Metal drills are indispensable tools that are used in production and at home to drill holes in objects with increased strength. When choosing this type of tool, first of all, it is necessary to focus on its declared performance characteristics, material of manufacture, sharpening angles and coating. Experts first of all recommend paying attention to the sharpening angles of cutting steel. The best metal drills, the ratings of which are presented below, have proven themselves to be the best and have received the largest number of positive reviews from consumers.

Irwin TurboMax 10503992

Irwin TurboMax 10503992 opens the ranking of the best metal drills. The tool is designed for work such as drilling holes in metal objects, plastic, and wood. The drills are also suitable for drilling holes in stainless steel with the obligatory use of coolant. The tip of the tools included in the kit is distinguished by a special sharpening, which ensures high drilling speed. The set includes 15 drills of different diameters and are highly durable. The cost of the kit is approximately 3,000 rubles.

9.Hawera HSS-C SpiralBohrer GQ-32692

Hawera HSS – C SpiralBohrer GQ -32692 is included in the list of the best metal drills. The set contains 25 twist drills with diameters from d 1.0 mm – 13.0 mm x with diameter increments of 0.5 mm. The surface of the working tools is coated with titanium nitride, which gives them special hardness and heat resistance. The tools are made of high-quality high-speed steel and are fully ground. These drills boast a long service life and impeccable operation throughout the entire period of operation. GQ-32692 is excellent for steel, alloy and non-alloy castings, brass, bronze, cast iron and cast iron. You can buy such a kit for 6,000 rubles.

How to choose

A smart choice that is made taking into account the following criteria will help you avoid unpleasant surprises when purchasing new equipment.

| Manufacturer | It is recommended to choose products from well-known brands. Trustworthy manufacturers include: BOSCH, DeWALT, STAYER, Hammer, matrix, RUKO, Metabo, Biber, Kraftool, etc. |

| Drill type | When choosing, it is important to clarify what type of equipment it is, that is, what materials it can be used with: metal, wood, concrete. There are also universal drills that are suitable for different materials. Screw products resemble spiral ones in appearance, but the working part is equipped with a pointed element similar to a screw. This part allows you to make deep holes and remove chips. |

| Shank | Cylindrical - used primarily in chucks with a key lock. Almost not subject to jamming, but does not provide good torque transmission. Hexagonal - installed in a ¼-inch drill hole or in a three-jaw chuck. It is almost impossible to turn the drill during operation. Triangular – used for three-jaw chucks. It is distinguished by its ability to transmit high torque due to its stable position. Weldon - suitable for working on machines. Capable of making holes up to 32D drill bits. SDS-plus - inserted into the hammer drill chuck. Shank diameter – 10 mm. The surface has two open grooves for guide wedges and two closed grooves for fastening with locking balls. |

| Shank diameter, mm | This indicator corresponds to the diameter of the resulting hole. In small sizes, a step of 0.5 mm is provided, in large sizes – 0.1-0.3 mm. Shank diameter range: 1-31.5 mm. |

| What material | Different materials and coatings are used to make drills:

Domestic products are marked with the letter M and a digital value that determines the characteristics of the metal (1; 2; 7; 50; 35; 42). The higher the number, the stronger the alloy. |

| Drill diameter, mm | When choosing a product, it is important to take into account that during drilling the working part beats against the surface of the material. The result is a hole slightly larger in diameter than the drill itself. Therefore, for work, take a product one size smaller. Common range of tool diameters: 1-13 mm. |

| Length, mm | The indicator is determined by the depth of the blind hole or the thickness of the material being drilled if it is planned to make a through hole. This takes into account the type of drill:

|

| Working part length, mm | This is a parameter that determines the length of the section of the product that is formed by the cutting edge. Working length range: 2.5-550 mm. |

| Sharpening angle, degrees | During the manufacturing process of drilling equipment, the cutting edge is sharpened at an angle from 90 to 140 degrees. When choosing a drill, you need to select a sharpening angle that is suitable for working with a particular material (thin-walled metal, sheet metal, copper, stainless steel, etc.). |

| Equipment | Drills are available for sale in sets and individually. In the first case, it is equipped with a case or a plastic box-case, in which it is convenient to store equipment. |

DeWALT DT7926 Extreme2 HSS

DeWALT DT7926 Extreme2 HSS is one of the best metal drill bits that can be used both in production and at home when working with drills.

They provide the cleanest and most accurate drilling possible, and are also characterized by high operating speed. The nanotechnology design of the tool prevents damage to the edges of the hole. The tip of the device has three flat edges that provide secure mounting in the chuck. The kit includes 29 drills with a diameter from 1 to 13 mm. The cost of a complete set is 5,000 rubles.

Shank

Different models of tools have different types of fastening, therefore, before choosing a drill for metal, it is worth checking the fastening method. Products are selected for the type of fastening of a specific drill. The following shank options are common:

- Cylindrical. A widely used option, used for fixation in key drill chucks. The advantage of a cylindrical shank is that it almost never jams, but due to its smooth shape it sometimes slips in the chuck.

- Hexagonal. The edges of the shank are rigidly positioned in the grooves of the three-jaw chuck. When rotating, the drill is held firmly in the chuck and does not rotate.

- Conical. A truncated cone shank is often found in drilling machine tooling. Sometimes the shank is threaded to improve retention.

Cylindrical and hexagonal shank Source instrumentgid.ru

Bison MET-SH H19 R6M5

Bison MET-SH H19 R6M5 is a drill from a domestic manufacturer, included in the list of the best. Used for drilling both alloy and carbon steel. The tools are made of high-speed steel R6M5, have a cylindrical shank and are characterized by high accuracy and drilling speed. They are self-centering due to the cross-shaped point. The set contains 19 pieces of devices with a diameter from 1 to 10 mm. You can purchase MET-SH H19 in an eraser box for 1000 rubles.

Drill design

It is easier to understand the types of drills if you know the design of the standard product. It consists of the following elements:

- paws;

- shank;

- necks;

- cutting part.

The largest area is occupied by the cutting part. In standard products it has a spiral shape with two edges. There is also a groove through which chips are removed.

Reference! In high-quality equipment, all elements are made with high precision milling and grinding.

Drills, their types and types, an overview of a small part of our collection

AEG HSS-G 4932430416

AEG HSS-G 4932430416 are one of the best metal drills in an affordable price category.

The devices are completely ground and made of high-strength and heat-resistant steel. The cutting head of the tool has a cross-shaped sharpening with an angle of 135 degrees, which ensures good alignment without the need for a core. 4932430416 are able to withstand high temperatures resulting from heating during drilling. Suitable for working with high-alloy steel and metal with a strength of more than 1000 N/mm². The set contains 19 pieces with a diameter from 2 to 10 mm. You can buy a set for 1500 rubles.

Types of drills

Different types of drilling products are produced, the main difference of which is their purpose.

Spiral . Used for making blind and through holes. The diameter of the working part is uniform, so the product can make holes of only one size. Design differences: cylindrical shape, two helical cutting edges, grooves through which chips are discharged.

Stepped . The product can be identified by its cone-shaped shape, the surface of which is designed in the form of steps. Each of them corresponds to the diameter of the resulting hole. The closer to the shank, the larger the diameter of the cutting element. The peculiarity of the equipment is the ability to make holes of different diameters using one drill. Find out more...

Crowned . The design feature is a hollow cylinder, the lower end of which has serrations. The appearance determines the name of the type of product.

Equipment is used for making holes of large diameters (more than 30 mm). It cannot be fixed to the chuck of a conventional drill or screwdriver.

The throughput capacity of the crown structure is sheet metal up to 10 mm thick. Products can be diamond coated or carbide tipped. The equipment is also suitable for working on concrete.

Feathers . The design is distinguished by a flat shape, at the end of which there is a trident. This solution allows you to make large-diameter holes, while the equipment is easily fixed on the chuck of a conventional drill. When drilling a small groove, a depression from the main tooth remains in the center. You need to work with a feather drill at low speeds. It is often used with a hand crank.

Screw . When making deep holes, it becomes difficult to remove chips. You have to stop drilling and move the working part out to clean the groove. You can speed up the process by using an auger drill.

Its difference from the spiral one is the large angle of inclination of the helical grooves, as well as the increased thickness of the core. The core has the same diameter along the entire length of the equipment, whereas in conventional designs this indicator changes (it thickens closer to the shank).

5. Metabo Bestell-Nr. 27,094 HSS-G

Metabo Bestell-Nr. 27 094 HSS – G – one of the best drills designed for metal work. Spiral type devices have a cylindrical shank with a 135 degree sharpening of the tip, which ensures fast and accurate drilling. In total, the set contains 25 pieces, the diameter of working tools varies from 1 to 13 mm. The cost of the set is approximately 1,700 rubles.

How to sharpen metal drills correctly

As the cutting edge of the drill becomes dull, it becomes necessary to sharpen it. This can be understood by the following signs: a characteristic squeal, rapid heating of the equipment, longer drilling, decreased accuracy, dullness is felt when touching the edge. To ensure quality work, it is recommended to take into account the following recommendations from experienced craftsmen.

An easy way to sharpen a drill

- Before sharpening, make sure that the sharpening tool/machine is in good working order and that it is in a stable position.

- Prepare a container with cold water to cool the metal.

- When passing the drill along the grinding wheel, you need to press the equipment tightly. Sharpening should begin from the back of the edge.

- When heating a metal, cool it in prepared water to avoid overheating.

- The sharpening angle is applied depending on the metal alloy used in the production of the drill.

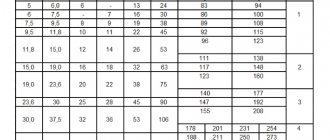

| Processed material | Vertex angles, degrees | Relief angle, degrees |

| Tool steel | 118-150 | 7-15 |

| Magnesium alloys | 70-118 | 12 |

| Copper | 100-118 | 12-15 |

| Titanium alloy | 135-140 | 12 |

| Durali | 90-140 | 12-17 |

| Bronze | 119-150 | 12-16 |

The entire cutting surface, including the side passages, must be sharpened.

Anchor 25219

Enkor 25219 is included in the rating of the best metal drills. The set includes tools of various diameters (from 1 to 10 mm). There are 19 working items in total. The tip of the devices is made of high-strength hard alloy, which ensures high speed and long service life. Enkor 25219 belongs to the category of budget drills intended for metal. It is quite possible to purchase a set of 19 pieces from a Russian manufacturer for 1000 rubles.

Marking features

Markings on drills depend on their technical properties and country of manufacture. Russian GOST requires markings on all drills with a diameter of two centimeters and above. It usually contains basic information about the product: the grade of steel and the diameter of the drill. The marking is located on the shank of the cutting tool. On domestically produced instruments you can see markings of this type: “Р6М5К”. This is a formula in which each symbol is detailed information about the drill. This marking, for example, means that the product is made of high-speed steel (P), the tungsten content in it is six percent (6), molybdenum - five percent (M5) and five percent cobalt (K5). Foreign-made drills bear the HSS marking and additional designations, which, just like those of domestic manufacturers, indicate the characteristics of the product. For example, "HSS-4241" means that this model is suitable for working with aluminum.

3. Wurth Zebra Spiralbohrersatz HSS

Wurth Zebra Spiralbohrersatz HSS are one of the best drill bits designed for metal work. Made from high-speed steel HSS. The devices provide maximum accuracy and drilling speed, and are also characterized by increased strength. Ideal for drilling holes in structural steel with a strength of up to 1000 N/mm², cast iron and plastic. Suitable for use in vertical drilling machines and electric drills. It is recommended to use a special coolant during operation. The kit includes 13 drills with different diameters, which are supplied in a plastic case. The cost of such a kit is approximately 700 rubles.

Marking of drills according to GOST

The marking of products for drilling is regulated by GOST 2034-80. This document stipulates that equipment whose diameter does not reach 2 mm is not applied to the drill. Information is indicated only on the packaging label.

Products with a diameter of 2-3 mm are marked on the shank indicating the diameter and steel grade. Encryption of equipment whose diameter exceeds 3 mm includes the following information:

- options;

- trademark;

- metal grade;

- strength class.

The metal grade is indicated in the domestic GOST version (for example, R6M7K6), or international (HSS). Information about additives (Co, Ni, Ti, etc.) can also be supplemented.

International standard color coding

| Color | Group | Processed materials |

| Golden | S | Heat-resistant alloys with the addition of titanium, cobalt, iron, nickel. |

| Green | N | Duroplasts, thermoplastics. Non-ferrous metals, alloys made from them. |

| Grey | H | Hard grades of hardened steel. |

| Red | K | Different grades of cast iron. |

| Blue | P | Steel for castings, some types of corrosion-resistant steel, carbon steel, tool steel. Alloyed. |

| Yellow | M | Austenitic steel is corrosion-resistant, some types of non-magnetic steel are wear-resistant. |

Attack N802-6

Attack N802-6 are not only one of the best, but also the most affordable metal drills. The tools included in the kit have excellent strength and provide good speed. There are 8 pieces in total in the set. The diameter of the drills varies from 3 to 10 mm. The hardness is 65.8 HRC. H802-6 not only provide high performance, but can last quite a long time. You can purchase a reliable tool kit from a Russian manufacturer for only 600 rubles.

Drill color, what it affects and what it means

If the marking is erased or there is no way to read it, you can try to determine the type of drill by its color. By the color of the drill, you can determine the quality of the drill and the material from which it is made.

- The black color of a metal drill means that during the production of the drill, namely at the end, the drill was treated with superheated steam, due to this the drill becomes more reliable. However, black drills can often be found of poor quality, so do not buy drills from unknown manufacturers.

- Gray color of the drill - This is a regular drill that has not undergone any additional processing. Such a drill will be less reliable, and during active work, it will require sharpening faster.

- Dark gold or golden color of the drill - During the production of the drill, tempering was used, which relieves the internal stress of the material. Due to this, the strength of the drill increases.

- Bright golden color of a drill for metal - Such drills are the most expensive, since in their manufacture a titanium alloy, namely titanium nitride, is used, which gives maximum reliability to the drill. Due to titanium, friction during drilling is reduced, which gives the drill durability. Such drills have a high price, but if you buy a drill more than once, it is worth spending money and buying a reliable drill.

Bosch 2607017154

Bosch 2607017154 completes the list of the best metal drills. This set is designed for making both through and blind holes in sheets of alloyed and non-alloyed steel with an allowable tensile strength of 900 N/sq.mm., copper, bronze, plexiglass, etc. Bosch 2607017154 are made of high-strength, high-quality and high-speed steel coated with titanium nitride. Not suitable for drilling aluminum. When working with the product, it is recommended to use coolant to increase service life. The kit is sold in a special plastic, shock-resistant box. In total, the set includes 25 pieces, the diameter of the products varies from 1 to 13 mm. You can purchase a set for about 3,000 rubles.

15 24

Classification of drills by material of manufacture

Which metal drills are the best for drilling particularly strong alloys is quite simple to answer:

- To process such material, you should choose products that have a plate of increased hardness on the cutting edge. Such gimlets are the best for processing hard alloys.

- The price of such products is low due to the fact that the main body of the cutting tool is made of ordinary tool steel.

Drills made of metal alloyed with cobalt have good characteristics.

They can withstand increased mechanical loads and excessive heating of the working surface during operation. The cost of the products is high, but if it is necessary to make holes in a hard alloy, then cobalt analogues are the best for performing such work.

Titanium drills are not inferior in strength to cobalt drills, and when drilling alloy steels and non-ferrous alloys they show even better results.

When used correctly, titanium models retain their factory sharpness for a long time, which will allow you to perform a significantly larger volume of work.

Video:

Inexpensive metal drills are made from ordinary high-speed steel P9 and P18. The cutting tool copes with its function perfectly, but the working surface quickly becomes dull, especially when a certain temperature threshold is exceeded.