Do-it-yourself vibrating tumbling, thoughts.

600 watts from an old washing machine (I hope there is enough power)

Hose adapter from drill

and parts that do not need photos: Springs, plywood, bolts.

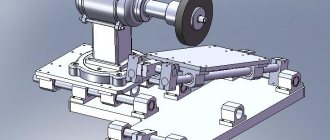

The action plan is as follows: Make a vibration table like this:

Install an eccentric under the tabletop at an angle. A basin with tumbling bodies is tightly pulled to the table by long pins. Under the basin there is a disk with several magnets that rotates from the eccentric shaft with transmission through a rubber wheel. The eccentric unwinds through a flexible attachment on the drill, the table begins to vibrate, the disk with magnets unwinds and the parts begin to move.

Moving on - we need an abrasive. Well, I don’t really want to buy bags at a price of 25 kg for 200 dollars, I’m looking for a solution. So far the thoughts are as follows: Polished marble chips for aquariums can be used as an abrasive (they are polished in tumbling drums). But it is heavy and suitable only for rough processing: to remove dirt, rust, patina, to make the texture uniform. removing burrs is already good, but the final goal is mirror polishing. Therefore, I’m thinking about how to make the tumbling bodies myself. From personal experience I know that goyim paste is a certain subtype of plasticine (when heated above 60 degrees it behaves exactly like plasticine). I also have a couple of bars with different abrasiveness, the standard green one for finishing. red, which I have never used before, and white, with a fairly large fraction and some kind of hard abrasive of a crystalline shape, the crystals sparkle in the sun, in my dreams this is diamond dust, but I think that everything is simpler). That's what I thought. Should I make some abrasives using goyim paste? The plan is this: Find some suitable plastic, melt it, pour goyi paste and wood flour (as a filler) into it, perhaps take fine-grained sandpaper, burn it and then use the ashes as a filler, mix it all thoroughly and pour it into molds

But again difficulties arise. In my opinion, the best choice would be some kind of elastic but hard plastic, such that it can be cut with a stationery knife, but the chips will not crack, but will be planed. 3 options would be ideal: polyethylene (oilcloth) and polyethylene terephthalate (plastic bottles) and nylon (cable ties, for example).

BUT again there are a lot of problems:

And now, if you have mastered this boring text, please share your opinion, experience or advice, perhaps someone will see some mistake in my scheme for this self-propelled gun or can make an improvement proposal, please write, advise, criticize. Now we really need an outside view and some thoughts about the topic. I would be grateful, thank you for your attention.

a couple more videos on the topic: Good try

and unsuccessful:

Tumbling of disks Z.Y. The text needs to be edited, there are a lot of errors, I know, I wrote it from a laptop in a hurry, if possible I will correct the grammar.

Source

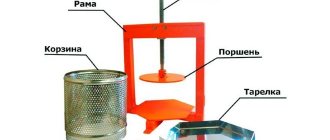

Do-it-yourself small tumbling machine

Greetings to DIY enthusiasts. I present for consideration a very useful, very necessary, and very easy to make homemade product. We will talk about a small tumbling machine. It will allow you to clean various small metal products and more in a fully automatic mode. These can be coins, bolts, fittings, nuts and other parts. When the machine is operating, a grinding process occurs in it, everything turns out quite well, the parts are cleaned very well, and most importantly, without your participation.

Assembling such a machine is very simple, you need a minimum of materials for its manufacture. If the project interests you, I suggest you familiarize yourself with it in more detail.

Materials and tools used by the author:

List of materials:

- plastic container (round container); — rubber (like bicycle tubes or similar); — 4 springs; — 4 bolts with nuts; - washers; — computer fan; - plywood; - door knob; — 12V power supply; — socket and socket for connecting a power supply; - switch; — abrasive (sand, small pebbles or the like); - a piece of aluminum corner; - automotive sealant.

List of tools:

- vice; - drill; - soldering iron; - screwdriver; - wire cutters; - scissors; - jigsaw, - marker, - syringe.

Homemade manufacturing process:

Step one. Manufacturing of shock absorbers

First we will make shock absorbers; a vibration platform with a bowl will be attached to them. To make them, the author used four small springs. They need to install rubber bushings. The rubber will come from a bicycle inner tube, cut it into strips, and then into small pieces, you will need 8 pieces in total. Each piece needs to be rolled up and put into a spring like the author’s in the photo. The result is a bushing; if you screw a screw into it, everything is held quite securely.

The author used a large computer fan as a vibration source. Their motors are brushless, these motors are durable and affordable. To get vibrations, we need to install a weight on the impeller. The further it is from the center of the engine axis, the stronger the vibrations will be. At first the author got very strong vibrations and moved the weight to the center. The author used a bolt with a nut as a weight, drill a hole, install the bolt and tighten the nut well.

Step three. Vibration platform assembly

To assemble the vibration platform, we still have to cut a rectangle out of plywood; this will be the basis for installing the bowl. We attach the plywood to the fan using long screws, and also screw the protective grille to it. The length of the screws is such that shock absorbers made of springs can also be screwed onto them from above.

Step four. Container

Now let's screw on the container where all the magic will happen. It is screwed to the plywood using small self-tapping screws. We will also need rubber washers and metal ones. Thanks to rubber washers, the container will not unscrew due to vibrations.

Step five. The basis

Let's make a base; the author cuts it out of plywood and gives it a neat appearance. In the end, all that remains is to drill holes for attaching the racks.

We also need to make legs so that the machine does not move on the table. The legs are made from four hexagon screws. You need to install rubber tips on the legs; the author easily cast them from silicone sealant. As a result, the legs turned out to be soft, and the machine has excellent grip on the surface.

Step six. Power switch and connector

Let's install a connector on the machine to connect the power supply. The author, if I'm not mistaken, used a headphone connector/jack for this. We will also install a switch for convenient control of the machine. The author installs all these parts on an aluminum corner.

Step seven. Pen

Finally, screw the handle to the lid. The author used something similar to a furniture handle.

Step eight. Tests

That's all, the car is ready, you can start testing. Pour abrasive into the container; coarse sand, small pebbles or something similar will do. Well, then we put the parts and start the device, the author shares the results of the work in an hour. The parts were polished perfectly, everything sparkles like new. Moreover, the tubes were polished even from the inside, which is quite difficult to do with other tools. That's all, the project is finished, I hope you liked the homemade product. Good luck and creative inspiration if you decide to repeat a similar project. Don't forget to share your homemade creations with us.

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Tumbling vibrating tumbling vibrating tumbling bodies

“Grinding and surface preparation technologies in the “GrindingTech 2015” section at the autumn project exhibition “Technoforum” Main topics: - Overview of the grinding market, - Advanced developments, - Increasing the efficiency of surface treatment. — Presentation of the section “ShlifTech 2015” (business program, special conditions, information platform)

As a potential exhibitor: • post information free of charge on the website of the “ShlifTech” section www.technoforum-expo.ru; www.shliftechexpo.ru • ask questions directly to the organizers • discuss opportunities for cooperation • receive additional privileges if you participate in the project

As a visitor to the exhibition: • Make a collective request to visit the exhibition • Find out about the program of the autumn project

Commercial Director Yakovlev Pavel Gennadievich Technical Director Babarykin Dmitry Aleksandrovich General Director Sedenkov Sergey Evgenievich

Download invitation in MS WORD format

Types of processing in a tumbling drum

There are two ways to grind and polish products:

- Dry. Used to achieve a mirror finish on the workpiece. A variety of fillers can be used as an abrasive for a tumbling installation: from walnut shells to special pebbles. To increase productivity, a special paste is used, which increases the intensity of interaction between bodies. Before final polishing, wet sanding is usually performed. The filler can be ordinary water from a household tap. To improve the quality characteristics of the surface, oil is used instead of water, which creates an anti-corrosion coating on the part and the internal walls of the tumbling unit.

- Wet. This type of polishing gives the surface a matte effect. The abrasive filler is a tumbling compound, which is selected individually, depending on the requirements of the technological process. The wet polishing method is characterized by a low degree of exposure to abrasive particles. A striking example of such elements are porcelain balls.

Magnetic tumbling is considered a separate method. It is characterized by the use of magnetic stainless steel needles. Used for cleaning and modification of various non-magnetic products.

Vibrating tumbler

Vibro polishing of discs

Public VKontakte: How to do mirror polishing of car rims If you like it, then put it on. Vibrating tumbling.

Vibrating tumbler 35 liters

Vibrating tumbling. Motor 550 watts, bowl volume 35 liters, vibration mechanism based on 8 springs.

Wheel polishing machine

Vibration tumbling of car and motorcycle rims, as well as any parts made of aluminum and stainless steel. Manufactured at the factory.

how to do tumbling

General description of the finishing shop. How to do tumbling, what is needed for this and what’s more.

10 maanden geleden

Vibrating tumbler

Vibrating tumbler

We manufacture equipment for tumbling. Saratov-Zinc.

VibroTumming Part 4

After 2 successful stages of processing (grinding, finishing), all the stones were immersed in tumbling, together with oxide.

P1050007

Homemade vibro tumbling (tumbler)

tumbling 002_first experience

Modernization comes with everything! See what you can make from stones and sticks! Subscribe to my channel.

What is stone tumbling and why is it so important

Welcome to the page dedicated to finishing natural stone! Is it possible to process stone at home on your own and how can special equipment help with this? The technological process of cleaning and grinding to obtain a polished surface with rounded edges is called stone tumbling, which refers to slabs of various parameters and shapes.

Processing of hard materials to obtain streamlined edges is carried out using special tumbling equipment. It is not easy to set up the process at home, but it is possible if you choose the appropriate equipment and strictly follow the instructions for use.

The level of complexity of processing natural stone depends on the type of material and its strength characteristics.

Considering that the degree of hardness of most types of natural stones exceeds the strength of abrasive chips, manipulation requires the use of proven specialized equipment, which is difficult to implement at home.

Abrasive chips (used as a filler in processing equipment) or as they are also called lapping bodies, can have different shapes:

- prisms;

- cone;

- Cuba;

- cylinder, etc.

Centrifugal vibration units cope well with the task of grinding natural stones using lapping bodies of various shapes. They are easy to control, adjusting the friction force, and with it improving the decorative parameters of the stones.

Vibrating tumbler

DIY Vibrating tumbler from Bazhaev V.S.

Vibro polishing of discs

Public VKontakte: How to do mirror polishing of car rims If you like it, then put it on. Vibrating tumbling.

Vibrating tumbler 35 liters

Vibrating tumbling. Motor 550 watts, bowl volume 35 liters, vibration mechanism based on 8 springs.

how to do tumbling

General description of the finishing shop. How to do tumbling, what is needed for this and what’s more.

Wheel polishing machine

Vibration tumbling of car and motorcycle rims, as well as any parts made of aluminum and stainless steel. Manufactured at the factory.

Vibrating tumbler

Vibrating tumbler

We manufacture equipment for tumbling. Saratov-Zinc.

VibroTumming Part 4

After 2 successful stages of processing (grinding, finishing), all the stones were immersed in tumbling, together with oxide.

P1050007

Homemade vibro tumbling (tumbler)

tumbling 002_first experience

Modernization comes with everything! See what you can make from stones and sticks! Subscribe to my channel.

Design Features

The device is a drum of round or multifaceted cross-section. With constant impact, the parts loaded into the tumbling drum are cleaned. The duration of the working cycle depends on the declared degree of processing.

The internal part is made in the form of a rotating multifaceted screw column, divided into sections. They can vary both in shape and in size, which gradually increases from loading to unloading. This is necessary for uniform exposure to abrasive elements.

The drum is mounted on the frame using support elements with bearings. The frame also contains an electric motor, which serves as a drive, and a reduction gearbox as a transmission. The connection to the drive can be made via a V-belt drive or a compensating clutch. According to safety and labor protection requirements, all moving elements must be hidden by a protective casing. For loading and unloading abrasive and workpieces, as well as carrying out maintenance and repair of the drum, it is equipped with a loading hole.

Vibrating tumbling machines SWECO. Tumbling SWECO. Vibrating tumbling. Vibration grinding. Final sanding

Additional Information

Vibration grinding, finishing grinding

Time-tested technology provides three-dimensional Vibratory Energy to all SWECO Vibratory Tumblers and a range of Vibratory Tumbling equipment. This movement of the immersed parts and abrasive media maintains a high-frequency oscillatory motion as the material moves in a spiral and orbital path around the chamber. As a result of the compressive action of cleaning, it cleans and removes burrs, rounds sharp corners, and smoothes the surface. Because the vertical and horizontal vibration amplitude and speed are fully adjustable, your grinding requirements can be met quickly and efficiently.

Vibrating tumbling machine with batch loading. Batch Mills.

The SWECO Batch Feed Vibratory Finisher is ideal for use with external separating systems, manual part unloading and for processes that do not have grinding abrasives and where the entire load can be easily unloaded through the bottom door. View the technical characteristics of the Vibrating Tumbler with Batch Loading. Batch Mills.

Vibrating tumbler with large radius. Long Radius Mills DLR series

SWECO's Large Radius Vibratory Finishers provide a convenient method for separating parts from abrasive media. Vibrating tumbling equipment of the DLR series provides both batch automatic and continuous grinding and vibroabrasive tumbling. The internal parts and filler of the separating tumbler use an oscillating paddle and a fixed separating screen installed in the block. The long radius toroidal chamber design has excellent discharge performance. View the technical characteristics of the Vibrating Tumbling Series with Large Radius.

Vibrating tumbling spiral (screw). Spiral Mills SLR series

Vibrating tumbler with removable central column

The SWECO Vibrator with Removable Central Column offers all the benefits of SWECO's unique vibration energy combined with design features to make work easier and increase efficiency. The chamber, which includes a removable central column, allows larger-than-usual parts to be processed. Adjustments in grinding action are easily made by changing the advance angle and adjusting the motor's eccentric weight. No tools are required to make these adjustments. The noise level has been reduced through the use of special materials and new production methods.

A full range of vibratory abrasive grinding from coarse to fine can be processed quickly and efficiently with this vibratory tumbling machine (Loading a batch of material). With the right sanding media, tumbling will do deburring, deglossing, nick removal, cleaning metal and rough work surfaces, and more. Available in 28 l, 85 l, 283 l, 397 l. and 651 liters.

Source

Application of a circular vibratory tumbling machine - Resource

Tumbling equipment is designed to allow the surfaces of metal products to be delicately processed. Additional capabilities of the unit include returning metal products to their marketable appearance. Thanks to the technique, the surface of the workpieces is ground and polished. The units are equipped with built-in separation, so the workpieces and abrasive elements are separated. Vibration is thought out in three directions. Due to this, metal products and abrasive are mixed continuously and evenly.

For vibrating tumbling, the bowl is made of a special shape. Therefore, when mixing, the parts are damaged as little as possible. When the operation is completed, separation is started. The machines are stable on the foundation, even without additional fastening. The design of the units is simple and durable.

Capabilities of tumbling equipment

The working process is based on applying vibrations in different directions. Products and abrasives are difficult to move. Metal products with certain standard sizes are loaded into the bowl. Metal products are loaded into equipment to achieve a specific purpose:

- volumetric grinding;

- polishing;

- removing burrs from the surface;

- processing of sharp edges, rounding of edges;

- flash removal;

- removal of deposits, scale, rust;

- cleaning of oxidized areas;

- removal of oils and various contaminants;

- external matting;

- achieving the required surface roughness;

- fine finishing.

The tumbling process has several main advantages:

- allows you to simultaneously process a huge number of metal products;

- the abrasives used in the process are available and effective;

- the equipment has a reasonable price;

- simple design of the unit;

- there are no burns.

The working process

Processing of parts of a given size occurs by mixing them with a filler - abrasive bodies (chips). One batch of chips is designed to carry out several technological operations. The products and filler are mixed, rubbed, and the desired effect is achieved. The chosen abrasive depends on:

- removed metal layer from products,

- the obtained degree of grinding,

- surface roughness.

The following parts are processed in the drums of tumbling units:

- medical instruments;

- plumbing and installation tools;

- auto parts;

- turbine blades;

- hardware;

- chains;

- metal fittings.

The drum lid is closed tightly, ensuring complete tightness, so that during the working process no dust flies out of the equipment or the solution spills out. With accelerated operation of the unit, tumbling occurs more intensely. But you must not exceed the maximum permissible speed limit.

The equipment not only cleans products. It significantly improves the quality of their surface. Abrasive substances are most often represented by sand particles, corundum, if the process occurs dry. During wet tumbling, chemical solutions are added inside the equipment. Polishing can also be dry or wet. In the first case, leather scraps and wood shavings are used. In the second case, alkalis and soap solutions are introduced. In modern units, workpieces made of any metals are processed.

When working with products made from alloys of non-ferrous metals, high-strength ferrous metals, with thick walls, without threads, preference is given to dry tumbling. To speed up processing, wet tumbling is used. The introduction of chemicals - lime, soda, alkali - gives an additional effect. The parts are washed and degreased. But both processes take a sufficient amount of time - a minimum of 2 hours, and a maximum of 40 hours.

The choice of the shape of the tumbling body (abrasive) depends on the geometric parameters of the workpieces being processed. It is important that all edges and contours of the metal product are processed. Round and soft bodies are less aggressive on parts. An abrasive with edges implies a more rigid processing of metal products. Coarse and heavy abrasives are suitable for rough grinding. The tumbling body and parts are chosen in different sizes to facilitate separation.

Go to list of articles >>

metalloobrabotka-zakazat.ru