A gun drill is a tool that is used to drill through and blind holes of considerable depth. Holes of this type are made in shafts for various purposes, in spindles, as well as in other parts characterized by a significant length. For this purpose, not only gun drills are used, but also, in particular, single-edged and double-edged drills with internal chip removal. Drilling with the help of the latter is characterized by low productivity, but the deep holes made are characterized by high cleanliness, accuracy of geometric parameters and straightness.

Deep drilling process on a turning-milling center

Features of drilling deep holes

Drilling is called deep if the depth of the hole exceeds five of its diameters. This technological operation is highly complex and labor-intensive, and the main condition for its high-quality implementation is the effective cooling of the tool used, which, as a rule, is carried out under pressure.

In order to perform deep drilling efficiently and accurately, it is very important to ensure the correct direction of the tool at the very beginning of processing. To do this, use a special conductor sleeve or carry out this procedure through a pre-made hole of a smaller diameter.

Due to technical difficulties, deep drilling should be performed using special equipment

A drill used for deep drilling must not be rotated at full speed outside the workpiece itself: this may lead to the cutting part being displaced from the required trajectory. In addition, when drilling deep holes with a long drill, unfavorable conditions are created for removing chips from the processing zone, which can also lead to the tool moving away from the specified direction.

Winding tape or wire

Use standard electrical tape as a visual guide.

To do this, you need to wind it around the drill bit clockwise so that only the part that will go into the material being drilled remains open.

It will not be possible to achieve high accuracy, but when drilling a wooden structure, the main thing is to determine its maximum permissible depth. For example, so that the drill cannot come out from the back of the part.

Remember that with a wood drill you need to take into account the length of the center.

The disadvantage of this option is that if you inadvertently exceed the force of pressure on the drill, it may go to a greater depth.

Also, if a very large number of holes need to be made, it will be quite tedious work to constantly ensure that the drill does not go beyond the stop.

Standard wire can also be used as a limiting element. Insert it into the clamp and wrap it around the drill bit.

It is necessary to perform this procedure specifically clockwise, because otherwise the wire will begin to unwind upon contact with the material being drilled by the drill.

In this case, the last turn must be pressed with needle-nose pliers. This is an excellent method because it allows you to mechanically and visually limit the drilling depth.

It is more convenient to use copper wire, but this material is quite expensive.

Types of deep drill bits

The following can be used as drills for deep drilling:

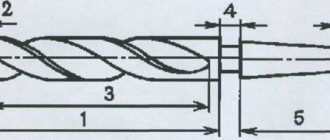

- spiral drills with a cylindrical shank, the parameters of which are regulated by GOST 886-77 (by design, spiral drills with a cylindrical shank belong to a long series of tools, with the help of which they create holes with a depth exceeding a value equal to 15 diameters);

- rifle, the cutting part of which is completely made of hard alloy;

- rifle, on the cutting part of which carbide plates are fixed by soldering;

- rifle, equipped not only with main, but also with intermediate carbide plates;

- ejector, which are used to perform deep drilling on machines with a horizontal cutting tool;

- cannon type, on the surface of which there is a V-shaped groove designed to remove chips (processing with drills of this type is an outdated method of producing deep holes).

Deep drill bits

You can familiarize yourself with the GOST requirements for long series drills by downloading the document in pdf format from the link below.

GOST 886-77 Twist drills with a cylindrical shank. Long series. Main Dimensions

Twist drills with a cylindrical shank, produced in accordance with the requirements specified by GOST 886-77, are distinguished by an elongated working part. In accordance with the provisions of the above-mentioned standard from the year 77, such an extended tool can be made entirely of high-speed steel or equipped with cutting inserts made of carbide.

GOST 886 from 1977 also stipulates that cooling of drills of this type can be ensured through not only external, but also internal coolant supply. Twist drills, as indicated by GOST 886-77, can be produced not only with a cylindrical shank, but also with conical shanks. The process of deep drilling itself, carried out using such drills, can be performed either with their periodic removal from the hole being made, which is necessary to remove the formed chips from it, or without performing such a procedure. If we compare spiral drills with gun and cannon drills, then when using the former, drilling productivity increases almost 8 times.

Examples of working heads for gun drills

Gun and gun drills are single-cut tools that can be used to create deep holes with diameters ranging from 0.5–100 mm. Cooling of drills of this type is carried out through a hole made in their internal part, and the chips formed during the processing process are removed using a special groove made on their outer surface. Gun and gun drills equipped with cutting carbide inserts are distinguished by a conical configuration of the working part, which ensures better direction of the tool into the processing area.

Ejector drills are more modern means of deep drilling. Due to the absence of chip grooves on their outer surface, they are characterized by high rigidity.

Operating principle of an ejector drill

How to choose the right tool

When choosing drills for deep drilling, you should consider a number of factors:

- diameter and depth of the hole to be made;

- characteristics of the processed material;

- the type of equipment that will be used to perform the processing.

Scheme for calculating drill length when working on a universal machine

It should be borne in mind that the device on which such a drill will be installed must be designed specifically for deep drilling.

Before starting drilling, you should select the optimal speed of rotation and feed of the cutting tool, as well as ensure its effective cooling. For materials that produce long chips when cutting, it is best to use a drill with polished flutes.

Gun drills can be single- or double-sided cutting

Pereosnastka.ru

Features of drilling small holes

TO

category:

Miniature technology

Features of drilling small holes

Currently, the minimum size of holes produced by drilling is 0.05 mm. The production of smaller holes by drilling is limited by the possibility of producing sufficiently high-quality and durable drills and the lack of precision, highly sensitive drilling equipment.

In addition, as studies have shown, holes with a diameter of 0.03 mm obtained by drilling, as a rule, do not have a clearly defined contour. The resulting chips and burrs become comparable to the hole. Removing chips is difficult.

Therefore, to obtain holes smaller than 0.05 mm, laser, electron beam and other methods are more effective.

Undoubtedly, drilling holes with dimensions close to the minimum limit value has its own characteristics compared to drilling holes with a diameter of about 1 mm and requires not only special tools and equipment, but also much greater caution.

The industry produces standard twist drills, the minimum diameter of which is 0.1 mm. To obtain smaller hole sizes, special drills are made.

The small size of drills for drilling holes with a diameter of 0.05-1 mm, their limited rigidity and strength determine the specific features of the drilling process.

The main feature is the sharper influence of a number of factors, such as the runout of the drill and machine spindle, the condition and quality of the surface of the product, the amount of drill overhang, the nature and uniformity of feed.

Worsening of any of these factors can result in drill bit failure or inaccurate holes.

Therefore, it is very important to study the influence of each of these factors on the drilling process, surface quality, processing accuracy and durability of drills.

Before starting drilling, it is necessary to ensure the correct installation of the drills in the collet or chuck, limit the spindle runout and the non-perpendicularity of its axis to the working surface of the table within 0.005 mm.

The runout of the cutting edges of the drill should be minimal and not exceed 0.015 mm. It is generally accepted that the installation of drills in the chuck is considered correct if, when the spindle rotates at a speed of less than 1.5 thousand.

rpm, when visually examined through a magnifying glass with 4-10x magnification, the drill appears in the form of a solid rod without chip flutes.

For a more accurate quantitative assessment of the runout of small-sized drills when installing them in a chuck and measuring wear, a special device is used.

It consists of a plate, a stereoscopic microscope head (MBS-2) mounted on it, and a bracket for attaching and moving an optical prism designed to rotate the image of the drill under study by 90°. Changing the image magnification from 4.8 to 56x is done by turning the nut.

The division value of the measuring eyepieces at maximum magnification is 0.015 mm. The eyepieces can be rotated in the tubes to set the scale to a position convenient for measurement. The light source is located in the sleeve, which, together with the bracket, is installed on the optical head housing.

Precise focusing of the image is achieved by moving the prism. If processing conditions require measuring the vertex angle, the prism can be additionally rotated to the appropriate angle and secured with a screw. If necessary, drill wear can be recorded on photographic film.

Rice. 1. Graph of the dependence of the “breaking” feed on the drill overhang value

At large values of drill overhang L and drilling depths h, the bending strength of drills decreases sharply. In Fig. Figure 32 shows the dependence of the “breaking” feed 5L0M on the overhang value at various drilling depths (for drills d = 0.5 mm and V = 3.1 m/min).

The overhang of small-sized drills has a significant impact on the processing performance and durability of small-sized drills. At large ratios Lid, under the influence of the cutting force, the longitudinal stability of the drills is lost, as a result of which their rectilinear shape is lost, which is preserved when drilling with an overhang of up to 10d.

Therefore, in all cases it is advisable to carry out processing with minimal (in relation to free chip exit) overhang.

If, according to technological conditions, the reach length is regulated, then the efficiency of using small-sized drills can be significantly increased by using a tool with a reduced length of the working part, which is quite acceptable, since the depth of holes with a diameter of up to 1 mm does not exceed (with rare exceptions) Ad.

It should be borne in mind that when drilling, holes are broken due to inevitable beats of the drill. Therefore, when drilling precise holes, the diameter of the drill should be selected taking into account the layout of the hole and taking into account the allowance for subsequent calibration. The latter is produced using calibrating punches or balls, first in advance, and then “to size”.

Drilling using conventional three-jaw chucks for fastening drills does not always provide the required accuracy and requires additional time for alignment. The use of cartridges at high rotation speeds (over 10 thousand/min) causes significant vibrations.

In this regard, for fastening small diameters, clamping collets are used, which have less mass and imbalance.

Technology stages

The process of deep hole drilling itself is performed in the following sequence.

- First of all, a pilot hole is made with an H8 tolerance.

- The tool, rotating at a low frequency, is brought to the surface of the workpiece.

- They include the required rotation speed of the drill and its feed rate, and ensure the supply of coolant to the processing zone.

- The hole is drilled to the required depth without retracting the tool.

- If a very long tool is used for deep drilling, then the first 25 mm of the hole depth is processed at reduced cutting conditions - 75% of the nominal ones.

- After reaching the required drilling depth, the coolant supply to the processing zone is turned off.

- After finishing drilling, the tool is quickly removed from the processing zone and its rotation is stopped.

There are several other deep hole drilling techniques, but the above is the most common one that is used in most cases.