In the process of making furniture, special equipment is used to drill holes for fasteners, fittings and hinges, which allows you to accurately and accurately cut out a piece of wood, plastic or metal without damaging the edges. The compact drilling and filler machine helps to increase the economic factor and productivity, reduce financial and material costs from defective parts.

Purpose of filler machines

drilling and filler machine

The holes made by drilling machines are needed to accommodate fasteners and fittings: pins, screws, screws, handles, hinges, hinges. The possibility and quality of assembling parts into a single whole depends on how accurately the holes are located. The size and location of the holes on the workpiece are strictly regulated; if they do not correspond to the drawings of the furniture body, it is impossible to assemble it. Often large batches of workpieces are returned to the factory due to mismatched fasteners. The error allowed is within 0.4 millimeters per 64 cm.

The additive machine operates on an aggregate principle - several tools of the same type are simultaneously involved - countersinks, drills, counterbores, mounted in a multi-spindle head.

Features of manufacturing a frame facade

To make a frame facade, a series of sequential actions are performed.

- Vertical and horizontal slats are sawed with some margin, so that later on an angle machine you can make cuts at an angle of 45°.

- When cutting out the final size, the exact size of the frame is maintained.

- Using a manual filler machine, holes are prepared for the final assembly of the facade.

- The chipboard core is cut out on a format-cutting machine (glass is cut to size on a glass cutting table and a reinforcing film is glued onto it).

- The work of assembling the facade is carried out on the table. To ensure that right angles are assembled, a jig is made. In it, the guides converge at an angle of 90°.

- Connect one pair of profiles, check the angle. It should be exactly 90°. Before assembly, the dowels are lubricated with polymer glue.

- Connect the second pair of profiles.

- Glue is applied to the edges of the filler, and then the filler is inserted into the first assembled corner.

- A second corner is mounted on the reverse side, and dowels coated with glue are first installed in it.

- With light blows of the mallet, the entire frame is finally assembled.

- The finished façade is put out to dry. Typically, polymer adhesives are completely polymerized within 24 hours.

The corner from the profile is assembled onto two dowels, as in the photo below. For them you need to drill two holes on the mating surfaces. For this you need an additive machine.

Types of filler machines

According to their purpose, the equipment of this group is divided into:

- universal;

- specialized;

- special.

Universal drilling and additive machines perform complete processing of holes from drilling to final processing with a turning or milling tool. They are used in series production and are equipped with many functions. Compact, low-power models are designed for home construction enthusiasts.

Specialized equipment operates automatically, processing several holes simultaneously. It can be reconfigured to perform various operations. Most manufacturing drilling and attachment machines fall into this category.

Special machines are created to work with certain types of workpieces. Most often, it is impossible to reconfigure them for other types of operations with your own hands.

Based on the number of functional traverses and spindles, machines are distinguished:

- semi-automatic drilling and filler;

- positional drilling and filler;

- drilling and filler machines with numerical control;

- additives for hinges.

Subscribe and receive

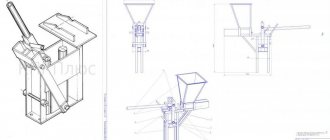

What is a filler mill and why is it needed?

A filler mill is a manual machine that allows you to make two holes at once, with a distance between the centers of the holes of 32 mm.

A convenient thing for assembling furniture on dowels.

So, I used a regular router, made a special platform for it and now it can make holes with a pitch of 32 mm, 64 mm. You can make holes both at the ends and in the plane and for parts with a thickness of 16 to 50 mm.

Read also: Do-it-yourself ball for a lathe

It still drills one hole at a time, but at the same time it allows you to drill a second hole at a distance of 32 or 64 mm from the first.

The error now for this router is 0.5 mm, which I consider quite acceptable for wood.

And as they say, it’s better to see once than to hear a hundred times, so watch...

It is quite possible to develop and manufacture this device yourself. You just need time and the desire to tinker with the calculations.

For those craftsmen who value their time and the work of others, I offer ready-made drawings of my filler milling machine.

If you see a blank page, it means you are not logged in to the site.

You only need to log in to read materials from the Premium section

Subscribe to the newsletter to gain access to the Premium section

Alexander Klimov

". The knowledge you receive here will help you make a home, a bedside table or chair, a toy for a child, or a wooden decoration that will serve for many years. "

Categories

Categories

Links

Individual entrepreneur Klimov Alexander Nikolaevich, acting on the basis of a Certificate of state registration of an individual as an individual entrepreneur, hereinafter referred to as the Seller, publishes this Public Offer about Digital Goods presented on the Seller’s website

1. GENERAL PROVISIONS. SUBJECT OF THE AGREEMENT

1.1. In accordance with Article 437 of the Civil Code of the Russian Federation (Civil Code of the Russian Federation), this document is a public offer, and if the conditions set out below are accepted, the individual accepting this offer makes payment for the Goods and/or Services in accordance with the terms of this Agreement. In accordance with paragraph 3 of Article 438 of the Civil Code of the Russian Federation, payment for the Goods by the Buyer is an acceptance of the offer, which is considered tantamount to concluding an Agreement on the terms set out in this offer.

1.2. Based on the above, carefully read the text of the public offer, and if you do not agree with any point of this offer, you are asked to refuse to purchase the Products and/or Services provided by the Seller.

1.3. In this offer, unless the context otherwise requires, the following terms have the following meanings:

Acceptance – full acceptance by the Buyer of the terms of the Agreement;

Offer is a public offer of the Seller addressed to any individual (citizen) to conclude a purchase and sale agreement with him (hereinafter referred to as the “Agreement”) on the existing conditions contained in the Agreement.

Buyer - Site visitor - an individual who has entered into an Agreement with the Seller on the terms contained in the Agreement and is purchasing Digital Goods (s) and/or services.

The parties are the Seller and the Buyer, referred to collectively.

Website is a platform located on the Internet with the domain name “vsumebelsam.ru”, which is an online store containing the Seller’s range of goods and services.

Digital product is a virtual product that is the subject of this agreement and has the following types:

a) finished digital goods – digital goods laid out for sale, having a completed appearance and ready for use.

b) courses – training programs using a distance learning system.

Delivery – delivery by the Seller of digital goods presented on the Site via electronic communication channels to the electronic mailbox whose address is specified by the Buyer in the Order;

Account is a virtual “office” of the Buyer, in which the registered user sees his personal data.

Registration is the process of the Buyer entering personal data into a special form on the Site when placing an Order (last name, first name, email address).

Order – individual items from the assortment list of Digital Goods specified by the Buyer when filling out an application to receive a Digital Good.

2. SUBJECT OF THE AGREEMENT

2.1. The Seller sells Digital Goods in accordance with the current price list published in the Seller’s online store on the website “vsumebelsam.ru”, and the Buyer makes payment and accepts the Goods in accordance with the terms of this Agreement.

2.2. The Seller delivers Digital Products exclusively in virtual form via email and does not ship printed products by mail.

2.3. This Agreement is an official document of the Seller.

3. ORDERING

3.1. The Order of the Goods is carried out by the Buyer by sending a properly completed form during the payment process. All fields of the payment form must be completed. In the absence of the necessary information to identify the Buyer and send him the Goods, the Order will not be accepted by the Seller.

3.2. When placing an Order, the Buyer undertakes to provide the following information about himself:

last name and first name, email address.

3.3. The Buyer gives his consent to the Seller’s processing of the Buyer’s personal data with or without the use of automation tools. This consent of the Buyer applies to his last name, first name and other information related to his personality and specified when placing the Order. Consent is provided to carry out any actions regarding personal data that are necessary for the proper execution of this Agreement, including without limitation: collection, systematization, accumulation, storage, clarification, use, distribution, blocking and destruction, as well as carrying out any other actions with personal data in accordance with the current legislation of the Russian Federation.

3.4. Payment by the Buyer for an Order placed on the website means the Buyer’s agreement with the terms of this Agreement. The day of payment for the Order is the date of conclusion of the Sale and Purchase Agreement between the Seller and the Buyer.

3.5. If the Buyer has any questions regarding the Product, before placing an Order, he must seek advice from the Seller by email at [email protected] or through the feedback form posted on the website.

Read also: Wiring the rj 45 network cable

4. CONDITIONS AND DELIVERY TIMES OF DIGITAL GOODS

4.1. Delivery of the paid goods to the Buyer is carried out by sending an email with a link to receive the Digital Goods to the email address that the Buyer specified during the Registration process. The deadline for sending the letter is 8 hours from the receipt of payment.

4.2. The Seller delivers the Goods based on the Order placed by the Buyer.

4.4. The Goods are considered received by the Buyer, and the Seller’s obligation to deliver the Goods is fulfilled from the moment the operation of sending the Goods is recorded via electronic communication channels to the Buyer’s electronic mailbox in the Seller’s automated electronic system.

4.5. In case of failure to receive the Goods by the Buyer within the period specified in clauses 4.1 and 4.2. of this Agreement, or due to technical problems with the mail server of the Buyer's provider or for other reasons, the Buyer must contact the Seller and report non-receipt of the Goods. In this case, the Seller will resupply the Goods free of charge within 2 (two) business days from the date of receipt of the corresponding message from the Buyer.

5. PRICES AND PAYMENT PROCEDURES

5.1. The range and price of Digital Goods are freely available on the Seller’s Website.

5.2. The cost of the Goods indicated on the website vsumebelsam.ru can be changed by the Seller unilaterally at any time.

5.3. Payment for Digital Goods occurs non-cash using the payment system installed on the seller’s website.

5.4. The Buyer's obligation to pay for the Goods is considered fulfilled from the moment funds are received into the Seller's bank account

6. TECHNICAL SPECIFICATIONS OF DIGITAL GOODS

6.1. Digital products are supplied in the following formats: PDF format, JPG format, mp4 format, XLS format.

7. RIGHTS AND OBLIGATIONS OF THE PARTIES

7.1. Rights and obligations of the Buyer:

7.1.1. The Buyer has the right to be provided with a Digital Good in accordance with the technical characteristics specified in this Agreement (clause 6)

7.1.2. The Buyer is obliged to pay for the Digital Goods in full before receiving the Digital Goods.

7.1.3. Products purchased from the Seller are intended for the personal use of the Buyer. The Buyer agrees not to distribute copies of the Digital Product in any form or manner.

7.2. Rights and obligations of the Seller:

7.2.1. The Seller has the right not to deliver Digital Goods for which it has not received full payment.

7.2.2. The Seller is obliged to supply the Digital Goods in proper quality in accordance with the technical characteristics specified in this Agreement (clause 4).

8. RESPONSIBILITY OF THE PARTIES

8.1. For failure to fulfill or improper fulfillment of obligations under this agreement, the Parties are liable in accordance with the current legislation of the Russian Federation.

8.2. The Seller is responsible for the compliance of the supplied Digital Goods with the technical characteristics indicated in clause 4, as well as for the compliance of the contents of the Digital Goods with all legal norms.

8.3. The Buyer is responsible for the proper use of the Digital Product in accordance with clause 7.1.3

8.4. The Seller is not responsible for the content and accuracy of the information provided by the Buyer when placing the Order.

8.5. The Buyer is responsible for the accuracy of the information provided when placing an Order.

IP Klimov Alexander Nikolaevich

This site is an information and educational Internet project of Klimov Alexander Nikolaevich (IP Klimov Alexander Nikolaevich. OGRNIP 311222511700014).

This site strictly adheres to the following privacy policy principles:

1. Subscription to the newsletter is carried out at the own discretion of anyone through the form on this website. To do this, your email address is requested. You must also confirm your consent to receive information materials from the site in the letter that arrives after filling out the form.

2. The personal data of each subscriber is used only to send him periodic newsletters, news and promotions of the project: https://vsumebelsam.ru/ and will never be transferred to third parties in any form.

3. To get an idea of the content of the newsletter releases, you can familiarize yourself with the contents of the “blog” section of the site: https://vsumebelsam.ru/

4. Each subscriber can unsubscribe from receiving newsletters at any time by clicking on the link present at the end of each letter.

By subscribing to the newsletter, you accept the terms of the privacy policy!

The user, by filling out the contact form, subscribing to the site's newsletter or filling out other forms on the website vsumebelsam.ru, agrees to accept this Consent to the processing of personal data (hereinafter referred to as the Consent).

The website vsumebelsam.ru belongs to Klimov Alexander Nikolaevich (IP Klimov Alexander Nikolaevich. OGRNIP 311222511700014).

The user gives his consent to the processing of his personal data under the following conditions:

The filler machine is designed for drilling holes for hinges and fasteners in the process of manufacturing cabinet furniture. They make multiple holes accurately and accurately, without tearing or chipping. High-quality equipment allows you to speed up the production process, reduce costs and reduce the percentage of defective workpieces.

Design of the most common types of additive machines

portable drilling and filler machine

The optimal result of using a drilling and filler machine in production is possible if you know the intricacies of its operation and design.

Machines with one multi-spindle head

The workpiece is placed on the tabletop in accordance with the stops and guide ruler, and is fixed with clamps (usually pneumatic). This positions the part relative to the cutting tools and holds it firmly during the drilling process. When the engine starts, the head with installed drills moves towards the edge of the workpiece, placed along the stop. At a moving speed of 5 to 10 meters per minute, it makes holes up to 4 cm deep and returns to the starting point. A worker from the console relaxes the clamps and replaces the workpiece.

Multifunctionality is achieved by rotating the head with spindles 90 degrees for finishing beveled edges and making grooves in the faces. There are special slots in the tabletop for drill passage from below. Furniture equipment of this type is quite compact and works great in small industries with small batches of various parts.

Machines with multiple multi-spindle heads

They are equipped with a wide range of working tools: several vertical drilling heads for making holes and one horizontal for finishing edges. They, as well as the positioning and feeding devices, are located in the frame. The bed is equipped with supports with the ability to place the workpiece relative to the executive bodies. The workpiece is placed on the slats in accordance with the stops and secured with clamps (pneumatic). When the engine starts, all heads start working simultaneously.

Such an additive machine costs more, so it is additionally equipped with electronic position controllers, drive speed adjustment, and adaptive control mechanisms.

Fundamental differences between multi-spindle devices and single-spindle devices:

- the position of the heads is determined electronically, so the settings are very accurate, additional adjustments are carried out quickly;

- two planes are processed simultaneously, twice as fast and more accurately. For a second run of a series of complex workpieces, there is no need to re-adjust the equipment;

- vertical drilling heads with spindles are capable of rotating relative to the center of the main drive, making holes at an angle;

- the supports are additionally equipped with devices for loading and unloading parts, completely freeing the operator from manual work. Such machines belong to position-through equipment and are used in production lines. They process the workpiece as it moves along the conveyor, which further saves time and eliminates the use of manual labor in production.

Communities › DIY › Blog › Tools for assembling furniture (personal experience).

In yesterday's topic about building cabinets, a lot of people asked to tell us what tools my friend and I used to assemble the furniture.

I believe that professionals will not be interested in this, and many will even say that they could have made the templates themselves and not spent money. It is possible, but without experience, it is difficult and time-consuming. We took the fast, but costly, route - we bought ready-made ones. However, I am very grateful to everyone who sent me drawings of their templates - it really helped me understand the topic and understand what's what.

In general, as I understand it, two approaches are used to connect chipboard using confirmations: 1) Templates for drilling end and front holes. They can be in the form of rulers (like Cheron) and in the form of drums. They can also consist of entire systems that are attached to a sheet of chipboard. But the general idea is that each sheet is drilled out one at a time. Perhaps you can save time and use another method. 2) Clamps for fixing chipboard sheets at the desired angle (usually 90 degrees) and a confirmatory drill. The advantage of this option is that in one pass we get both holes at once and can immediately tighten the confirmation. It would seem that everything is easy and simple, but now try to combine panels with a length of 2600 and 1200 mm at an angle in an apartment. Hard? running away? yes, and not alone at all (not like in the first option).

Let's summarize the pros and cons of each option. Templates/conductors: + Easy to use. + you can work alone. + no need to worry about the centering of the drill - as a rule, templates/jigs have steel inserts that allow you to drill directly through them. - You will need several pieces to work. - expensive (if you buy). — you need to have either drawings or well-developed spatial thinking, since each part is drilled separately.

Clamps and confirmation drill: + Quick and easy to use. + in one “pass” we get ready-made holes in two parts at once. + inexpensive. — it’s hard to work alone, especially if the parts are large. - problem with drill alignment.

What to choose, everyone decides for themselves. But, most likely, you, like us, will compile both options into one =) For example, a confirmatory drill is very convenient for tackling “in place” already connected large parts.

So, to assemble the furniture, we bought templates from Cheron (they have a website of the same name). Don’t take this as an advertisement, but they were able to competently present their product - they have videos on their website that help you get an idea of how to work with their products. Well, they were recommended during the drive. In the end we decided to buy them. And now I will tell you about them and how to work with them.

Let's start with the simplest thing - a template for furniture handles. I bought MSh-22 (96,128,160,192mm), but you can get something simpler and cheaper (there are 96 and 128 mm). In principle, you can do without it, but I repeat - there were a lot of parts, and assembly was carried out in the evenings. Those who prioritized saving time and facilitating working conditions. Working with this template is simple: mark the middle of the handle, apply MSh-22 and mark the mounting location with the required distance from the edge of the door (I took 40 mm).

Multi-spindle drilling head

multi-spindle head

An additive machine of any type certainly contains this element.

The head consists of spindles installed in a row at equal intervals of 3.2 cm. This is a standard for furniture equipment that almost all manufacturers adhere to.

Differences are possible for special devices, for example, those that make holes for façade hinges. Drilling parameters depend on the characteristics of the hinges.

The movement from the electric motor comes through gears located inside the head. The head, depending on the number of spindles, can be equipped with a pair of electric motors. A similar scheme determines the rotation of the spindles in different directions. Therefore, drills with right and left screws can be used as executive bodies. Spindles rotating from the same motor are marked with the same color.

The spindle speed is maintained within 2700 rpm. Most often, multi-spindle heads contain 21 or 27 spindles. The gap between the outer drills in such devices is 64 and 83.2 cm. Drills with a diameter of 5 mm and 10 mm are easily inserted into chucks.

The head feed mechanism consists of a pneumatic drive and guides. You can adjust the drill feed rate along the axis using electronic sensors or stops; it varies from 4 to 9 cm and determines the depth of the holes in the workpiece.

Frame facades in exclusive furniture

What does everyone see when entering a room or kitchen where cabinet furniture is installed? The eye first stops at the doors and drawers. Furniture makers call these elements furniture facades.

Using MDF profiles, you can select different wood textures. They are modeled by a film that is hot-glued. Internal filling is performed using different types of fillers:

- Plates made of laminated chipboard with a thickness of 8-10 mm - they are cut to the size formed by the internal contour of the grooves obtained after connecting the frame elements.

- MDF boards covered with films of various types - they also fill the grooves milled inside the profiles.

- Glass – usually reinforced with various types of glass films are used. In addition to transparent films, they are used in different shades and with patterns. Glazed fronts look great in bookcases, wardrobes and kitchen cabinets.

- Mirrors are used to create the effect of expanding space, as well as for practical use to look at yourself.

- Rattan panels decorate any facade; such material gives any furniture a solid look.