Advantages of plastic compared to other materials

Before the advent of plastic, other materials were used in the construction of sewage systems.

At the domestic level, pipes made of asbestos cement, ceramics and cast iron were used to transport wastewater in the outer part of the sewer system. Asbestos cement is a fragile material and has a short service life under conditions of constant exposure to moisture (soil and internal). Ceramic sewer pipes are a little stronger and last longer, but are more expensive and more difficult to install. Cast iron pipes are expensive, but the worst thing is that at small slope angles they are prone to silting, and if sealing is lost, the external sewage system loses its ability to self-clean, which leads to blockages that are difficult to remove. Plastic pipes do not have these disadvantages.

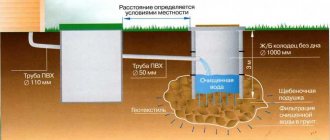

To collect and partially process wastewater, wells made of reinforced concrete rings, bricks or monolithic concrete were usually installed. Sometimes welded tanks made of steel sheets were used as sewage containers. But all these materials have disadvantages that plastic does not have.

Concrete and metal septic tanks are significantly inferior in characteristics to plastic ones Source avokzal70.ru

A storage tank for sewerage assembled from reinforced concrete rings is still relevant today. Strong, reliable and durable material fully meets the requirements that are placed on it. Provided that the manufacturer produces rings without violating technology. Concrete is a “capricious” material - low-quality ingredients (for example, expired cement, quarry sand mixed with clay) or skimping on additives can significantly reduce the service life of a sewer well. The “weakest” link is the joints of the rings with each other and with the bottom. And in order for them to remain airtight, it is necessary to carry out reliable waterproofing. And the main disadvantage is that a storage tank or septic tank made of reinforced concrete rings is expensive, even when the volume of wastewater is small.

A brick storage tank is now not considered at all and as a cesspool. The high hygroscopicity of the material, even with external waterproofing with rolled materials, leads to rapid destruction and loss of tightness.

A brick septic tank is the lot of self-construction - impractical and ineffective, in comparison with a plastic container for sewerage in a country house Source rinnipool.ru

See also: Catalog of companies that specialize in installation and design of sewerage and water supply

In terms of production time and costs, a container made of monolithic concrete is similar to a small permanent pool without finishing. Such a structure is then very difficult to dismantle if there is a need to modernize the autonomous sewer system or redevelop the site.

A tank made of ordinary steel will not last long in conditions of high humidity and aggressive environments, and is more expensive than a plastic one. And using a stainless steel container is expensive and impractical.

A plastic container for a septic tank and wastewater storage tank does not have the above disadvantages. Its advantages:

- affordable price;

- inertness towards any type of domestic waste;

- absolute tightness;

- environmental Safety;

- high bending and tensile strength;

- light weight (simplifies transportation and installation);

- long service life.

The only drawback is the need to rigidly fix the container in the pit (for example, to a concrete slab at the base) and take measures to reduce the impact of heaving forces. This must be done so that the container does not “float” to the surface.

The plastic septic tank is fixed on a concrete slab or on reliable guy wires Source skopelitissa.com

Only peat bogs and the humus (fertile) layer have a low density (1150-1200 kg/m3), and the lightest loams and sandy loams (1600-1700 kg/m3) are much heavier than a plastic tank with wastewater. Therefore, heaving forces will tend to push it to the surface.

Septic tanks made of polypropylene and HDPE.

Plastic septic tanks are made mainly from polypropylene (Tver, Bioksi, Deka) and low-density polyethylene (HDPE) (Tank, Uponor, Dochista, Bars, Rostok, Chistok).

| Physical and mechanical properties at 20°C: | Polypropylene | HDPE |

| Density, g/cm3 | 0,90—0,91 | 0,94-0,96 |

| Breaking tensile stress, kgf/cm² | 250—400 | 100—170 |

| Elongation at break, % | 200—800 | 500—600 |

| Brinell hardness, kgf/mm² | 6,0—6,5 | 1,4-2,5 |

| Heat resistance, °C | + 140 °C | + 129 |

| Brittleness temperature, °C | -5 °С – -15 °С | -70 °C |

As can be seen from the table, polypropylene is superior to polyethylene in heat resistance, but inferior to it in frost resistance. Products made of polypropylene can withstand temperatures up to +140 °C without any changes in shape or properties. The brittleness temperature of polypropylene is -5 ° C - -15 ° C., however, it should be remembered that one of the most important components of plastics are fillers, which have a great influence on such important properties as strength, hardness, heat resistance, and thermal conductivity. Thanks to these additives, the brittleness temperature of polypropylene can be reduced to -60°C.

This is quite an important point, because... Many buyers make their choice of a septic tank based only on the thickness of the plastic from which it is made. In other words, the container can be made of thicker plastic, but not intended for freezing temperatures.

The situation is similar with concrete.

The grade and class of concrete for frost resistance is designated by the letter F and, according to standards, ranges from 25 to 1000 (the number of freezing and thawing cycles).

| Frost resistance group | Designation | Note |

| Low | less than F50 | Not widely used. |

| Moderate | F50 – F150 | The frost resistance and water resistance of concrete in this group has optimal indicators. Such mixtures are the most common. |

| Increased | F150 – F300 | The frost resistance of the foundation concrete mixture in this range makes it possible to operate buildings in fairly harsh conditions. |

| High | F300 – F500 | Such solutions are required in special cases, for example, when operating with variable moisture levels. |

| Particularly high | over F500 | Frost-resistant concrete is obtained by injecting special additives. It is used in the construction of structures that last for centuries. |

The body of polypropylene septic tanks is made of sheets (panels) that are joined by extrusion.

Advantages of polypropylene and low-density polyethylene (HDPE):

- Ability to produce fairly complex products. That is why biological wastewater treatment plants, more advanced than simple septic tanks, are made of polypropylene rather than HDPE.

- Possibility to make any modifications, best suited to the needs of a specific customer. For example, “Tver” exists in 9 performance options

- 0.35m3 (per day; 1-2 residents)

- 0.50m3 (2-3 residents)

- 0.75m3 (3-4 residents)

- 0.85m3 (4-5 residents)

- 1.0m3 (5-6 residents)

- 1.20m3 (6-7 residents)

- 1.50m3 (7-9 residents)

- 2.0m3 (10-12 residents)

- 3.0m3 (12-17 residents)

Standard containers have a height of 1.60 m, to the bottom of the DN100 tray -0.30 m. Depending on the depth of the pipeline (up to -0.90 m incl.), each of the 9 basic models can be manufactured in 7 height modifications in increments of 0, 10m:

| Modification | Height, m | Bottom of tray DN100, m |

| standard | 1,60 | -0,30 |

| +0.10 neck | 1,70 | -0,40 |

| +0.20 neck | 1,80 | -0,50 |

| +0.30 walls | 1,90 | -0,60 |

| +0.40 walls (0.30) and neck (0.10) | 2,00 | -0,70 |

| +0.50 walls (0.30) and neck (0.20) | 2,10 | -0,80 |

| +0.60 walls (0.30) and neck (0.30) | 2,20 | -0,90 |

9x7=63 modifications.

When the pipeline depth is > 0.90 m and up to - 1.60 m, 7 more modifications are manufactured with an additional chamber for the fecal pump (the length of the base tank increases by approximately 0.35 m). 63x2=126 modifications. According to the method of draining purified water, there is a gravity option (without a pump chamber) and a pressure option using a drainage pump. Total: 126x2=252 modifications.

Septic tanks made of polyethylene, due to the peculiarities of their manufacturing, usually have a limited range of models.

Types of sewage containers

There are three main schemes for constructing an autonomous sewer system. In each of them, the plastic container performs its task and differs in its internal structure.

Storage capacity

In function, this is a typical storage sewer. Refers to the simplest and most affordable scheme. The container does not have internal partitions, and its task is to collect household wastewater for subsequent pumping with a sewage disposal machine.

Inside, only natural processes of waste decomposition occur without separation into fractions and wastewater treatment. The frequency of calling vacuum cleaners depends on the intensity of use, and this is the main drawback that determines the scope of use - summer cottages, small country houses for seasonal residence.

The storage septic tank simply collects wastewater, which is then pumped out by a sewer truck Source gorobzor.ru

Features of installation and operation of sewer tanks

When choosing a place to install a container, it is necessary to take into account the gravity drainage of wastewater - if the site is located on a slope, then it should be located below the level of the house.

The bottom of the pit must be smooth and strong, preventing the possibility of the container moving so that the tightness of the connection with the sewer pipe is not compromised.

To anchor the container, use a reinforced concrete slab laid at the bottom of the pit with the obligatory arrangement of a cushion of crushed stone and sand.

To reduce the buoyancy forces of heaving, a pit is dug larger than the dimensions of the container, and the sinuses are filled with a mixture of sand and excavated soil or sand and crushed stone.

Prices for Germes-Plast-OS tanks (underground version)

Price list for containers manufactured for installation in dry soil (SG)

| № | Name of container (reservoir) | Volume, m³ | Length, mm | Width, mm | Height, mm | Depth, | Price, rub | |

| 1 | Germes-Plast-OS-3000 | 3 | 1700 | 1550 | 1800 | up to 2 m | 66400 | ORDER |

| 2 | Germes-Plast-OS-4000 | 4 | 2300 | 1550 | 1800 | up to 2 m | 74300 | ORDER |

| 3 | Germes-Plast-OS-5000 | 5 | 2850 | 1550 | 1800 | up to 2 m | 81500 | ORDER |

| 4 | Germes-Plast-OS-6000 | 6 | 3400 | 1550 | 1800 | up to 2 m | 88700 | ORDER |

| 5 | Germes-Plast-OS-8000 | 8 | 4550 | 1550 | 1800 | up to 2 m | 103800 | ORDER |

| 6 | Germes-Plast-OS-10000 | 10 | 5700 | 1550 | 1800 | up to 2 m | 113200 | ORDER |

| 7 | Germes-Plast-OS-12000 | 12 | 6800 | 1550 | 1800 | up to 2 m | 126700 | ORDER |

| 8 | Germes-Plast-OS-15000 | 15 | 8500 | 1550 | 1800 | up to 2 m | 153200 | ORDER |

| 9 | Germes-Plast-OS-15000 | 15 | 4800 | 2078 | 2400 | up to 2 m | 170000 | ORDER |

| 10 | Germes-Plast-OS-20000 | 20 | 6400 | 2078 | 2400 | up to 2 m | 200300 | ORDER |

| 11 | Germes-Plast-OS-25000 | 25 | 8000 | 2078 | 2400 | up to 2 m | 242000 | ORDER |

| 12 | Germes-Plast-OS-30000 | 30 | 9600 | 2078 | 2400 | up to 2 m | 275700 | ORDER |

| 13 | Germes-Plast-OS-40000 | 40 | 12800 | 2078 | 2400 | up to 2 m | 535500 | ORDER |

| 14 | Germes-Plast-OS-50000 | 50 | 16000 | 2078 | 2400 | up to 2 m | 407000 | ORDER |

| 15 | Germes-Plast-OS-50000 | 50 | 13200 | 2324 | 2750 | up to 2 m | 621500 | ORDER |

| 16 | Germes-Plast-OS-60000* | 60 | 16000 | 2324 | 2750 | up to 2 m | 733000 | ORDER |

| 17 | Germes-Plast-OS-80000* | 80 | 21000 | 2324 | 2750 | up to 2 m | 922300 | ORDER |

| 18 | Germes-Plast-OS-100000* | 100 | 26400 | 2324 | 2750 | up to 2 m | 1120000 | ORDER |

| 19 | Germes-Plast-OS-60000 | 60 | 10100 | 3060 | 3400 | up to 2 m | on request | ORDER |

| 20 | Germes-Plast-OS-80000 | 80 | 13300 | 3060 | 3400 | up to 2 m | on request | ORDER |

| 21 | Germes-Plast-OS-100000 | 100 | 16600 | 3060 | 3400 | up to 2 m | on request | ORDER |

* - consist of two tanks of equal volume and assembly and welding is carried out at the installation site

Price list for tanks made for installation in wet soil (WG)

| № | Name of container (reservoir) | Volume, m³ | Length, mm | Width, mm | Height, mm | Depth, | Price, rub | |

| 1 | Germes-Plast-OS-3000 | 3 | 1700 | 1578 | 1800 | up to 2 m | 70500 | ORDER |

| 2 | Germes-Plast-OS-4000 | 4 | 2300 | 1578 | 1800 | up to 2 m | 80000 | ORDER |

| 3 | Germes-Plast-OS-5000 | 5 | 2850 | 1578 | 1800 | up to 2 m | 90240 | ORDER |

| 4 | Germes-Plast-OS-6000 | 6 | 3400 | 1578 | 1800 | up to 2 m | 98000 | ORDER |

| 5 | Germes-Plast-OS-8000 | 8 | 4550 | 1578 | 1800 | up to 2 m | 115500 | ORDER |

| 6 | Germes-Plast-OS-10000 | 10 | 5700 | 1578 | 1800 | up to 2 m | 132000 | ORDER |

| 7 | Germes-Plast-OS-12000 | 12 | 6800 | 1578 | 1800 | up to 2 m | 149000 | ORDER |

| 8 | Germes-Plast-OS-15000 | 15 | 8500 | 1578 | 1800 | up to 2 m | 180000 | ORDER |

| 9 | Germes-Plast-OS-15000 | 15 | 4800 | 2124 | 2400 | up to 2 m | 238000 | ORDER |

| 10 | Germes-Plast-OS-20000 | 20 | 6400 | 2124 | 2400 | up to 2 m | 292000 | ORDER |

| 11 | Germes-Plast-OS-25000 | 25 | 8000 | 2124 | 2400 | up to 2 m | 356500 | ORDER |

| 12 | Germes-Plast-OS-30000 | 30 | 9600 | 2124 | 2400 | up to 2 m | 413000 | ORDER |

| 13 | Germes-Plast-OS-40000 | 40 | 12800 | 2124 | 2400 | up to 2 m | 518500 | ORDER |

| 14 | Germes-Plast-OS-50000 | 50 | 16000 | 2124 | 2400 | up to 2 m | 635800 | ORDER |

| 15 | Germes-Plast-OS-50000 | 50 | 13200 | 2370 | 2750 | up to 2 m | 759000 | ORDER |

| 16 | Germes-Plast-OS-60000* | 60 | 16000 | 2370 | 2750 | up to 2 m | 899000 | ORDER |

| 17 | Germes-Plast-OS-80000* | 80 | 21000 | 2370 | 2750 | up to 2 m | 1140700 | ORDER |

| 18 | Germes-Plast-OS-100000* | 100 | 26400 | 2370 | 2750 | up to 2 m | 1412000 | ORDER |

| 19 | Germes-Plast-OS-60000 | 60 | 10100 | 3100 | 3400 | up to 2 m | on request | ORDER |

| 20 | Germes-Plast-OS-80000 | 80 | 13300 | 3060 | 3400 | up to 2 m | on request | ORDER |

| 21 | Germes-Plast-OS-100000 | 100 | 16600 | 3060 | 3400 | up to 2 m | on request | ORDER |

* - consist of two containers of equal volume and assembly and welding is carried out at the installation site

Price list for containers made for installation in quicksand soil (P)

Price, rub

| № | Name of container (reservoir) | Volume, m³ | Length, mm | Width, mm | Height, mm | Depth, | ||

| 1 | Germes-Plast-OS-3000 | 3 | 1700 | 1624 | 1800 | up to 2 m | 96500 | ORDER |

| 2 | Germes-Plast-OS-4000 | 4 | 2300 | 1624 | 1800 | up to 2 m | 113200 | ORDER |

| 3 | Germes-Plast-OS-5000 | 5 | 2850 | 1624 | 1800 | up to 2 m | 128400 | ORDER |

| 4 | Germes-Plast-OS-6000 | 6 | 3400 | 1624 | 1800 | up to 2 m | 135400 | ORDER |

| 5 | Germes-Plast-OS-8000 | 8 | 4550 | 1624 | 1800 | up to 2 m | 163800 | ORDER |

| 6 | Germes-Plast-OS-10000 | 10 | 5700 | 1624 | 1800 | up to 2 m | 192200 | ORDER |

| 7 | Germes-Plast-OS-12000 | 12 | 6800 | 1624 | 1800 | up to 2 m | 220000 | ORDER |

| 8 | Germes-Plast-OS-15000 | 15 | 8500 | 1624 | 1800 | up to 2 m | 267900 | ORDER |

| 9 | Germes-Plast-OS-15000 | 15 | 4800 | 2210 | 2400 | up to 2 m | 305000 | ORDER |

| 10 | Germes-Plast-OS-20000 | 20 | 6400 | 2210 | 2400 | up to 2 m | 370900 | ORDER |

| 11 | Germes-Plast-OS-25000 | 25 | 8000 | 2210 | 2400 | up to 2 m | 450000 | ORDER |

| 12 | Germes-Plast-OS-30000 | 30 | 9600 | 2210 | 2400 | up to 2 m | 515000 | ORDER |

| 13 | Germes-Plast-OS-40000 | 40 | 12800 | 2210 | 2400 | up to 2 m | 650000 | ORDER |

| 14 | Germes-Plast-OS-50000 | 50 | 16000 | 2210 | 2400 | up to 2 m | 790000 | ORDER |

| 15 | Germes-Plast-OS-50000 | 50 | 13200 | 2430 | 2750 | up to 2 m | 826000 | ORDER |

| 16 | Germes-Plast-OS-60000* | 60 | 16000 | 2430 | 2750 | up to 2 m | 977000 | ORDER |

| 17 | Germes-Plast-OS-80000* | 80 | 21000 | 2430 | 2750 | up to 2 m | 1256000 | ORDER |

| 18 | Germes-Plast-OS-100000* | 100 | 26400 | 2430 | 2750 | up to 2 m | 1530000 | ORDER |

| 19 | Germes-Plast-OS-60000 | 60 | 10100 | 3100 | 3400 | up to 2 m | on request | ORDER |

| 20 | Germes-Plast-OS-80000 | 80 | 13300 | 3100 | 3400 | up to 2 m | on request | ORDER |

| 21 | Germes-Plast-OS-100000 | 100 | 16600 | 3100 | 3400 | up to 2 m | on request | ORDER |

* - consist of two containers of equal volume and assembly and welding is carried out at the installation site

Additional equipment compatible with the Germes-Plast-OS series

| Name of components | Length, mm | Width, mm | Height, mm | order | |||

| Cover C | 640 | 160 | 2500 | ORDER | |||

| Neck G300 | 690 | 370 | 2500 | ORDER | |||

| Neck G500 | 690 | 570 | 3000 | ORDER | |||

| Neck G1000 | 690 | 1020 | 4700 | ORDER | |||

Cap and extension necks not included