19.02

2020

ANO-21 electrodes are one of the most universal brands. Developed at the Institute of Electric Welding named after. E.O. Paton (Academy of Sciences of Ukraine). Currently produced by all leading specialized enterprises in Russia. They are mainly used for connecting thin-walled (up to 5 mm) structures designed to operate under conditions of low operating pressure.

Quality regulating standards - GOST 9466-75, GOST 9467-75, TU 1272-007-58965179-2006. The most famous foreign analogue is ESAB OK 46.00.

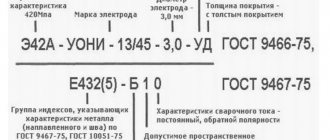

Full decoding using the example of E46-ANO-21-d-UD E 430/3/-R 11

- E46 – electrode type

- AN – Academy of Sciences

- O - coated

- 21 – development model

- d – diameter

- U – carbon and low-alloy steels

- D – thick coating

- 43 – temporary tensile strength after welding is not less than 46 kgf/mm² at normal temperature

- O – relative elongation less than 18%

- /3/ – impact strength of the deposited metal

- R – rutile coating

- 1 – welding in all spatial positions without exception

- 1 – welding with direct current of any polarity or alternating current with an open circuit voltage of 50±5V

Technical specifications

ANO-21 welding electrodes are used for welding parts from 1 to 4 mm, pipelines and vessels under low pressure . Excellent for creating short seams.

Rutile coating based on titanium dioxide allows you to weld workpieces in a wet state and with traces of corrosion. The product is capable of working in all welding positions and directions, which is especially important for welding fixed pipeline joints.

The no-load voltage must be at least 50 volts; you can operate with direct and reverse polarity, as well as alternating current.

ANO-21 are produced with a diameter of 2; 2.5; 3 and 4 mm. Special mention should be made of such technical operational parameters as:

- facilitated arc ignition;

- combustion stability;

- reduced splashing.

The welding wire used for the production of ANO-21 contains additives that increase the surface tension coefficient of the melt . This allows you to weld ceiling and vertical seams without fear of metal leaking out of the weld pool.

Features and Benefits

ANO-21 welding electrodes have a rutile coating (titanium dioxide). Thanks to the high resistance of TiO2, the weld pool is reliably protected from slag. As a result, for high-quality welding, a lower content of magnesium and silicon is required, which makes the gases and welding aerosols formed as a result of the reaction with “deoxidizers” less toxic.

In addition to the low toxicity of the material, the advantages include:

- ease of first, repeated, multiple ignitions even without contact of the rod and the surface of the part;

- resistance of the seam to the appearance of pores when changing the length of the arc;

- possibility of welding in any position without exception, including vertical from top to bottom;

- low splash rates;

- creating an even fine-scaled seam;

- Works with damp, primed surfaces and metals with traces of corrosion.

ANO-21 are electrodes whose characteristics allow them to be used for both industrial and household work. This is one of those brands that is equally suitable for professional welders and beginners. Work can be carried out with alternating current (using a transformer) or direct current of different polarity (using an inverter).

Advantages and disadvantages

Welding electrodes ANO-21 have the following advantages:

- availability;

- fast ignition of the electric arc;

- formation of a light and quickly removable slag layer on top of the weld material; layer;

- strength, durability and seam tightness.

The product also has a number of disadvantages:

- small range of workpiece thicknesses;

- the need for additional fluxes;

- unsuitable for welding joints in pipelines and high-pressure vessels.

These disadvantages are compensated by an affordable price and attentiveness to the rules of application. If you don’t try to use ANO to connect thick workpieces or high-pressure joints, they will not disappoint the buyer.

Recommended current when welding with ANO-21 electrodes, A

| Diameter, mm | Seam position | |||

| Lower | Vertical | Ceiling | Top down | |

| 2 | 40-60 | 40-60 | 40-60 | — |

| 2,5 | 70-90 | 60-100 | 60-100 | — |

| 3 | 100-140 | 80-110 | 80-110 | 140-170 |

| 4 | 160-200 | 140-180 | 140-180 | — |

| 5 | 180-260 | 160-200 | — | — |

Areas of application

The product is used during manual electric arc welding (MMA) of workpieces made of carbon alloys. The most common areas of application are the following:

- installation and field repair of pipelines and vessels operating under low pressure;

- assembly of critical structures with butt, corner and overlap seams;

- welding root seams on thick workpieces.

ANO-21 is used at industrial enterprises in the field of shipbuilding, mechanical engineering, distribution networks in housing and communal services . Both repair shops and home craftsmen use electrodes with pleasure.

Features of application

The main area of use is the installation of gas and pipeline systems. In particular, these are utility network, ship and machine pipelines.

- The products are used in welding thin-walled structures with a thickness of no more than 5 mm, designed for low pressure working media (up to 12 atmospheres).

- Excellent welding of ordinary and butt joints.

- They have proven themselves when working with partially defective metal (oxidized surfaces of steel parts, oxide film on aluminum).

The humidity level of products of this brand should not exceed 0.5%. If storage conditions are not met, the rods must be calcined for 40–60 minutes at a temperature of 120–150°C.

Some of the best domestic examples of this brand are products of the Magnitogorsk Electrode Plant. These are, in particular, the electrodes of the Standard line, which meet all the requirements of state standards and have proven themselves to be excellent among both beginners and professionals. Electrodes are produced in the most popular and sought-after diameters - 2.5, 3.0, 4.0 mm. All products are certified.

Core

Consumable type metal rods used when working with an inverter are selected in accordance with the type of metal of the parts and structures being welded. The welding wire from which the electrode core is made must comply with state standards.

There are three types of electrodes for inverter devices: alloyed, highly alloyed and carbon. Each of them is made from a corresponding type of welding wire. When working with high-alloy and stainless steel, experts recommend using rods TsL-11, carbon steel - ANO-21, UONI-13/45, MR-3S, cast iron - OZCH-2, low-carbon steel - ANO-4 and ANO-6.

The best electrodes for inverter welding

Today you can find a wide variety of electrodes on sale.

And, as the ratings show, the following brands of electrodes for inverter welding are the most popular:

- ANO electrodes are highly flammable and do not stick, so they do not require pre-calcination. Electrodes for this brand of inverter are ideal for both beginners and experienced welders;

- MP-3S electrodes - provide a reliable welded connection;

- MP-3 electrodes are universal, and their advantage is that they hold a stable arc even if there is rust on the metal;

- UONI 13/55 electrodes provide the highest quality welding seam and are used where strict requirements are imposed on metal welding.

Purpose

The electrodes of the brand in question are designed for manual welding of a variety of products made of carbon steel, providing high-quality seams that must meet high requirements in terms of strength. The welding process is characterized by the fact that the melting of the coating and the electrode rod itself occurs at the same speed. At the same time, ANO-21 electrodes cannot be used to connect lines used for the delivery of fuel oil and oil.

Dimensions and packaging

After release, the finished products are placed in moisture-proof film and a cardboard box. Packages of 1 or 5 kg are available for sale.

| Rod Diameter (mm) | Length(cm) | Weight 1 pc. (G) | Quantity per 1 kg |

| 1,6 | 25 | – | – |

| 2,0 | 25 | – | – |

| 2,5 | 30 | 17,0 | 58-59 |

| 3,0 | 30 or 35 | 26,5 | 38 |

| 4,0 | 45 | 53,0 | 18-19 |

| 5,0 | 45 | 84,5 | 12 |

| 6,0 | 45 | 135,0 | 7 |

We recommend reading Characteristics and operation of non-consumable electrodes

Small packages are convenient for home use.

Consumption rate

When connecting parts in small volumes, a competent calculation of the required number of electrodes and the diameter of the rod will ensure the continuous activity of the master and eliminate unjustified monetary costs.

This requires parameters that are inserted into tables developed by scientists from the Montazhspetsstroy Research Institute and other organizations. Detailed information about the types of welding is presented in document VSN 452-84.

In practice, the consumption is 1.65 kg for every hour of operation.

Features of work

The main feature of ANO-21, like other products with rutile coating, is the ability to work in difficult conditions, on wet workpieces with traces of corrosion. However, the electrode itself must be almost completely dry. To do this, they are stored in sealed packaging, and if moistened, they must be calcined for 40 to 60 minutes at a temperature of 120°C.

Welding modes depend on the diameter of the product:

| Diameter, mm | Length, mm | Quantity per 1 kg, pcs. | Operating current, A | ||

| Lower | Vertical | Ceiling | |||

| 2 | 300 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 300 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 350 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | — | — | 160-190 | 150-170 | 150-180 |

You should not try to weld workpieces thicker than 5 mm or pipe joints that must work under pressure with such electrodes. Such attempts will not lead to anything good. It performs the work for which ANO-21 was designed almost flawlessly

The best welding electrodes with basic coating "B"

The main purpose of product coating is to protect the welding arc, as well as provide the necessary quality of the seams. This material does not allow the arc to come into contact with hydrogen, nitrogen or oxygen. Mandatory requirements:

- easy initial and repeated excitation of the welding arc;

- soft continuous burning;

- uniform surface melting;

- minimum splashes;

- high-quality welding seam;

- rapid separation of slag crust.

Hansa Pioneer ANO-46

The product has a diameter of 3 mm, the package contains 5 kg. The main advantage is the easy turning and initial state of the welding arc. During operation, soft and stable combustion occurs. Using this device, you can obtain a high-quality, uniform seam with an aesthetic appearance.

Hansa Pioneer ANO-46

The material has no special requirements for the quality of edge preparation. Therefore, the series is very popular among inexperienced welders. The price for a 5 kg package is 570 rubles.

SSSI 13/55

This option is used in the DC welding process. It is considered the best option for working in the most critical places. Users note increased reliability of the product and protection of the weld pool from oxygen due to the presence of carbon dioxide, which is released when the coating burns. 1 kg of material will cost relatively inexpensively, only 95 rubles, but it should be taken into account that the product is often sold in packs weighing 3 kg.

SSSI 13/55

Pros:

- absence of ulcers on the seams;

- aesthetics and strength of the connection;

- minimum price;

- availability.

Minuses:

- difficult to light;

- re-ignition requires preliminary cleaning of the surface.

Separately, it should be noted that coating also plays a negative role here, since it significantly complicates the process of igniting the product. Some inexperienced welders can spend a lot of time on this activity. In addition, difficulties may arise with re-ignition. The finishing melt quickly hardens and isolates the metal as much as possible, which requires mandatory cleaning. But users claim that with the help of UONI 13/55 you can create not only durable, but also aesthetic seams.

OZS-4

The model is used for manual arc welding. It is used for joining carbon steel substrates in various conditions, since it does not have increased sensitivity to cleanliness.

OZS-4, 3mm

When working with an alternating current transformer, it is necessary to create a voltage of 50 V. Such elements produce a minimum of defects, which often depends not on the product itself, but on the skill of the specialist. Another important advantage was noticed in OZS-4 - minimal spattering and the absence of hot cracks. The resulting seam must be pierced at a temperature of about 170°C for 30 minutes.

Products are manufactured in accordance with GOST 4966-70 standards. There are variations on the market with a diameter from 2 to 6 mm. The downside of the product is that it costs a lot. For 1 kg of deposited metal it is necessary to use 1.7 kg of electrodes. The result is a neat, strong and reliable seam.

Kobelco LB-52U

LB-52U are manufactured in Japanese factories, which is actually why they have a high pricing policy. As a rule, such products are sold in packages and weigh from 5 kg, the price of this product is 1800 rubles.

Kobelco LB-52U

The main distinguishing feature of this option is the ability to work with low-carbon steel material, where double-sided welding is not suitable. Using a series of LB-52U electrodes, a pipeline system is welded. The result is a strong and reliable connection. In most cases, the strength indicator is 588 N/mm2.

To simplify the ignition process, it is recommended to calcinate it at a temperature of 300°C before use. This way you can remove moisture, which will not only allow the material to ignite faster, but also improve the quality of the seam.

Comparison table

Electrode products, including ANO-21, are produced by several enterprises. The manufacturing technology is not followed at all, for this reason the properties of products from different manufacturers differ in ignition, maintaining arc stability and the appearance of pores.

We recommend reading Welding with tungsten electrodes

Masters conducted comparison tests with the participation of ANO-21, MR-3 and SSSI. The test results depending on the welding direction are shown in the table.

| Index | ANO-21 | MR-3 | SSSI |

| Metal consumption (1 kg) | 1,7 | 1,7 | 1,6 |

| Viscosity (J/cm²) | 80 | 80 | 200 |

| Elongation (%) | 18 | 18 | 26 |

| Capacity (kg/h) | 1,4 | 1,7 | 1,3 |

| Yield Strength (MPa) | 460 | 400 | 350 |

| Maximum current (A) | 220 | 260 | 200 |

| Minimum current (A) | 40 | 30 | 40 |

| Calcination (min.) | 60 | 60 | 60 |

The table will help in selecting the electrodes needed for the job.