Carbide drills for metal products are used for efficient and productive drilling, reaming and drilling of holes in alloy and heat-resistant steels, ductile, bleached and gray cast iron, non-ferrous metals and alloys, as well as in materials of non-metallic origin of increased strength (marble, stone, brick, polymers etc.). The drills were named so because of the material used for the cutting part: it is made of special hard alloys, characterized by high levels of hardness, heat resistance and wear resistance. Consumables are produced by manufacturers in different countries with a diameter of 0.1 to 150 mm to solve various problems. It is also used to perform the following technological operations: chamfering and boring previously made holes.

Tool design features

Drills with carbide inserts are characterized by a number of design features. Let's list the most important ones.

- The working length of the drill is reduced by 20–35% due to the fact that its regrinding is carried out only on a carbide plate. The length of drills of this type, if they are used in conjunction with a jig, can be the same as that of a high-speed tool.

- The increase in the diameter of the drill core towards the shank is within 1.4–1.8 mm for every 100 mm of length, as with drilling tools of other categories.

- The angle of inclination of the helical groove of the tool depends on how deep the hole needs to be made.

- On the transverse edge of the drill, it is necessary to make a point with dimensions of 1.8–3.5 mm, which allows to reduce axial forces and reduce the load on the tool body.

- The tapered shank, with which the drill is fixed in the machine spindle, must be precisely adjusted to the seating part, which will increase the rigidity of the drill fastening and minimize the risk of vibration loads, which can cause chipping of the carbide insert and even its breakage.

- To increase the reliability of using carbide drills for metal, a hole is often made in their inner part to supply coolant. This allows you to reduce the cutting temperature, reduce the intensity of tool wear, and also facilitate the process of removing chips from the processing zone.

Drill device with removable plates

To give the working part of the drill the required hardness (56–62 units on the HRC scale), the tool is subjected to heat treatment, which, as a rule, is performed simultaneously with soldering of carbide plates.

High processing performance, as well as stability of drills in this category are ensured by a number of parameters. This includes the shape of the carbide plate, the geometric parameters of its front surface, as well as the material from which such a plate is made. Currently, the most widely used tools are those with carbide inserts of regular three- and tetrahedral configurations, which allow drilling holes with an almost flat bottom.

Drills with such inserts, the cutting part of which is made in the shape of a wave, allow processing using step-by-step cutting technology. The use of the latter not only ensures stabilization of the position of the tool at the moment of its cutting into the material being processed, but also minimizes the risk of its withdrawal during further processing. In addition, a drill with a wave-shaped cutting edge can significantly reduce the cutting forces generated during the drilling process.

Drills with mechanical fastening of replaceable polyhedral inserts (drills with MNP)

The design of drills equipped with removable carbide inserts allows them to be used not only for drilling, but also for such technological operations as boring pre-made holes and chamfering. In such cases, a peripheral carbide insert mounted on the tool is used.

Solid insert drills, which are mechanically attached to the tool, are effectively used for machining inclined and concave surfaces, and machining with such a tool can be carried out without pre-drilling holes. To successfully cope with such a technological task, the feed rate with which the tool cuts into the material being processed must be reduced by 50–70%.

Sharpening

To give the required hardness to the drill in its working part (measured in accordance with the HRC scale), it is treated thermally, basically this process coincides with soldering the plates themselves. If the plates are profiled, the drilling result will be much better. Removable plates on spiral or solid drills are suitable not only for drilling holes, but also for boring ready-made recesses and holes.

If the drill is equipped with wave-shaped plates, it can be used in a more subtle technique - step-by-step insertion. This technology stabilizes the position of the drill or hammer drill in the initial stage of tapping, and also minimizes the risk that the tool will “lead” during the work process.

How to sharpen carbide drills is shown in the following video.

How to choose?

When choosing carbide bits, you need to consider two main factors: what surface you plan to machine, and what depth and diameter the hole should have. This will allow you to immediately narrow down the choice to a small group of drills.

Next you need to pay attention to what material the cutting edges are made of, how strong the carbide is

The reputation of the manufacturer of the product and its quality are no less important, because, as a rule, the price of such gimlets is quite high. Therefore, you should carefully study the properties of the product before paying for it. Of course, the more famous the manufacturer of the drill, the higher the price, but the quality of such products is also quite high.

Is it necessary to pay for tools whose manufacturer is unknown, and whose quality raises many doubts? Each buyer answers this question for himself.

What factors should be considered when choosing funds?

Among the devices available for drilling, several of the most common types can be distinguished:

- cylindrical;

- end;

- keyed

It is possible to make the right decision in favor of the appropriate type only if the buyer has an idea of what he plans to use this device for. In addition to the drilling depth, you need to know about the material that will have to be processed.

At the stage of selecting carbide drills for metal, the following parameters deserve the greatest attention:

- strength;

- quality of execution;

- brand and country of origin;

- material used for manufacturing;

- price;

- reliability.

The best solution would be if the buyer chooses drills from trusted manufacturers. By acting in this way, we can guarantee that there will be no forced interruptions during drilling , and low quality of finished products will also be eliminated.

Design of drills with pobedit plates

Drills produced with a pobedit tip initially have the required cutting angles, so there is no need to sharpen them additionally. The cutting part of the drill with pobedite tips is formed from two “shoulders”, approximately equal in width. The point at which such “shoulders” intersect will coincide with the center of the hole being formed, and the size of the widest one will correspond to its diameter. The axis of rotation of the Pobedit drill will coincide with the center of the hole if the width of the “shoulders” is the same. If there is a difference between the width of the “shoulders,” then the diameter of the hole being formed will differ from the transverse dimension of the tool by its value. If there is a difference in width between the elements of the cutting part, this can lead not only to an increase in the load on the drill and the operator’s hands, but also to breakage of the drill.

Designs of pobedit drills

If drills with pobedit tips become dull, they can be sharpened in the same way as regular ones. When sharpening, you should keep in mind that the alpha angle of the cutting part of the drill should be smaller, the harder the material being processed. Pobedit is very afraid of overheating, and this should definitely be taken into account when sharpening. In order not to encounter a situation where the pobedit carbide tip begins to crack or even separate from the main part of the tool, it is necessary not to let it overheat and cool it as often as possible, for which you can also use ordinary water. If, nevertheless, the victorious elements of the drill overheat, they should be allowed to cool in natural conditions and in no case subjected to sudden cooling with liquid (this can lead to their cracking).

The modern market offers a wide variety of drills with carbide-tipped pobedit tips, which are designed for processing certain materials. Information about the purpose of such drills, if they are produced in serial conditions, can be found on the packaging.

Shapes of sharpening drills with pobedit tips (according to GOST 22735-77)

Technical recommendations for drilling metals

To properly center a metal drill, you must use a centering pin. To do this, you should mark the hole, focusing on the markings. then inserted into the recess and the magnet is turned on .

Next, you should re-check that the pin is positioned correctly, since the tripod often moves when the magnet is working. Decide on the optimal speed. This parameter is of great importance. Please note that if you select a higher speed than recommended, the drilling job will not be completed. It is imperative to ensure a rotation speed of at least 25% of the recommended one. When working with carbide drills, remember that they are sensitive to excessively low speeds . In this case, you may encounter phenomena such as increased vibration and chipping of teeth. If the speed is increased by more than 20%, then when using drills made of high-speed and powder steel, the latter will quickly become unusable.

You need to choose the right feed. At the beginning of work, it is necessary to set the flow at a level 2 times lower than the recommended one. It should be kept in mind that if there is too much pressure on the drill, the speed will remain the same. To achieve greater productivity, it is recommended to use equipment with increased rotation speed in combination with carbide drills . Sometimes you may need to apply more force while drilling. If this happens, then there is a high probability that you are working with a dull drill bit or are trying to create a hole in a material that is too hard.

Overview of species

Today, customers are offered a wide range of drills with plates made of hard alloys, which can be used to process metal and other materials. These nozzles can be classified according to a number of parameters, for example:

- according to the material from which the records are made;

- according to the method of attaching these plates to the working part of the nozzle;

- according to the shape of the plates;

- According to the shape of the grooves between the cutting surfaces of the nozzle, these grooves are designed to effectively remove chips and other waste generated during the drilling process.

Nozzles equipped with hard alloy plates have some design features that distinguish them from other “brothers”.

This is, first of all, a shorter working part - compared to other types of drills, it is 20-30% smaller. This is due to the process of drill regrinding - it can only be done on carbide inserts. If the drill and jig make up a set, then the length of the drill is equal to the length of a regular gimlet.

The diameter in the core of the nozzle in the direction of the shank increases every 10 cm from 1.4 to 1.8 mm. The angle at which you hold the bit is directly related to the depth of the hole you need to drill. The cone-shaped shank must be well adjusted to the spindle in the machine, because how rigid and strong the grip is depends on how accurate and high-quality the drilling process will be.

According to the method of fastening the plates

Fixation of carbide plates occurs on the cutting parts either by soldering or by a screw (mechanical) connection, then the plates are replaceable. If soldering is used, then re-sharpening is possible only a few times, after which the drill becomes unusable.

Types of drills with carbide inserts

The modern market offers a wide variety of carbide drills designed for working on metal and other materials. The classification of such a tool is carried out according to several parameters, which, in particular, include:

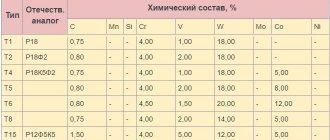

- material for manufacturing a carbide plate, which can be alloys of grades VK6, VK8, etc.;

- method of attaching carbide inserts to the main part of the drill;

- the shape of carbide plates;

- the shape of the grooves between the working surfaces of the drill, designed for effective removal of processing waste.

Alloys of the tungsten-carbide group are predominantly used as the material for the manufacture of cutting inserts that are equipped with a carbide drill. The most popular is the VK8 alloy.

Properties and applications of tungsten group alloys

Such alloys, produced mainly by powder metallurgy methods, fully correspond to their name - “hard”. In particular, the hardness of the popular VK8 alloy, depending on the conditions of its production, is in the range of 1670–2800 units on the Rockwell scale. Thanks to this, a drill equipped with cutting inserts made of VK8 alloy can be successfully used to make holes in materials such as alloy steel (including heat-resistant steel), cast iron, and hard wood. It is also important that the VK8 alloy, compared to other carbide materials, is affordable.

Carbide inserts can be fixed to the cutting part of the drill by soldering or by means of a screw (mechanical) connection. In the first case, carbide inserts can be ground a limited number of times, although they are characterized by higher reliability. In addition, they break quite often. That is why tools with non-sharpening cutting inserts that are attached mechanically have become very popular.

Types of Carbide Inserts Used for Drills

To equip drills of this type, carbide inserts are used in the form:

- parallelogram;

- rectangle;

- rhombus;

- irregular triangle (such plates are characterized by the presence of six cutting edges).

When using carbide drills for processing metal and other materials, the shape of the grooves between the working surfaces of the tool is of great importance. Regardless of the shape of such grooves, their internal surface must be carefully polished to ensure effective removal of chips from the processing zone.

Carbide drill with internal coolant supply

Cooling and lubrication of carbide drills

As mentioned above, to make machining with carbide drills more efficient, it is necessary to ensure internal cooling of the tool. When using such drills, you can avoid using lubricating and cooling liquid in cases where the depth of the hole being formed does not exceed one tool diameter.

The quality of the hole being made, as well as the speed of its drilling, is influenced not only by the amount of coolant supplied to the internal cavity of the drill (at least 12–15 l/min), but also by the pressure value (at least 12–15 atm). The lubricating and cooling liquid supplied to the processing zone in such quantity and with such pressure provides not only intensive cooling of the tool, but also effective removal of chips and other drilling waste.

Drilling with external coolant supply

Use at home

Despite the fact that centering drills are professional, many home craftsmen have found successful use for them. Such drills are very popular among radio amateurs, who often have to drill small-diameter holes in printed circuit boards. Possessing high rigidity due to the features of their design, centering type drills in such situations are more preferable than a standard small-diameter drilling tool.

Drilling holes in a printed circuit board

One of the operations that can be successfully performed using a centering tool is drilling out screws or screws that cannot be removed with a regular screwdriver. Using a centering tool, the heads of such recalcitrant fasteners are simply drilled out, after which they can be easily unscrewed. The easiest way to solve this problem is to drill out the head of a screw or screw, which has slots for Phillips-type screwdrivers. If we are talking about a head with slots for a straight screwdriver, then it must first be marked to indicate the exact location of the drill.

Centering drill with screw sharpening and Morse taper shank

It will not be difficult for any home craftsman to purchase a centering tool of any diameter. Today there is a large assortment of drills available for free sale, including both domestic and foreign brands.

If we talk about the preferences of home craftsmen, then, judging by reviews and recommendations, centering drills produced under the well-known Dormer brand are very popular among them. This tool is distinguished by high quality workmanship, as can be judged even from its photo; it is reliable and durable in use.

Dormer center drills are made from high speed tool steel HSS

The centering tool TM Dormer is made of high-speed steel and is subjected to special heat treatment to ensure high hardness of the finished product. As a result of such technological manipulations, a tool is obtained that can easily drill very hard metals, including stainless steel.

The manufacturer adds cobalt to the metal from which Dormer centering drills are made, which allows the cutting tool to maintain its original hardness even at elevated processing temperatures. The wear resistance of the products of this brand also deserves praise.

What types of carbide drills are there?

A characteristic feature of carbide drills for metal is a very durable titanium-tungsten base, the beneficial effect of which is to ensure high speed of work . In addition to this, the advantage of such products is their high resistance to external influences.

Types of drills

It is customary to distinguish the following types of carbide drills for metal:

- solid;

- welded;

- equipped with plates.

If there is a need to purchase carbide drills, it is advisable to consider models from well-known companies. This gives confidence in the high quality and reliability of the purchased product.