Preparing to perform a manual operation

It is believed that the history of the first screw connections began long before the birth of Christ. The pioneer is the ancient philosopher, mathematician and mechanic Archytas of Tarentum, who lived in the 3rd century BC. His follower was the world-famous Archimedes, who took advantage of this teaching and applied science in practice to move liquids and solids. However, theoretical teachings were not included in textbooks or were forgotten (exactly unknown), and the technological peak occurred in the 19th century AD. The English scientist or inventor Henry Maudsley first introduced to the scientific community an apparatus in the form of a screw-cutting lathe, with the help of which point cutting was carried out. As a result, the date of creation of the equipment is equated to the industrial revolution, since until that time nothing like this had been invented and it was from this moment that a breakthrough occurred in all sectors of the national economy throughout the world. Scientists involved in the problems of metallurgy, mechanical engineering, materials science, machine tool building and other applied sciences that are important for life had their hands in this process.

Now let's look at the preparatory work for cutting pipe threads by hand.

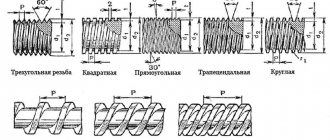

First, let's figure out what this means and what its parameters are. These are cut grooves with a uniform pitch between turns and with the same geometric profile on a material of conical or cylindrical shape. They are used to connect various parts and assemblies everywhere from house construction and water supply to machine and shipbuilding.

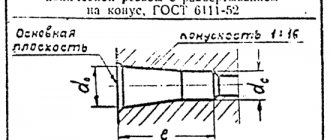

We provide you with a schematic diagram to refresh your memory.

a – denotes external thread. More often, citizens have to cut this type themselves to connect plumbing fixtures.

b – internal processing.

In the picture, in both versions, the diameter is indicated by the English letters d, d1 and, accordingly, D, D1.

You are mistaken in thinking that threading cannot be done at home without the use of special equipment. Everything can be made independently without excessive financial investments using available tools.

To do this, before starting work, you should pay attention to the following points:

- Contamination of the workpiece. If there are foreign inclusions, soil, rust, scale, oily deposits, traces of petroleum products, etc. on the surface, then it is absolutely clear that these problems must be eliminated by cleaning. Otherwise, foreign inclusions will likely deteriorate the quality of the turns made.

- From manufacturers we often receive a part with a chamfer at the end, that is, with a turn. This defect must be eliminated using a grinder, or best of all, a file. This way you will get a high quality sample.

- If you want to get the product to the required level, you will have to apply a lubricant.

We recommend that you listen to our advice, otherwise the working part may wear out greatly, and the event itself will drag on indefinitely and it is likely that failure to comply with the conditions can lead to deformation of the part and ultimately to its failure.

Features of the technology

When cutting internal threads with a tap, the following method is used.

- In the place on the surface of the workpiece where the hole for cutting the thread will be drilled, you need to form a recess for a clearer entry of the drill, using a core and an ordinary hammer. The drill is fixed in the chuck of an electric drill or drilling machine, on which low rotation speeds of the tool are set. Before drilling, the cutting part of the drill must be treated with a lubricating compound: a lubricated tool enters the structure of the material being processed more easily and causes the least friction in the processing area. You can lubricate the drill with a piece of ordinary lard or grease, and when processing viscous materials, machine oil is used for these purposes.

- If you need to cut threads in small parts, they should be fixed in advance using a bench vice. When starting drilling, the tool fixed in the equipment chuck must be positioned strictly perpendicular to the surface of the workpiece. You should often lubricate the tap and make sure that it does not warp and moves strictly in the given direction.

- At the entrance to the hole, as mentioned above, you need to remove the chamfer, the depth of which should be 0.5–1 mm (depending on the diameter of the hole). For this purpose, you can use a drill of larger diameter or a countersink, installing them in the chuck of drilling equipment.

- The process of cutting internal threads begins with a tap. which is the first to be installed in the knob. Do not forget about the lubricant, which must certainly be applied to the tap for threading. The position of the tap relative to the hole being machined must be set at the very beginning of the work, because later, when the tool is already inside the hole, this will not be possible. When cutting a thread with a tap, you must adhere to the following rule: 2 turns of the tap are made in the direction of cutting the thread, 1 - against the direction. When the tap makes one revolution in reverse, chips are thrown off its cutting part and the load on it is reduced. Thread cutting with a die is carried out using a similar technique.

- Cutting the thread with a tap. The tool is installed in the knob. and after it - Processing is carried out according to the above method. When cutting threads with taps and dies, you need to feel when the tool begins to rotate with force. When such a moment comes, you should turn the knob in the opposite direction to throw the chips off the cutting part of the tool.

READ Remaking the Battery for a Screwdriver Interskol 14 4

The harder the material being processed, the more abundantly the tap needs to be lubricated during the thread cutting process.

Before making internal threads with a tap or cutting threads with a die on external surfaces, you should thoroughly study these procedures and strictly follow the rules for their implementation. Only in this case can you count on the fact that the result will satisfy you with its quality and accuracy.

A tap is a tool with which you can quickly and accurately cut threads in a prepared hole. This is a rod divided into a working part and a shank. The shank is used for fixation in the driver or chuck of the machine. Chip removal is provided by longitudinal or helical grooves located on the cutting part. To produce this tool, carbon or high-speed steels are used. To cut an internal thread perfectly, you should know how to choose the right tap and prepare the hole.

How to Manually Cut Threads with a Die on a Pipe - Step-by-Step Guide

A power tool is essentially a nut made from hardened, high-quality steel.

At the end there are holes in the form of flower petals, necessary for removing waste chips. The inner part is represented by sharp cutting edges. There are two holes drilled on the body into which the handle is inserted to ensure uniform impact. It is the most common model due to its ease and ease of use:

- We fix the vertically located pipe using clamps (vices).

- We clean the surface from dirt.

- We create a chamfer for precise alignment.

- We apply oil to the plane for better movement of the die.

- We insert the element strictly perpendicular to the workpiece to avoid distortion, which even at a slight degree can lead to incorrect creation of turns.

- We turn the handle clockwise, make two turns and come back. In this way we release waste chips.

Cutting with a hand clamp

In a home workshop, it is recommended to carry out the cutting using a hand clamp. Among the features of such a process, the following points can be noted:

- The working part is installed in a special holder made in the form of a ratchet. It greatly simplifies the process of cutting coils on the pipe surface.

- You can start by cleaning the pipe. It is worth considering that when cutting turns, it is possible only if there are no strong flaws.

- The surface is cleaned down to the metal until it begins to shine.

- The outer edge is machined to obtain a chamfer. Because of this, the entry of the tool is ensured.

- The surface is treated with technical Vaseline. It reduces the degree of friction and makes the tool move smoother.

- The pipe is secured in a vice; you can also hold it with a gas wrench. It is important to exclude the possibility of tilting or displacement of the pipe when the highest load is placed on it.

The work involves making several turns clockwise, then in the opposite direction. This is done in order to remove chips from the cutting zone.

Cutting pipe threads with a clamp

Such a mechanical kit is sold in any specialized stores and is especially popular among users, since there is no need to carry out an alignment operation. This feature is included in the package.

The external structure of the clamp looks more complex, but the internal contents are so constructive that it allows you to get the job done quickly and efficiently.

The tool consists of:

- Round metal frame cast from durable alloy.

- Four removable cutters or blade combs. The second sample has a tremendous advantage. When moving, the first cutters make shallow grooves, and the next, higher ones, sliding along the “rough” path, cut out a full-fledged one, ready for use.

- A wide holder with a guide tube that minimizes the process of distortion.

Instructions for use:

- The clamp is installed in the ratchet, and a guide is installed on the edge of the workpiece.

- The cutters are lubricated for smooth operation/

- The work of the ratchet begins, which rotates around its axis.

Cutting a thread on a pipe near the wall

If the workpiece is located in a place where there is no space to approach and carry out the operation, then we offer several methods that minimize the financial costs that will certainly arise in an unusual situation:

- If it is possible to dismantle a small section of the wall, for example, removing ceramic tiles, then take advantage of this. This will free up a significant amount of space for you to complete the task at hand.

- The pipeline consists of several parts. You will have to disassemble the line and cut on the removed section.

- As we wrote above, cutters need constant lubrication. However, oil drains from a horizontal surface. Therefore, it is recommended to perform the manipulation in several passes - this way an ideal surface quality is created.

- Strictly control the position of the tool parallel to the axis and apply sufficient load.

How to properly cut internal pipe threads

Professionals and amateurs know about the existence of such an element as a tap.

This is a tool with which you can make a screw hole in a regular home workshop that meets the requirements of GOST. It consists of intake, calibrating and tail parts. Allows, depending on the technological solution of the manufacturers, to create a thread in a prepared through or blind hole in one/two/three passes using a reciprocating movement.

The workflow consists of several stages:

The pipe is placed strictly perpendicular to the horizontal surface.

Preparing to cut internal threads

In order for the process of cutting internal threads using a tap to not cause any particular difficulties and result in a high-quality result, you need to properly prepare for this technological operation. All methods of cutting threads using a tap imply that a hole with a suitable diameter has already been made in the workpiece. If the internal thread that needs to be cut has a standard size, then a special table with data in accordance with GOST can be used to determine the diameter of the preliminary hole.

Table 1. Diameters of holes drilled for standard metric threads

In this case, if the thread that needs to be cut does not belong to the standard category, you can calculate the diameter of the hole to make it using a universal formula. First you need to study the markings of the tap, in which the type of thread being cut, its diameter and pitch, measured in millimeters (for metric), are indicated in an indispensable order. Then, to find the cross-sectional size of the hole that needs to be drilled for the thread, just take a step from its diameter. For example, if a tool marked M6x0.75 is used to cut an unusual internal thread, then the diameter of the preliminary hole is calculated as follows: 6 – 0.75 = 5.25 mm.

For standard threads belonging to the inch category, there is also a table that allows you to correctly select the drill with which preliminary work is done.

Table 2. Diameters of holes drilled for inch threads

The most important question to obtain a high-quality result is not only what to use to cut the thread, but also what drill to use to make the preparation hole. When choosing a drill, you need to pay attention to the characteristics and quality of its sharpening, and also to ensure that it rotates in the chuck of the equipment used without wobbling.

The sharpening angle of the cutting part is selected depending on the hardness of the material that needs to be drilled. The higher the hardness of the material, the greater the sharpening angle of the drill should be, but this value should not exceed 140°.

When drilling blind holes, control the drilling depth

How to cut a thread correctly? First you need to select tools and consumables:

- an electric drill or drilling machine capable of operating at low speeds;

- a drill whose diameter is calculated or selected using reference tables;

- a drill or countersink, with the help of which a chamfer will be removed from the edge of the prepared hole;

- a set of taps of the appropriate size;

- manual holder for taps (drives);

- bench vice (if the product in which the thread needs to be cut needs to be fixed);

- core;

- hammer;

- machine oil or another composition that needs to be used to lubricate both the tap and the thread section being cut during processing;

- rags.

Grooving machine

The configuration is possible in different modifications, it all depends on the manufacturer.

However, the essence of all machines is the same - they are used to cut threads on an industrial scale. The advantages include:

There is a function for programming diameter and pitch parameters with automatic reverse.

Thread standards

Let's consider several options. It is worth considering that some have ceased to be used in production altogether. Therefore, we focus your attention on specific types that are in demand all over the world.

G - Straight (inch) pipe thread

In the Russian standardization system it is designated GOST 6357-81, in the world arena – BSPP. These products are in most cases used when working with gas or water pipes and are sold at any retail outlet. As a rule, bronze, steel, or brass plumbing fixtures are equipped with this standard. As for cutting it yourself, you will have to use the English abbreviation.

The advantages are as follows:

G is an international thread mark that is understandable to everyone.

| Pitch in mm, P | Number of turns |

| 0,907 | 28 |

| 1,337 | 19 |

| 1,814 | 14 |

| 2,309 | 11 |

The decoding is very simple and you can use it to understand which parameter means what. So:

For a complete understanding, you need to familiarize yourself with the table and use it in the future, since it is the values presented that are most often found in home engineering structures.

| Thread size G | Step in millimeters | Diameters (mm) |

| Row 1 Row 2 | d=D d2=D2 d1=D1 | |

| 1/8 | 0,907 | 9,728 9,147 8,566 |

| 1/4 | 1,337 | 13,154 12,301 11,445 |

| 3/8 | 16,662 15,806 14,95 | |

| 1/2 | 1,814 | 20,955 19,793 18,631 |

| 5/8 | 22,911 21,749 20,587 | |

| 3/4 | 26,441 25,279 24,117 | |

| 7/8 | 30,201 29,039 27,877 | |

| 1 | 2,309 | 33,249 31,77 30,291 |

| 1/8 | 37,897 36,418 34,939 | |

| 1-1/4 | 41,91 40,431 38,952 | |

| 3/8 | 44,323 42,844 41,365 | |

| 1-1/2 | 47,803 46,324 44,845 | |

| 3/4 | 53,746 52,267 50,788 | |

| 2 | 59,614 58,135 56,656 |

R - taper pipe thread standard

BSPT is an abbreviation of international significance and is subject to the domestic standard according to GOST number 6211-81.

In its structure, the process resembles the action with a cylindrical workpiece, but only with a slight slope on a scale of 1:16.

According to the state standard, this process must meet the following requirements:

- The profile angle is 55 degrees.

- The step creation corresponds to a specific pipe size.

- The maximum possible diameter of the product used is 6 inches. Wider samples cannot be screwed together; in such cases, welding or flanges are used.

Connecting fittings of this standard are used in places with high pressure and temperature for maximum sealing of the system. Therefore, it is necessary to strictly comply with the standard for the ratio of parameters established by the country.

Other standards

There are several other types, but we will write very little about them, since a citizen most likely will not use them in everyday life:

- Metric cutting, which is not suitable for pipe installation. From the name it is clear that in diagrams and drawings the unit of measurement is the derivative of the meter, that is, the millimeter.

- The letters Kr on the product indicate that this is a plumbing product with a unique profile and smooth round thread.

- NPSM, NPT, NPTF are the designations of the American standardization system. The product has the shape of an isosceles triangle and differs from its analogues in the profile angle, which corresponds to 60 rather than 55 degrees.

Of course, these types of standards are unlikely to be suitable for your work, but it is worth recalling the BSPP parameters so that you can distinguish them from others if necessary.

| Designation of conditional passage | Number of turns per 1 inch | d=D | d2=D2 | d1=D1 |

| 1|8 | 27 | 10,272 | 9,510 | 8,766 |

| 1|4 | 18 | 13,572 | 12,443 | 11,314 |

| 3|8 | 17,055 | 15,926 | 14,797 | |

| 1|2 | 14 | 21,223 | 19,772 | 18,321 |

| 3|4 | 26,568 | 25,117 | 23,666 | |

| 1 | 11 1|2 | 33,228 | 31,461 | 29,694 |

| 1 1|4 | 41,985 | 40,218 | 38,451 | |

| 1 1|2 | 48,054 | 46,287 | 44,52 | |

| 2 | 60,092 | 58,325 | 56,558 |

How and with what to cut a thread on a pipe with your own hands: tools, methods and types of threads

A threaded connection is the most convenient for installing plumbing communications. Its strength indicators are lower compared to welding. But, if you need to replace the pipe, just unscrew the nut and gain access to the entire system.

Most pipes come off the assembly line without a threaded joint. In this case, pipe threads can be cut yourself.

Sources:

https://mnogotolka.ru/info/mozhno-li-narezat-rezbu-na-nerzhavejke/ https://flagman-ug.ru/nerzhavejka/narezka-rezby-na-nerzhaveyushhej-trube-vruchnuyu.html

On stainless steel

This steel has excellent anti-corrosion characteristics, however, high strength and toughness due to the abundance of alloying substances in the composition leads to difficulties in the processing process.

To make the task easier, a special type of lubricant and compliance with the requirements for sharpening the tool are required. We provide you with a video on manual tapping of water pipes. After studying the material, you will be able to do the work yourself without invited specialists: