Using a bolt tap

The option when the size of the new bolt is not of fundamental importance allows you to use the simplest method of restoring a threaded connection.

All you need to do if you find a problem is:

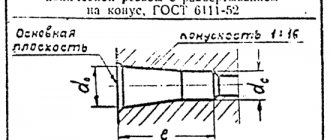

- Take a bolt of the appropriate size and grind it down. Sanding is extremely important as even the smallest piece of rust will become a problem when cutting new threads.

- Having installed the future tap in a vice, grind it like a cone, as in the photo. This will make it easy to insert an improvised tap into a hole of a smaller diameter and distribute it to the desired size.

- After this, cut 3 grooves through which the chips will exit. It is important to cut them at the same angle to the longitudinal rod.

All that remains to be done to obtain a new thread is to clamp the bolt head with pliers, a wrench or an open-end wrench and carefully, but with some pressure, screw a homemade tap into the hole.

All movements must be smooth. Chips that will be displaced during the manufacture of the inner rings must be removed using a soft brush.

With repair insert

In the case where the above method is not suitable, a repair insert or foot will help out.

This device allows you to use a bolt of the same diameter that was used before the damage.

The operating procedure is as follows:

- We prepare a footer of the required size.

- Using a tap whose size corresponds to the outer diameter of the insert, we cut a hole for screwing in the fitting.

- After thoroughly cleaning the chips, install the insert and secure it with a retaining ring. As a result, the hole will look like in the photo and will be completely identical to the old one.

If you follow all the details of installing an insert with a double-sided thread, then the reliability of this repair method will be the highest. The only disadvantage of this type of repair is the need to have a lot of inserts of the required diameter and a tap in stock.

There are many reasons for thread damage on aluminum parts. One careless movement or too much force to tighten becomes the beginning of a new problem. But it can be solved very easily if you know and correctly apply the repair methods used by experienced car enthusiasts and professional car mechanics.

What is cold welding

It is a method of growing and combining metal elements without the influence of high temperatures. In this case, the surfaces are not welded, but glued together. The cold welding compound begins to deform and then penetrates into the parts used for the work. Here there is no mutual penetration of substances into each other, the appearance of interatomic bonds, but a tight connection occurs. At the same time, this method helps to restore candle threads, recreate lost elements and repair damage.

How to restore a thread with a tap

Before restoring a thread with a tap, determine whether it is possible to increase its diameter or cut a new one in a different location. If yes, then the repair will take place very quickly.

Cut new thread.

Photo No. 1: tapping threads

When working, observe the following basic rules.

Drill the hole strictly at a right angle

Use two new taps of the required diameter (for roughing and finishing).

Be careful when cutting threads. Avoid distortions and sudden movements.

It is advisable to cut the thread using a wrench. If you don't have one, take an adjustable wrench.

Useful tips

- In order to correctly cut threads in metals with low hardness and high viscosity, such as aluminum, alloys based on it, copper, babbitt, it is recommended to periodically remove the tap to clean the channels from adhering chips.

- When using complete models, the complete set should be used. Skipping the roughing tool does not speed up, but slows down cutting. Such a violation of technology leads to a decrease in the quality of the result, and sometimes to failure of the tap.

- To prevent the tap from skewing, check the verticality of its position after 2-3 threads using a square. This precaution is especially important for blind and small holes.

The process must be carried out using liquids intended for lubrication and cooling:

- emulsions, linseed oil, and drying oil are used in steel elements;

- in products made of aluminum and its alloys - kerosene;

- when processing copper - turpentine.

It is possible to cut threads in parts made of cast iron or bronze without the use of lubricant.

How to restore a thread with a tap while maintaining its diameter and location

If you need to restore the thread while maintaining its diameter, use one of the following methods.

Welding the hole and then cutting a new thread

This method is rarely used due to the fact that the strength of the new thread obtained using this technology will be lower. This method is also chosen in the absence of special devices (screws and spiral inserts).

This method of thread restoration includes the following steps.

Removing old threads by drilling.

Welding the hole. The choice of technologies depends on the materials of the parts.

To weld holes in steel products, electric arc or gas welding is used in protective environments.

When working with cast iron parts, gas or electric arc welding is used in a cold state or with general/local heating.

Electrodes (MNCh-1, OZCh-1, TsCh-1), cast iron rods with a high silicon content and other materials are used as additives.

Machining the hole flush with the base metal.

Cutting a new thread.

Note! When working with aluminum products, this method of thread restoration is usually not used. This is due to the fact that the metal actively absorbs gases during welding. Pores form in the deposited layers. With severe shrinkage, cracks appear.

Restoring threads using a screwdriver

Screwdrivers are special cylindrical devices that have threads of the required diameter and pitch on the inside and large threads on the outside. Such products are made from steel, brass, bronze, copper and other materials. At the final stages of production, the screws are hardened and further strengthened.

Photo No. 2: screwdriver for thread restoration

If you need to restore the thread while maintaining the diameter using a screwdriver, proceed as follows.

Drill out the hole. The drill must be selected in such a way that the diameter of the resulting hole allows cutting a thread for screwing in the screw.

Cut the thread with a tap. Follow the rules listed above.

Screw in the screwdriver. It needs to be installed flush. If this is not possible, mill the part and remove the protruding part of the fixture.

At the border of the new thread and the screw, apply notches using a core. This will prevent the device from unscrewing spontaneously.

Repairing threads using a spiral insert

Spiral (also called wire and spring) inserts are also often used to restore damaged threads.

Photo No. 3: spiral inserts for thread restoration

These devices have high-precision rhombic threaded profiles on the inside. Almost all models are equipped with special driving tongues designed for screwing in devices.

For the manufacture of such products, especially durable high-quality stainless steel is used. This guarantees the resistance of the restored thread to deformation and corrosion.

Restoring threads using a spiral insert includes 4 stages.

Drilling. Drill out the hole. Select the diameter of the cutting tool according to the table that manufacturers provide with spiral inserts.

Image #1: Drilling the hole for the spiral insert

Thread formation. Note! To cut threads, use special taps that differ from standard ones and come with spiral inserts. Follow all rules and recommendations.

Image #2: Forming a thread for a spiral insert

Installation of the device. Place the spiral insert onto the supplied special tool and screw it into the hole.

Image #3: screwing the spiral insert into the hole

Removing the drive tongue. You can get rid of it using a special tool (manufacturers also supply it). To remove tabs from large-diameter inserts, ordinary pliers are suitable.

Using professional spiral thread inserts has the following advantages.

The required tension is ensured at the insert landing site. This completely prevents twisting. The devices are located in the receiving threads with virtually no gaps. There is no need to use glue for additional fixation of products.

Due to the elasticity of the inserts, loads and stresses are distributed evenly. This creates ideal conditions for the transfer of forces between the bolts and the receiving threads.

Spiral inserts are universal. They are used not only to restore threads, but also when it is necessary to strengthen connections. Spiral inserts are used when working with products made of low-medium and high-strength metals, as well as plastic and wood.

Threaded hole repair (restoring damaged threads)

Our company does not restore threads. This article is intended solely to introduce you to the thread restoration process. In our stores you can buy fittings (threaded inserts), drills, taps, thread restoration kits.

The information is intended for persons carrying out repairs in a personal garage and car repair shops. In accordance with this, the text is structured and recommendations are given. The use of this method in manufacturing enterprises involves the use of specific tools and devices, and other technology.

Carrying out work

Today you can find in stores a large list of goods of foreign and Russian production. It is worth noting two main types: plasticine and liquid. The latter have two components, which are the main mass used in gluing and a hardener. Plasticine-like products consist of a bar with one or more layers, which requires mixing before use. In order to restore internal threads by cold welding, it is advisable to purchase a two-component product, sold in two bottles.

Preliminary degreasing of all surfaces and anti-adhesive treatment both outside and inside is required, since the presence of plaque and small particles can worsen the result. Next, the components from two bottles are mixed on a plastic or wooden surface. The resulting mass is applied to the thread, which is screwed in and left until completely dry. If the temperature regime is observed, thread restoration will be completed after the time specified in the instructions.

Thread restoration method

Damaged threads can be completely restored using the following technology:

1. Drill the threaded hole to the diameter indicated in the table below 2. special profile thread in it Screw a spiral repair insert (a durable stainless steel sleeve) into the resulting thread using a special tool.

Threaded insert

After such an operation, the thread becomes stronger than the original one in good condition. This effect is especially noticeable when the carving is made in a soft material such as aluminum. When a bolt (stud) breaks off in a threaded insert, there is no “biting” effect. A broken bolt (stud) can be easily removed.