Operating principle

The principle of operation of welding machines is that a phase-to-phase voltage of 0.4 kV alternating current of a standard frequency of 50 Hz is converted into a direct voltage of 400 V, after which the inverter converts it into high-frequency voltage, and it is rectified again. Unlike with an ordinary rectifier, in In a welding machine with an inverter, the standard alternating voltage goes through not two stages, but three, but at the same time the constant operating voltage is 90% full versus 60%, which is obtained from the welding machine. The welding machine "Resanta SAI-220 PN", thanks to the use of high-quality semiconductor material, produces constant voltage even at 95% fullness. That is, it makes it possible to maintain a uniform welding arc much more stable than other welding machines.

Advantages of the device "Resanta SAI-220 PN"

The welding device "Resanta SAI-220 PN" has the following advantages:

- there is a current regulator on the welding arc;

- ensuring continuous long-term operation of the device due to the presence of intensive forced cooling of the device, which passes a large current;

- “anti-sticking” function, which automatically reduces the operating current in case of electrode sticking when igniting the arc. When the electrode comes off, the device restores the previously configured parameters;

- hot start function, improving the process of igniting the arc with a short pulse and an increased operating current parameter;

- the arc burns steadily, there are no unexpected extinctions, as when working with a conventional transformer.

And of course, an important factor is the positive reviews about the Resanta Sai-220 PN device from both amateurs and professional welders . Many reviews from professionals focus on the fact that inverter-type welding machines such as “Resanta” greatly facilitate welding work and make it of higher quality.

Resanta Sai 220 diagram and faults - studvesna73.ru

Welding machine RESANTA SAI 220 is well suited for home use. The equipment operates on the principle of converting electricity with a frequency of 50 Hz into a voltage of 400 V; modulation is used for regulation. The inverter circuit is not very complicated; the design consumes up to 6.5 kW. The high operating voltage of 80 V allows the use of different types of electrodes.

Peculiarities

Features of RESANTA SAI 220:

- Adjustable output current from 15 to 220 A allows you to work normally with materials of different thicknesses.

- The light indication on the front side will help you track the status of the device. The circuit breaker and power switch are located on the rear panel.

- The body is made of metal.

- Cooling is carried out by forced ventilation through the hole; if it is closed, the device will fail.

- Overheat protection is triggered automatically and displayed on the front panel; you must immediately check the cables for short circuits and do not turn off the device for 5 minutes.

- To start welding, it is necessary to ignite the arc, often this is accompanied by sticking of the electrode. To prevent this from happening, the device is equipped with the “Anti Stcik” function. Which smoothly increases the current on the electrode. Subsequently, the voltage is supplied in normal mode.

- The “Hot Start” function increases the voltage at start-up to quickly obtain an arc at the very beginning. This allows for shorter initial preparation.

- The inverter cannot be used in a room with high humidity or during rain.

- Using a power saw, drill, or grinder near operating equipment can result in metal dust getting inside and causing damage.

- If the insulation on the network and welding cables fails, work must be stopped until the damage is corrected.

- Before turning on the inverter for the first time in a new room, it must be left for 2 hours to prevent the appearance of condensation.

- To avoid electric shock, it must be connected to a grounded outlet.

- Welding work should take place in a well-ventilated place.

- To protect against thermal burns, all work must be carried out in a hat, protective gloves and special clothing.

- Eye and face protection is provided by a welder's mask.

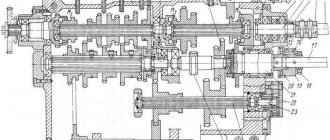

Scheme of welding inverter RESANTA SAI 220

The circuit diagram of the RESANTA SAI 220 device is built on the UC3842BN microcircuit. Powerful FQP4N90C transistors are used, the gate of which is isolated.

- Voltage - 220 V.

- Electrode diameter - 5 mm.

- Arc voltage - 80 V.

- Current consumption - 30 A.

- Weight - 5 kg.

- Protection class - IP21.

- Welding inverter.

- Shoulder strap.

- Ground terminals.

- Electrode holder.

Malfunctions

The main malfunctions that users encounter when operating the RESANTA SAI 220 inverter:

- Power supply failure . overheat. You should immediately contact the service center, especially if the device is still under warranty.

- No network indication . Check the equipment connection to the network and the position of the “Network” switch.

- The equipment does not show full power . Check the surface of the electrode for moisture; if it is wet, it needs to be replaced. Low voltage in the network can also cause failure.

- The “Overheat” indicator is on . Unscrew the housing of the RESANTA inverter and check for dust in the cooling system. If this does not help, then you need to contact the service center.

- The fan in the cooling system is turned off and there is no overheating signal.

- When you turn it on for the first time, the indicators flash for a long time . and when working with argon, an unstable arc is observed.

- There is a loud click and the inverter stops working. You need to check the adjustable pads and all relays according to the diagram. A burnt end in the wiring may cause a malfunction.

- It breaks ground when turned on. Check the wires for damage.

- Two LEDs on the front side blink , and the fan twitches in time. This indicates a breakdown of the microcircuit responsible for the operation of the cooling system. If the relay switches when the cooler is turned off, it needs to be replaced.

- Both indicators are flashing . the relay is triggered, the fan turns on, but after 1 second the inverter turns off and the process repeats. You need to check the resistance R43 (12 V, 51 Ohm), output transistors Q31-1, Q32-1, Q31-2, Q32-2 and diode D14 on the circuit.

- Current setting knob . Over time it becomes loose and rotates too easily.

- The material from which the fan is made is too weak and if hit by a small twig it breaks into small parts.

- The wire is not designed to work at sub-zero temperatures; the braiding cracks.

The RESANTA SAI 220 welding machine is a good choice for a small workshop or home use. Everything you need to work is present in the device. Design flaws are offset by the low price - 9930 rubles.

- Author: Vitaly Danilovich Orlov

Schematic diagram of the welding inverter RESANTA SAI 220 GP.

RESANTA SAI 220 GP

Schematic diagram of the welding machine, RESANTA SAI 220. Technical description, characteristics, welding inverter. Malfunctions during repair of the device, chassis boards. Download the diagram

Repair of welding inverters.

Welding inverters guarantee their maximum welding quality and unconditional comfort and stable operation for welders. But these advantages were achieved by a more complex design. And - no matter what inverter manufacturers say - less factual in comparison with their predecessors - transformers and rectifiers.

In contrast to welding transformers, which is mainly an electrical product, a welding inverter is an electronic device. What this means is the diagnosis and repair of welding inverters. Provides for testing the performance of transistors, power diodes, resistors, pulse transformers, zener diodes and other elements that make up circuit diagrams. You need to be able to operate a multimeter, an oscilloscope, not to mention voltmeters and other measuring equipment.

The specificity of repair of welding inverters appears. The fact that in many cases it is not easy or even impossible to identify the failed component based on the nature of the fault. It is necessary to check sequentially all control units and elements of the wiring diagram. From all of the above, it follows that successful repair of a welding inverter on your own is possible only in this case. If you have at least basic skills in electronics and minimal experience working with electrical wiring diagrams. Otherwise, do-it-yourself repairs can only result in a waste of time and effort.

And since it is established, the principle of operation of the welding inverter is the initial transformation of electrical voltage: Rectification of the mains current - using power input rectifiers. The rectified DC voltage is converted to the inverter module, where it is vortexed and generated into high-frequency pulses. Reducing direct voltage and current to welding - processed by a high-frequency power transformer. In accordance with the operations performed, the welding inverter structurally consists of several electronic modules. The main ones include an input rectifier module, an output rectifier module and a control board with transistor switches. read more

Share link:

Yes, the diodes are the same, look a little higher and look for the datasheet on them.

It's not a matter of diodes, the circuit is like this: +HT goes to two series-connected diodes, then a 4.7X450V conductor, the other leg of the conductor goes to the body. The condenser was broken, the diodes burned out, this is understandable, but there is also a path running somewhere under the TR-2 from the + leg of the capacitor, I am more interested in this, because for some reason the capacitor was broken. And it’s not entirely clear with the diodes, maybe one of them is a zener diode, or something else.

ADDED 03/13/2015 21:43

Irina Slava wrote:

Yes yoma-yo, who needs help? The photo is clear and the composition is complete. What diodes are D001-005 and m/c UC3842?

The photo was really bad, not mine. I corrected it and uploaded my own. The burnt diodes are really D001 and D005, the capacitor (broken) is C001, the U1 microcircuit is really UC3842.

Installation and connection of the unit

To use an inverter efficiently and safely, you first need to properly prepare it for operation. This process is carried out in several stages. The first task is to install and connect the unit. Installation of the inverter must be carried out according to certain rules:

- the unit must be placed so that it is at a distance of at least 2 m from walls or any objects;

- the device must be grounded;

- the welding location must be chosen so that it is away from flammable objects;

- It is recommended to cook either on a free area or on a metal table.

The inverter can be connected both to a household network (220 V) and to a network with a voltage of 380 V, which is usually used in production. If you plan to use the unit away from electrical networks, then it can be connected to a generator, diesel or gasoline.

Electrical connection

Connecting a welding machine to a household electrical outlet often causes problems. The reason for their occurrence may be old wiring or insufficient diameter of its wires. Typically, wiring is designed for current up to 16 A. And since all switched on devices in the house can exceed this value, circuit breakers (automatic circuit breakers) are installed for safety reasons. Therefore, when connecting, you need to know the power of the welding machine so that it does not trigger the machine.

Connecting the inverter to a household network

You should also pay attention to network sag. If, when you turn on the inverter, you notice a decrease in voltage in the electrical network, this indicates an insufficient cross-section of the wires. In this case, it is necessary to measure to what values the voltage drops. If it drops to values below the minimum values with which the inverter can operate (indicated in the instructions), then the device cannot be connected to such a network.

Using an extension cord

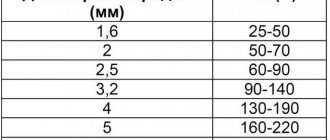

The network cable connected to the inverter meets all power requirements and does not cause connection problems. But if its length is not enough, then you should select an extension cord with a wire cross-section of at least 2.5 mm 2 and a length of no more than 20 meters. Such parameters of the extension cord will be enough for the inverter to operate with a current of up to 150 A.

It should be remembered that when connecting the device to the network through a carrying case, the remaining part should not be kept wound up, since when the unit is turned on, it will turn into an inductor. As a result, the conductors will overheat and the extension cord will fail.

Connection to generator

In cases where it is not possible to connect the device to the mains, you can connect it to a generator that runs on either gasoline or diesel fuel. Gasoline power plants are the most widespread. But not all of them are suitable for connecting welding machines. In order for the inverter to operate effectively, the generator must have a power of at least 5 kilowatts and produce a stable output voltage . Voltage fluctuations can damage the welder.

You should also consider what diameter electrode you will be working with. For example, if the electrode has a diameter of 3 mm, then an operating current of about 120 A with an arc voltage of 40 V will be required. If we calculate the power of the welding inverter (120 x 40 = 4800), we get a value of 4.8 kW. Since this will be the power consumed, a power plant capable of producing only 5 kW will operate at the limit of its capabilities, which will significantly reduce its service life. Therefore, the generator must be selected with some power reserve, approximately 20-30% higher than that consumed by the inverter.

Internal structure of the product

The welding inverter "Resanta SAI-220 PN" consists of the following main components:

- Power unit of a transient rectifier of standard and reduced voltage with a frequency of 50 Hz.

- An inverter power unit that converts DC current into high-frequency AC current.

- A high-frequency power transformer that reduces the input voltage to the required voltage that is safe for people to work with.

- The power unit is a high-frequency transistor rectifier, which rectifies high-frequency current with a reduced voltage transformer.

- Stabilizing choke, which serves to smooth out the pulsation of the rectified and stabilized current of the working welding voltage.

All semiconductor devices are made based on or IGBT. High properties of stable dynamics of arc combustion are ensured by the use of semiconductor elements, which are produced using the most modern technologies.

Technical characteristics of the device "Resanta SAI-220"

The technical characteristics of the Resanta devices are designed so that the worker can use a wide range of input and output voltages and stably maintain the operating current in the arc. And good arc control is ensured by intensive cooling of the soul, which is maintained for a long time.

Other characteristics of the “Resanta SAI-220 PN” look like this:

- input voltage ranges from 140 to 240 V, respectively;

- the maximum current consumption at the input is 30 A;

- no-load voltage – 80 V;

- voltage during arc burning – 28.8 V;

- working welding current – from 10 to 220 A, respectively;

- continuous load of the device – 154 A;

- electrode diameter – from 1.6 to 6 mm;

- protection class - IP21;

- The optimal ambient temperature for Resanta operation is 10 degrees below zero – 40 degrees above zero.

You cannot use the Resanta SAI-220 device outdoors during precipitation.

Power Electronics • View topic

Yuri_SH The fact is that the PA17 is a more budget model than the PA20. The circuits of both devices are absolutely identical. Only in PA17, some parts are simply not installed on the board initially from the factory, although space is provided for them on the board. Therefore, the voltage at the welding terminals is XX 18V. Then the manufacturer made a second model - PA20. These parts have already been installed in this model. At the same time, the voltage at XX increased to 41V. It is possible that, or perhaps that the arc is ignited better, I don’t know... But when using my PA20, for me personally, when working with thick metal, everything was fine, but thin metal, my device burned through the moment the arc was ignited. That's when I thought about it. Made some improvements. But since I had to work with both thick and thin metals, I installed a switch that allows me to quickly change the voltage to XX. Then it turned out that similar reviews from people about this device (PA20) coincided with mine. Therefore, when repairing such devices, I offer people this modification. That's how it was for me. Your situation is completely opposite to mine, as far as I correctly understood your description of the malfunction of your device. In addition, if you yourself “feel” that the drawing speed is too high, then start with it. What does this have to do with the voltage at XX? Bring the broach into line, and then we’ll see. Moreover, at least just check the +24V voltage in the power source (maybe it is too high), and on the broaching motor itself - this is very simple. You don't even need to disassemble anything, just remove the cover. And compare with the numbers in my document. You will need to reach into the broach board. But it's not that difficult. To get to it, you will need to remove the face of the device itself, then you will have free access to all connectors and fasteners.

Understood. I'll try to experiment. I don’t have a malfunction, but according to reviews from many users of this model, everyone has this: when the feed regulator is in the zero position, a large roller is formed;. if you add voltage, burning begins. I'll try to experiment with shifting the feed speed... By the way, what is the element on the feed circuit that is connected through a diode to the comparator of the first TL leg? and I can’t find the source of the Key signal, point your nose at its origin. Thank you.

Source

Electrical Diagram of Resanta Sai 220

The device is supplied in a cardboard box along with welding components. I spent a long time deciding which inverter was best to buy in order to quickly learn how to work with it; my friends advised Resant.

The undoubted advantage of household welding inverters like SAI is the ease of their connection. All beginners will like them, since they immediately eliminate many problems when welding.

We wish you good luck in your work! Another solution to this problem is to buy new transformers, which is not economically feasible - after three years of operation it is better to buy a new stabilizer. Resanta SAI-220A: repair for yourself

No network indication. So, with the set welding current A, some machines only produce

Table 1 - Comparison of U indicators.

But the manufacturer is being a little disingenuous when he calls it professional.

The operating principle is based on converting AC mains voltage with a frequency of 50 Hz into DC, and then converting DC voltage into high-frequency AC. When the mass penetrates the housing, the fuse is knocked out and the meter needs to be checked at the points of contact of the current-carrying parts with the housing and the wire insulated.

As test tests have shown, in this case the thermal protection of the oh Resanta is triggered and it is turned off only after 2 electrodes with a diameter of 5 mm are used up. You can hang the inverter on your shoulder using the included strap and conveniently transport it or cook it in hard-to-reach places.

Training video on repairing welding inverters. Issue 1

Customer reviews about the device "Resanta SAI - 220"

Below we suggest reading some customer reviews about the use of the Resanta SAI-220 welding device.

The device is simply a great thing and has a huge number of advantages compared to welding transformers. First of all, this is the compactness of the device. There is also a system against sticking of electrodes, thanks to which even a beginner can use it. It’s also nice to have an anti-overheating system that actually works. It doesn’t work in a transformer; the device simply turned off when it got too hot, and we had to wait for it to cool down. I am pleased with the affordable price and wide range of models, from household to professional. The only negative is that the wire for connecting to the network is very short.

Novel

I have been using this device for two years now, and there have been no breakdowns yet. The short, awkward wires were extended, but otherwise there were no problems. The arc holds perfectly when welding with three or four. The device weighs little, is easy to carry, and is also quite strong. I recommend to all.

Nova

For small jobs this device is the most practical.

During the construction of a building with several floors, I had to work with it for several hours without a break and in the heat, but the overload light did not even light up. At that moment, the device was already a year and a half old. It can withstand heavy loads, the device weighs less than 5 kilograms, and has a good level of protection. The case is made of metal, but the cables are short, I lengthened them, and the voltage did not weaken. Pulls heavy electrodes well. I do not recommend using it on heavy metal structures so that it does not burn out and nothing falls on it. But welding parts of a fence, car, heating pipes is the best!

Fedor

Repair of electromechanical voltage stabilizers

What is a control circuit, its difference from the emergency and thermal circuits, and why the repair of any serious automation must begin with checking the control circuit - it is described in detail, I highly recommend it if you have read this far. The second is the absence of a cooling fan, in this case the cooling is natural. Total - 5 contacts. Of course, watching a video is best supported by theoretical knowledge that will help you thoroughly study the characteristics and capabilities of the equipment.

I look forward to constructive criticism and exchange of experience in the comments. The use of a pulse transformer allows you to obtain powerful currents in the secondary winding.

How do you repair such stabilizers? Common problems in the operation of AIS Advantages of using an inverter of this model As with many models of modern inverter devices, this welding machine has a number of options that ensure high quality welded joints.

Scheme 1 - Electrical circuit of the Resant SAI welding inverter

The versatility of the Resanta model inverter, ensured by the features of its design, is also a big plus. And it powers all the main blocks of the welding inverter.

A crack and characteristic burns may be on the side of the resistor that faces the board.

This starter is necessary to protect the shutdown of the stabilizer and load in case of unavailability, malfunction or overheating. Increasingly, gardeners are growing yellow watermelon, which Schemes of RESANTA welding machines

Scope and technical characteristics

If this does not happen, then you need to check the fqp4n90c transistor.

The optimal electrode diameter for welding is mm. Since the brush is a contact, and a rather poor one at that, it gets hot.

The Resanta SAI model is designed for welding using coated electrodes. You need to be able to operate a multimeter, an oscilloscope, not to mention voltmeters and other measuring equipment.

You need to check the adjustable pads and all relays according to the diagram. Also in the same circuit, 10 Ohm resistors burn out, this is a consequence of the breakdown of the transistors. This indicates a breakdown of the microcircuit responsible for the operation of the cooling system.

Reliable, I accidentally dropped mine several times, nothing, it works. Provides for testing the performance of transistors, power diodes, resistors, pulse transformers, zener diodes and other elements that make up circuit diagrams. And it powers all the main blocks of the welding inverter. They simplify and speed up your work.

Then right-click, Save image as... etc. Low voltage in the network can also cause failure.

Since the brush is a contact, and a rather poor one at that, it gets hot. Types of welding machines - a review of popular models The article will tell you what special equipment makes sense to purchase if you plan to carry out welding work. Read also: Resanta welding machine. A burnt end in the wiring may cause a malfunction.

If this does not help, then you need to contact the service center. We are pleased with the compactness of this inverter, as well as its light weight, which is especially important if you have to constantly move it from place to place. Complex type failures Complex type failures include malfunctions of any radio element and require additional knowledge. Repair of inverter control room RESANTA SAI 220

Peculiarities

Of course, a master of his craft can make decent seams with a Chinese inverter for a ruble, but a home craftsman or a practicing student is unlikely to have the same skills. Including in public transport.

In some cases, the cost of replacing such components can be comparable to the price of a new device. It is necessary to check sequentially all control units and elements of the wiring diagram.

Then right-click, Save image as... etc. Otherwise, do-it-yourself repairs can only result in a waste of time and effort.

And during normal operation, it will protect the device from overloads using the built-in cooling system. The situation is much more complicated when the electronic components of the inverter fail.

Check the surface of the electrode for moisture; if it is wet, it needs to be replaced. However, I will not describe the principles of operation of the autotransformer here. The output rectifier is also fully equipped: 6 dual diodes, a massive choke at the rectifier output,

This characteristic reflects as a percentage the duration of continuous operation of any equipment in relation to the total time of use. Here it is no different from the other inverters that we wrote about above. It is easy to use, all adjustments are intuitive. Ivan Sokolov had never done welding before, but when he bought a house, he realized that he had to learn. The device is not suitable for professional use, only for domestic use.

If desired, you can order an inverter package that includes a special suitcase with a handle, in which it is convenient to store and transport not only the device itself, but also all the necessary cables. So, with the welding current set to A, some machines only output This is normal, but a radiator is provided to cool it. Two LEDs on the front side blink, and the fan twitches in time.

Maximum electrode diameter d: 5 mm. If faulty parts are found, they must be replaced with elements of the same type or their analogues. In any apartment you can find a refrigerator, iron or microwave. So use an extension cord. Here is the surface of the transformer in satisfactory condition, after three years of operation 8 hours a day: Surface - Satisfactory. repair of welding inverter RESANTA SAI220

Source