Tab. 2. Purpose of welding electrodes according to GOST 9466-75.

| Steel type | Designation (letter) | GOST |

| low-alloy structural and carbon steels with certain parameters (up to 60 kgf/mm² (600 MPa) tensile strength | U | 9467-75 |

| similar in parameters, but alloyed structural steel | L | 9467-75 |

| heat resistant alloy steels | T | 9467-75 |

| highly alloyed with special properties | IN | 10052-75 |

| surface layers (surfacing) | N | 10051-75 |

- material of manufacture;

Electrode characteristics

Consumables are made from welding wire Sv-08 or Sv-08A (GOST 2246-70). Its length is 45 cm.

GOST and other requirements

The necessary technical characteristics and designation rules for electrodes are given in GOST 9466-75 and 9467-75. According to these documents, the manufacturer is required to label the packaging. Some companies indicate it on the product itself.

What metal does it apply to?

E42 consumables are used for welding the following types of steels:

- carbon;

- low-alloy, for example grades 09G2 and 14G2.

E42 consumables are used for welding carbon steel.

They are not suitable for working with copper and other non-ferrous metals.

Physical and chemical properties of the seam

The composition of the electrode and its coating must provide the following indicators:

- Temporary tensile strength – 42 kgf/sq.m. mm.

- Relative elongation – up to 22%.

- Impact strength (resistance to brittle fracture, cold brittleness) – 150 J/sq. cm at +20°C and 35 at -40°C.

- Surfacing coefficient – 10 g/A*h.

- Consumption per 1 kg of seam – 1.6 (kg).

Content of chemical elements in the product core:

- Carbon (C) – 0.08%.

- Manganese (Mn) – 0.7%.

- Silicon (Si) – 0.1%.

- Sulfur (S) – 0.035%.

- Phosphorus (P) – 0.035%.

Welding electrodes are necessary when creating metal structures.

Operating temperature range – from -20°C to +20°C.

For electrodes less than 3 mm

The consumption per 1 kg of seam is 1.6 kg, and the bend angle is 150°.

The share of chemical elements in the weld metal or surfacing:

- sulfur – no more than 0.04%;

- phosphorus – up to 0.045%.

Temporary tensile strength – 42 kgf/sq.m. cm.

Tab. 1. Electrodes based on material of manufacture.

| Non-metallic | Metal | ||

| Non-melting | Melting | ||

| Covered | Uncoated | ||

|

| in its modern version it is a continuous welding wire for working in shielding gases | |

- coating composition.

Tab. 3. Types of coating of welding electrodes.

| Coating | Designation | |

| ISO | GOST 9466-75 | |

| Basic | B | B |

| Sour | A | A |

| Rutile | R | R |

| Pulp | C | C |

| Mixed coatings | ||

| Rutile-cellulose | R.C. | RC |

| Rutile-basic | R.B. | RB |

| Acid-rutile | AR | AR |

| With iron powder rutile | R.R. | RJ |

| Others | S | P |

Certificate for NAKS electrodes

This is the abbreviation of the “National Welding Control Agency” - a specially created non-profit partnership within the framework of a professional SRO, with its own standards, rules and certification system. NAKS is represented in almost all regions of the Russian Federation and is involved in, among other things, certification of various elements of welding production. NAKS electrodes is the most convincing confirmation of their quality in Russia. The system enjoys well-deserved authority - for example, QMS NAKS has an ISO 9001-2008 certificate from DVS ZERT.

Certificate for electrodes Uoni 13/55

Electrodes of this brand differ from others in impact strength, bending angle, etc., i.e. Can be used to work with both carbon and low alloy steel or when a ductile weld is required. These electrodes are used to cook at extremely low (≤ -40°) and very high temperatures, in almost any position and with reverse polarity of direct current. Voluntary certification allows you to choose evaluation criteria, so the certificate obtained at the request of the supplier for electrodes Uoni 13/45 or 13/55, OZS-12, ANO-21, MP-3 and any others is a unique opportunity to officially confirm their strengths and advantages.

Description and scope of application

The consumable type is a steel rod with a protective coating. Under the influence of high temperature, the coating burns out and turns into a gas, separating the molten metal from the oxygen of the atmospheric air.

Most electrodes of this type are used for the manufacture of:

- lightly loaded structures;

- thin-walled pipes and low-pressure tanks.

It is allowed to carry out surfacing repairs with their help.

The scope of application depends on the brand of E42 electrodes. They are available in different designs, differing in diameter and composition of the protective coating.

Improved SSSI E42A

The only variety with basic coating.

It contains phosphorus compounds and carbides, prevents the appearance of hot cracks and gives the weld the following properties:

- plastic;

- impact strength.

These features are indicated by the index “A” in the marking.

They allow the use of E42A type electrodes for the manufacture of structures:

- placing high demands on reliability, including those experiencing alternating loads;

- operated at low temperatures.

UONI E42A electrodes contain phosphorus compounds and carbides.

Consumables are produced in the UONI 13/45 category and have the following distinctive features:

- They work only with direct current of reverse polarity (electrode-positive).

- They require cleaning the joined workpieces from rust, oil stains, dirt and water.

- Not suitable for welding in high humidity conditions.

- They are used economically due to the presence of iron powder in the coating, which compensates for the loss of metal due to evaporation and splashes.

UONI E42A electrodes are intended for the manufacture of critical structures in the workshop.

They are capricious, so the welder requires experience and dexterity. Inverter-type welding machines are used; rectifiers are not capable of ensuring stable arc burning. The current should not be increased, as this has a bad effect on the quality of the seam.

Types of coating and diameters

In addition to the main coating, the following is used:

- Sour. It contains oxides of iron, silicon and manganese. Such electrodes are used to weld with caution due to the high probability of so-called formation in the seam. hot microcracks (intergranular fractures).

- Rutile. Rutile is a mineral with large amounts of titanium dioxide. The consumables coated with it form a plastic seam, the level of deoxidation corresponding to semi-quiet steel. They tolerate high current well and do not allow the appearance of hot microcracks.

Acidic electrodes contain oxides of iron, silicon and manganese.

Acid and rutile electrodes of the E42 type are produced under many brands, for example OMA-2, VSTs-4 and 4M, Ogonyok, OZS-23, ANO-6, 6M, 17, etc. They cook well not only permanently, but also AC powered and suitable for beginners.

The diameter of E42 consumables is 2-12 mm. It is selected in accordance with the thickness of the smaller workpiece. This parameter determines the current strength. Thus, to weld corner No. 5 according to GOST 8509-93 with a flange thickness of 6 mm, an electrode of size 4 (mm) is required. The amperage is 120-200 A.

Thick consumables are used to connect massive parts in one pass. In this they are superior to semi-automatic installations on non-consumable electrodes with filler wire supply.

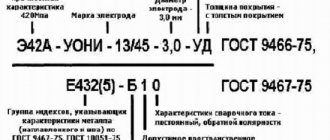

Explanation of markings

The letter “E” means “electrode for manual arc welding”, the number 42 is the temporary tensile strength, which is 42 kgf/sq. mm.

We recommend reading Description of ANO-21 electrodes

The full electrode marking also contains other data, for example E42A-UONI-13/45 SM-4.0-UD GOST 9467-60.

Explanation of product markings:

- SM-4.0 – made of welding wire with a diameter of 4 mm.

- U - intended for welding carbon steel.

- D – has a thick coating. Other options: S – medium, M – thin.

The product meets the requirements of GOST 9467-60.

Decoding the names of electrodes.

Where to order a certificate of conformity for electrodes

In addition to the above certificates, you can order from us:

- certificate for LB (recommended by VNIIST), for repair of main pipelines and construction;

- certificate for electrodes OK 46 , which are used to weld carbon steels, incl. galvanized, galvanized, marine and automotive steel;

- a certificate for E42 electrodes will confirm the special parameters of the weld; as with OK46, welding is possible with any, etc., but they are also used for low-alloy steel.

The certificate is issued for 1-3 years (Rosstandart form), it depends (certification scheme) on your status, type of production and delivery features. It is better to entrust the choice of scheme to specialists, because the duration and degree of complexity of certification depends on it. As soon as possible. Accredited laboratory. Our specialists will select samples, develop the missing technical documentation, select technical specification codes, conduct all examinations and tests, and obtain all the certificates and permits required for your products. All you need to do is send your application and documents:

- registration (OGRN, INN, Unified State Register of Legal Entities);

- NTD (can be ordered);

- details (organization card);

- Contract.

Features of operation

E42 electrodes are easy to use, easy to ignite and withstand voltage surges well. Most types weld rusty and damp metal without losing the strength and ductility of the joint.

The slag crust on the weld surface is easily separated, which reduces the cost and speeds up finishing.

Welding modes

This concept denotes actions and parameters designed to ensure high quality welds under given conditions.

Welding modes provide high quality seams.

Indicators are divided into 2 groups:

- basic;

- additional.

The first include:

- type and strength of current;

- electrode diameter;

- arc voltage.

Additional:

- spatial position of the seam;

- speed of movement of the consumable;

- composition and thickness of the metal.

E42 electrodes are used to cook with direct and alternating current, in the first case with reverse polarity. The amperage is related to the diameter of the consumable and the thickness of the workpieces being connected.

The data is summarized in the table:

We recommend reading Composition of electrode coating

| Thickness of welded parts, mm | 0,5 | 1-2 | 3 | 4-5 | 6-8 | 9-12 | 13-15 | 16 |

| Electrode diameter, mm | 1 | 1,5-2 | 3 | 3-4 | 4 | 4-5 | 5 | 6-8 |

| Current strength, A | 10-20 | 30-45 | 65-100 | 100-160 | 120-200 | 150-200 | 160-250 | 200-350 |

Wrong choice of electrode leads to the fact that the diameter becomes:

- Reduced. The coating is damaged and the arc loses stability.

- Enlarged. The current density drops and the arc is drawn across the surface of the workpiece. Because It is difficult to maintain a constant length, the seam becomes crooked and loses strength.

The welding mode is selected taking into account the capabilities of the inverter, i.e. maximum amperage for this model. Vertical and ceiling seams are welded with a consumable with a diameter of 4 millimeters, regardless of the thickness of the parts being connected.

The welding mode is selected taking into account the capabilities of the inverter.

The speed of the process affects the width of the seam. When moving quickly, it narrows, and vice versa. It is necessary to maintain the optimal speed, determined empirically.

Otherwise, the following consequences are observed:

- Acceleration. The material does not have time to warm up and melt, the joint turns out to be poorly welded.

- Slowdown. The metal flows out, the cross-section of the surfacing and, as a result, its strength decreases.

The optimal arc length is 3-4 mm. Stretching has a negative effect:

- During the journey from the electrode to the workpiece, the metal has time to oxidize.

- The arc is drawn across the surface, the heat is distributed over a larger area, and the material warms up worse. Melted drops freeze on it, clogging the seam.

The width of the joint and the penetration depth depend on the trajectory of the consumable. In addition to linear movement, zigzag and herringbone are used.

Existing restrictions

E42 consumables are not suitable for the following conditions:

- Perform vertical seams from top to bottom. Metal from the weld pool flows onto the untreated area.

- Connections of workpieces made of medium and high alloy steel, cast iron, non-ferrous metals.

- Welding with direct current of straight polarity (electrode-negative).

Consumables E42 are not suitable for vertical seams.

In the latter case, the cathode is the consumable. Compared to the anode, its temperature is higher (for melting products).

The parts being connected heat up worse, the penetration depth decreases; the coating on the electrode burns out too quickly and does not provide the required protection to the joint.

Is it possible to work with stainless steel?

Such materials are welded with electrodes containing nickel and chromium. E42 does not belong to this category, therefore it is not suitable for working with stainless steels.

Electrode storage

The coating of consumables, due to its porous structure, is hygroscopic, i.e. has a tendency to absorb moisture. Damp coating crumbles and burns poorly, as a result of which the seam does not receive protection from atmospheric oxygen and becomes weak and brittle.

Therefore, the following requirements are put forward for the storage location of electrodes:

- Relative humidity – less than 50%.

- The readings on the thermometer are not lower than +15°C. This means that during the cold season, consumables should be in a heated room.

- No temperature changes.

- Protection from direct sunlight.

If the packaging is opened, it is recommended to place the consumables in a special sealed case.

Points 2 and 3 are designed to prevent moisture condensation on products.

The specified conditions are also met if the electrodes are in sealed original packaging. With high humidity, they can become damp over time.

If the packaging is opened, it is recommended to transfer the consumables into a special sealed case with insulated walls. You can make it yourself from a plastic pipe of medium or large diameter.

We recommend reading: How to use OK 46 electrodes

Before use, the products are calcined, i.e. heated to dry the coating. The procedure time and temperature are indicated on the packaging; you must strictly adhere to them. Overheating is especially dangerous for consumables with organic substances in the coating.

Dried electrodes are suitable for use for 8 hours. If they have not been used during this time, the calcination can be repeated. But the number of procedures is limited and for different models it is 2-4. Subsequent heating will cause the coating to peel off.