Cold forming is considered an advanced method in metal processing. Using this technology, various parts, shapes and designs can be produced. The whole process is simplified due to the fact that after cold working the parts do not require additional thermal exposure and are ready for use. To understand how finished structures and shapes are obtained, it is necessary to understand the features of the process.

Metal sheet stamp

History of the process

Metal stamping has undergone changes throughout history. The first upsurge in this process was noted in the 1850s. From this period of time, machines began to be used in metal stamping, which improved the quality of the finished product.

The next advance in the stamping process occurred in the 20th century. Thanks to the development of new technologies, the automotive industry began to actively develop. Using stamping, parts of the body and internal mechanisms of the car were made.

In the 1930s, the stamping process began to be used in ship and aircraft construction. 20 years later, this technology gained popularity in the field of rocket science.

There are several reasons explaining the growing popularity of this part processing technology:

- It is possible to produce both finished parts and blanks for further processing. The shape and parameters can be any.

- The stamping process can produce parts with low mass and high strength.

- High precision of work eliminates the need for additional processing of the part with other tools.

- The rotary conveyor line, operating automatically, facilitated and accelerated the production process.

Cold stamping can produce structures and parts of various shapes, but there are limitations regarding dimensions. This technology is designed for the production of workpieces weighing up to 1 ton. If you need a part of greater mass, it is not advisable to use a cold metal processing method.

Thread rolling

A technological procedure such as thread rolling is performed using special rollers, the cylindrical surface of which has the profile of the thread being formed. During the thread rolling process, the profile that the rolling tool has is materialized on the workpiece by pressing it into it.

One of the main advantages of such a technological process as thread rolling is that in its process it is not cutting that occurs, but plastic deformation of the metal. For this reason, the thread has not only a clean and smooth surface, but also a compacted surface. In most cases, a procedure such as thread rolling is used in mass and large-scale production, since it is characterized by high productivity as well as sufficient accuracy.

a brief description of

In cold sheet stamping, blanks are processed on special equipment under high pressure. Their shape and size changes. Other geometric characteristics of the parts remain in their original state.

During the stamping process, the metal becomes much stronger. However, as strength increases, the fragility of the metal increases. To reduce the influence of this negative factor on the condition of the finished part, an additional heat treatment process is carried out. It is called recrystallization annealing. Thanks to this stage, optimal fragility and strength of the metal are achieved.

Principle of work

There is hot and cold processing of metals. If the manufacturing process does not involve any high temperature steps (other than recrystallization annealing), then the processing is called cold processing.

The process takes place using special dies in which the metal is strengthened under high pressure. Metal that has gone through the rolling stage is used as blanks. The output is a sheet or strip, which is rolled into a roll and sent for stamping processing. The main feature of this process is that the temperature to which the workpieces are heated must be equal to or lower than the forging temperature.

Carrying out work

Service maintenance of cold heading equipment

Our service department is made up of experienced engineers who regularly undergo training at equipment manufacturers in Europe to improve their skills, which ensures prompt and high-quality performance of work for the customer. We offer:

- equipment inspection and drawing up a defect list;

- installation of equipment;

- commissioning works;

- training;

- warranty and post-warranty service;

- maintenance and repair;

- remote software maintenance via modem or Internet;

- supply of consumables and spare parts.

We will always be happy to answer all your questions.

Equipment and materials

To perform cold stamping, it is important to choose the right materials. To make parts of various shapes and dimensions, low-carbon and alloy steel, brass, copper, and magnesium alloys are used. Aluminum stamping, which uses aluminum and its alloys, is very popular.

Special equipment is used in the production of blanks. This includes machine guns and presses.

Pressing machines are divided into two groups:

- Mechanical. This group includes single-position and multi-position equipment. Multi-station machines can combine several operations, which speeds up production.

- Hydraulic. They are used in small-scale production. Using hydraulic presses, elongated parts are produced. Such equipment has many advantages. Hydraulic presses are not afraid of heavy loads, they can be adjusted to force, and it becomes possible to change the speed of movement of the slider. If you reduce the speed of the working part at the moment of its contact with the workpiece, you can reduce the dynamic shock. However, hydraulic presses have serious disadvantages. They have low productivity. In addition to this, the moving mechanism has an uneven speed, which is why it quickly fails or damages the workpiece.

Automatic machines for cold stamping can perform various operations - upsetting, extrusion, upsetting, crimping, cutting, calibrating, embossing. The ability to produce complex parts depends on the number of operations.

Equipment for the production of nuts

The main equipment for production are machines for upsetting and threading.

Most enterprises purchase equipment from Taiwan. Presses must have a closed design for safe cutting of products. It is advisable to choose forming matrices in a round shape, as it provides excellent balancing characteristics. The connecting rod mechanism must be made of alloy steel

An important feature is the oil filtration system (usually magnetic), which reduces costs

Nut setting machine from Taiwan

For thread cutting, it is recommended to use pneumatic machines with multiple spindles for high speed operation. Such spindles can be programmed for different types of work, for example, for long and short threads or left and right. It is also worth taking care of overload and jam fuses.

https://youtube.com/watch?v=j0-GQJXEA0k%3F

Progressive methods of sheet metal stamping

There are several innovative cold stamping methods:

- Liquid treatment. With the help of high pressure and liquid, the metal is deformed. As a result, it takes the form of a matrix. This method is used for the manufacture of hollow, oblong parts.

- Explosion stamping. To change the shape of the metal, explosive gases (RDX, methane, propane) are used. The explosion creates high pressure. Because of this, the initial blank takes the shape of a previously prepared stamp. The pressure created by explosive gases makes it possible to produce parts of large sizes and complex shapes. The main advantage of such processing is the minimal cost of processing workpieces and eliminating the need to purchase expensive equipment.

- Rubber treatment. This method is used only for processing thin sheet metal (up to 2 mm).

- Electrohydraulic processing. The peculiarity of this method is that a high voltage electric charge is an energy carrier. The discharge passes through the liquid and causes a shock wave. Under the influence of pressure, the shape of the workpiece changes. The key advantages of this method are high accuracy and low energy consumption for the production process.

Every year new metal processing technologies appear that are more economical and more productive than the old ones.

Electrohydraulic processing

Cold heading, its essence, products

Cold die forging, the essence of the process.

2. Cold extrusion. The essence of direct, reverse, lateral and combined extrusion methods. Products and their application.

4. Sequence of manufacturing products using cold heading machines. Features of cold volumetric molding.

5. Advantages and disadvantages of cold stamping.

1. Volumetric cold stamping is a process in which the ductility of the metal decreases and its strength simultaneously increases. Due to the strengthening that occurs at certain stages of processing, deformation of the workpiece during subsequent operations is difficult. The harmful effects of hardening can be eliminated by using in-process heat treatment or recrystallization annealing.

Volumetric cold stamping makes it possible to obtain high-precision parts. The surface of such parts is of good quality, and there is almost no need for cutting during the manufacturing process of the part. Cold stamping eliminates heating of the product during its production; due to the absence of heating, favorable preconditions are formed for automation of the technological process. The latter, in turn, affects the improvement of working conditions, which naturally leads to increased productivity.

For the mass production of small forgings, usually without subsequent mechanical processing, cold metal stamping is used on forging machines - cold heading, trimming, bending, etc.

This type of stamping includes volumetric stamping without heating: upsetting, extrusion, upsetting, calibration, embossing.

Cold die stamping produces small parts from steel, non-ferrous metals and their alloys. At the same time, compared with cutting processing, technological waste of metal and processing time are reduced several times.

2. Cold extrusion is an operation for the formation of solid or hollow products due to the plastic flow of metal from a closed volume through holes of the appropriate shape. A feature of the process is the formation of a triaxial uneven compression pattern in the deformation zone, which increases the technological plasticity of the material.

Cold extrusion is one of the most common cold forming operations. Its essence lies in the fact that a massive workpiece under pressure from the punch moves into the annular gap between the matrix and the punch and forms a hollow part with a bottom or a tube with a flange.

Depending on the direction of metal flow, there are:

— direct extrusion – used to produce continuous elongated forgings;

— reverse extrusion – used to produce hollow forgings;

— lateral extrusion – used to produce forgings with branches;

- combined extrusion.

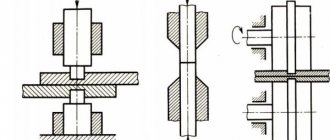

There are four methods of extrusion: direct, reverse, combined and lateral.

Direct method

(Fig. 49, a) is characterized by the fact that the workpiece moves in the direction of movement of the punch. This method is used for the production of hollow parts with a flange and sometimes for rods with large thickenings, which are impractical to produce by upsetting (tubes with a flange, a glass with a flange).

Reverse method

(Fig. 49, b), most often found in production, is characterized by the fact that the metal flows in the direction opposite to the movement of the punch. This method produces hollow parts with a thickened bottom that have a round, rectangular or oval shape in plan, for example, capacitor housings, toothpaste tubes, etc.

Combined method

(Fig. 49, c) is a combination of direct and reverse methods, i.e. metal flows in several directions. Combinations of different schemes are possible.

During lateral extrusion

metal flows into the side holes of the die at an angle to the direction of movement of the punch. Thus, it is possible to obtain parts such as tees, crosses, etc. To ensure the removal of blanks from the stamp, the matrix is made of two halves with a parting plane passing through the axial lines of the original blank and the resulting process.

Fig.49 Cold extrusion methods:

a – straight; b – reverse; c – combined; 1 – punch; 2 – workpiece; 3 – matrix

Fig.50 Examples of parts made by cold extrusion:

a – straight; b – reverse; c – combined

3. Cold heading of products (Fig. 51) is a technological process, as a result of which the cross-section in given areas of the workpiece increases due to plastic deformation in the dies without preheating the metal.

Cold heading ensures a favorable arrangement of the macrostructure fibers, resulting in increased part strength and abrasion resistance. The increase in the diameter of the workpiece during upsetting is limited by its longitudinal stability or the likelihood of destruction with the formation of longitudinal cracks. Loss of stability (axis curvature) does not occur if the length of the planted part is less than 2.5 times the diameter of the workpiece. If it is necessary to plant a longer section of the workpiece, planting is carried out in several transitions, successively increasing the diameter with a corresponding decrease in the length of the planted part. To reduce the risk of workpiece destruction, multi-transition upsetting with intermediate recrystallization annealing is used.

What operations does cold stamping involve?

Cold metal stamping involves the presence of various stages of processing of workpieces. They can be divided into two large groups:

- Separation operations. These include rough processing of workpieces. This includes operations of cutting, trimming, trimming, making cuts, stripping sheets, and punching holes.

- Form-changing operations. This includes crimping blanks, calibrating, straightening, upsetting, upsetting, molding, embossing, branding, and bending.

Also, a separate group can be divided into combined operations, which are a combination of several processing methods. This reduces the cost of parts produced by cold stamping.

Process technology

Cold metal processing technology involves choosing one of several operations:

- Extrusion. Used for the manufacture of bar blanks.

- Cold landing. Using this method, rivets, bolts, nuts, studs, and screws are produced.

- Molding. Closed and open dies are used for this operation. In this way, parts of complex shapes are manufactured.

First of all, a sketch of the stamp is drawn up.

Then its dimensions are checked and adjusted on a computer. Technological holes in the working surfaces of the stamp are indicated. The mold is made. To reduce the strength of the metal, the workpiece is subjected to heat treatment. The surface of the future part is being prepared. Stamping is carried out using the chosen method. Cold metal stamping is suitable for mass production of parts and objects of various shapes. The main limitation is the size of the finished structure. If you need to make a large part, then it is advisable to choose a hot processing method.