Description and characteristics of nickel alloys

The production of nickel alloys is carried out at modern metallurgical and mining enterprises. The raw material is a special alloy, the base of which is copper, and the main alloying component is nickel. As a result of their effective interaction, the resulting alloy has excellent quality properties. Thus, the entire range of metal products created from this alloy will have the following properties:

- Electrical resistance;

- Resistance to corrosion;

- Strength.

The most common are alloys in which titanium, aluminum, molybdenum, copper and chromium serve as additional elements. Nickel alloys are divided into acid and temperature resistant.

Alloys

Nickel is the basis of many alloys. It is worth taking a closer look at the most popular compounds based on this metal.

Nickel based alloy

With copper

The most popular compounds are nickel and copper. The result is a material that is not similar in its characteristics to the original metal. In the manufacture of metal mixtures, 3 popular compounds can be distinguished:

- Monel is a material that contains approximately 67% nickel. Has a high strength index. It can be compared with different types of steels. Used in aircraft manufacturing, shipbuilding, and in the manufacture of power tools. You can find monel parts in musical instruments.

- Cupronickel is a well-known alloy whose main component is copper. Nickel in the composition can contain up to 30%. Used in the manufacture of jewelry, figurines, cutlery.

- Copel is a mixture of 44% nickel. The wire from which compensation wires are made is made from it.

There are other mixtures with the addition of zinc, which have their own characteristics and characteristics.

With chrome

Compounds of chromium and nickel are known to many as nichrome. The peculiarity of this alloy is its high electrical resistance and high melting point. Nichrome also has good strength and heat capacity. Applications:

- Manufacturing of parts for devices operating in aggressive environmental conditions.

- Production of heating elements and equipment for heat treatment.

- Nichrome wire is used in the manufacture of electric furnaces.

- This alloy is used to make evaporation filaments used in electronic cigarettes.

If nichrome is coated with a silicon-based alloying layer, it can be used in the chemical industry. The additional coating makes the material resistant to acids.

With molybdenum and other metals

When combining nickel with molybdenum, chromium is added to the composition. The percentage of base metal reaches 77%. In this case, molybdenum in the composition can contain up to 9%. The rest is occupied by chromium. The peculiarity of the connection is its high strength and rigidity.

An alloy with molybdenum is used in medicine. Bridges are made from it. Difficult to process. It is almost impossible to make castings from such material. However, due to their characteristics and low cost, alloys with molybdenum are highly popular.

With iron

This mixture is called invar. It is a compound of iron and nickel. They use ready-made material in the manufacture of parts for mechanical watches.

Compound of iron and nickel

Acid resistant

This group of nickel alloys includes alloys with copper, chromium, tungsten and molybdenum. Such alloys are resistant to aggressive oxidized and non-oxidized environments.

Nickel with copper

Copper-nickel alloy (Monel) has increased corrosion resistance, high tensile strength parameters and excellent ductility in different temperature conditions. Because of this, it is often used in the field of electrical engineering, the chemical industry and in the creation of equipment for naval ships. Such alloys are also used in the construction of nuclear reactors. One of the most common alloys is Monel 400.

Nickel with chromium and iron

Inconel is an alloy containing chromium and iron as alloying substances. The resulting metal is used to create elements that operate at high temperatures. However, it is not recommended for use in parts that are exposed to temperatures above 850°C.

Nickel with molybdenum

The alloy is made from nickel, iron and molybdenum, and is used in casting elements of mechanisms that are exposed to hydrochloric acid and temperatures not exceeding 70°C. The metal is resistant to corrosion. These include the brand ХН65МВ and its analogue – Hastelloy C276.

Nickel with different metals

Nionel is an alloy whose main components are nickel, chromium, iron, molybdenum, copper and titanium. It can be used to create containers in which caustic soda solution, as well as sulfuric and phosphoric acid are stored.

Use in its pure form

Nickel is a silver-colored metal. It has high strength and ductility. It has ferromagnetic properties, is well welded, forged and stamped. Resistant to acids and alkalis. Will not oxidize in open air due to the oxide film.

Areas of application of the material in its pure form:

- Used as a protective coating for other metal surfaces. In this case, the protective layer is applied using cladding or galvanoplasty methods. Protects other metals from corrosive processes.

- Containers for storing and transporting chemicals, acids, and alkalis are made of metal.

- It is often used as a catalyst. This is due to the catalytic properties of the material, which are similar to palladium. However, this metal is much cheaper.

- Manufacturing of neutron beam choppers. Thanks to this, the metal became widespread in nuclear physics.

In addition to its use in the food and chemical industries, the pure material is used in the manufacture of alkaline batteries.

Heat resistant

To create heat-resistant properties, titanium, aluminum, molybdenum, tungsten, niobium, rhenium, ruthenium and strontium are added to the nickel solution. This alloy is characterized by long-term strength, excellent manufacturability and resistance to high temperatures. The characteristics of alloy grades depend on the percentage of a certain metal in the composition.

For example, Inconel 600 alloy is used to create parts for gas turbines. They can withstand temperatures up to 750°C and have a high degree of resistance to oxidation and metal fatigue. And Inconel 718 is suitable for creating rotor blades in gas turbine engines that operate at temperatures of 800-850°C. After heat treatment, the alloy is not notch sensitive.

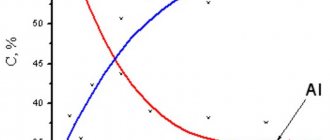

Copper-nickel alloys are classified into two subgroups:

- Structural – this type includes cupronickel and nickel silver. Most often, iron and manganese are taken as alloying elements. The most common ratio is ~5-30% Ni, the rest is Cu.;

- Electrical - one of the representatives of this category are Copel or Constantan. Distinctive features are high electrical resistance and thermoelectromotive force. Most often, the alloy consists of ~60% copper, with the rest provided by nickel and other alloying parts.

Features of nickel and its alloys

Nickel has special characteristics that are highly valued in industrial production. Due to its good ductility, it is easy to produce products of various shapes using cold and hot deformation technologies. At the same time, the weldability of nickel-based alloys is at a high level.

It is worth noting the high resistance of nickel to the aggressive environment of alkaline solutions and other chemicals. It does not react with oxygen under normal conditions, even when heated to temperatures of 800 degrees due to its heat resistance. Its density can vary depending on the presence of gases such as oxygen, carbon monoxide and hydrogen, as well as sulfur, iron, silicon, lead, manganese, zinc and other elements.

Nickel interacts well in alloys with most metals due to the property of active catalysis. With its help, you can significantly improve or change the properties of various materials, which allows you to obtain the most valuable products. To date, more than 3,000 alloys using this element are known.

Heat-resistant nickel alloys contain manganese, cobalt, palladium, copper, platinum and iron.

But in addition to alloys based on it, nickel can be used in its pure form. Very often it is used to form anti-corrosion protection. To apply it, they usually use the galvanization or cladding method, which is used to protect iron and steel. Using this method, it is possible to obtain a material that is practically not inferior in properties to pure metal, and at the same time it is possible to significantly reduce the cost of the product. Using the galvanization method, aluminum, cast iron, magnesium and zinc are protected.

Despite its high cost, various instruments and apparatus, as well as crucibles for metallurgy, are very often produced from pure metal. The chemical industry uses tanks, reservoirs and tubes made of this metal, which are used for storing and handling food products, alkaline and other substances.

In the hydrogen production process, it is used as capacitors. It is also worth noting the medical field, where nickel tools and devices are often used.

It should also be noted that it is especially popular in the field of building radio devices and television gadgets. It can be considered indispensable in the nuclear field, since without its use it is impossible to obtain high-precision remote control devices.

Granular nickel is widely used as a catalyst for many chemical reactions involving hydrocarbons, alcohols and aldehydes. They usually replace platinum and palladium, since the properties of this granulated metal are not inferior to those above, and it is cheaper.

Granular Nickel

Nickel powder

Powdered nickel is also used as an element of filter devices necessary for the purification of gases, fuel liquids and other substances produced by the chemical industry.

Also, such a powder is excellent for the production of alloys, so very often this physical state of the metal is preferred in metallurgy.

Resistance to alkali allows the use of such metal in alkaline batteries as electrodes.

In the steel industry, many types of steel, especially structural steel, are produced with nickel as an alloying component. There is no difference whether it is magnetic, non-magnetic, or heat-resistant nickel alloys.

Nickel is most often used in alloys together with copper. This makes it possible to obtain a material with increased resistance to aggressive environments, especially alkaline, sea water and high humidity. That is why they are widely used in medicine, maritime, chemical and food industries.

Alloys of silver and nickel have interesting properties: when only these two elements are fused, an unstable material is obtained, characterized by brittleness and a predisposition to cracks. But when these alloys are used as alloying elements in alloys based on other metals, corrosion resistance can be significantly increased.

Pure Nickel

In jewelry, its alloy with gold is often used. It produces durable jewelry, which is characterized by a white color. But some people have an allergic reaction to such products.

Also, nickel in its pure form and as part of alloys is often used for the production of heating elements and devices.

Copper alloys

The combination of nickel and copper is quite widely used to produce materials with properties different from those of pure metals.

Today, the most widely used copper alloys are:

- monel;

- cupronickel;

- nickel silver.

When producing Monel, nickel is used as the main component, the amount of which in the alloy should be about 67%. Monel is characterized by high strength, exceeding the characteristics of most types of steel, which is why this alloy has gained wide popularity in aircraft construction, the production of power tools, shipbuilding, and also in the manufacture of musical instruments.

Monel

Cupronickel is an alloy of nickel and copper, the base of which is copper, and the amount of nickel can vary from 5% to 30%. This alloy is used to produce various types of kitchen utensils, cheap jewelry, figurines and other works of art.

It is also easy to meet in everyday life, since most modern coins are made from cupronickel. It is excellent for these purposes, as it is very plastic and lends itself well to pressing. At the same time, it is quite durable and resistant to wear and damage. Cupronickel is resistant to seawater and is used to make many structural and boat parts.

Nickel silver teaspoons

Nickel silver is distinguished by the presence of zinc in its composition. It is quite plastic, but very durable and resistant to corrosion. Used in the production of electrical appliances, cutlery, jewelry, coins and awards.