Types of flotation devices

The main options can be identified:

- A film layer is created on the liquid , onto which insoluble dirt elements stick.

- Foamy - gases and foaming reagents are injected into the liquid. Gas capsules attract and transport insoluble substances to the top. Chemicals are necessary to stabilize the foam head, which is removed mechanically. It is then concentrated and filtered.

- Oily – drops of oils tend upward, picking up suspended matter along the way. After this, the oil layer is removed and cleaned.

Important. Most often, treatment complexes use the principle of froth flotation. This option for getting rid of pollutants is the most effective.

In addition, the equipment is classified according to the type of formation of air capsules.

Mechanical type

Flotation equipment of a simple type - tanks in which sewage waste is mixed with blades .

The equipment is suitable for liquids with a high amount of suspended contaminants prone to foaming.

Pressure

The most effective and most common are flotation units with gases supplied to water by pressure. It is used if the density of the suspension is comparable to the density of the liquid. In this option, finely dispersed contaminants do not precipitate.

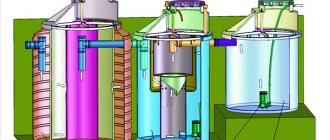

Pressure flotator

The basis of this method is the introduction of gases into water under pressure in special containers. Then the air-water mixture is fed into the wastewater tank. Due to the pressure difference, the active formation of small gas capsules occurs.

The action of surface tension forces attaches them to contaminant molecules. The formed flotation sludge floats to the top of the tank. Here it is mechanically removed.

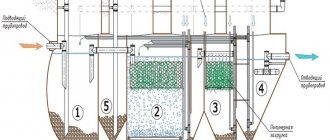

The operating principle of the simplest flotation machine:

- Air and water enter the mixing chamber of the pump. This is where gas is dissolved in liquid. The remaining excess air is released through the valve.

- The water mixture with air capsules enters the flotation unit tank through a pipe system.

- Sewage, which has been pre-treated in a sump, is also poured into this container.

- In the tank, suspended contaminants are collected through gas capsules.

- Photosludge is collected in the upper part of the container in the form of a foam layer, which is removed mechanically.

Almost pure water is drained from the flotation tank. Some of it is redirected to the pump to be remixed with gas.

Electric

Electric current is also used to separate suspended contaminants from the sewer mass .

Electric flotator

Operating principle of an electric type wastewater treatment flotator:

- Electrodes are placed in a reservoir of contaminated water.

- After applying voltage, water molecules are separated into oxygen and hydrogen. Capsules with electrolytic gases are formed at the ends of the electric rods.

- They rise upward, collecting particles of pollution.

Reference. When carrying out electrical wastewater treatment, a minimum amount of chemical additives is used.

This option is quite effective when installing rods made of aluminum or iron. Metal ions act as auxiliary reagents for the formation of stable compounds of mud suspensions and gas capsules.

The great advantage of using electrical installations is their simple design, which does not take up much space .

Such equipment does not contain containers for reagents and saturators. But energy costs increase during cleaning work. In addition, equipment for hydrogen removal is required.

Various materials with a porous structure are also used to introduce air into water. Some equipment produces gas as a result of chemical reactions.

Reagents in flotation

In order to improve the quality of filtration of waste liquids, active additives are used:

- to adjust the pH - alkali, acid (reagents are introduced into the liquid to create optimal conditions for the interaction of impurities with the coagulant and flocculants);

- coagulants - substances that promote the formation of foam (iron salts, aluminum salts);

- flocculants are polyacrylamide compounds that clean wastewater from impurities by forming flakes from colloidal and fine particles.

A negative factor of the reagent method of processing liquids is the mandatory presence of a relatively large site for installation of equipment, as well as the presence of additional maintenance personnel.

Chemical additives

Reagents for flotation purification of liquids significantly increase the efficiency of equipment.

Flotation reagents are classified into three main groups:

Collectors – designed to remove a water film from the surface of suspended particles. This ensures the possibility of combining suspensions with gas bubbles.- Foaming agents – form a dense shell of gas capsules. They also regulate the size of the bubbles, preventing them from increasing.

- Modifiers or regulators - affect the number of molecules that adhere to molecular suspensions. In addition, the degree of consolidation of the connection depends on them.

The selection of reagents is carried out depending on the type of equipment and the composition of the liquid being purified.

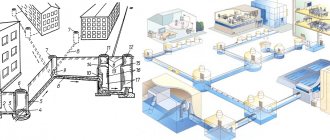

Why do you need to purify water?

Of the total supply of the World Ocean, only 3% is fresh water, of which 68% is glaciers (not suitable for drinking), 30% is underground sources (often polluted from soils) and only 2% is land-based water supplies. From the global picture of the world it is clear that the availability of clean fresh water is not just a necessity, but sometimes a luxury.

Wastewater generated during the economic activities of enterprises contains a large amount of pollutants in concentrations exceeding permissible and regulatory standards. As a rule, we are talking about heavy metals (iron, nickel, copper, lead, mercury, cadmium, etc.), petroleum products, suspended solids, aluminum, surfactants (synthetic surfactants, for the average person this is everything that foams). When these substances enter water bodies, they disrupt the normal functioning of aquatic biogeocenoses, poison the soil, provoke the growth of blue-green algae, and are toxic to animals. These pollutants are also toxic to humans.

Human economic activity in residential apartment buildings and private buildings also produces a large amount of pollutants. These are mainly surfactants and organic waste, but metal salts also end up in the sewer system.

Who does the production?

Before purchasing flotation machines, you need to clearly define the parameters.

The parameters are selected based on the following conditions:

- Composition and nature of sewage waste.

- Temperature and uniformity of water supply.

- Where is treated water discharged?

In Moscow and St. Petersburg, quite a few companies are engaged in the implementation of installations:

- — TR brand flotators, cost from 313,500 rubles.

- Trading house "Water treatment equipment" - pressure units of the DAF brand.

- Rosintereko LLC - flotators and two-stage units of the Angara brand.

Important. It is necessary to take into account the requirements for processing and removal of sediment, the degree of disinfection.

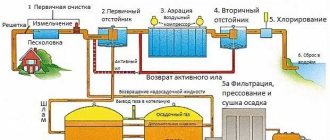

Scheme including a flotator for wastewater treatment

Technology that uses a flotator as the main processing module always includes a reagent facility and a device for creating air bubbles. The reagent facility consists of a container with reagents (coagulants, flocculants, alkali for pH adjustment) and a reactor for mixing the reagent with water.

As a rule, a saturator is used as a device for creating air bubbles, which is a chamber for mixing air with water to create a water-air mixture. This mixture is then sent to the flotator. The saturation device is equipped with a powerful air pump.

The skimmer is never used separately; it is always included in the overall water purification scheme. The complete scheme, as a rule, consists of the stages of preliminary sedimentation, physical and chemical treatment (flotator or coagulator) and subsequent mechanical purification on filters.

In other words, the flotator cannot provide all the cleaning; it is only a separate unit that requires pre-treatment and subsequent treatment. If sand or other coarse impurities get into the flotator, it will damage the device. Also, this device cannot provide disinfection and complete purification from petroleum products. Therefore, after it, an ultraviolet installation and sorption (or mechanical) filters are necessary.

The concept is based on the flotation process. Flotation is the treatment of wastewater with air bubbles to extract soluble and emulsified substances. Water flows to the main processing module. A pre-prepared reagent in the reactor is supplied there in pressure (or non-pressure) mode. Air bubbles are also supplied to the flotator using a saturation device. In a flotator for water purification, wastewater is treated with reagents and air bubbles, and most of the flocs float to the surface in the form of flotation sludge. The floating sludge is removed from the surface of the water by a scraper conveyor into a sludge collector.

This sludge is very unstable to mechanical rutting, so it is collected carefully from the surface of the water so as not to break the foam.

Installation

Mounting of flotators is carried out according to the operating instructions. It is supplied in a set of documents along with the installation.

Stages of work:

- The machine is mounted on the foundation and secured.

- The pipelines are connected.

- Power cables are supplied to the installation.

- Install and connect automated control systems.

All installations undergo hydrotesting before sale .

When selecting the type of flotation equipment, it is worth considering:

- type of sewerage;

- degree of contamination of the liquid medium;

- volumes of purification.

Why choose EKOVODSTROYTECH® technological solutions:

- technological processes occur autonomously without operator assistance, they are fully automated;

- the equipment is easily integrated into wastewater treatment plant systems;

- an expanded model line allows you to choose the best option for any object;

- comprehensive wastewater treatment from inorganic impurities;

- high degree of purification in accordance with the standards established in the territory of the countries of the Customs Union;

- the equipment is compact and requires a small area for placement;

- the flotation unit can be located either in close proximity to the source of wastewater or at a considerable distance;

- ease of operation and maintenance;

- the ability to purify wastewater, recover and selectively isolate impurities;

- the equipment is immune to salvo discharges.

Scope of application of Flamingo M flotators:

- Fermented milk production;

- Meat processing industry;

- Fish processing plants;

- Confectionery factories;

- Breweries and distilleries;

- Tobacco factories;

- Tanneries;

- Oil and fat production;

- Paper industry;

- Cardboard factories;

- Textile factories;

- Domestic wastewater;

- Petrochemical industry;

- Paint factories, etc.

Flamingo M flotators are designed for extracting suspended substances, petroleum products, fats, oils, resins, iron, surfactants, surfactants and other undissolved contaminants from wastewater.

Indirect flotation units have proven themselves as a preliminary step to biological treatment. In addition to extracting a significant part of the contaminants, wastewater is saturated with dissolved oxygen, thereby enhancing oxidative processes in aeration tanks and biological filters.

All Flamingo M installations are equipped with standard dispensers. The equipment is equipped with several entry points to supply different types of liquid reagent. The entry points differ in the speed of liquid flow in the flotator. This ensures the possibility of smooth supply of reagents into a laminar flow or their introduction with intensive mixing.

The equipment is designed to operate in automatic mode.

The main advantage of indirect flotation flotators over direct flotation flotators is the presence of a separate flotation pump. On direct flotation flotators, one pump performs both feed and flotation functions simultaneously. This solution is suitable for wastewater with relatively low pollution (water treatment, surface runoff, etc.). With an increase in the concentration of pollutants (sand, suspended matter, wool, fibers, grease, etc.), the load on the pump increases; this may cause it to break.

On Flamingo M indirect flotation flotators, wastewater supply and flotation are carried out by different pumps (effluent supply can be carried out by gravity). This solution makes it possible to increase the permissible concentration of pollutants at the entrance to the installation, while reducing the risk of pump failure; To supply wastewater, a fecal pump is selected that is designed for high concentrations of pollutants, and to carry out the flotation process, a pump is selected that ensures good mixing of oxygen with water. The flotation pump's resistance to contamination is compromised by the fact that it operates in a purified water chamber. Thus, indirect flotation allows you to avoid excessive mixing, emulsification of wastewater at the inlet to the flotator and improve the quality of the water-air mixture on a separate flotation pump. All this leads to an increase in cleaning efficiency compared to direct flotation flotators.

Differences between flocculants and coagulants

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

They have one purpose of implementation - water purification - but the difference between them is significant, and it, first of all, lies in the mechanism of action.

Any flocculant creates polymer bonds between individual particles of contaminants, which causes them to strengthen (change the phase to solid) and enlarge (combine), and then, under the weight of their weight, settle on the bottom and walls of the pool, from where they are easier to remove.

Whereas the coagulant destabilizes the negative charge of impurities, due to which they lose movement, begin to come closer and adhere, becoming from small, previously elusive fractions to large ones that no longer pass through the sieve of the sand filter. The same colloidal dirt, which was present in suspension and made the liquid cloudy, turns into flakes, which are much easier to remove.

Another key difference is in the speed of reaction:

- flocculation takes from half an hour to an hour - this is due to settling, the sediment takes time to form and fall out;

- coagulation occurs in 2-3 minutes, but under strict adherence to certain conditions, that is, maintaining the ambient temperature at 20-25 0C and with thorough mixing and only after the additive is well mixed with the liquid.

Yes, the substances we are considering are not the fastest-acting, but they still give results quite quickly and are not so dependent on external conditions and can be used in almost any climate, this is their absolute advantage and lies the reason for their popularity and widespread use.

Necessary conditions for long-term and efficient operation of FT installations

FT flotators will maintain the technical characteristics declared by the manufacturer for a long time and purify wastewater to the levels given in Table 2, subject to the following requirements:

- the temperature of the wastewater at the entrance to the installation should not be more than +40 degrees C; if liquid is supplied to the equipment, heating it to +60 degrees C, it must be equipped with a special pump;

- the pH value of the inlet liquid can vary from 6.5 to 8.5; in case of deviations from these values, equipment made of corrosion-resistant materials should be used;

- equipment should not operate for more than 16 hours during the day.

What it is?

A flotator is a device for removing suspended particles and organic matter from water by a combination of physical and chemical processes.

Using flotation, wastewater is purified from:

- oils;

- fatty contaminants;

- petroleum products;

- surfactants;

- organic impurities.

Reference. Depending on the type of contamination, the type of installation is selected.

Operating principles

An air mixture is supplied to the wastewater that is being purified in a variety of ways. Undissolved particles are attached to capsules of gas passing through the liquid medium. Then the containers float to the top in a state of foam (photosludge).

It is collected from the surface of the wastewater mechanically using special scrapers. Purified water is removed from the flotation chamber.

There are several ways to saturate liquid with gas capsules:

- mechanically;

- pressure;

- vacuum.

Mechanized filling of contaminated liquid with gaseous mixtures is carried out in the following steps:

- In centrifuges, wastewater is mixed until uniform. At the same time, the mass is filled with gases. The resulting capsules attract and bring polluting particles to the surface.

- Thoroughly churning the effluent in a tank equipped with paddles attached to wheels.

- An aeration option is to fill the drains with a water-air mixture through pipes located in the lower part of the tank.

When using the pressure method, oxygen is pumped into the contaminated liquid using pressure. The use of a vacuum option - sewage is saturated with air molecules in special containers.

In order for the air capsules to have the required volume, they are crushed using:

- turbines;

- nozzles;

- porous plates;

- gratings.

Interesting. In order to increase the efficiency of collecting finely dispersed contaminants in flotation plants, special reagents are often used. They increase the degree of adhesion of suspensions with air molecules.

Advantages and disadvantages

Advantages of using flotation units:

- The device is highly effective for removing many types of fine substances.

- Flotation copes quite quickly with the purification of waste liquids.

- The work of purifying purification is carried out continuously.

- All equipment has a simple design.

- Maintenance work on flotators does not involve large expenses.

- The price of the equipment is quite low.

At the same time, there are certain disadvantages of flotation cleaning:

- This option does not allow removing all types of suspensions from a liquid medium.

- Some processes use reagents, which increases the cost of purification.

- It is necessary to constantly monitor the parameters of the supplied gases. Otherwise, the effectiveness of cleansing will be significantly reduced.

effective in combination with other settling tank options Important. After treatment with a flotator, disinfection and subsequent passing of water through special filters is necessary.

- The greater the amount of suspended matter in sewage, the higher the productivity of the flotation unit.

- The effectiveness of purification is largely determined by the volume of gas capsules. A bubble that is not large enough will not have time to rise to the surface. They will dissolve on the way up. Large bubbles will rise very quickly. Therefore, they will not collect a lot of suspended matter.

The principle of operation of the flotator

The efficiency of operation also depends on:

- flotator type;

- its performance;

- degree of automation of the process.

Application area

Flotators are used mainly in purification systems in industries:

- municipal wastewater treatment plants;

- meat and dairy plants;

- poultry farms;

- canneries;

- oil factories and fat production;

- oil and gas industry.

In mining operations, this method is often used to enrich rock.