Decoding the abbreviation and brand

Decoding the name of the electrode E42 and E42A is quite simple. The abbreviation encodes the main characteristic that distinguishes the welding material from others. This is the strength of the suture material, equal to 420 MPa. E stands for arc welding electrode.

Popular brands of E42 are:

- OZS-42;

- OZS-12I/42;

- OMA-2;

- Ogonyok;

- OZS-23.

In addition, a modified version is widely known among professionals: E42A electrodes of the UONI-13/45 brand. The technical characteristics of the improved E42A electrodes are noticeably superior to the basic model.

Description and scope of application

The consumable type is a steel rod with a protective coating. Under the influence of high temperature, the coating burns out and turns into a gas, separating the molten metal from the oxygen of the atmospheric air.

Most electrodes of this type are used for the manufacture of:

- lightly loaded structures;

- thin-walled pipes and low-pressure tanks.

It is allowed to carry out surfacing repairs with their help.

The scope of application depends on the brand of E42 electrodes. They are available in different designs, differing in diameter and composition of the protective coating.

Improved SSSI E42A

The only variety with basic coating.

It contains phosphorus compounds and carbides, prevents the appearance of hot cracks and gives the weld the following properties:

- plastic;

- impact strength.

These features are indicated by the index “A” in the marking.

They allow the use of E42A type electrodes for the manufacture of structures:

- placing high demands on reliability, including those experiencing alternating loads;

- operated at low temperatures.

UONI E42A electrodes contain phosphorus compounds and carbides.

Consumables are produced in the UONI 13/45 category and have the following distinctive features:

- They work only with direct current of reverse polarity (electrode-positive).

- They require cleaning the joined workpieces from rust, oil stains, dirt and water.

- Not suitable for welding in high humidity conditions.

- They are used economically due to the presence of iron powder in the coating, which compensates for the loss of metal due to evaporation and splashes.

UONI E42A electrodes are intended for the manufacture of critical structures in the workshop.

They are capricious, so the welder requires experience and dexterity. Inverter-type welding machines are used; rectifiers are not capable of ensuring stable arc burning. The current should not be increased, as this has a bad effect on the quality of the seam.

Types of coating and diameters

In addition to the main coating, the following is used:

- Sour. It contains oxides of iron, silicon and manganese. Such electrodes are used to weld with caution due to the high probability of so-called formation in the seam. hot microcracks (intergranular fractures).

- Rutile. Rutile is a mineral with large amounts of titanium dioxide. The consumables coated with it form a plastic seam, the level of deoxidation corresponding to semi-quiet steel. They tolerate high current well and do not allow the appearance of hot microcracks.

Acidic electrodes contain oxides of iron, silicon and manganese.

Acid and rutile electrodes of the E42 type are produced under many brands, for example OMA-2, VSTs-4 and 4M, Ogonyok, OZS-23, ANO-6, 6M, 17, etc. They cook well not only permanently, but also AC powered and suitable for beginners.

The diameter of E42 consumables is 2-12 mm. It is selected in accordance with the thickness of the smaller workpiece. This parameter determines the current strength. Thus, to weld corner No. 5 according to GOST 8509-93 with a flange thickness of 6 mm, an electrode of size 4 (mm) is required. The amperage is 120-200 A.

Thick consumables are used to connect massive parts in one pass. In this they are superior to semi-automatic installations on non-consumable electrodes with filler wire supply.

Explanation of markings

The letter “E” means “electrode for manual arc welding”, the number 42 is the temporary tensile strength, which is 42 kgf/sq. mm.

We recommend reading: The main features and nuances of using electrodes of the E50A type

The full electrode marking also contains other data, for example E42A-UONI-13/45 SM-4.0-UD GOST 9467-60.

Explanation of product markings:

- SM-4.0 – made of welding wire with a diameter of 4 mm.

- U - intended for welding carbon steel.

- D – has a thick coating. Other options: S – medium, M – thin.

The product meets the requirements of GOST 9467-60.

Decoding the names of electrodes.

Application area

Welding consumables of the E42 series are used in the assembly of critical products from carbon alloys.

They are also used for installing pipes with thin walls for transporting liquids and substances under low and medium pressure.

Electrodes E 42 do not require high qualifications from the welder, so they are readily used not only by professionals, but also by novice craftsmen in car service centers and home workshops.

The affordable price of the product only adds to its attractiveness.

Distinctive features and specific application

Type E42 is a universal product for mass use. However, some features of E42 electrodes can be noted for it:

- The resulting welded joint is strong and ductile, and is highly resistant to fracture loads.

- The resulting slag crust is easily separated from the suture material.

- The connection is characterized by a highly homogeneous structure, low porosity and the absence of cavities.

- The product does not require high qualifications and experience for successful use; it is enough to strictly follow the welding modes and welding technology.

- Easy arc ignition.

- Low material consumption per kilogram of seam.

- Wide range of flux coatings.

- Wide range of diameters – up to 12 mm.

- Excellent price/quality and price/functionality ratio.

Electrodes of small diameters are successfully used for welding structures at home, both with an inverter welding machine and with outdated bulky welding transformers and rectifiers. As long as the specified distance from the tip of the rod to the part is maintained, voltage surges in the network have a negligible effect on the stability of the arc.

Electrodes E42 diameter 5.0 mm

Diameters of 6-12 mm are used mainly in industrial environments, together with professional high-performance welding stations that develop operating currents of up to 600-800 amperes. E42 electrodes with a diameter of 8 mm allow you to weld parts with a thickness of over 8 mm in one pass, which makes them competitive in performance with semi-automatic machines that use welding wire.

E42 is not recommended for working on high-alloy alloys, stainless steel, non-ferrous alloys, and cast iron.

Specifications

In accordance with the requirements of GOST 9466 and GOST 9467, E42 are designed to operate with both alternating and direct current . The coating can be either acid-based or based on the mineral rutile (titanium dioxide). Acidic coatings often result in multiple cracks. For alloys characterized as calm or semi-quiet, it is preferable to use rutile coating.

When the coating burns in an electric arc flame, a cloud of protective gas is formed, displacing air from the working area and preventing contact of the molten metal with oxygen and nitrogen, as well as with water vapor. In addition, the additives contained in E42 act as alloying components.

The products of the series are characterized by the following physical and mechanical parameters:

- temporary tensile strength: 420 MPa;

- impact strength of suture material at normal temperature: 150 J/cm2;

- the same at -40C: 35 J/cm2;

- relative elongation up to 22%;

- temperature range of application: -20+20°C;

- deposition factor: 1.6.

The parameters of the series products make them a good choice for the installation of complex technological structures designed to operate at low temperatures, both for cryogenic equipment and for polar vehicles and infrastructure elements. The high strength of the suture material opens a wide way for electrodes to be used in welding critical, highly loaded metal structures in construction, mechanical engineering, and the defense industry.

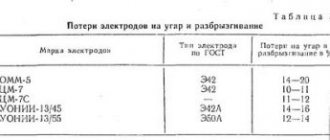

Theoretical and practical calculations

The consumption of electrodes can be calculated from a theoretical point of view using a large number of special formulas. Let's look at the most common ones.

The first method - by coefficient - is used to calculate the consumption of various welding materials, and not just electrodes:

H = M * K, where M is the mass of the structure being welded; K is a special flow coefficient from the directory, which varies in the range from 1.5 to 1.9.

The second method is based on calculations depending on the physical properties of the electrode and the metal structure . Allows you to determine the mass of deposited metal. Here the performer will need to know the reference data, and it is also necessary to measure the connecting seam:

G = F * L * M, where F is the cross-sectional area; L – weld length; M – mass of wire (1 cm3).

Practical calculation involves carrying out test work. After their completion, the welder should perform the following actions:

- measure the cinder;

- take into account voltage and current;

- determine the length of the welded joint.

These data make it possible to determine the consumption of welding electrodes when welding structures with a seam of a certain length.

The contractor will be able to obtain accurate indicators only if the external data and the position angle during the main work are identical to those that were during testing. To avoid inaccuracy of parameters, it is recommended to carry out the experiment 3-4 times. This will allow you to obtain more accurate calculations than using theoretical formulas.

Using these methods, you can easily calculate the consumption of electrodes per ton of metal structures. However, you should remember that there is an error.

Diameters

The thickness of the electrode is calculated by the diameter of the welding wire core. Products of the E42 series are available in diameters from 1.6 to 6 millimeters . This makes it possible to select the appropriate thickness for both thin-sheet and solid structures of various spatial configurations. The coating diameter of the E42 series electrode depends on the thickness of the rod. Thicknesses of 1.6-3 mm correspond to the usual length of 25-30 cm, electrodes with a diameter of 4 mm E42, as well as 6 mm ones, are available in both 30 and 45 cm. Products are shipped in packs or in sealed containers.

Acquaintance

Electrodes E42 (GOST No. 9466, 9467) are metal rods equipped with a special coating. During welding operations they are used as auxiliary filler materials.

The range of these products on the modern market is quite wide. The consumer can purchase E42 electrodes with a diameter of 1.6 mm, 2-3 mm and 4-6 mm. Standard sizes of auxiliary products vary between 250-400 mm. The length of E42 electrodes with a diameter of 4 mm can reach 450 mm.

Product Features

According to the technical specifications, it is permissible to work with E42 products in all welding positions and directions, excluding vertical from top to bottom . Special additives reduce the fluidity of the melt, keeping it within the boundaries of the weld pool. This gives technologists ample opportunities to design and optimize welding processes.

The suture material resulting from the operation of the electrode is characterized by a highly homogeneous structure and minimal void defects. After combustion of the coating, an easily removable slag crust is formed.

E42 is also characterized by easy ignition and high stability of the electric arc.

The suture material is characterized by high strength and sufficient ductility. This increases the ability of structures to withstand both static and dynamic loads.

Electrodes are characterized by reduced requirements for surface preparation and operating conditions . Even wet workpieces with traces of corrosion can be welded with sufficient quality.

Features of operation

E42 electrodes are easy to use, easy to ignite and withstand voltage surges well. Most types weld rusty and damp metal without losing the strength and ductility of the joint.

The slag crust on the weld surface is easily separated, which reduces the cost and speeds up finishing.

Welding modes

This concept denotes actions and parameters designed to ensure high quality welds under given conditions.

Welding modes provide high quality seams.

Indicators are divided into 2 groups:

- basic;

- additional.

The first include:

- type and strength of current;

- electrode diameter;

- arc voltage.

Additional:

- spatial position of the seam;

- speed of movement of the consumable;

- composition and thickness of the metal.

E42 electrodes are used to cook with direct and alternating current, in the first case with reverse polarity. The amperage is related to the diameter of the consumable and the thickness of the workpieces being connected.

The data is summarized in the table:

We recommend reading: What are the types of electrodes for welding?

| Thickness of welded parts, mm | 0,5 | 1-2 | 3 | 4-5 | 6-8 | 9-12 | 13-15 | 16 |

| Electrode diameter, mm | 1 | 1,5-2 | 3 | 3-4 | 4 | 4-5 | 5 | 6-8 |

| Current strength, A | 10-20 | 30-45 | 65-100 | 100-160 | 120-200 | 150-200 | 160-250 | 200-350 |

Wrong choice of electrode leads to the fact that the diameter becomes:

- Reduced. The coating is damaged and the arc loses stability.

- Enlarged. The current density drops and the arc is drawn across the surface of the workpiece. Because It is difficult to maintain a constant length, the seam becomes crooked and loses strength.

The welding mode is selected taking into account the capabilities of the inverter, i.e. maximum amperage for this model. Vertical and ceiling seams are welded with a consumable with a diameter of 4 millimeters, regardless of the thickness of the parts being connected.

The welding mode is selected taking into account the capabilities of the inverter.

The speed of the process affects the width of the seam. When moving quickly, it narrows, and vice versa. It is necessary to maintain the optimal speed, determined empirically.

Otherwise, the following consequences are observed:

- Acceleration. The material does not have time to warm up and melt, the joint turns out to be poorly welded.

- Slowdown. The metal flows out, the cross-section of the surfacing and, as a result, its strength decreases.

The optimal arc length is 3-4 mm. Stretching has a negative effect:

- During the journey from the electrode to the workpiece, the metal has time to oxidize.

- The arc is drawn across the surface, the heat is distributed over a larger area, and the material warms up worse. Melted drops freeze on it, clogging the seam.

The width of the joint and the penetration depth depend on the trajectory of the consumable. In addition to linear movement, zigzag and herringbone are used.

Existing restrictions

E42 consumables are not suitable for the following conditions:

- Perform vertical seams from top to bottom. Metal from the weld pool flows onto the untreated area.

- Connections of workpieces made of medium and high alloy steel, cast iron, non-ferrous metals.

- Welding with direct current of straight polarity (electrode-negative).

Consumables E42 are not suitable for vertical seams.

In the latter case, the cathode is the consumable. Compared to the anode, its temperature is higher (for melting products).

The parts being connected heat up worse, the penetration depth decreases; the coating on the electrode burns out too quickly and does not provide the required protection to the joint.

Is it possible to work with stainless steel?

Such materials are welded with electrodes containing nickel and chromium. E42 does not belong to this category, therefore it is not suitable for working with stainless steels.

Electrode storage

The coating of consumables, due to its porous structure, is hygroscopic, i.e. has a tendency to absorb moisture. Damp coating crumbles and burns poorly, as a result of which the seam does not receive protection from atmospheric oxygen and becomes weak and brittle.

Therefore, the following requirements are put forward for the storage location of electrodes:

- Relative humidity – less than 50%.

- The readings on the thermometer are not lower than +15°C. This means that during the cold season, consumables should be in a heated room.

- No temperature changes.

- Protection from direct sunlight.

If the packaging is opened, it is recommended to place the consumables in a special sealed case.

Points 2 and 3 are designed to prevent moisture condensation on products.

The specified conditions are also met if the electrodes are in sealed original packaging. With high humidity, they can become damp over time.

If the packaging is opened, it is recommended to transfer the consumables into a special sealed case with insulated walls. You can make it yourself from a plastic pipe of medium or large diameter.

We recommend reading Characteristics and operation of non-consumable electrodes

Before use, the products are calcined, i.e. heated to dry the coating. The procedure time and temperature are indicated on the packaging; you must strictly adhere to them. Overheating is especially dangerous for consumables with organic substances in the coating.

Dried electrodes are suitable for use for 8 hours. If they have not been used during this time, the calcination can be repeated. But the number of procedures is limited and for different models it is 2-4. Subsequent heating will cause the coating to peel off.

Weld metal or surfacing

During the surfacing operation, a layer of metal, or filler material, is applied to the surface of the workpiece. The reasons for performing surfacing operations may be the following:

- repair of a worn or damaged mechanism unit;

- bringing the geometric dimensions of the workpiece to those specified in the project when establishing the fact of a removable defect;

- creating a metal coating in order to improve the physical and chemical properties of the main part, such as strength or corrosion resistance;

When performing a surfacing operation, the electrode follows a given path above the surface of the main part. The metal melts and, mixing with the metal of the electrode, forms a continuous deposited layer on the surface of the part. Sometimes surfacing is carried out in several layers; its mass on particularly large parts can reach several tons.

Upon completion of surfacing, the part is subjected to mechanical processing to accurately bring the geometric dimensions to the specified values . If small volume surfacing is required, E42 is quite capable of replacing specialized surfacing electrodes.

Analogs

Products of the E42 series have electrodes with similar properties, which, under certain restrictions, can be used as a replacement . The determining factor in the selection of analogues is the chemical composition of the welding wire underlying the product.

The standard allows the use of wire grades Sv 08 and Sv 08a. Practically, any electrode on such a basis will produce similar physical and mechanical parameters of the suture material, highly viscous and plastic.

The following brands are close functional analogues of E42:

- Ogonek , allows you to weld workpieces with a thickness of 1 to 3 mm, the direction from top to bottom in a vertical welding position is allowed;

- ANO 6m , works both on shortened and regular arc lengths, metal spatter is reduced;

- ANO-17 , specialized for working with workpieces of large thickness and extended connections, an analogue of E42a electrodes with a diameter of 4-6 mm;

- VSC-4 (m) , adapted for pipeline welding;

- OZS 23 , adapted for connecting light-weight thin-sheet structures, does not emit harmful substances into the atmosphere;

- OMA 2 , for working with an increased arc length along vertical seams, for workpieces up to 3 mm thick, with reduced penetration.

Electrodes produced by ESAB OK-4600 and OK Pipeweld-6010 are considered to be a complete functional analogue of E42, even superior to it in a number of parameters.

Parameters affecting flow

Before calculating the number of electrodes for welding, you should find out which indicators are of utmost importance:

- Weight of material deposited on the connection. The volume of this parameter should not exceed 1.5% of the total mass of the entire structure.

- Duration and depth of the weld.

- Total mass of surfacing per 1 m.p. connections. Electrode consumption rates per 1 meter of seam are reference indicators presented in VSN 452-84.

- Welding type.

Restrictions

Despite all the positive qualities of the E42 series product, they physically cannot be absolutely universal electrodes suitable for welding anything and anywhere. They are not suitable for use in the following conditions:

- welding of stainless steel products, for this purpose the wire does not contain enough chromium and nickel, the coating will also not be able to reliably isolate the weld pool from nitrogen, oxygen and water vapor, the seam will be the weak point of the product;

- welding in a vertical welding position in the direction from top to bottom, the gap between the workpieces will become clogged with melt drips from the weld pool;

- welding of non-ferrous metals;

- connection of parts made of high-alloy alloys and cast iron.

E42s do what they were designed to do well. Attempts to use them in atypical conditions will not be successful.

GOST requirements

GOST 9467-75 defines technical conditions for production, requirements for the chemical composition and physical and mechanical properties of electrodes. It also regulates:

- quality control procedures;

- product acceptance;

- packaging and shipping;

- storage order.

All manufacturing plants wishing to supply electrodes of type E42 and E42A to the market are required to comply with GOST requirements and undergo periodic certification by authorized organizations. By special agreement between the manufacturer and supplier, deviations from GOST requirements are possible. In this case, the product is manufactured according to technical specifications approved by both parties.

Quality certification

Welding electrodes type E42A have a GOST R certificate confirming compliance with GOST 9466-75; NAKS certificate; River Registers of the Russian Federation: Certificate of approval, Certificate of recognition No. ВВФ030; Maritime Register of Shipping of the Russian Federation: Certificate of approval of welding materials; Sanitary and epidemiological report on the electrodes.

For your information! Although certification of electrodes in the Russian Federation is voluntary, nevertheless, the E42A material always has a certificate, since it is used for work in places where increased responsibility is required.