Thread restoration

Threaded connections are the most widely used today. They are used in various industries. During operation, the working part of the thread may be damaged, resulting in reduced strength and reliability. There are quite a large number of different ways to restore a damaged working part, all of them are characterized by their own specific features.

Thread restorer

Technology for restoring internal and external threads

Today, thread restorer is used extremely rarely in work. The most commonly used common tools are:

- A drill is used to change the size of a hole.

- The tap and die are designed for direct cutting of turns. They are inexpensive and are often used to cut a new surface, but they can also be used to restore a damaged one.

- Spindle or tool for screwing in the insert. It is characterized by the fact that the working part resembles a threaded one; there is a special hook at the end.

- Repair insert, represented by a diamond-shaped spiral.

A leash was made at one end, due to which it rotates due to connection with the spindle. Spindle

In addition, some technologies involve the use of epoxy glue, cold welding or other materials. The choice is made depending on the specific case

Thread restoration method

Each thread restoration method is suitable for a specific case. An example is the use of epoxy glue, which can repair minor damage to the coils.

If it is possible to change the size of the hole, then a tap is used. It is selected depending on the parameters of the existing turns.

The tool in question is designed to produce turns on metal.

In some cases, it is impossible to increase the diameter, then a screwdriver is used. Such a cylindrical device has coils on the outside and inside with the required pitch.

Tap

In some cases, the damage is represented by a hole that can be repaired by welding. After this, thread restoration is also carried out using the most suitable tool.

Application of epoxy glue

Using epoxy glue can significantly speed up the process of thread restoration. Among the features of the restoration work, we note the following points:

- The hole is filled with a special substance, after which you need to wait a little until it hardens.

- The bolt is screwed in to form the required surface, after which the substance hardens.

Epoxy glueRestoring threads with epoxy glue

This method is not suitable when fasteners are used under conditions of high loads or vibration. This is due to the fact that the polymer does not form a durable and hard surface after hardening.

Cold welding can be used instead of polymer glue. It is also applied as a paste, after hardening it forms a strong and hard surface. The recovery process is as follows:

- Both components are mixed to obtain the required paste.

- The paste is filled with the damaged surface, after which you need to wait a little.

- The bolt is screwed in.

Cold welding

Cold welding can withstand a fairly large load, but is easy to use and inexpensive.

The tap is used to cut grooves, due to which the required geometry is formed. The instrument in question consists of two parts and can be classified according to a large number of criteria. The features of the work carried out include the following points:

- The tool is lubricated with oil. Due to this, the process of forming turns is simplified.

- When working three turns along the way, there are 1.5 turns in the opposite direction. This is done in order to remove chips from the cutting zone.

- The tool must be positioned strictly vertical to the surface.

- After the required surface has been formed, a control bolt is used. The first pass may be under a slight load, but after that there should be no problems.

It takes a relatively short amount of time to form turns. In this case, you can get high-quality and reliable threads that will last for a long period.

Using a screwdriver

When using a screwdriver, a hole is drilled with a suitable drill, after which a tap of the appropriate diameter is selected. A screwdriver is installed in the hole, the upper part is cut off if necessary.

Screwdriver for thread restoration

After this, notches are made on the boundary using a core. This is done so that the screw does not unscrew from the hole. There are a wide variety of screwdriver options on sale, so there will be no problems with selection.

Welding to restore threads

In order to seal a hole on a damaged surface, welding can be used. Among the features we note the following points:

- A variety of cooking methods can be used.

- The restoration process can become more difficult if the hole is long.

- After welding the hole, cutting is carried out using a tap.

The process is quite simple, but the resulting turns will not be able to withstand high loads.

Such fasteners can also be restored by using futorka. This type of threaded connection is a bushing that has a large outer diameter and a smaller inner diameter.

Set of footwear

The scope of application of futorks is very large. An example is the manufacture of furniture or the connection of various pipes, fastening paired wheels.

In some cases, when it is possible to change the diameter of the connection, futorok is used when the turns are damaged.

Restoring threads by cold welding

Cold welding is used extremely often today. After hardening, the resulting paste becomes strong and hard. It applies in the following cases:

- The connection is not subject to vibration.

- The applied load is low.

- When restoring non-essential parts.

When using a special paste, you can get almost any surface. This is due to the fact that until it hardens completely, it is in a plastic state.

Selecting Cold Weld for Threads

There are various types of the substance in question on sale. When choosing, the following points are taken into account:

- Recommended area of application.

- Features of manufacturing the working mixture.

- Operating conditions: temperature, humidity and some other points.

Restoring threads by cold welding

Most versions are represented by two components that are mixed to obtain a paste. It is worth considering that the substance does not remain in a plastic state for long.

Disadvantages and advantages

Each method has its own advantages and disadvantages. Let's take the following as an example:

- Cold welding and polymers can be used when the hole diameter cannot be changed. However, the resulting coils are characterized by low strength.

- The tap is used only when the hole can be slightly enlarged. This produces high-quality and durable coils.

- Inserts allow you to expand the range of application of the cutting tool, but the restored thread is also not designed for heavy loads.

DOMOSTROYPlumbing and construction

Good day to all! Probably, many of you have encountered such a problem as broken threads: whether it is a thread in metal or on a plastic part. Agree - this is not a pleasant thing. There are many ways to restore broken threads on metal: - using repair kits (screws); — welding followed by drilling a hole and cutting a new thread with a tap; - using cold welding; There are quite a lot of ways. There are also several ways to restore threads on plastic: - using a hot glue gun; - by surfacing the missing or damaged thread section with a soldering iron; As you can see, there are not many options, and they cannot always be applied in a given situation. I'll tell you in more detail using one example. Perhaps this will be useful to someone.

In general, it so happened that during the operation of the car, or rather, its maintenance, the thread in the lower part of the air filter housing was torn off. The factory screws were screwed in, but did not hold when tightened (screwed).

It was decided to eliminate this problem using a glue gun. Everything is quite simple: remove the air filter cover, place heated glue in the hole under the screw and, before the glue has time to harden, quickly screw all the screws into place. This method was enough for me for exactly one maintenance. After the next unscrewing and screwing in the screws, the threads disappeared again.

What I finally came up with. I bought furniture fasteners from Leroy Merlin.

Threads are best produced in engineering plastics using comb or routing thread cutting tools. External threads on plastic parts are cut with cutters, dies, cutters, internal threads - with taps and cutters.

The choice of one or another thread cutting method depends on the design and material of the workpiece, the size of the thread, and the scale of production. Thread milling is the most productive and economical way to form threads in serial and mass production. However, it is advisable to mill threads on parts made of hard materials with mandatory cooling.

Tools

- Threads are best applied using a thread comb.

- Double-toothed tool avoids burr formation

- It is not recommended to use threaded washers, as removing the washer will result in re-threading.

Thread cutting with cutters

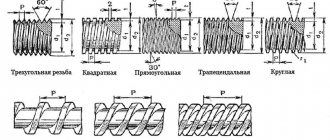

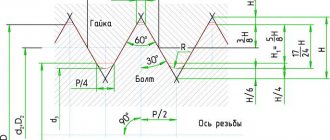

For cutting threads, rod, prismatic and round cutters are used, the profile of the cutting edges of which corresponds to the profile of the thread (Fig. 5).

Standard metal-cutting rod cutters made of high-speed steel and hard alloys are used for cutting threads in plastics with appropriate regrinding. Prismatic and round threaded cutters are used in the serial production of parts. Compared to rod cutters, they allow a greater number of regrinds.

To maintain a constant profile size of threaded cutters, regrinding is carried out only along the front surface. When designing prismatic and round cutters, the angle and dimensions of the thread profile must be reread in connection with the specific installation of the cutter on the machine.

When cutting threads with cutters, the rotation speed of the part and the feed rate of the support with the cutting tool must be coordinated: on the reverse of the part, the tool must move along the axis of the part by the amount of thread pitch s. The rotational speed of the part is determined by the cutting speed and can be calculated using the formula: n=1000*V/πd, where d is the outer diameter of the thread.

How to restore threads in plastic?

» Other »

Question for experts: restoration of threads in plastic using epoxy resin

Best regards, Nikolai Prokofev

Best answers

and you don’t have to cut it. pour epoxy and screw in the bolt lubricated with CIATIM (so that the bolt does not stick). Once the resin hardens, remove the bolt. the carving is ready.

Fill the hole and re-cut?

It’s better to take a nut and fuse it with a soldering iron

It is better to cut to the next one - for example M3 to M4, etc. - epoxy will not hold. And by the way, instead of a thread in plastic, it holds well - a SCREW!!!

-answer

This video will help you figure it out

Answers from experts

either make it larger in diameter if the thickness of the part allows, or seal the hole with plastic, then make a threaded hole by carefully melting the screw in with a soldering iron and unscrewing it while warm

coat the screw with glue and screw it in

Doesn't depend on the material. The techniques for repairing threads are the same as for example in metal...

Spread superglue on a thin piece of plastic and stick it there. When dry, screw in the screws. They are so small - small tubes like in a repair kit for remote controls for 49 cents. I don’t recommend epoxy. Because you can’t unscrew these screws anymore, you’ll rather rip the slot off the screw.

Epoxy. But in general, any glue in this case is garbage...

You are unlikely to restore the thread. and place the screws on epoxy resin

... as an option - thicker screws.

epoxy - but there is a chance that it will turn out tougher than the original plastic - if you need it tightly - an excellent option, or any acrylic adhesive-sealant - it will stick, but it’s purely decorative

You can carefully glue the ring itself to the lens. And you won't even need screws

A self-tapping screw and a screwdriver will help you.

Epoxy is radical. What if you try a thread locker (threadlocker, glue-fixer)? Just choose one designed for plastic parts so that the caprolon does not corrode.

The best depends on the goal and objectives, and on the available opportunities. In such cases, from century to century, plumbers use winding with paint, builders prefer a chopik (often with glue or paint), etc., etc. I prefer metallization (because it is more reliable than the original).

...The options are endless.

For a more serious answer, neither the parameters of the screws, nor the topology, nor other specifics of the joints are known. And without this: blah blah blah - what if I guess.

UNCLE S explained and proposed a solution quite competently, because he understands that under certain conditions the threaded socket will certainly be destroyed in this way. Is this so in your case, - almost in his own words, - for some reason you hid it from us.

So it turns out: in order not to be made a fool, you should not answer such questions at all. Or, in short and more precisely: what is the question, so are the answers; it is a pity that the brief accuracy is not always adequately understood by everyone and/or. Everyone is looking for the "magic button" or the pleasure of guessing the taste of fools.

For equal strength restoration, it is enough to dissolve homogeneous plastic, fill the damaged socket with it, and insert a needle of a suitable diameter into the socket.

After the solvent has evaporated, remove the needle, and after a while, do not screw it in completely with graphite dust - you can scrape a self-tapping screw from a pencil lead (it will seal the fresh plastic) and unscrew it, after two or three days you can fasten it thoroughly, lubricating the screw with technical petroleum jelly or resp. oil

In the case of a bayonet flange, in order to avoid misalignment or distortions, it is often preferable to restore the sockets sequentially, according to the principle of fixing one thing - the remaining screws hold the flange strictly in the same place. If the flange is positioned accurately enough without fastening, you can repair the sockets all at once.

Metallization is already extra-class, for yourself and other loved ones, and even then, not without exceptions.

The situation in your case is known only to you, only to you, and to no one except you. For us it remained a mystery.

If the question were specific, this would be my short answer. And as it is, there are a lot of hardly acceptable words, but no answer to the hidden essence of the question.

If it weren’t for the “goodbye” (smoothly “going to the bottom”), I would not have answered at all.

You find a tube with an outer diameter suitable for the groove and an inner diameter of the self-tapping screw (inner post). You glue the tube and re-cut the thread. The plastic must be hard. If there is no tube, you can use a plastic rod, but then you will have to cut out the internal cavity. I hope I made it clear! God help you! If there was a picture, it would be easier to tell or even draw

Source: https://dom-voprosov.ru/prochee/kak-vosstanovit-rezbu-v-plastike

How to restore a broken internal thread?

No one is immune from the fact that when repairing a car or in other work situations, damage to a threaded connection may occur. How to restore functionality to a seemingly faulty thread?

Many craftsmen use the traditional method, the essence of which boils down to drilling a hole with a drill of a larger diameter and cutting a new thread with a tap. However, after such a repair, you will have to use a counter element (bolt, pin, spark plug) of a larger diameter, which is not always possible. This method will not work if the supply of “body” for drilling is insufficient.

How to repair a threaded hole while maintaining its original diameter?

Currently, a simple and reliable way to restore threads has been found, which has been used all over the world for quite a long time.

In our country, unfortunately, it is slowly gaining popularity, both due to our ignorance and the inability to purchase special spring inserts and auxiliary installation tools in stores. Many well-known manufacturers are engaged in the development and production of inserts. Products from different companies may vary slightly in name (screws, fittings), design and material, but the principle of operation and installation technology are the same for all. On sale you can find not only sets of screws of various lengths, diameters and thread pitches, but also entire kits for restoring threads, which, in addition to inserts, include drills, taps, an installation device and a mandrel for breaking off the mounting lead. Such solutions are offered by the German manufacturer of metal-cutting tools Volkel and the Russian Delo Tekhniki. Some brands call this technology and tool a “system”, for example:

Repair of broken hardware fastening threads - okna-remont.org - MirTesen media platform

When installing plastic windows, you can often encounter various kinds of problems. Since a plastic window consists of many elements that perform their functions and are fixed to the plastic frame using self-tapping screws, there is a problem of thread breakage when fastening the fittings. But how to fix the fastening of fittings with broken threads ? This will be discussed in this article.

Problems you may encounter when installing plastic windows

Quite often the following problems occur that require hardware replacement or repair:

- The window handle may fail, break, and need to be replaced.

- The sash handle may become jammed, making it impossible to open or close the window.

- The hardware lock fails.

- There is mechanical damage to the fittings that requires replacement.

- The window may not open or close well.

- The window may fall off its hinges.

- In a house or apartment, drafts arise through closed windows and strong air blows through them.

- In winter, at low temperatures, a crust of ice may form on the outside of the window.

- The window profile may bend under the influence of various factors.

- Mechanical damage to the glass unit may occur.

In such cases, it is very often necessary to repair the fittings . To do this, you need to remove it and see what is the cause of its malfunction or replace it with a new one. But since plastic is a rather fragile material, thread failure may occur when unscrewing and tightening screws into it.

Restoring threads using Cold Welding glue

The “Cold Welding” glue stick is used to connect metal parts, build up chips, and fill cracks. A distinctive feature of the method is that there is no need for heating or increased temperature exposure.

The connection occurs as a gluing process, called welding because of the strength of the resulting seam. The mass of glue does not penetrate at the intra-atomic level into the surface of the parts that need to be connected. The permanent connection occurs due to other characteristics.

Restoration of metal threads

With intensive use or improper use, chips, holes, and deformations appear on the threads. “Cold welding” allows you to fix parts of parts and bring them to normal condition. This method is used for plumbing parts, repair of automotive and technical parts. Manufacturing procedures facilitate the restoration of thread structure without complex fixtures using cold welding.

Glue composition

The components included in the adhesive mass are aimed at creating a homogeneous mixture. Plastic properties are created by epoxy resin. It improves the composition and makes it softer and more comfortable to use. To obtain a single solid component with metal, metallic substances are added. During the process of filling and repairing the chip, the polymer welding mass fills the parts that have received a defect.

The quality of the welding mass requires unique properties. They make cold welding common and attractive to consumers with different professional and construction needs. The seam obtained by cold welding will be inferior in some characteristics to the standard method, but will provide advantages in terms of speed of work, conditions and simplicity of the procedure.

Advantages of working with adhesive mass

Restoring chips and cracks on the threads of metal parts using the “Cold Welding” composition has a number of advantages.

- Product availability. Glue can be purchased at a price acceptable to a specific buyer, the required capacity and the chosen brand;

- Variety and wide selection of products. There are a large number of brands and manufacturers of the composition;

- There is no need to dismantle structures before starting work;

- Does not corrode the surface;

- Ease of use. Preparing the glue for use does not require a lengthy procedure; numerous additional devices are not needed;

- No training required. The client gains experience working with glue independently, carefully following the instructions;

- There is no need for heat treatment of metal products, so the properties of the parts do not change. This method is especially convenient for small chips, holes or cracks. It is also mainly used if the thread thickness is small;

- Low price.

Disadvantages of cold welding

The Cold Weld Rod is not a substitute for the actual standard welding procedure. Therefore, to use the composition, those jobs that it is capable of performing are selected. The disadvantages are as follows:

- Relatively low quality of strength;

- Various metals on workpieces and elements restored by welding;

- Not recommended in areas with an increased area of responsibility;

- Subject to temperature changes and negative environmental changes.

Product selection options

A diverse product range is presented from offers from Russian and foreign manufacturers. Among all types, the composition is divided into two groups:

- Liquid. They consist of two liquids of different consistency: a hardening mass and the main adhesive;

- Plasticine-shaped. Similar in shape to the plasticine block from a children's art set. They can be one- or two-layer. Before use, they are mixed until a dense mass is obtained.

How to restore threads in plastic?

Window fittings are a system of mechanisms that provide the functional side of window operation. With its help, window sashes can be opened, closed, blocked, limited, or fixed in a certain position.

The fittings are also responsible for the tight fit of the window elements to the frame and for protection against burglary. But, like any mechanism, fittings are susceptible to breakdowns. One of the common defects is broken threads.

Reasons for thread failure on window fittings

The fittings for plastic windows are secured using self-tapping screws screwed into the plastic part of the metal-plastic profile. Its design provides for the presence of several chambers, one of which is needed specifically for attaching fittings.

Thread failure can be a big problem. That is, the wall of the hole for the self-tapping screw is destroyed, and the fittings begin to “hang out”. If no action is taken, this defect can lead to even greater destruction.

The causes of thread failure are two main factors:

- When installing the fittings, the self-tapping screw was tightened with excessive force and as a result damaged the plastic.

- When installing the fittings, the self-tapping screw was not screwed in completely and during operation of the window it was loosened, as a result of which it damaged the walls of the hole.

The causes of thread failure can also be improper installation of the window, poor-quality fastening material, or poor-quality window profile.

If the reason for the failure of the fitting threads was an error by the installer (overtightened/undertightened the self-tapping screw) or incorrect technology for installing the window and its fittings, then you can contact the company that did the installation; they should eliminate the defect under warranty. However, it is not so easy to prove that you are right, because if the thread of the fittings was torn off for other reasons, then the installation company is not responsible for this and will not fix it under warranty.

Read more about the defects of plastic windows in this article.

How to fix fastening hardware with broken threads

If the warranty does not cover the cost of repairing the broken threads of fastening the fittings, then you will have to resolve the issue yourself. There are several repair methods:

- Fill the hole for the screw with liquid plastic or its equivalent. Wait for the product to dry completely and screw the screw back into the same place.

- Cut a piece of tin the same width as the hole and fold it into a “Y” shape. Insert the resulting element into the hole, and then screw in the screw. The metal plate will act as a very strong spacer. This method is effective and virtually cost-free. Instead of a tin plate, you can use a piece of plastic together with PVC glue.

- Increase the diameter or length of the self-tapping screw, if the design of the window and fittings allows it. However, it should be remembered that if you increase the length of the screw, you can damage other elements of the window, for example, a double-glazed window.

- Move the fittings fastening a few millimeters to the side, if the design of the window and fittings allows this. Old screw holes can be sealed with any sealant, such as silicone or liquid plastic.

How and with what to cut wood threads (internal and external)?

It is necessary to cut threads on a wooden rod and in a wooden blank, how is this done?

Cutting metric or inch threads on wood is not as easy as it seems at first glance. It would seem simpler, we take a rod, a die to the size and off we go, but that’s not the case, the die is designed for metal, which it kind of tears out, and the wood needs to be cut, and then there are layers of wood that are easier to “layer” than to cut .

There are special dies for wood (more precisely, there were, in the photo), but they can no longer be found.

It is easier to cut external threads on dense woods: oak, maple, ash, apple tree.

Do not cut the inner one to the end; if it is used for fastening with a metal bolt, it will cut on its own and will be tighter.

The larger the thread, the stronger and more reliable it is.

These are on sale:

Moreover, with the help of such a tool you can cut both external and internal threads.

That is, essentially there are taps (the correct name for this tool is cutter, driller) and dies, but for woodworking.

This is a hand tool, meaning no lathe is needed.

It is important to consider that the wood must be dense; not all wood can be threaded.

If it is an internal thread, then first we drill a hole in the wood, the diameter of the hole depends on the diameter of the thread.

Next, remove any remaining wood chips from the hole.

To avoid problems when cutting threads, I advise you to use oil, for example linseed, drop literally a few drops of oil into the hole and use the tap with a driver from the kit.

The tap is held at right angles to the surface, that is, distortions are unacceptable.

The external thread is cut almost the same way; the diameter of the workpiece rod should be equal to the diameter of the die.

We use oil in the same way.

Several times I cut an external thread on a round workpiece using a regular nut.

We clamp the workpiece in a vice (you can place pieces of wood under the “jaws” of the vice), lubricate it with linseed oil and then slowly “screw” the nut onto the wooden workpiece; the nut is screwed on using an open-end wrench of the required number.

We cut the required number of threads, again slowly unscrew the nut.

When cutting internal threads, consider the thickness of the material.

Several times I had to cut the carvings in the wood myself, and by the way, just the outer and inner ones; one person needed to do this for a toy. The thread was cut using M24.

At first I tried to cut it just like on metal, but it just doesn’t cut it, but tears it out in pieces, people advised this:

Take machine taps, there are 2 of them with different thread rolls, they are run in two stages, first number 1, then number two.

So you need to take the first two numbers and cut off one of them, make a smoother approach so that initially the thread does not roll, but only leaves risks.

It’s worse with a die; you can’t really trim it, so if the wood is soft, then the carving won’t be beautiful, a thread will break somewhere anyway.

It is best to cut external threads on a machine with a cutter at fairly high speeds and in several steps, i.e. first at risk, and then gradually increasing the depth.

Also, in order for the thread to roll better, the surface where the turns will be cut must be set on fire, i.e. At high speeds, rub another piece of wood over the main one; the friction will release temperature and slightly harden the surface.

There is another way, you can buy a screw and a tap (a set for cutting screw wood carvings), but the price is off the charts, the cheapest is about 5,000 rubles, and a pro for 20,000 rubles

So if the diameter allows, it is best to use a lathe!