Sandblasting from Karcher: nozzle for Karcher high pressure washer

A DIY sandblasting attachment used for installation on a standard Karcher machine will allow you to turn such equipment into a full-fledged sandblasting unit, useful in many situations.

Most Karcher washing machines operate under high pressure, so their technical capabilities are quite sufficient to supply sand through such a nozzle.

The difference between such a homemade device and a classic sandblaster will be that sand will be supplied through its nozzle along with water, but this is not critical for many situations.

Kärcher wet sandblasting kit

How does a sandblasting nozzle work?

The operating principle of any sandblasting installation is that abrasive material from a special hopper enters the nozzle under the influence of an air flow supplied under high pressure.

In serial installations, a separate compressor is used to create such pressure, due to which a significant amount of kinetic energy is imparted to the sand stream emerging from the nozzle. In the case of a Karcher washing machine, the pneumatic equipment built into it will be used for these purposes.

As a nozzle for such equipment, you can use a serial gun, specially designed for equipping pneumatic treatment plants, but in order not to spend money on such a device, you can easily make it yourself.

In order for your homemade sandblasting nozzle, which you will use for installation on a Karcher device, to be effective and not malfunction, you must use high-quality materials for its manufacture.

Operating principle of wet sandblasting rust cleaning machine

Of course, equipment assembled in this way can, with great stretch, be considered as a full-fledged sandblaster, but it is quite suitable for cleaning various surfaces with a stream of water mixed with sand. When using such a sandblasting device, it is very important to adhere to two recommendations:

- It is better to use distilled water as the working fluid, which will avoid corrosion of the metal elements of the nozzle;

- the sand that will be used as an abrasive must be of a very fine fraction and carefully sifted.

Diagram of a sandblasting nozzle (click to enlarge)

A self-assembled sandblasting machine, the basic elements of which are a Karcher mini-washer and a homemade nozzle, will work according to the following scheme.

- When you press the start button on the nozzle gun, water under high pressure created by the compressor flows past the opening of the intake hose, the other end of which is placed in a hopper with sand. This creates a vacuum in the intake hose.

- Under the influence of vacuum, sand is sucked from the hopper into the main hose, where it is mixed with the water flow.

In order to minimize sand consumption and bring this parameter to a value of 30 kg of abrasive for processing a surface area with a diameter of 70–80 cm, the design of this equipment must be supplemented with taps and dispensers.

Homemade mixer from water taps and tees

Making a homemade nozzle

In order to turn a Karcher mini washer into an effective sandblasting unit using a homemade nozzle, you will need the following structural elements:

- a nozzle through which a mixture of water and sand will be supplied to the treatment zone;

- trigger;

- reinforced hose that will be able to withstand high pressure;

- dispenser necessary to make the consumption of abrasive material more economical.

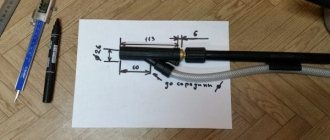

Nozzle diagram: 1 – thread; 2 – low pressure chamber; 3 – nozzle; 4 – fitting for sand supply; 5 – junction of two parts of the nozzle; 6 – smooth tapering transition

For the nozzle, if you intend to use your sandblaster regularly, it is best to purchase one that is made of ceramic. This type of attachment, which is constantly exposed to abrasive material, will last you much longer than its metal counterpart.

Homemade water sand blasting nozzle

Nozzle details: 1 – pistol; 2 – nozzle; 3 – nozzle holder; 4 – sandblasting nozzle

The efficiency of the sandblasting machine with a homemade nozzle, which you will equip your Karcher sink with, is greatly influenced by the quality of the nozzle.

It’s worth starting to create such an element yourself only if you have the opportunity to drill an exact hole in a metal rod, the diameter of which is at least 15 mm.

But if this is not possible, then it is better to purchase a factory nozzle, the quality of which will determine the operation of the entire device. The advisability of purchasing a serial nozzle also lies in the fact that some models of such products are already immediately equipped with triggers.

When choosing a hose, the length of which must be at least 2 meters, you should pay attention only to reinforced products. This is explained not only by the fact that such a hose will work under high pressure created by the compressor, but also by the fact that its internal walls will be constantly exposed to abrasive, which will quickly render the unreinforced product unusable.

When starting to assemble and attach the nozzle to equip the Karcher washing machine, you should adhere to the following algorithm of actions:

- a ceramic or metal tip must be fixed to the nozzle of your homemade nozzle using a threaded connection;

- the dispenser, with which you will regulate the flow of the water-sand mixture coming under high pressure from the nozzle, should be attached to the metal or ceramic tip of the nozzle;

- the hose through which sand will be supplied from the hopper must be secured to the back of the nozzle, for which a fitting and a clamp of the appropriate diameter are used.

Scheme of operation and example of manufacturing a nozzle for collecting sand

When assembling and installing a nozzle for Karcher, you should take into account the fact that all elements of such a device will operate under high pressure created by the compressor of the device.

That is why all formed connections must be ensured with maximum tightness and reliability.

It is not difficult to fulfill this requirement if you make such connections using a special fum tape.

There is one more trick that will allow you to save abrasive material. It consists of the following: cleaning must be performed over a special container with a grid into which the waste mixture of water and sand will be collected.

This mixture can be reused by lowering the end of a reinforced hose into it, which is connected to the nozzle of the device.

There must be a grate on the top of this container; it is necessary in order to hold processing waste and prevent it from getting into the water-sand mixture.

Karcher sink with sandblasting nozzle in use

What can you use a homemade sandblasting machine for?

The effectiveness of using a sandblasting unit with a homemade nozzle, assembled on the basis of a Karcher apparatus, is ensured by the fact that sand mixed with water is supplied from a nozzle under high pressure, which is created by the built-in compressor of the device. Possessing significant kinetic energy, such an abrasive jet is capable of effectively cleaning various surfaces.

Main components of sandblasting machine

Homemade sandblasting is assembled on the basis of standard schemes, differing in the method of supplying sand to the contaminated part. Despite the existing design differences, the components for both options are the same:

- compressor - a device for pumping air mass;

- a receiver necessary to create the necessary air supply;

- abrasive tank;

- gun - the main device designed to supply an abrasive mixture to the surface to be cleaned;

- hoses.

Sandblasting machine device

The device, regardless of the assembly scheme, forms a combined output flow of air and abrasive. When assembled according to a pressure circuit, sand under the influence of pressure enters the outlet pipe, in which it is mixed with the air supplied from the compressor. To form a vacuum in the abrasive supply channel in ejector devices, the Bernoulli effect is used. Sand is fed into the mixing zone under the influence of only atmospheric pressure.

The existence of many options for sandblasting manufacturing schemes is explained by the possibility of creating it from materials at hand, which often seem unnecessary. To understand the essence of the process, it is enough to consider the general principles of assembly.

Sandblasting nozzle for high pressure washer

On page: 15 25 50 75 100

Default Name (A -> Z) Name (Z -> A) Price (00 -> 0000) Price (0000 - > 00) Rating (Best first) Rating (Best last) Model (A -> Z) Model (Z -> A)

Sandblasting nozzle for Karcher

The Karcher Sink Blasting Kit is a tool for removing rust, old paint and stubborn stains. Hydrop..

RUB 1,550.00

Sandblasting nozzle for Stihl

The abrasive blast cleaning kit for Shtil sinks is a tool for removing rust, old paint and stubborn stains. Hydrosand..

RUB 1,650.00

Sandblasting nozzle for Huter

The Huter Sink Blasting Kit is a tool for removing rust, old paint and stubborn stains. Hydrosand..

RUB 1,650.00

Sandblasting nozzle for Interskol

A set for jet abrasive cleaning for Interskol sinks is a tool for removing rust, old paint and difficult stains. Hydr..

RUB 1,650.00

Sandblasting nozzle for Bosch

The Bosch Sink Blasting Kit is a tool for removing rust, old paint and stubborn stains. Hydrosand..

RUB 1,650.00

Sandblasting nozzle for Sterwins

The Sterwins Sink Blasting Kit is a tool for removing rust, old paint and tough stains. Hydro..

RUB 1,650.00

Sandblasting nozzle for Daewoo

The abrasive blast cleaning kit for Daewoo sinks is a tool for removing rust, old paint and stubborn stains. Hydrope..

RUB 1,650.00

Sandblasting nozzle for Greenworks

The Greenworks Sink Blasting Kit is a tool for removing rust, old paint and tough stains. Guide..

RUB 1,650.00

Sandblasting nozzle for Patriot

The Patriot Sink Blasting Kit is a tool for removing rust, old paint and tough stains. Hydrop..

RUB 1,650.00

Sandblasting nozzle for Kolner

The Kolner Sink Blasting Kit is a tool for removing rust, old paint and tough stains. Hydrope..

RUB 1,650.00

Source: https://pennik.ru/peskostruinaia-nasadka-dlia-moiki/

Areas of use

The high pressure created by the Karcher compressor allows a jet of water mixed with sand to be thrown through the nozzle, thus effectively and quickly cleaning many surfaces.

The sandblasting nozzle will easily allow you to cope with some tasks in a very short time:

- cleaning various surfaces from complex contaminants;

- removal of building mixtures, glue, paint, varnish;

- cleaning metal from rust and corrosion;

- carrying out stripping of metal products for subsequent processing.

The simplicity of the design and the ease of self-production can significantly facilitate and increase the quality of the work you perform. This attachment will save your time and effort.

Sandblasting nozzle for karcher. Finding the limits of possibilities

How does a sandblasting nozzle work?

Karcher with a sandblasting nozzle consists of the following components:

- AWD Preus mini-compressor, which is included when the consumer purchases basic cleaning equipment from the Kärcher brand.

- A serial gun that controls the flow.

- Adapter attachment designed for use with water-sand mixture.

- A hose whose manufacturing technology takes into account the significant abrasive effect of the flow on the walls.

- Containers with sand.

- Receiving nozzle for sand selection.

When all of the above elements are connected to each other, the receiving nozzle is immersed almost to the bottom of the container with abrasive, after which the high-pressure water supply is turned on.

By adjusting the flow rate using an adapter, you can control the diameter of the water-sand mixture and the intensity of its impact on the surface being cleaned.

The duration of sandblasting is determined by the amount of sand in the container.

The characteristics of the sandblasting nozzle for kärcher declared by the manufacturer are:

- The maximum developed pressure is up to 140 at;

- The recommended distance from the adapter to the surface to be treated is no more than 300 mm;

- Hose length – 3 m;

- The nominal consumption of abrasive for processing flat surfaces is 50...60 kg/m2;

It should be noted that, for the compactness of the installation, it does not include dispensers and control valves, and sand is sucked in exclusively due to the vacuum created in the main water line. Judging by user reviews, this is a significant design flaw in the device.

However, the features of the practical use of the hydrosandblasting nozzle for Karcher are not only this.

Sand for hydrosandblasting

It’s worth starting with the choice of consumables, since the principle of sandblasting itself is trivial. Unless the flow of sand is supplied directly from the compressor unit, but is captured from the tank by a flow of water, which has a sufficiently high kinetic energy for these purposes. This is precisely the subtlety of using sandblasting nozzles for Karcher

The instructions for use recommend that the user only use sand supplied by the nozzle manufacturer. And this is no coincidence. Those who did not pay attention to this detail then pay with a sharp decrease in the speed of the cleaning mixture, and, accordingly, a decrease in the efficiency of sandblasting. There are plenty of reviews on the problem that has arisen.

Sand used in sandblasting nozzles has a number of features:

- Extremely uniform in fraction - 0.3...0.5 mm, no more and no less (a finer fraction will only produce grinding; the disadvantages of larger fractions will be discussed later).

- The particles have a rounded shape in plan, without sharp protrusions and corners.

- The sand must be strong enough so that it does not crush and disintegrate into smaller fractions after the first use.

- The supplied material must be completely dry before mixing with water.

Sandblasting with a high-pressure washer can be used to clean relatively small surfaces of a simple, flat shape (the sand consumption coefficient when working with more complex configurations will be several times higher). The sand itself cannot be recycled or recycled after processing. This is explained not only by the difficulty of collection, but also by the need for particularly thorough cleaning, since waste sand contains particles of materials torn off from the cleaned surface.

Nissan Patrol QD32 › Logbook › Sandblasting from Karcher and eliminating bugs

The patrol is a good car. But it is highly susceptible to corrosion. I wanted to treat the hidden cavities with a liquid rast-stop, and from the bottom outside with a thick one. Rust-stop is a good thing, but if it somehow stays in cracks and hidden cavities, then in open, level places it is quickly washed away, especially by reagents and petroleum products that somehow get on the asphalt (everyone has noticed that on the highway, “windshield wipers” smear on an oily film on the glass?). Therefore, I couldn’t smear it, I had to eliminate the bugs at least in open areas and paint it. This is what the frame and side members looked like before work began:

These are the worst places. At the same time, I feel the frame and side members inside with my finger through the technological holes - everything is smooth there, i.e. The paint is still in place. It’s strange, on Padzherik it was the other way around.

I was puzzled as to how to clean off the rust. It’s not realistic to use your hands; you can’t get anywhere with a drill or an angle grinder with a carriage brush. The ideal option is sandblasting. But I need a powerful compressor, which I don’t have. And then on the internet I came across a sandblasting attachment for a Karcher. This is what she looks like:

I immediately ordered it on ozone and the next day I held it in my hands. Of course, the money they ask for it (4200 rubles) is probably not worth it as a product (like all Karcher products have an inflated price tag). But looking ahead, I will say that I have never regretted the purchase, because... it saved me a lot of time and effort. All that remained was to find sand. There are no instructions for the attachment, only pictures on the box. The picture shows a bucket of abrasive and its number according to the original catalog. Having punched the number, I found out that the original abrasive comes with a fraction of 0.2-0.8mm. I started looking for fractional sand.

In our village this is a hopeless occupation. But a friend helped me by fitting an open bag from his work. This bag was enough... um... well, just to start. The 15-20 kg that remained in it ended instantly. The consumption of sand turned out to be simply enormous. I started scouring the internet for ordering fractional sand. I found some website (for some reason it can’t be Googled now), placed an order for the minimum quantity (500 kg), but the manager never contacted me. I went to Leroy Merlin and bought regular construction sand “Bolars” in 25 kg bags. I took 6 bags. The website says that the fraction is 1-2mm. In fact, it was different in each bag, from small to large. So 1-2mm is probably the maximum size of sand grains. Unlike the fractional one, it contains dust, which clogs the nozzle. But you can work if you get used to it.

Started to get sandy. I removed the pegs for better access. At first I worked as a Karcher K5 (borrowed from my brother). Then I finished it with K3. The latter takes a little longer to clean, but the difference is small. The advantage of water sandblasting is that there is no dust. The downside is that the cleaned metal surface is quickly covered with a thin layer of rye. In progress:

Where the rust is ingrained and has grooves, it is better to use fine sand, because... large ones take a long time to get it out of the cracks. It is better to clean off scale with coarse sand. All this action requires good equipment. The glasses that come with the attachment are UG. Uncomfortable and do not fit well, sand flies into the cracks. In general, after the sandblasting procedure, the underbody washing I experienced earlier seemed like a children's party.

It's time for painting. After drying, a coating of rye appeared on the metal.

It can be easily removed by any rust converter. But here is a pipe and a jug. After the reaction, the converter must either be cleaned or washed off with water. It’s not possible to clean it off everywhere, but when you wash it off with water, you get back a coating of rye. I tried to wash it off with gasoline, but it didn’t wash off. Therefore, after washing it is necessary to quickly dry, degrease, prime and paint.

After painting, I covered the sills with anti-gravel BODY 950 and put a couple more layers of paint on top (since the body is porous, it is better to paint it on top). Later I’ll go through everything with a rust-stop. In the next part I’ll tell you about the rear arches

Sandblasting nozzle for a Karcher: do-it-yourself sandblasting from a sink

To quickly and efficiently clean surfaces from dirt, old paint and rust, it is best to use sandblasting.

This type of cleaning is carried out using special equipment - cameras, guns.

If you have a high-pressure washer, you can save on the purchase: the sandblasting nozzle on the Karcher will help in everyday life and repairs, and you can make it yourself.

Operating principle of the nozzle

Whatever the sandblasting machine, the principle of its operation is as follows: as a result of the operation of the compressor, the air flow is under high pressure, due to which abrasive (usually sand) enters the nozzle of the device. The latter is fed through the outlet hole in a thin but strong stream directly onto the object being processed, as a result of which the top layer is removed.

Sandblasting for Karcher is a device that can make a high-pressure washer suitable for work like a sandblasting gun.

This attachment will not replace professional equipment, but it is perfect for cleaning small surfaces.

Instead of air, the charge of kinetic energy will be given to each portion of sand by water, but otherwise the principle of operation of the device will remain the same:

- under the influence of the high pressure created by the compressor, water passes through the intake hole of the hose, the other end of which is placed in a container with sand;

- a vacuum is created in the intake hose, which helps the abrasive move into the main hose;

- After mixing sand and water, the flow is supplied through the outlet to the surface of the product.

To reduce sand consumption and increase processing efficiency, dispensers and taps can be introduced into the specified design. Typically, a sandblasting nozzle for Karcher consumes 30 kg of sand for every 0.8-1 square meter of surface.

Application areas of the nozzle

Due to the high power of the jet, using the Karcher nozzle you can process various surfaces:

- clean wood and concrete from plaster, old paint, varnishes, building mixtures;

- remove rust and scale from metal;

- clean various products before processing, applying protective and finishing coatings;

- get rid of stubborn stains;

- remove stains and drips of glue and polyurethane foam.

Making a homemade nozzle

A special nozzle for a high-pressure washer turns the latter into a good sandblasting unit; it is only important to purchase high-quality components. You will need:

- reliable hose with the ability to work under pressure;

- dispenser to save abrasive;

- nozzle for throwing sand and water;

- trigger hook;

- clamp and fitting.

The quality of the nozzle will determine the durability of the nozzle and the final result, so it is better not to skimp on it. Ceramic devices fail faster than those made from tungsten and cobalt alloys.

However, metal nozzles can be susceptible to rust due to the presence of water in the sink, so sooner or later any nozzle can deteriorate.

For more expensive devices, the trigger is included, otherwise you will have to buy it separately.

The nozzle on a Karcher for sandblasting must include a reinforced hose at least two meters long. You should not purchase hoses without additional reinforcement of the frame - they are not capable of operating under pressure of several atmospheres. A product of dubious quality will tear quite quickly.

Algorithm of actions

To make a nozzle with your own hands, you need to proceed as follows:

- fix the nozzle tip with the thread;

- attach a dispenser to regulate the supply of water with abrasive to the nozzle;

- combine the container with sand and the main device using a hose, clamp, or fitting of the required size.

All structural elements must be screwed tightly and correctly, because they will be influenced by the pressure created by the compressor. The joints must be completely sealed, and FUM tape can be used to strengthen them.

To save money, it is better to carry out all work over a container with a grid on which the product being processed is conveniently placed. Afterwards, the water and sand can be collected and reused by lowering a hose into it to collect the solution.

Recommendations for safe use of the nozzle

In order not to harm yourself, it is necessary to work with the high-pressure washer and the nozzle in compliance with safety precautions, otherwise the water-sand mixture can cause injury. The advantage of such a device over a conventional sandblasting gun is the absence of dust settling in the lungs, so there is no need for a respirator. But you need to follow these tips:

- wear durable protective clothing;

- wear comfortable closed shoes;

- Clean products outdoors rather than indoors.

If you have a Karcher sink or its equivalent, it is not difficult to build a sandblasting unit yourself. This will save money and allow for high-quality surface treatment for every need that arises.

Source: https://kraska.guru/specmaterialy/korroziya/peskostruj-iz-mojki-karcher.html

Nozzle manufacturing process

A homemade nozzle for Karcher can turn a washing unit into a functional sandblasting unit for home use. You will need the following set of consumables:

- a hose that can withstand high water pressure;

- trigger hook;

- dispenser to save abrasive consumption;

- a nozzle into which a mixture of water and sand will come out.

Do not experiment with making a homemade nozzle if you are not a professional in this matter. It is necessary to accurately drill a hole with the required diameter. The market is saturated with ready-made parts and consumables of decent quality at reasonable prices, so it’s better to purchase them. In addition, the finished parts already have a trigger mechanism in the kit - a hook.

The hose you will use must be at least two meters long, durable and reinforced. A stream of water with high pressure will pass through it, which will be created by the compressor. Strength is also important because the unit will work with abrasives, so a product of dubious quality will not last long.

Algorithm of actions

- Using a thread, the tip is fixed to the nozzle.

- A dispenser is also attached to the nozzle, which regulates the supply of sand-water mixture.

- The container with sand is connected via a hose; for this, a suitable clamp and fitting are used.

To save the most sand, you should prepare a special container with a grate. Above it, you need to carry out the necessary cleaning of the surface using a sandblasting nozzle. The water-sand mixture will accumulate in this container. This mixture can be used again if a reinforced intake hose is lowered into it. The grate covering the container is needed to keep waste from being cleaned so that it does not contaminate the sand and water mixture.