Table of contents

Appendix Drill diameters for holes for taper pipe threads

×

| Date of introduction: | 01.01.1977 |

| Added to the database: | 01.09.2013 |

| Update: | 01.01.2019 |

This GOST is located in:

- Section: Ecology

- Subsection: 21 MECHANICAL SYSTEMS AND GENERAL PURPOSE DEVICES

- Subsection: 21.040 Screw threads

- Subsection: 21.040.30 Special threads

- Section: Electricity

- Subsection: 21 MECHANICAL SYSTEMS AND GENERAL PURPOSE DEVICES

- Subsection: 21.040 Screw threads

- Subsection: 21.040.30 Special threads

GOST 21350-75 Holes for cutting conical pipe threads. Diameters

STATE STANDARD OF THE USSR UNION

HOLES FOR TAPERED PIPE THREAD

DIAMETERS

GOST 21350-75

STATE COMMITTEE OF STANDARDS OF THE COUNCIL OF MINISTERS OF THE USSR

Moscow

DEVELOPED, INTRODUCED AND PREPARED FOR APPROVAL by the All-Union Scientific Research Institute for Normalization in Mechanical Engineering (VNIINMASH)

And about. Director Gerasimov N.N.

Topic leader and performer Zaroslova M.P.

APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated December 12, 1975 No. 3877

STATE STANDARD OF THE USSR UNION

| HOLES FOR TAPERED PIPE THREAD Diameters Holes for threading pipe taper screw thread. Diameters | GOST 21350-75 Instead of MN 5389-64 |

By Decree of the State Committee of Standards of the Council of Ministers of the USSR dated December 12, 1975 No. 3877, the validity period was established

from 01.01.77

1. This standard establishes the diameters of holes for cutting conical pipe threads in accordance with GOST 6211-69 in steel products in accordance with GOST 380-71, GOST 4543-71, GOST 1050-74, GOST 5058-75 and GOST 5632-72 (except for alloys on nickel base) and copper according to GOST 859-66.

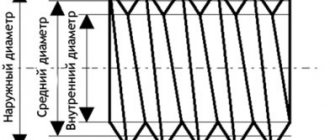

2. The diameters of the holes with reaming to a cone and their maximum deviations must correspond to those indicated in the drawing. 1 and in table. 1.

Crap. 1

Table 1

Dimensions in mm

| Nominal thread size in inches | Number of threads per 1? | Step P | Hole diameter | Drilling depth l | |||

| d c | d o | ||||||

| Nom. | Prev. off | Nom. | Prev. off | ||||

| 1/8 | 28 | 0,907 | 8,10 | + 0,20 | 8,57 | + 0,10 | 15 |

| 1/4 | 19 | 1,337 | 10,80 | + 0,24 | 11,45 | 20 | |

| 3/8 | 14,30 | 14,95 | 24 | ||||

| 1/2 | 14 | 1,814 | 17,90 | 18,63 | 29 | ||

| 3/4 | 23,35 | + 0,28 | 24,12 | 31 | |||

| 1 | 11 | 2,309 | 29,35 | 30,29 | 37 | ||

| 1 1/4 | 37,80 | + 0,34 | 38,95 | 40 | |||

| 1 1/2 | 43,70 | 44,85 | 42 | ||||

| 2 | 55,25 | + 0,40 | 56,66 | 44 | |||

Note. For threads with a nominal size above 2? nominal hole diameters d

o and their maximum deviations must be equal to those established by GOST 6211-69 for the internal diameter of the thread.

3. The diameters of the holes without turning to a cone and their maximum deviations must correspond to those indicated in the drawing. 2 and in table. 2.

Crap. 2

4. It is allowed to use holes of other diameters obtained on the basis of experimental data for cutting conical pipe threads.

5. Drill diameters for tapping holes are indicated in the recommended application.

table 2

Dimensions in mm

| Nominal thread size in inches | Number of threads per 1? | Step P | Hole diameter d c | Drilling depth l | |

| Nom. | Prev. off | ||||

| 1/8 | 28 | 0,907 | 8,25 | + 0,20 | 15 |

| 1/4 | 19 | 1,337 | 11,05 | + 0,24 | 20 |

| 3/8 | 14,50 | 24 | |||

| 1/2 | 14 | 1,814 | 18,10 | + 0,28 | 29 |

| 3/4 | 23,60 | 31 | |||

| 1 | 11 | 2,309 | 29,65 | 37 | |

| 1 1/4 | 38,30 | + 0,34 | 40 | ||

| 1 1/2 | 44,20 | 42 | |||

| 2 | 56,00 | + 0,40 | 44 | ||

APPLICATION

Recommended

Diameters of drills for holes for cutting conical pipe threads

Dimensions in mm

| Nominal thread size in inches | Number of threads per 1? | Step P | Drill diameter for hole | |

| with cone deployment | without cone deployment | |||

| 1/8 | 28 | 0,907 | 8,1 | 8,3 |

| 1/4 | 19 | 1,337 | 10,8 | 11,1 |

| 3/8 | 14,25 | 14,5 | ||

| 1/2 | 14 | 1,814 | — | — |

| 3/4 | 23,25 | — | ||

| 1 | 11 | 2,309 | — | — |

| 1 1/4 | — | 38,25 | ||

| 1 1/2 | — | — | ||

| 2 | — | 56,00 | ||

Holes for threading pipe taper screw thread. Diameters

Normative references

- GOST 380-94 Carbon steel of ordinary quality. Stamps. Replaced by GOST 380-2005.

- GOST 1050-88 Long-rolled products, calibrated, with special surface finishing, made of high-quality carbon structural steel. General technical conditions. Replaced by GOST 1050-2013.

- GOST 5632-72 High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant alloys. Stamps. Replaced by GOST 5632-2014.

- GOST 25820-2000 Lightweight concrete. Technical conditions. Replaced by GOST 25820-2014.

- GOST 6211-81 Basic standards of interchangeability. Conical pipe thread

- GOST 859-2001 Copper. Stamps. Replaced by GOST 859-2014.

For free

download this document in PDF format, support our site and click the button:

STATE STANDARD OF THE USSR UNION

HOLES FOR TAPERED PIPE THREAD

STATE COMMITTEE OF STANDARDS OF THE COUNCIL OF MINISTERS OF THE USSR

DEVELOPED, INTRODUCED AND PREPARED FOR APPROVAL by the All-Union Scientific Research Institute for Normalization in Mechanical Engineering (VNIINMASH)

And about. Director Gerasimov N.N.

Topic leader and performer Zaroslova M.P.

APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated December 12, 1975 No. 3877

STATE STANDARD OF THE USSR UNION

HOLES FOR TAPERED PIPE THREAD

Read also: What device is designed to change the direction of movement

Holes for threading pipe taper screw thread. Diameters

By Decree of the State Committee of Standards of the Council of Ministers of the USSR dated December 12, 1975 No. 3877, the validity period was established

1. This standard establishes the diameters of holes for cutting conical pipe threads in accordance with GOST 6211-69 in steel products in accordance with GOST 380-71, GOST 4543-71, GOST 1050-74, GOST 5058-75 and GOST 5632-72 (except for alloys on nickel base) and copper according to GOST 859-66.

2. The diameters of the holes with reaming to a cone and their maximum deviations must correspond to those indicated in the drawing. 1 and in table. 1.

Nominal thread size in inches

Number of threads per 1²

Drilling depth l

Note. For threads with nominal size above 2², nominal hole diameters d

o and their maximum deviations must be equal to those established by GOST 6211-69 for the internal diameter of the thread.

3. The diameters of the holes without turning to a cone and their maximum deviations must correspond to those indicated in the drawing. 2 and in table. 2.

4. It is allowed to use holes of other diameters obtained on the basis of experimental data for cutting conical pipe threads.

5. Drill diameters for tapping holes are indicated in the recommended application.

HOLES FOR TAPERED PIPE THREAD

Holes for threading pipe taper screw thread. Diameters

Date of introduction 01/01/77

1. This standard establishes the diameters of holes for cutting conical pipe threads in accordance with GOST 6211 in products made of steel in accordance with GOST 380, GOST 4543, GOST 1050, GOST 19281 and GOST 5632 (except for nickel-based alloys), GOST 20072 and copper in accordance with GOST 859.

Nominal thread size, inches

Number of threads per 1²

Hole diameter, mm

Drilling depth l, mm

Note: For threads with a nominal size greater than 2 ¢ ¢, the nominal diameters of the holes do and their maximum deviations must be equal to those established by GOST 6211 for the internal diameter of the thread.

Read also: How to convert a screwdriver battery to lithium

3. The diameters of the holes without turning to a cone and their maximum deviations must correspond to those indicated in the drawing. 2 and in table. 2.

Diameter of hole for GOST thread (Table)

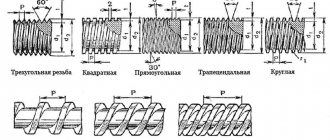

The reference tables contain the dimensions of the diameters of holes for threading according to GOST 9150-59, GOST 6357-52, GOST 6111-52 and GOST 6211-52

1. The tables are for reference, issued on the basis of the plant’s guidelines 01.2РМ31-65 and normals МН5384-5389-64 and are intended for foremen, technologists and workers of main and auxiliary production.

2. The sizes of holes for threads with large pitches are highlighted in bold text.

3. The diameter of holes indicated without tolerances is carried out according to class 4 accuracy.

Diameters of holes for threading according to GOST 9150-59

| Nominal thread diameter | Diameters of holes for threading according to GOST 9150-59 | |||||||||||||

| Thread pitches S | ||||||||||||||

| 0,2 | 0,25 | 0,3 | 0,35 | 0,4 | 0,45 | 0,5 | 0,6 | 0,7 | 0,75 | 0,8 | 1 | 1,25 | 1,5 | |

| 1 | 0,8 | 0,75 | ||||||||||||

| 1,4 | 1,1 | |||||||||||||

| 1,6 | 1,25 | |||||||||||||

| 2,0 | 1,75 | 1,6 | ||||||||||||

| 2,5 | 2,15 | 2,05 | ||||||||||||

| 3 | 2,65 | 2,5 | ||||||||||||

| 3,5 | 3,15 | 2,9 | ||||||||||||

| 4 | 3,5 | 3,3 | ||||||||||||

| 4,5 | 4 | 3,8 | ||||||||||||

| 5 | 4,5 | 4,2 | ||||||||||||

| 6 | 5,5 | 5,2 | 5 | |||||||||||

| 8 | 7,5 | 7,2 | 7 | 6,7 | ||||||||||

| 10 | 9,5 | 9,2 | 9 | 8,7 | 8,5 | |||||||||

| Nominal thread diameter | Diameter of holes for threading according to GOST 9150-59 | |||||||||

| Thread pitches S | ||||||||||

| 0,75 | 1 | 1,25 | 1,5 | 1,75 | 2 | 2,5 | 3 | 3,5 | 4 | |

| 12 | 11,2 | 11 | 10,7 | 10,5 | 10,2 | |||||

| 14 | 13,2 | 13 | 12,7 | 12,5 | 11.9A5 | |||||

| 16 | 15,25 | 15 | 14,5 | 14 | ||||||

| 18 | 17 | 16,5 | 16 | 15.35A5 | ||||||

| 20 | 18,95 | 18,45 | 18 | 17.35A5 | ||||||

| 22 | 20,95 | 20,45 | 20 | 19.35A5 | ||||||

| 24 | 22,45 | 21.85A5 | 20.85A5 | |||||||

| 27 | 25,45 | 25 | 23.85A5 | |||||||

| 30 | 28,45 | 28 | 26.85A5 | |||||||

| 33 | 29.85A5 | 29.35A5 | ||||||||

| 36 | 32.8A5 | 31.8A5 | ||||||||

| 39 | 34.8A5 | |||||||||

| Nominal thread diameter | Diameters of holes for threading according to GOST 9150-59 | |||||||||

| Thread pitches S | ||||||||||

| 1 | 1,5 | 2 | 3 | 4 | 4,5 | 5 | 5,5 | 6 | ||

| 42 | 40,95 | 40,45 | — | 38,9 | 37.8A5 | 37,ZA5 | — | — | — | |

| 45 | 43,95 | 43,45 | 42,95 | 41,9 | 40.8A5 | 40,ZA5 | — | — | — | |

| 48 | 46,95 | 46,45 | 45,95 | 44,9 | 43.8A5 | 42.8A5 | — | — | ||

| 52 | 50,43 | 45,95 | 48,9 | 47.8A5 | — | 46.8A5 | — | — | ||

| 56 | 54,43 | 53,9 | 52,9 | 51,9 | — | — | 50,ZA5 | — | ||

| 60 | 58,4 | 57,9 | 56,9 | 55,9 | — | — | 54,ZA5 | — | ||

| 64 | 62,4 | 61,9 | 60,9 | 59,9 | — | — | — | 57.8A5 | ||

| 68 | 66,4 | 65,9 | 64,9 | 63,9 | — | — | — | 61.8A5 | ||

| 72 | 70,4 | 69,9 | 68,9 | 67,9 | — | — | — | 65.8A5 | ‘ | |

| 76 | 74,4 | 73,9 | 72,9 | 71,9 | — | — | — | 69.8A5 | ||

| 80 | 78,4 | 77,9 | 76,9 | 75,9 | — | — | — | 73.8A5 | ||

| 85 | 83,4 | 82,9 | 81,9 | 80,9 | — | — | — | 78.8A5 | ||

| 90 | 88,4 | 87,9 | 86,9 | 85,9 | — | — | — | 83.75A5 | ||

| For metals of high viscosity / (aluminum-magnesium alloys) | ||||||||||||||

| Nominal thread diameter | Diameter for holes for threading according to GOST 9150-59 | |||||||||||||

| Thread pitches S | ||||||||||||||

| 0,25 | 0,3 | 0,35 | 0,4 | 0,45 | 0,5 | 0,6 | 0,7 | 0,8 | 1 | 1,25 | 1,5 | 1,75 | 2 | |

| 1 | 0,8 | |||||||||||||

| 1,4 | 1.15 | |||||||||||||

| 1,6 | 1,3 | |||||||||||||

| 2 | 1,65 | |||||||||||||

| 2,5 | 2,15 | |||||||||||||

| 3 | 2,6 | |||||||||||||

| 3,5 | 3 | |||||||||||||

| 4 | 3,35 | |||||||||||||

| 5 | 4,25 | |||||||||||||

| 6 | 5,1 | |||||||||||||

| 8 | 6,8 | |||||||||||||

| 10 | 8,6 | |||||||||||||

| 12 | 10,8 | 10,6 | ||||||||||||

| 14 | 12,6 | 12,1 | ||||||||||||

Diameters of holes for cutting cylindrical pipe threads according to GOST 6357-52

| Diameters of holes for cutting cylindrical pipe threads according to GOST 6357-52 | ||

| Thread designation, inches | drill diameter, mm | |

| thread accuracy class | ||

| 2 | 3 | |

| 1/8 | 8.65A4 | 8.7A5 |

| 1/4 | 11.5A4 | 11.5A5 |

| 3/8 | 15A4 | 15A5 |

| 1/2 | 18.7A, | 18.7A5 |

| 5/8 | 20,7+0,12 | 20.7A5 |

| 3/4 | 24,2+0,15 | 24.2A5 |

| 7/8 | 28+0,12 | 28A5 |

| 1 | 30,43+0,16 | 30,43+0,29 |

| 1·1/8 | 35A4 | 35A5 |

| 1·1/4 | 39A4 | 39A5 |

| 1·3/8 | — | 41.5A5 |

| 1·1/2 | — | 45A5 |

Diameters of holes for threading according to OST NKTP 1260

| Diameters of holes for cutting inch threads according to OST NKTP 1260 | |||

| Thread designation, inches | Drill diameter, mm | Thread designation, inches | Drill diameter, mm |

| 3/16 | 3,6 | 1 | 22 |

| 1/4 | 5 | 1·1/8 | 24,75 |

| 5/16 | 6,4 | 1·1/4 | 27,75 |

| 3/8 | 7,8 | 1·3/8 | 30,25 |

| 7/16 | 9,1 | 1·1/2 | 33,5 |

| 1/2 | 10,4 | 1·5/8 | 35,75 |

| 9/16 | 12 | 1·3/8 | 39 |

| 5/8 | 13,3 | 1·7/8 | 41,5 |

| 3/4 | 16,25 | 2 | 44,5 |

| 7/8 | 19,25 | ||

Hole diameter GOST 6111-52

| Diameter of holes for cutting inch conical threads with reaming to a cone, GOST 6111-52 | ||||

| Thread diameter | Number of threads per 1″ | dc | do | Drill depth. e mm |

| 1/8 | 27 | 8,ZA5 | 8.76A4 | 15 |

| 1/4 | 18 | 10.7A5 | 11.31A4 | 20 |

| 3/8 | 14.25A5 | 14.8A4 | 22 | |

| 1/2 | 14 | 17.5A5 | 18.32A4 | 28 |

| 3/4 | 22.9A5 | 23.66A4 | 28 | |

| 1 | 11·1/2 | 28.75A5 | 29.69A4 | 35 |

| 1·1/4 | 37.43A5 | 38.45A4 | 36 | |

| 1·1/2 | 43.5A5 | 44.52A4 | 36 | |

| 2 | 55.5A4 | 56.54A4 | 37 | |

Hole diameter GOST 6211-52

| Diameter of holes for cutting conical pipe threads with reaming to a cone, GOST 6211-52 | ||||

| Thread diameter | Number of threads per 1″ | dc | d° | I'll drill the depth. e mm |

| 1/8 | 28 | 8.1A5 | 8.57A4 | 15 |

| 1/4 | 19 | 10.8A5 | 11.45A4 | 20 |

| 3/8 | 14.25A5 | 14,95+0,1 | 24 | |

| 1/2 | 14 | 17.9A5 | 18,63+0,1 | 29 |

| 3/4 | 23.25A5 | 24,12+0,1 | 31 | |

| 1 | 11 | 29.25A5 | 30.30А3а | 37 |

| 1·1/4 | 37.75A5 | 38.95A3a | 40 | |

| 1·1/2 | 43.5A5 | 44.83A3a | 42 | |

| 2 | 55A5 | 56.54A3a | 44 | |

Source of information: PA “Mashzavod im. October Revolution" 1986.

Selecting drill size

The diameter of the drill for a hole for a metric thread is also determined by formula (2), taking into account its main parameters.

It is worth noting that when cutting in ductile materials, such as steel or brass, the turns increase, so it is necessary to choose a larger drill diameter for the thread than for brittle materials, such as cast iron or bronze.

In practice, drill sizes are usually slightly smaller than the required hole. Thus, Table 2 shows the ratio of the nominal and outer thread diameters, the pitch, the diameters of the hole and the drill for cutting metric threads.

Table 2. The relationship between the main parameters of metric threads with normal pitch and the diameters of the hole and drill

| Nominal diameter, mm | Outer diameter, mm | Pitch, mm | Largest hole diameter, mm | Drill diameter, mm |

| 1 | 0,97 | 0,25 | 0,785 | 0,75 |

| 2 | 1,94 | 0,4 | 1,679 | 1,60 |

| 3 | 2,92 | 0,5 | 2,559 | 2,50 |

| 4 | 3,91 | 0,7 | 3,422 | 3,30 |

| 5 | 4,9 | 0,8 | 4,334 | 4,20 |

| 6 | 5,88 | 1,0 | 5,153 | 5,00 |

| 7 | 6,88 | 1,0 | 6,153 | 6,00 |

| 8 | 7,87 | 1,25 | 6,912 | 6,80 |

| 9 | 8,87 | 1,25 | 7,912 | 7,80 |

| 10 | 9,95 | 1,5 | 8,676 | 8,50 |

As can be seen from the table, there is a certain dimensional limit, which is calculated taking into account thread tolerances.

The size of the drill is much smaller than the hole. So, for example, for an M6 thread, the outer diameter of which is 5.88 mm, and its largest hole value should not exceed 5.153 mm, you should use a 5 mm drill.

A hole for an M8 thread with an outer diameter of 7.87 mm will be only 6.912 mm, which means the drill for it will be 6.8 mm.

The quality of the thread depends on many factors when cutting it: from the choice of tool to the correctly calculated and prepared hole. Too little will lead to increased roughness and even breakage of the tap. Large forces applied to the tap contribute to non-compliance with tolerances and, as a result, dimensions are not maintained.