Resanta welding machines are simply extremely popular in Russia. The equipment is reliable and, of course, convenient to use. Instruments of this brand have been known on the domestic market for a very long time - since 1993. They can be used both at home and at work.

The model range of the Resanta brand presented on the domestic market is quite wide. If desired, consumers have the opportunity to purchase equipment of this brand with a variety of technical characteristics and functionality. At the same time, one of the most popular models from this manufacturer is the Resanta 160 device. This equipment has received simply excellent consumer reviews.

Who releases

is a Latvian company SIA RESANTA. This company began its activities in 1993. Initially, it was engaged only in the production of voltage stabilizers. These company products are also well known throughout the former USSR.

The quality of the devices is really quite good. And therefore it has always enjoyed enormous popularity among consumers. Thanks to this, by 2008 the company was able to increase its production volumes 10 times compared to 1993.

Today, in addition to voltage stabilizers, the company produces compressors, multimeters, thermal equipment, testers, etc. And of course, this company also supplies high-quality inverters to the market.

Main advantages of the model

The Resanta 160 welding machine has many advantages. These include, for example:

- high level of operating current;

- ability to work at low voltage;

- Possibility of use at unstable network voltage.

This device is also compact. It is believed that it is simply ideal for work in domestic conditions. But, unlike many other Resant models, this equipment can also be used in production. This device belongs to the inverter type devices. That is, its design contains a unit designed to convert alternating current from the network into direct current.

Specifications

The Resanta inverter model SAI-160 has the following technical characteristics.

- The maximum current consumption is 22 A.

- The voltage required for the device to operate is 220 V. The inverter of this model is capable of operating stably with voltage surges from -30 to +10 percent. With even more significant voltage drops, a modernized model of this device - Resanta SAI-160 PN - can operate.

- The duration of time under load at the maximum value of the welding current is 70 percent for this device.

- The welding current can be adjusted in the range of 10–160 A.

- The voltage when the welding arc is burning and when the equipment is idling is 26 and 80 V, respectively.

- Equipment weight - 4.5 kg.

Technical characteristics of Resanta inverters, including SAI-160

Protection class SAI-160 according to the international classification is IP21; for working on such equipment it is allowed to use electrodes whose diameter does not exceed 4 mm. Operating this inverter, as indicated in its data sheet, is permitted at ambient temperatures from -10 to +40 degrees.

As is clear from the characteristics of the equipment of this model, it is preferable to use it for semi-professional welding work; its properties will not be enough for use in industrial conditions.

General description of the model

One of the undoubted advantages of the Resanta SAI 160 inverter welding machines is a wide range of current strength. At the same time, the wizard can set the required value manually. Thanks to this feature of the device, it can be used both for delicate welding using thin electrodes and, for example, for cutting thick metal.

The housing of the Resanta 160 welding machine is equipped with fans. These elements perfectly complement the natural air cooling of the device. If desired, models 160 can be used in low power networks. It is also possible to connect them through generators.

Of course, this model has all the functions that distinguish modern inverters from previously produced less advanced and convenient devices:

- preventing sticking;

- hot start.

If the electrode sticks to the surface being welded, the current in the machine automatically decreases. And this, in turn, reduces heating. As a result, the electrode easily comes off the metal.

At the very beginning of operation of the Resanta 160 inverter, the current increases sharply. This leads to rapid heating in the place where the electrode contacts the metal surface. Therefore, a welder using this equipment never has problems with electrode sticking at the beginning of work.

Modifications of Resanta SAI 160

There are several modifications in the Resanta Sai 160 inverter line.

Resanta SAI 160A

A device with a maximum operating current of 160 A. A basic, inexpensive and compact unit for welding RDS with a stick electrode equipped with a protective coating.

Suitable for domestic use, as a training model or as a first welding machine. With its help, the user can easily repair metal gates, install metal supports and wires for the fence, repair the greenhouse and perform other work that requires welding.

The device is supplied with an electrode holder, a terminal, two two-meter cables, and a power cable that connects to a regular outlet.

The technical capabilities of the model include hot start and anti-sticking. Experts advise learning how to independently ignite the arc and set the welding mode to extend its service life.

Resanta SAI 160PN

Not much different from the previous model, but costs much more. Has a low voltage function. The abbreviation PN in the model name directly indicates that the device will be able to carry out welding at reduced voltage in the network or its instability.

If the power grid “suffers” from such voltage surges, then it is more profitable to buy an SAI 160PN than to buy an additional stabilizer in addition to the cheap SAI 160. This is relevant for work in the country, where the quality of the electricity supply, including voltage, leaves much to be desired.

Resanta SAI 160K

This is an indispensable carrying device. Its weight is only three kilograms, and its dimensions allow it to be hidden in an ordinary backpack. The user can easily move with it in public transport, which is important for on-site repair technicians at the customer’s site.

Despite its compact size, this “baby” can easily cope with welding thick-walled parts or surfaces. The technical characteristics of the device allow it to be used with a short-term voltage drop to 210V. But under the condition of constantly unstable operation of the electrical network, a voltage stabilizer is needed.

Mains voltage and electrode diameter

The technical characteristics of the welding machine "Resanta 160" are really quite good. The ease of use, and therefore the popularity among consumers of this model, is explained, of course, primarily by the thoughtfulness of its design. In everyday life, the use of 160 devices became possible due to the fact that they operate from a 220 V network. For industrial equipment of this type, as is known, 380 V is required. Previously produced welding machines were designed to operate from precisely such networks.

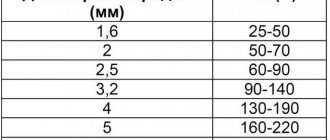

The maximum current of this model, as can be judged by its name, is 160 A (with a minimum of 10 A). If necessary, welding can be performed with the Resanata 160 machine using fairly thick electrodes. The maximum diameter of the latter for this model is 4 mm. The minimum electrode diameter for the device is 1.6 mm.

Modifications

Resanta SAI 160 (aka 160A)

Price: ≈5500 rubles (≈80$)

Resanta SAI 160, also called SAI 160A, is an inexpensive and compact entry-level inverter. It is designed for RDS welding using a stick electrode with a protective coating. The manufacturer positions this device as a household device, and we agree with this. SAI 160 is perfect for a student for training or a home handyman as a first inverter.

The maximum welding current is 160 Amps. Not much, and not little. This is enough for training and simple repairs of a garage door, fence gate, greenhouse or steel barrel. In a word, for non-professional work. SAI 160 plugs directly into the outlet. You can use a regular household outlet in your home. For welding, it is recommended to use electrodes with a diameter of up to 4 mm.

The SAI 160 kit is small. In the box you will find 2 cables with an electrode holder and a terminal. Both are two meters long, which is enough for everyday tasks. And if you need a longer length, you can purchase an extension cord separately. Also included is a power cable. It is, in our opinion, a bit short. Length only 1.7 meters.

Open circuit voltage

This figure for the model is 85 V. This figure, in comparison with many other modern devices, is quite large. This no-load voltage makes it very easy to ignite the arc in Resanta 160 devices. However, at the same time, the high value of 85 V, unfortunately, somewhat reduces the safety of use (discharge from accidental contact can cause harm to health) of this equipment. However, model 160, like most other modern ones, is equipped with a special function of protection against electric shock to the master.

Features and advantages of the Resanta SAI 160K compact model:

- Despite its compact size and low power consumption, it works effectively with electrodes up to 4 mm in diameter;

- It tolerates power surges well up to 20V in both directions thanks to the built-in stabilizer;

- Demonstrates high stability of operation at low temperatures down to -10 degrees;

- Provides uniform processing of the electrode core, which has a good effect on the quality of the seams. The error per 1 meter of continuous length is no more than 0.5 mm;

- Reliable function of protection against sticking of the electrode on the surface when welding large sheet parts;

- Intuitive settings are the best solution for a novice amateur welder;

- Proper arrangement of internal elements to protect against breakdown on the device body;

- Sufficient length of all welding wires, it is unlikely that you will have to buy additional terminals and sharpen the wiring;

- Low maximum current consumption, which allows you to use household sockets and connect to a simple network without direct connection to the panel;

- Can be used not only for welding, but also for cutting. At maximum power, the device burns sheets, pipes, and fittings;

- Shockproof arrangement of elements in the housing. Can withstand harsh operating conditions, including minor shocks and drops;

- Very low price, especially compared to imported analogues.

Cooling system and protection class

The Resanta 160 model can serve in the household for a very long time. A good welding machine nowadays should also have an effective cooling system. Of course, when developing the Resanta 160, the designers took this into account. As soon as the equipment warms up to a certain temperature during operation, its fans automatically turn on. “Resanata 160” has two of the latter, which is a good indicator for a modern budget device.

When purchasing an inverter, you should also pay attention to its protection class. Of course, carrying out welding work, for example, in the rain using such equipment is strictly prohibited. However, the higher the protection class of the model, the better, of course. After all, anything can happen in life and the device can, for example, be forgotten on the street. Or it may suddenly rain while working. Resanta 160 models belong to IP21 protection class. This means that they can remain safe in direct rain. When oblique, it is better not to use them under any circumstances.

SAI 160 inverter circuit

The circuit of the Resanta SAI 160 welding inverter is in many ways similar to the circuits of other inverters from the same line. Below we attach several diagrams that will be useful to you for repairing the SAI 160 or for assembling a similar inverter at home. All images can be viewed in high resolution, just open them in new tabs.

Reviews about the model

The opinion of consumers on the Resanta 160 welding machines, as already mentioned, is simply excellent. The undoubted advantages of this model include, of course, the ability to work at unstable or low voltage, as well as compactness and low weight. Another advantage of this inverter is its relatively low cost. The price for Resanta 160 devices is approximately 7,000 rubles. That is, this equipment costs much less than much other similar modern equipment.

The 160 inverter rarely requires repairs. The equipment is quite reliable and durable. However, if it breaks, it will not be particularly difficult to repair it. Service points specializing in this brand are available in many cities of the country.

Thus, this model has many advantages. This is a really good welding machine. But this inverter, of course, according to consumers, also has some disadvantages. Masters include, first of all, as already mentioned, short cables. Also, some consumers note the fact that defects are sometimes found in batches of Resanta 160. In this case, the device must be repaired or replaced with a new one.