 x 19 mm, length 115 mm, shaft ø 2.4 mm |

| 21191-054 | Spatula electrode, curved, 2.3 x 19 mm, length 115 mm, shaft ø 4 mm |

| 21191-111 | Knife electrode, curved, 2.4 x 12 mm, length 115 mm, rod ø 2.4 mm |

| 21191-011 | Knife electrode, curved, 2.4 x 12 mm, length 115 mm, rod ø 4 mm |

| 21191-171 | Needle electrode, straight, ø 0.8 x 17 mm, length 35 mm, shaft ø 2.4 mm |

| 21191-071 | Needle electrode, straight, ø 0.8 x 17 mm, length 35 mm, shaft ø 4 mm |

| 21191-112 | Needle electrode, straight, ø 0.8 x 22 mm, rod ø 2.4 mm |

| 21191-012 | Needle electrode, straight, ø 0.8 x 22 mm, rod ø 4 mm |

| 21191-168 | Needle electrode, straight, insulated, ø 0.8 x 22 mm, length 40 mm, rod ø 2.4 mm |

| 21191-068 | Needle electrode, straight, insulated, ø 0.8 x 22 mm, length 40 mm, rod ø 4 mm |

| 21191-113 | Needle electrode, straight, ø 0.8 x 29 mm, length 65 mm, shaft ø 2.4 mm |

| 21191-013 | Needle electrode, straight, ø 0.8 x 29 mm, length 65 mm, shaft ø 4 mm |

| 21191-169 | Needle electrode, straight, ø 0.8 x 15 mm, length 115 mm, rod ø 2.4 mm |

| 21191-069 | Needle electrode, straight, ø 0.8 x 15 mm, length 115 mm, rod ø 4 mm |

| 21191-120 | Needle electrode, straight, ø 0.8 x 15 mm, length 120 mm, rod ø 2.4 mm |

| 21191-020 | Needle electrode, straight, ø 0.8 x 15 mm, length 120 mm, rod ø 4 mm |

| 21191-170 | Needle electrode, straight, ø 0.8 x 15 mm, length 180 mm, rod ø 2.4 mm |

| 21191-070 | Needle electrode, straight, ø 0.8 x 15 mm, length 180 mm, rod ø 4 mm |

| 21191-115 | Needle electrode, curved, ø 0.8 x 20 mm, length 35 mm, shaft ø 2.4 mm |

| 21191-015 | Needle electrode, curved, ø 0.8 x 20 mm, length 35 mm, shaft ø 4 mm |

| 21191-151 | Needle electrode, curved, ø 0.8 x 12 mm, length 45 mm, shaft ø 2.4 mm |

| 21191-051 | Needle electrode, curved, ø 0.8 x 12 mm, length 45 mm, shaft ø 4 mm |

| 21191-121 | Needle electrode, curved, ø 0.8 x 10 mm, length 120 mm, shaft ø 2.4 mm |

| 21191-021 | Needle electrode, curved, ø 0.8 x 10 mm, length 120 mm, shaft ø 4 mm |

| 21191-116 | Tungsten needle electrode, straight, insulated ø 0.5 x 3 mm, length 40 mm, rod ø 2.4 mm |

| 21191-016 | Tungsten needle electrode, straight, insulated ø 0.5 x 3 mm, length 40 mm, rod ø 4 mm |

| 21191-118 | Tungsten needle electrode, straight, insulated ø 0.5 x 3 mm, length 55 mm, rod ø 2.4 mm |

| 21191-018 | Tungsten needle electrode, straight, insulated ø 0.5 x 3 mm, length 55 mm, rod ø 4 mm |

| 21191-117 | Tungsten needle electrode, curved, insulated ø 0.5 x 3 mm, length 35 mm, shaft ø 2.4 mm |

| 21191-017 | Tungsten needle electrode, curved, insulated ø 0.5 x 3 mm, length 35 mm, shaft ø 4 mm |

| 21191-119 | Tungsten needle electrode, curved, insulated ø 0.5 x 3 mm, length 55 mm, shaft ø 2.4 mm |

| 21191-019 | Tungsten needle electrode, curved, insulated ø 0.5 x 3 mm, length 55 mm, shaft ø 4 mm |

| 21191-114 | Coagulation electrode, straight, insulated, ø 1 mm, length 120 mm, rod ø 2.4 mm |

| 21191-014 | Coagulation electrode, straight, insulated, ø 1 mm, length 120 mm, rod ø 4 mm |

| 21191-122 | Coagulation electrode, curved, insulated, ø 1 mm, length 115 mm, rod ø 2.4 mm |

| 21191-022 | Coagulation electrode, curved, insulated, ø 1 mm, length 115 mm, rod ø 4 mm |

| 21191-123 | Ball electrode, straight, ø 2 mm, length 40 mm, rod ø 2.4 mm |

| 21191-023 | Ball electrode, straight, ø 2 mm, length 40 mm, rod ø 4 mm |

| 21191-163 | Ball electrode, straight, ø 3 mm, length 40 mm, rod ø 2.4 mm |

| 21191-063 | Ball electrode, straight, ø 3 mm, length 40 mm, rod ø 4 mm |

| 21191-124 | Ball electrode, straight, ø 4 mm, length 40 mm, rod ø 2.4 mm |

| 21191-024 | Ball electrode, straight, ø 4 mm, length 40 mm, rod ø 4 mm |

| 21191-164 | Ball electrode, straight, ø 5 mm, length 40 mm, rod ø 2.4 mm |

| 21191-064 | Ball electrode, straight, ø 5 mm, length 40 mm, rod ø 4 mm |

| 21191-125 | Ball electrode, straight, ø 6 mm, length 40 mm, rod ø 2.4 mm |

| 21191-025 | Ball electrode, straight, ø 6 mm, length 40 mm, rod ø 4 mm |

| 21191-165 | Ball electrode, straight, ø 3 mm, length 110 mm, rod ø 2.4 mm |

| 21191-065 | Ball electrode, straight, ø 3 mm, length 110 mm, rod ø 4 mm |

| 21191-128 | Ball electrode, straight, ø 4 mm, length 110 mm, rod ø 2.4 mm |

| 21191-028 | Ball electrode, straight, ø 4 mm, length 110 mm, rod ø 4 mm |

| 21191-166 | Ball electrode, straight, ø 5 mm, length 110 mm, rod ø 2.4 mm |

| 21191-066 | Ball electrode, straight, ø 5 mm, length 110 mm, rod ø 4 mm |

| 21191-129 | Ball electrode, straight, ø 6 mm, length 115 mm, rod ø 2.4 mm |

| 21191-029 | Ball electrode, straight, ø 6 mm, length 115 mm, rod ø 4 mm |

| 21191-126 | Ball electrode, curved, ø 2 mm, length 35 mm, rod ø 2.4 mm |

| 21191-026 | Ball electrode, curved, ø 2 mm, length 35 mm, rod ø 4 mm |

| 21191-127 | Ball electrode, curved, ø 4 mm, length 35 mm, rod ø 2.4 mm |

| 21191-027 | Ball electrode, curved, ø 4 mm, length 35 mm, rod ø 4 mm |

| 21191-130 | Ball electrode, curved, ø 2 mm, length 115 mm, rod ø 2.4 mm |

| 21191-030 | Ball electrode, curved, ø 2 mm, length 115 mm, rod ø 4 mm |

| 21191-131 | Ball electrode, curved, ø 4 mm, length 115 mm, rod ø 2.4 mm |

| 21191-031 | Ball electrode, curved, ø 4 mm, length 115 mm, rod ø 4 mm |

| 21191-132 | Ball electrode, curved, ø 8 mm, length 190 mm, rod ø 2.4 mm |

| 21191-032 | Ball electrode, curved, ø 8 mm, length 190 mm, rod ø 4 mm |

| 21191-133 | Ball electrode, curved, ø 10 mm, length 190 mm, rod ø 2.4 mm |

| 21191-033 | Ball electrode, curved, ø 10 mm, length 190 mm, rod ø 4 mm |

| 21191-134 | Ball electrode, curved, ø 8 mm, length 240 mm, rod ø 2.4 mm |

| 21191-034 | Ball electrode, curved, ø 8 mm, length 240 mm, rod ø 4 mm |

| 21191-135 | Wire loop electrode, straight, ø 6 mm, length 40 mm, rod ø 2.4 mm |

| 21191-035 | Wire loop electrode, straight, ø 6 mm, length 40 mm, shaft ø 4 mm |

| 21191-136 | Tape loop electrode, straight, ø 12 mm, length 40 mm, rod ø 2.4 mm |

| 21191-036 | Tape loop electrode, straight, ø 12 mm, length 40 mm, rod ø 4 mm |

| 21191-137 | Tape loop electrode, straight, ø 16 mm, length 40 mm, rod ø 2.4 mm |

| 21191-037 | Tape loop electrode, straight, ø 16 mm, length 40 mm, rod ø 4 mm |

| 21191-138 | Tape loop electrode, straight, ø 12 mm, length 40 mm, rod ø 2.4 mm |

| 21191-038 | Tape loop electrode, straight, ø 12 mm, length 40 mm, rod ø 4 mm |

| 21191-139 | Tape loop electrode, straight, ø 16 mm, length 40 mm, rod ø 2.4 mm |

| 21191-039 | Tape loop electrode, straight, ø 16 mm, length 40 mm, rod ø 4 mm |

| 21191-140 | Tungsten electrode, wire loop type, straight, ø 5 mm, length 105 mm, rod ø 2.4 mm |

| 21191-040 | Tungsten electrode, wire loop type, straight, ø 5 mm, length 105 mm, shaft ø 4 mm |

| 21191-141 | Tungsten electrode "tape loop" type, straight, ø 10 mm, length 105 mm, rod ø 2.4 mm |

| 21191-041 | Tungsten electrode tape loop type, straight, ø 10 mm, length 105 mm, rod ø 4 mm |

| 21191-167 | Tungsten electrode tape loop, straight, 5 x 5 mm, length 125 mm, shaft ø 2.4 mm |

| 21191-067 | Tungsten electrode tape loop, straight, 5 x 5 mm, length 125 mm, shaft ø 4 mm |

| 21191-149 | Tungsten electrode tape loop, straight, 6 x 15 mm, length 125 mm, shaft ø 2.4 mm |

| 21191-049 | Tungsten electrode tape loop, straight, 6 x 15 mm, length 125 mm, shaft ø 4 mm |

| 21191-147 | Tungsten electrode "tape loop", straight, 10 x 12 mm, length 135 mm, rod ø 2.4 mm |

| 21191-047 | Tungsten electrode "tape loop", straight, 10 x 12 mm, length 135 mm, rod ø 4 mm |

| 21191-146 | Tungsten electrode "tape loop", straight, 10 x 15 mm, length 135 mm, rod ø 2.4 mm |

| 21191-046 | Tungsten electrode "tape loop", straight, 10 x 15 mm, length 135 mm, rod ø 4 mm |

| 21191-148 | Tungsten electrode "tape loop" type, straight, 15 x 20 mm, length 140 mm, rod ø 2.4 mm |

| 21191-048 | Tungsten electrode "tape loop", straight, 15 x 20 mm, length 140 mm, rod ø 4 mm |

| 21191-142 | Tungsten electrode "tape loop" type, straight, ø 10 mm, length 130 mm, rod ø 2.4 mm |

| 21191-042 | Tungsten electrode tape loop type, straight, ø 10 mm, length 130 mm, rod ø 4 mm |

| 21191-143 | Tungsten electrode "tape loop" type, straight, ø 15 mm, length 135 mm, rod ø 2.4 mm |

| 21191-043 | Tungsten electrode tape loop type, straight, ø 15 mm, length 135 mm, rod ø 4 mm |

| 21191-144 | Tungsten electrode "tape loop" type, straight, ø 20 mm, length 140 mm, rod ø 2.4 mm |

| 21191-044 | Tungsten electrode tape loop type, straight, ø 20 mm, length 140 mm, rod ø 4 mm |

| 21191-145 | Tungsten electrode "tape loop" type, straight, ø 25 mm, length 145 mm, rod ø 2.4 mm |

| 21191-045 | Tungsten electrode "tape loop", straight, ø 25 mm, length 145 mm, rod ø 4 mm |

| 21191-150 | Tungsten electrode "tape loop" type, straight, ø 30 mm, length 150 mm, rod ø 2.4 mm |

| 21191-050 | Tungsten electrode tape loop type, straight, ø 30 mm, length 150 mm, rod ø 4 mm |

Correct selection of electrodes

The diameter of the electrodes used for welding must be selected taking into account the thickness of the workpieces. In this case, the composition of the surfacing and base material should be as similar as possible, which will allow for a uniform, strong connection. It is also necessary to take into account the melting temperature of the parts being connected, which must be the same. In the event that metal products with a thickness of 1-3 millimeters are welded, then two-millimeter electrodes and an operating current of the inverter from 25 to 100 Amperes can be used. If you are welding parts with a thickness of 3 to 6 millimeters, then electrodes with a thickness of 3-4 millimeters can be used. The optimal operating current is 150-200 Amperes. Welding surfacing materials with a diameter of more than six millimeters can be used to weld metal with a thickness of 10 centimeters or more.

Important. Before starting welding, you should evaluate the condition of the coating, which should not be damaged, which can significantly deteriorate the quality of the weld.

The length of the electrode is important in cases where it is undesirable to interrupt the welding process, which can lead to a deterioration in the quality of the work performed. For example, when repairing sealed containers for high-pressure pipelines, interrupting the welding process and using several rods to weld one joint can lead to a significant decrease in reliability. As a result, expensive and complex repairs will be required in the future. There are also certain metal alloys for which interruption of welding will invariably lead to deterioration in the quality of the joint. That is why, when choosing the length, it is necessary to proceed from the length of the weld and select the rods in such a way that their size is larger than the weld.

By choosing the right welding rods, taking into account their length and thickness, you can ensure a high-quality connection, while the resulting seam will have the necessary decorative effect, mechanical strength, durability and corrosion protection.

Electrodes of different diameters: application specifics

A high-quality connection of the metal being welded, in addition to the specifics of connecting the welding machine, largely depends on the specification of the electrode. The diameter of the metal rod of the electrode is also important for the correct connection of materials, as is knowledge of the specifics of the materials themselves.

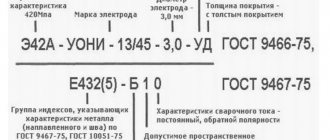

For electric arc welding, the thickness of the electrode is an important characteristic that requires not only adjustment of the corresponding current indicator, but also the ability to melt the welded surfaces of the workpieces. Electrode diameter markings are always indicated on the packaging. This marking allows you to select the optimal current strength and calculate the thickness of the parts to be welded, that is, calculate the power of the welding machine and set the necessary indicators for work.

To weld thin-bodied parts, for example, sheet metal, manual arc welding machines are used, which use the technology of welding metal in a protective environment of inert gases; this is mainly manual argon arc welding, or as it is also called semi-automatic welding. This feature is due to the fact that the thinnest electrodes of 1.2-1.6 mm in diameter are usually not used in home workshops, because they require a highly qualified welder.

The most popular sizes are 3 or 3.2 mm in diameter. This is the main operating range used everywhere. It is worth noting that most household welding machines cope well with most tasks using such electrodes.

Electrodes thicker than 6 mm are mainly used for restoring damaged surfaces or surfacing metal; this is a special type of product that requires significant current, which most household inverters are simply not able to provide due to their characteristics.

In general, the thickness of the electrodes can be used to weld parts, depending on their thickness

:

- 1-2 mm of metal is connected with 1.5-2 mm electrodes;

- for metal 3-5 mm, 3-4 mm grades are suitable;

- metal structures of 6-12 mm are welded with 4-5 mm electrodes;

- for metal 12-15 mm, 5 mm is suitable;

- 16-20 mm require a diameter of 6-8 mm;

- more powerful structures are welded with 8-10 mm rods.

The second important indicator of the electrode diameter is the need for the welding machine to maintain the set welding current value:

- 1.5-2 mm require 30-45 A;

- 3-4 mm corresponds to a current indicator of 65-200, and depending on the thickness of the metal being welded;

- 5-6 mm 200-250 A;

- 8 and above from 250A.

In addition to the fact that the packaging indicates the marking of the diameter of the electrode and the correspondence to the required current strength, the decoding also indicates the intended purpose for using the compound of a specific material. This specification allows you to use electrodes of the required size and prevent excessive heating of the metal at the weld site, that is, prevent the metal from changing its properties.

So, today, in most cases, metal is used as structural elements, labeled as:

- carbon and low-alloy steels;

- structural alloy steels and structures;

- heat-resistant alloy steels;

- high-alloy steels with special properties;

The corresponding designation must be indicated on the packaging, which has the corresponding alphanumeric code:

- “U” – used for joining carbon and low-alloy steels and structures;

- “L” – intended for alloyed structural steels;

- “T” – special alloyed heat-resistant steels;

- “B” – high-alloy steels;

- “N” – materials used for surfacing layers on the metal surface.

Designation in accordance with the position of the seam in spatial

For reliable connection of parts, a factor such as the spatial position of the seam plays an important role. For different types of work, manufacturers have developed electrodes with special properties that can provide a reliable arc in the positions for which they are intended.

The easiest position is considered to be the horizontal position of the parts being welded, in this position the parts are at the bottom and the welding electrode is at the top, this is the so-called basic position; welding parts in this position does not require special skills, and special properties of the electrodes are not needed here.

In the alphanumeric code, this designation appears under the number 1.

For work in all positions of welded parts and surfaces, except for applying a seam from top to bottom, the marking corresponds to the number 2.

For most surfaces, lower, horizontal and vertical in the direction of the weld “from bottom to top”, nomenclature 3 corresponds.

For the lower position and the lower “boat” position, the so-called ceiling work, electrodes marked 4 are used.

Electrodes that are universal in purpose, including those for special welds, are marked with the number 5.

Those who are just starting to get involved in welding are recommended to use conventional welding electrodes of the very first level. This is the most optimal option, provided that most of the parts will be located in a horizontal position and welding will be done from top to bottom. The weld pool of metal formed when an electric arc occurs in this position does not leak anywhere, remains in place and allows the formation of a reliable seam.

Using the properties of electrodes depending on the quality of ease of use

One of the important properties of the electric welding process is the stability of the electric arc that occurs at the moment of contact between the electrode and the part being welded. In this process, the quality and composition of the electrode coating or its coating plays a role in the formation of the correct metal pool to be welded. Today, depending on the production technology, four main types of rod coating are used, which have differences:

- by the thickness of the coating layer;

- quality of workmanship;

- composition of the main components.

The layer thickness is marked on the packaging with a code designation and letter coding

:

- M – the thinnest coating;

- C – medium thickness coating;

- D – thick layer of coating;

- G – special increased thick layer of coating.

The quality of workmanship is indicated by a digital designation at the bottom of the marking, the highest quality corresponds to 1, average 2, low quality 3.

To create normal conditions for welding metal, an important role is played not only by the quality, but also by the composition of the coating, which forms the slag surface and forms the space around the weld pool of metal with a special environment necessary for melting the metal.

Manufacturers today create coatings from the main four types of rod coatings:

- “A” – acid coating;

- “B” – main type of coating;

- “C” – cellulose or organic coating;

- “R” – rutile.

For each type of coating there are specific operating features and quality indicators characteristic only of these types, both weld pools and the degree of formation of metal droplets and their spattering.

Marked with the letter “A” - electrodes with an acid type of coating, during operation are characterized by the formation of a particularly liquid weld pool, this is due to the fact that the metal of the electrode rod passes into it already in a liquid state.

This behavior is typical for an unstable, unstable arc; during the formation of the pool, the metal splashes and there is a high probability of a sharp increase in the temperature of the workpieces being welded. Acid coating requires care and skill in operation, as it is not uncommon to burn through the surface, especially thin sheet metal. It is not always possible to create a strong seam; when welding with such an electrode, an oxygen-saturated seam is formed, which does not add strength to the joint.

The main coating, marked with the letter “B”, among its features, forms a short arc; this feature is manifested in the formation of a bath with low mobility. When melting the metal, the electrode forms drops of mainly medium and large sizes; this size of the drop prevents the metal from spreading and the seam becomes more rigid. When using AC welding machines, you should be especially careful, since the fluorspar coating CaF2 gives an additional crust, which significantly complicates the welding process.

On the other hand, this is the type of coating that, among all types, has the best viscosity and density characteristics. A weld seam using electrodes with a basic coating practically does not form cracks or tears; the metal perfectly fills voids and reliably connects workpieces. Basic coated electrodes for manual arc welding are not only used for welding simple structures, they are widely used for structures with high loads and those that have special requirements, such as suppression tanks.

However, such an excellent result requires the use of electrodes with a basic coating and additional surface preparation:

- arrangement of workpiece chamfers;

- cutting edges;

- rust removal and treatment from organic impurities;

- reliable and tight joint of parts.

As an additional preparation, it is recommended to calcinate the surfaces to improve the properties of the weld.

Organic substances used in the formation of electrode coatings are marked on the packaging with the letter “C”; this designation indicates that cellulose is among the main substances involved in the formation of the coating. A characteristic feature of such materials is their versatility in terms of spatial seam placement; they are suitable for all types of seams. However, you should be especially careful when welding vertical seams and seams with a lower location - the cellulose coating causes a lot of metal spattering, which leads to a rough, wide seam. It will be extremely difficult for a beginner to obtain a beautiful seam using an electrode with an organic coating, and experienced welders, as practice shows, practically do not use this type of coating when forming single-pass facial welds. The high content of gas-forming substances and components in cellulose that release huge amounts of gas during combustion, on the other hand, perfectly form a gas-protective layer of the bath and do not allow the arc to go out.

The saturation of the gas-protective layer around the weld pool makes it possible to form a reliable weld, since large drops of metal do not spread and cool well. Cellulose-coated electrodes are indispensable for vertical seams, critical joints as a first-pass structural seam, and top-down seams.

Rutile coating today is the best option for those who are just about to start using the connection of parts using electric arc welding. Electrodes marked on the packaging with the letter “P” are characterized by easy arc initiation, stable arc maintenance, excellent shape and neatness of the seam. In addition to all the listed characteristics, one should also add the excellent quality of the weld, which perfectly connects the surfaces.

Another characteristic feature of rutile surfaces is the possibility of passing a second seam over the first one without removing the slag. TiO2, included as one of the main components of the coating, provides this opportunity, which significantly saves effort and capabilities. In practice, when using rutile electrodes, there is no release of toxic substances and allows you to control the welding process in literally any position. The formed joint seam has a low porosity of the internal structure and excellent slag separability. These electrodes are excellent for joining tack welds, fillet joints and forming face welds.