A chisel is a percussion-cutting tool designed for chopping or chipping metal and stone. It is a steel rod with double-sided sharpening and a flat butt designed for striking with a hammer. The design of the chisel can position it as a hand tool or as an attachment for mounting in a hammer drill. The cross-section of the rod can be in the shape of a circle, rectangle, oval or polyhedron. To reduce the risk of injury, an expanding mushroom made of rubber or other metal can be installed on the striking part of the tool, providing a more comfortable hammer hit and dampening recoil.

Scope of application

The tool is designed for mechanical impact with destructive force. The scope of its use is quite extensive, but in most cases it is limited to:

- By chipping stones.

- Metal chopping.

- Knocking down ceramic tiles.

- By beating off the rivet heads.

- Unscrewing bolts and nuts with torn edges.

To work, you need to lean the sharp part of the chisel against the surface that needs to be knocked off, chipped or cut, and then apply a strong blow to the butt of the tool with a hammer. If it is necessary to unscrew a bolt or nut with torn edges, then the sharp edge is leaned at an angle, after which several light taps are applied to obtain a notch. After a groove is formed on the surface of the metal, several powerful blows are made to the butt of the chisel. In this case, the direction of the push force must correspond to the movement of the thread for unwinding. After using a chisel, the nut or bolt becomes completely unusable.

Types of chisels and their purpose

Despite the fact that the tool has a simple design, there are several varieties designed to perform specific tasks.

The following types of chisels exist:

- Metalworking.

- Kreuzmeisel.

- Ditcher.

- Pike.

- Kuznechnoye.

- Boaster.

The bench chisel is designed for cutting unhardened metals. It is quite sharp and can be used both for marking sheet material and for unscrewing bolted joints, knocking down rivets and other impromptu tasks. The cutting tip of the tool is slightly wider than the rod. The two-sided slopes gradually taper. Sometimes you can find a microchamfer on a chisel.

The Kreutzmeisel is a fairly recognizable tool with a narrowed cutting edge, which allows cutting out grooves and various grooves. Such a tool is more highly specialized than a metalworking tool, and therefore is not found as often. However, they can be completely used when knocking down ceramic tiles or rivet heads if there is no more suitable tool at hand.

A groover is an even more narrowly targeted tool designed for cutting out shaped channels. It is usually used when it is necessary to manually cut cylinder head gaskets from rigid sheet material, as well as other specific tasks when it is impossible to get by with another tool. The shape of the cutting edge can be wavy, semicircular, oval and U-shaped.

Similar chapters from other books

Sharpening the scythe when mowing

Applying and leveling plaster mortar manually

Applying and leveling plaster mortar manually You can apply the mortar by throwing or spreading it using various tools. Spreading is a fairly simple method of plastering, but you only have to use fairly thick

Sharpening chisels on a machine by hand

Sharpening chisels on a machine by hand The chisel used for cutting must be sharply sharpened; Using a dull chisel leads to it sliding off the surface being cut; the person working with such a tool gets tired and loses the correct blow. Sharpening chisels and

Sharpening

Sharpening Knives of planing tools must be sharpened. There are three types of sharpening a knife, depending on the wear of the chamfer and dullness of the blade. The first type of sharpening is used in cases where it is necessary to restore the chamfer of the knife or when the blade has chipped

A chisel is a percussion tool that is used when working with wood, metal, concrete, natural and artificial stone. It is used to make various grooves, grooves, and indentations of complex shapes. When working with metal, the sharp part becomes dull over time, which is why it needs to be sharpened. The procedure can be carried out only taking into account the sharpening angle of the chisel, performing the procedure in a certain order.

Sharpening the chisel, cutting edge and shank

The blade is shaped like a wedge, but the wedge varies, and the sharpening angle of the chisel depends on its use. It seems that the sharper the angle, the less force must be applied to strike. But the sharper the angle, the faster it becomes dull when working with hard materials. Therefore, many years of experience working with chisels smoothly leads us to a compromise. To cut fragile materials (cast iron, bronze, hard steel), the chisel blade is sharpened at an angle of 70 degrees. For medium-hard steel, a 60-degree angle is used. Soft materials (copper, brass) are cut with a sharpening angle of 45 degrees. Aluminum and zinc can be cut with a blade angle of 35 degrees.

It is, of course, better to sharpen a chisel when coolant is supplied to the sharpener, but at home this is almost impossible. Because of this, when dry sharpening you need to be careful not to overheat the tool above 110 degrees, otherwise its hardness will decrease. After sharpening, the cutting edges should have the same angle and width, so it is better to work on each side a little while working, often turning the chisel over. At the end of the blade sharpening process, we also chamfer the shank, giving it the shape of a truncated cone. Don’t forget about safety rules - use glasses or a protective screen. Dust from emery is extremely harmful.

A concrete chisel for a hammer drill requires almost no sharpening. All manufacturers use Long Life technology. The blade of such a tool sharpens itself during operation. A high-quality hardened chisel will be less deformed and abraded during operation. And proper sharpening will help cut any steel and crumble any material.

- Author: Manager Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(2 votes, average: 28 out of 5)

Share with your friends!

Device and characteristics

A chisel is a metalworking tool that is used for chopping and creating recesses in hard materials. It is a steel rod, one of which is blunt, the other is sharpened at two edges. On the blunt side (butt), the master strikes with a hammer.

There are two types of chisels available for sale. Some are designed for manual work, others are installed in special equipment.

Material

When choosing a chisel, special attention is paid to the material from which it is made. The alloy must be shock-resistant and not crumble from physical impact. There are two options for manufacturing the working parts of the tool:

- Tool steels.

- Carbide plates made of structural steels.

The most common material is carbon steel. Previously, instruments were made of aluminum, however, it is soft and quickly deforms from impacts.

Dimensions and weight

Two more factors that the buyer pays attention to when choosing are size and weight. Dimensions:

- Possible length options are from 10 to 20 cm.

- The width division is from 5 to 25 mm.

- Options for the length of the working part are 25–60 mm.

Types and purpose

Hand tools are classified according to various factors. Sharpening the chisel varies depending on what type of device the master has. The main varieties include:

- Classic carpentry metal rods behind the sharp working part. Used for processing non-hardened surfaces.

- Peak-shaped metal rods that are used for crushing stone and concrete. They are often used as attachments for rotary hammers and jackhammers.

- Kreuzmeisel is a groove type of chisel used for making recesses of various shapes.

- A metalworker's cylindrical rod, sharpened on one side.

- Blacksmith chisel. The presence of a handle allows you to use it during cold or hot cutting.

Tools are selected depending on what technological operation needs to be carried out.

How to use a chisel?

To properly use a metal chisel when processing steel workpieces, you must consider the following rules:

- Before starting work, check the integrity of the working part of the metal rod and the reliability of the handle.

- Wear gloves and safety glasses to prevent shards of metal or stone from getting into your eyes.

- Start processing with light blows of the hammer on the butt.

The tool must be dry so that it does not fly out of your hand when working. Experienced mechanics recommend buying metal rods with a fungus on the butt. This will ensure greater reliability in holding it in your hand during impacts.

Cutting metal with a chisel - like clockwork

A metal chisel (metal chisel) is a rod of rectangular cross-section. The cutting edge consists of four planes, two main and two auxiliary. The impact part usually has the shape of a truncated cone, this helps ensure the correct direction of the impact. The most commonly used tool is 75-200 mm long, with an edge of 20-25 mm. To cut grooves in metal, a crossmeisel (a type of chisel) is used; it has a slightly shorter length, 150-175 mm, and an edge of 5-10 mm, but it can no longer be found anywhere except in my grandfather’s workshop.

Serious chisel work on steel is no longer seen. The rough work is done by grinders and gas cutters, and the finishing work is done by milling machines. Cutting metal with a chisel is already a classic, but we must not forget it; let’s remember how workpieces are processed in a yew. The future part is cut off either at the level or above the level of the yew jaws. When cutting by level, the cut is smoother, and the workpiece is not subject to deformation. The metal is tightly clamped in a yew so that the upper edge of the cut edge protrudes by 3-4 mm, this is the most optimal value. If you make it larger, the chips will be more difficult to remove; if you make it smaller, the processing process will take longer. The protruding part is cut down, then the part is rearranged, releasing 3-4 mm from the top of the yew jaws again, and the shavings are removed again. This operation is repeated until the required size is reached. If processing is carried out above the level of the jaws, then the workpiece is clamped so that the processing line is parallel to the jaws and 3-4 mm above them.

During operation, the cutting edge of the tool should be located at an angle of 45 degrees to the metal being processed, and the striking part should be raised 25-40 degrees upward. This arrangement helps to achieve a more even log line. For simple operations with steel strip or reinforcement, for example, chopping, the chisel is placed perpendicular to the material, then the strip is cut halfway with one or more blows. They do the same on the other side of the workpiece, and if it is round, then the rod is turned, processing the rod around the circumference. Only work with metal on an anvil or thick steel sheet.

The process of sharpening a chisel

Before resharpening, you need to find out how damaged the working part is. To do this, you can run the metal along the back of your hand. Clinging material indicates that action needs to be taken.

You can sharpen a chisel correctly using a sharpening machine and abrasive stones. Step-by-step instruction:

- Clean the cutting parts from dirt and debris and wipe with acetone.

- Wear safety glasses, gloves, and overalls.

- Check the integrity of the abrasive wheel before starting the machine. For ease of work, it is advisable to use a parallel stop, which will help maintain the required angle.

- Turn on the machine at low speed. Slowly move the cutting edge relative to the abrasive wheel, maintaining the required angle. When regrinding, moisten the abrasive with water to avoid overheating.

In addition to wetting the wheel, it is necessary to cool the sharpened part of the chisel in cold water for 1 minute. Overheating can lead to loss of hardness. Small irregularities and burrs can be corrected using abrasive stones. To do this, it is necessary to use several stones of different grain sizes. The last step will be finishing the working part using fine sandpaper. If the metal rod has large chips or cracks, it must be replaced with a new one.

The chisel is used to work with hard materials. It should be in any forge. However, over time, the working part becomes unusable and requires regrinding. To do this, you need to select the sharpening angle and carry out processing using an abrasive wheel. Finish the edge using sandpaper or sharpening stones.

§ 4. CUT OF METAL.

Section: LIBRARY OF TECHNICAL LITERATURE Short path https://bibt.ru<<Previous page Book table of contents Next page>>

Chopping is a metalworking operation in which, using a cutting tool (chisel, crosspiece), excess layers of metal are removed from the workpiece or it is cut into pieces. Chopping is performed in cases where it is difficult or irrational to process workpieces on metal-cutting machines or when high precision processing is not required.

Tools.

The chisel (Fig. 17, a) is made of tool carbon steel U7A.

The cutting part of the chisel has the shape of a wedge (Fig. 17, c), which is sharpened at a certain angle. The sharpening angle of the chisel is selected depending on the hardness of the material being processed: the harder the material, the larger the angle. The following sharpening angles are used (in degrees):

for cutting cast iron and bronze 70

for cutting steel 60

for cutting brass and copper 45

for cutting aluminum and zinc 35

Chisels come in lengths of 100, 125, 150, 175, 200 mm. The cutting part of the chisel is hardened to a Rockwell hardness of HRC 53-56, and the tail part is hardened to a hardness of HRC 30-35.

Rice. 17. Tools for chopping metal:

a - chisel, b - cross-section, c - corners of the cutting tool

Kreutsmeisel (Fig. 17, b) is designed for cutting out narrow grooves and keyways. It differs from a chisel in that it has a narrower cutting part. The sharpening angles are exactly the same as those of a chisel.

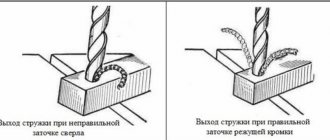

The chisel and crosspieces are sharpened with a regular grinding wheel on sharpening machines. For sharpening, a chisel or crosspiece is placed on tool rest 1, as shown in Fig. 18, and with light pressure slowly move across the entire width of the circle.

Rice. 18. Sharpening the chisel:

1 — tool rest, 2 — protective screen, 3 — sharpener casing

In this case, you should avoid pressing hard on the chisel, as this will lead to heating and tempering, as a result of which the cutting part of the chisel will lose its hardness. It is best to sharpen while cooling.

Hammers are designed to deliver blows when performing most metalworking operations (cutting, riveting, straightening, bending, chasing, assembling, etc.).

In the middle part of the hammer there is an oval-shaped hole with a double conical extension for securing the handle. The length of the handle should be 200-260 mm for small hammers, 270-350 mm for medium ones, and 380-400 mm for heavy hammers. The weight of hammers, depending on the nature of the work performed, varies: 50, 100, 150, 200, 300 g (light hammers for tooling and marking work); from 300 to 500 g (medium hammers) and from 500 to 800 g (heavy hammers for repair and other work). Wooden hammers with fiber, copper and rubber tips are used for installation and assembly work.

Skip to navigation