What is wheel balancing

If all the other shafts and rotating parts work in a closed volume and they absolutely do not care what happens outside the crankcase, block or housing, then the wheels have a hard time. Even if the tire and disk assembly are perfectly balanced, during operation anything can happen to them, from deformation to the accumulation of dirt. All this affects the balancing of the wheel. What is this, balancing?

Balancing a car wheel is all about eliminating radial mass differences. That is, if the wheel is lighter on one side and heavier on the other, then it will vibrate when rotating. The higher the rotation speed, the greater the vibration.

Why and how often to do balancing

Needless to say, constant vibration on the steering wheel even at the lowest speeds is simply unacceptable. Wheel imbalance leads to:

- deterioration of wheel adhesion to the road;

- rapid wear of tires, chassis and car suspension;

- a sharp deterioration in controllability;

- deterioration of the brake system.

Read also: How to polish brass to a shine

Wheels are balanced if necessary, when vibrations occur, as well as after replacing tires, after repairing them and vulcanizing the tubes, after straightening or rolling out steel wheels.

In addition to safety, reduced service life and high fuel consumption, wheel imbalance does not bring much comfort to the car interior. Therefore, balancing wheels with your own hands should become a habitual procedure for every motorist. At least in order to understand how and how this is done.

Why do you need to balance car wheels?

A completely fair and logical question. It would seem that you “put on” tires and drive a car for your own pleasure. In fact, not everything is as simple as it seems to many. Balancing a car wheel is an important procedure that directly affects traffic safety.

The procedure for balancing car wheels is performed in the following cases:

- Replacing summer tires with winter tires or in reverse order. The rims remain the same, but the tires change. Driving on summer tires in winter is prohibited by law in many countries around the world.

- Frequently falling into holes or hitting other obstacles can lead to wheel imbalance. Often the force of the impact turns out to be so impressive that the discs have to be replaced due to their damage.

- Experts recommend balancing vehicle wheels after 20 thousand kilometers. The car does not always move on a well-maintained road surface. The presence of holes, potholes and other road surface defects negatively affects wheel balancing.

- If the rubber surface is damaged, it is dismantled and repaired. It is necessary to balance the wheels after such intervention.

- Long trips over distances of more than 2 thousand kilometers require a mandatory wheel balancing check for safety reasons.

It is not always possible or desirable to go to a tire shop to balance the wheels of a vehicle. By connecting your head and hands, growing from the right place, you can do this work yourself without outside help. There is nothing complicated in this procedure. There is no need to rush, otherwise the quality of the work performed may suffer.

The process of balancing car wheels with your own hands can be divided into several stages:

Preparation.

Includes the purchase of self-adhesive weights that act as balancers. They are glued to the wheel to ensure balance in the rotation of the wheel when the vehicle is moving.

The car wheels must be washed and all pebbles stuck in the tread must be removed. There should be no dirt on the tires, otherwise the correct balancing can be called into question. Be sure to remove the cap if it is installed.

Next, take an ordinary jack. One side of the car lifts up, releasing two wheels. It is necessary to check their free rotation. They can be spun by hand in any direction. The wheels should spin without overcoming resistance. In some cases, to ensure free rotation, it will be necessary to loosen the hub mount. You just need to loosen the bolts a little. Don't forget to remove old weights from the wheel.

Heavy point of the wheel.

To determine the heaviest point of the wheel, you need to perform the following sequence of actions:

- the wheel spins clockwise, after it stops you need to mark the lowest point of the wheel. Using a marker with a rich yellow color, you need to put a mark

- the wheel spins counterclockwise. If after the wheel stops the mark is down again, then the heaviest point has been detected

- To balance the wheel on the opposite side from the heavy point, weights are installed on both sides of the rim of the disk

Poorly balanced car wheels lead to a significant lengthening of the braking distance. All this can lead to emergency situations on the roads. Often the contact area is reduced and the level of adhesion of the tire to the asphalt drops.

Controllability decreases.

The vibration of the steering wheel when driving a car is not only annoying, but can also reduce controllability. This phenomenon is especially dangerous at high speeds. The chances of getting into an accident increase many times over.

Suspension load.

Improper balancing of vehicle wheels leads to accelerated wear of the vehicle's suspension components. Individual elements may even be partially destroyed during long-term operation of the machine.

Uneven tire wear on wheels is the first sign of imbalance. Even new high-quality and expensive tires can be ruined in a relatively short period of time if measures are not taken in time. As practice shows, wear occurs on the outside or inside of the wheel.

In total, we can distinguish two types of imbalance associated with violation of the vehicle wheel balancing procedure:

Dynamic.

The incorrectly distributed weight of the wheel when it moves creates oscillatory movements. It begins to wiggle from side to side. The phenomenon occurs if the weight was unevenly distributed on both or one side of the wheel centerline.

Many car enthusiasts underestimate the importance of wheel balancing, considering such a popular event a waste of money. But this is a big mistake.

Such an attitude can lead not only to costs in the future, but also to a serious accident with unpredictable consequences.

Remember that timely wheel balancing is one of the main tasks for any driver. Moreover, we will look at how, when and why this is done in the article.

When it is necessary?

Experts identify several basic requirements regarding wheel balancing.

This work must be performed in the following cases:

- When replacing tires from winter to summer (and vice versa). Usually, at normal service stations, when “re-shoeing” a car, balancing is done immediately and is included in the cost of the service. If you change the tires yourself, you will also have to do the balancing work yourself;

- In case of hitting a curb, falling into a hole or passing a concrete policeman at speed. Such situations rarely end without a trace for the car's drive. Even a minimal defect can lead to wheel imbalance. Therefore, contacting a tire service is also mandatory;

- Every 15,000 kilometers. Few car enthusiasts cover such a distance within one year, so balancing when changing tires seasonally is sufficient. But there are also “truck drivers” who have to do this work twice a year;

- Every 7000-8000 kilometers - for those who like fast and aggressive driving;

- Before a long trip (1.5-2 thousand kilometers and above) and after it. This requirement is based on safety reasons.

What is the danger?

It would seem that what can happen if wheel balancing is not done in a timely manner? We often forget that each wheel has its own individual weight, pressure, technical characteristics, oval shape and defects. Therefore, the issue of balancing it is very important.

If this is not done, the consequences may be as follows.

- The braking distance of the car increases.

- This is easy to explain - the contact area between the tire and the asphalt decreases, grip deteriorates, and traffic safety decreases.

- Controllability decreases.

- The reasons are the same as in the previous case.

- There is a beating in the steering wheel.

- The imbalance in the wheel is transmitted to the suspension, and then to the steering wheel. The stronger it is, the greater the vibrations the driver feels. In this case, driving a car is very dangerous.

- Suspension wear accelerates.

- Poor balancing (or lack thereof) most affects the suspension bearings and hubs. Due to imbalance, these elements of the chassis system may even collapse. The result is loss of controllability and the likelihood of an accident.

- Increased tire wear.

The reasons are uneven distribution of forces and the appearance of vibration. Essentially, the tires will be “eaten up” on one side.

Types of imbalance

Today there are two main types of wheel imbalance:

Static imbalance.

This implies an uneven distribution of the mass of the product along the axis; the wheel begins to “beat” in the vertical plane. In fact, there is no center of gravity on the wheel axle at all. This problem sooner or later leads to destruction of the suspension.

Dynamic imbalance

— unevenness in the plane of the wheel. In this case, there is a center of gravity, and it is on the axis of rotation (where it should be). The only difference is that the axis of inertia and the center of gravity do not coincide.

The cause of the imbalance may be the design features of the wheel (tread pattern, location of the valve hole, inaccuracies in geometry, dimensions, and so on).

In this case, the greatest imbalance can be caused by the car tire itself. Here, a lot depends on the rubber material, weight, structure, and so on.

Signs of poor quality work

Wheel balancing is not always done well. There are several factors by which this can be determined:

The service station does not take any measurements before carrying out work. A good mechanic should definitely check the wheel and tire runout parameters. At the same time, it is advisable to do this as accurately as possible, taking into account radial and lateral runout;

All dirt from the tire and excess elements from the tread must be removed. If this is not done, then balancing becomes a completely useless exercise. Before starting work, the wheel must be perfectly cleaned;

Pay attention to the appearance of the balancing machine. If it is dirty, then it is very difficult to count on accurate data and high-quality balancing.

Final balancing

Final balancing is performed on wheels that are already installed on the car. The advantage of the work is that not only the wheels are adjusted, but also the brake discs, CV joints, hubs and axle shafts.

This type of balancing ensures a real smooth ride, improves wheel grip and allows you to achieve a number of other positive aspects.

We do the work with our own hands

To perform balancing, you need to prepare a special set of weights (you can buy it in the store).

At the same time, for cast and forged wheels, balancers are sold that are glued to the wheel (they should be given preference).

The sequence of actions is as follows.

- Raise the wheel with a jack and make sure it rotates easily. If there is friction, loosen the hub nut slightly. Clean the wheel from dirt and remove all stones from the tread (they will interfere with balancing).

- Be sure to check the tire pressure. It must be in accordance with the recommendations specified in the car's operating manual.

- Remove the old balance weights.

- After this, spin the wheel counterclockwise and wait until it stops completely. Now you can mark the top point with chalk (this is the easiest place).

- Next, rotate the wheel clockwise and place the mark again (also at the top point). Between the first and second mark is the lightest part of the wheel.

- Glue balancers weighing 30 grams on both sides.

But that is not all.

We spin the wheel in any direction and see that after it stops, the weights should be at the bottom. With this we found out the point of necessary balancing. If the result is different, select heavier weights, but do not overdo it.

Having achieved the result, move the weights to the right or left from the last point. It is necessary to ensure that the wheel stops at different positions of the point.

Now move on to the rest of the wheels and proceed in the same sequence.

How do professionals work?

In professional workshops, wheel balancing is performed on special computer-controlled machines. Human participation in such work is minimal.

Laser equipment accurately determines the installation location and weight of the required balancers. In this case, all data is displayed on the monitor screen.

This balancing allows you to eliminate any type of runout of the wheel and disk assembly.

Conclusion

Remember that wheels need periodic balancing, and the technical condition of the vehicle and your health directly depend on this.

You need to understand that self-balancing wheels does not give an accurate result, only modern high-tech equipment can give an ideal result, and you can only find it in a good car service center.

Video Wheel Balancing:

Readers asked to tell us about the device that was used in the USSR to balance wheels during self-balancing.

Everything ingenious is simple! This is how you can describe the principle on which the operation of the device is based.

It consisted of two parts - a support and a “top”, which was installed on the hub in the area of the central hole.

Next, the wheel is mounted horizontally on the support. If there is an imbalance, it will tilt towards the heavier part. The task is to place the weights on the rim so that the wheel takes a horizontal position (parallel to the surface on which the support stands). That's all!

In practice, such a simple device provided a completely acceptable level of balancing - at least the wheels did not subjectively “beat”.

This was the so-called static balancing.

But there were also devices for dynamic balancing!

Our car needs harmony and balance not only in the figurative sense, but also in the direct sense. Without balancing, not a single rotating part will work correctly, and in the worst case, it will simply smash the entire assembly or assembly into pieces when the vibration frequency enters into resonance with the vibrations of other parts. Therefore, designers try their best to balance all rotating parts. This applies to driveshafts, crankshafts, flywheels, axle shafts and, of course, wheels.

Types of imbalance

And in order to understand the methods of balancing, you need to know the enemy in person, that is, imbalance. Taking into account the simple laws of physics, one can guess that imbalance can be of two types - dynamic and static.

- Static imbalance occurs when the wheel's center of gravity moves away from the axis of rotation. The simplest type of imbalance and do-it-yourself wheel balancing is most often aimed at eliminating static imbalance. The wheel vibrates up/down.

- Dynamic imbalance is the case when it can only be caught when the wheel rotates, and at fairly high speeds, close to operating conditions. This type of imbalance is characterized by a displacement of the center of gravity of the wheel not only beyond the axis of rotation, but also by an uneven displacement of several centers of gravity relative to each other in a perpendicular plane. The wheel wobbles and vibrates. The diagram will explain this more simply.

It turns out that it is not for nothing that every tire shop has stands for wheel balancing, since any vulcanization is, although minimal, a shift in the center of gravity of the entire wheel, which must be balanced. The cost of balancing wheels on a machine is pennies, but if it is not done, the consequences can be the most depressing.

Why balancing is needed

Uneven tire wear or damage to the disc leads to imbalance, that is, an imbalance in the distribution of wheel mass relative to the horizontal and vertical planes. There are two types of imbalance:

- Static, when the axis of rotation shifts relative to the axis of inertia and begins to move the center of gravity up and down.

- Dynamic, when the axis of rotation intersects with the axis of inertia, disrupting the horizontal distribution of the wheel mass. The disk makes a figure eight while the car is moving.

There are two types of imbalance: static and dynamic

Imbalance causes the wheels to vibrate while driving. Wheel imbalance, especially when driving at high speed, worsens handling, increases the braking distance, and leads to premature wear of chassis parts.

Unbalanced wheels cause loss of control when driving at high speed. But even if an accident does not happen, constant vibration causes the hub bearing to become unusable, and over time, the entire chassis system of the vehicle breaks down.

The purpose of the procedure is to restore balance to the wheels during rotation. The result of balancing is a uniform distribution of wheel mass relative to the axes of rotation.

DIY wheel balancing technology

The simplest and most accessible method of static balancing is available to anyone who is able to hang a car on a jack. Moreover, it is recommended to check wheel balancing after each wheel replacement, regardless of whether it has been balanced before or not. And it couldn’t be easier to do this.

- The car is hung on a jack, after which one of the wheels should rotate freely on the hub.

- The wheel spins slightly, if the brake pads are in the way, you need to negotiate with them so that they do not prevent the wheel from rotating completely freely. The same goes for the wheel bearing. Sometimes it becomes necessary to let it go, and after balancing, do not forget to tighten it again.

- The wheel rotates freely in one direction, and the place that will be at the bottom is marked with chalk. The wheel spins in the other direction. The corresponding mark is placed again. And so - several times. If the marks never coincide, the wheel does not need static balancing.

- Otherwise, a weight is installed on the side of the wheel diametrically opposite the mark. The mass of the weight is selected empirically, since the exact weight of the weight cannot be determined by eye. Only a tire balancing stand can do this.

Read also: Polishing attachment for grinder

Congratulations. The static balancing of one of the wheels is completed, now you can begin balancing the rest. Upon completion, sea trials must be carried out. As a rule, an unbalanced wheel begins to vibrate at a speed of about 70-90 km/h.

By the way, the simplest balancing machine can be assembled around an old hub in which the bearing has not yet died. You just have to install the homemade stand perfectly evenly in all planes. Balanced wheels for all and a pleasant driving experience!

Balancing machines detect irregularities on parts during rotation and help eliminate them. Most often, devices with this operating principle are used in tire shops. In addition, these devices have found application in the mechanical engineering industry, where they help balance propellers, turbines and other parts.

Such devices may be equipped with equipment to automatically correct irregularities. In this article we will talk about calibrating a balancing machine with our own hands and describe its structure.

Have a great day everyone! In this post I will talk about how to balance a wheel if you are in self-isolation and don’t want to go to a tire shop

Why did I do this?

Suddenly the tires were blown down to the cord, I saw this at the dacha. It was scary to drive one. I ordered a rear tire from SDEK. I decided that rather than removing the wheel and taking it to a tire shop in the nearest town, it would be easier to change the shoes myself. The only problem is how to balance the wheel? I didn’t really want to buy a machine for 5 thousand, if I was going to buy it, it would be with all sorts of probes, and that’s far from 5 thousand... In short, it was decided to do it myself! Besides, no one, alas, will do it the way he himself does. They won’t put a siding cover under the mounting so as not to scratch the disc, they won’t wash everything inside with kerosene, they won’t put lubricant in each nipple of the spokes under the rubber band, and so on.

By the way, since we’re talking about something cut from siding... I started working with this Chinese... device. Do not buy. It is thick and soft, it breaks with installation in a couple of movements, it is inconvenient to insert, and difficult to rearrange. If anyone is interested, I’ll take a photo of the siding overlays.

UPD: And here are the pieces of siding. They work great, they don’t interfere with removing the tire, the mounting glides on them better, they don’t have holes, the price is minuscule. Cut from the bottom of the siding, from where it clings to the previous row.

Choice of design.

Typically, static balancing stands have a body like this, on which two pairs of bearings are mounted. The products are, as a rule, factory-made, made with a precision inaccessible to my hands . When welding, something would almost certainly fail; I don’t have a fleet of machines, not even a single drilling machine - and that’s not it.

The products are, as a rule, factory-made, made with a precision inaccessible to my hands . When welding, something would almost certainly fail; I don’t have a fleet of machines, not even a single drilling machine - and that’s not it.

In general, I decided that it was almost impossible to accurately install two pairs of bearings so that they would contact the same balancing axle using the means available to me. The second point is that for normal operation they need an axle on which cones are installed that center the wheel. These cones must fit tightly to the axis itself and not dangle, otherwise there is no point in this work. The axle with cones is in my case the most expensive structural element, because I don’t have not only a drilling machine, but also a lathe, as a result of which I decided to abandon this part of the design. There is a video on the Internet where a friend makes a similar machine for balancing a wheel on a motorcycle axle instead of an axle with movable cones, but this design has a number of disadvantages: 1) It cannot balance wheels of different widths and different axle lengths. Accordingly, something needs to be done to regulate the width. 2) On my motorcycle, the front axle has different diameters on the right and left, but the rear axle has the same diameter. Accordingly, it is necessary to make some kind of gadget to regulate the height.

I decided that it would be better to make the pairs of bearings suspended and movable. In this case, they themselves will be centered on the axle, and the wheel can be installed horizontally due to the suspension. And then, the influence of a precisely aligned horizontal axis on the balancing result should be minimal, so you don’t have to bother too much with this.

I estimated the dimensions and the next day I went to SDEK for a tire, a construction market and an auto parts store. Actually, you don’t have to worry about the sizes and do it somehow. The only thing that is important is the distance between the bearing axes, symmetry, and that the hole in the center is enough to insert the axle.

Preparation

What will you need? Materials: 1) 4 bearings - 360 rubles in a car store. 2) 6 bolts, 6 nuts and half a handful of washers - about 80 rubles for everything. 3) Two slings for securing the load - about 100 rubles. 4) Something from which the body can be cut. Looking ahead, it is advisable to take something metal sheet so that the thickness is smaller and the structure itself is more compact. Or, as an option, plexiglass. But I found a piece of plywood in the barn. Total amounted to 600 rubles. Tools: 1) Drill with drill bits for bolts and an attachment for drilling a large hole. Well, or instead of a nozzle, you can cut it out with a jigsaw. 2) A jigsaw with a file according to what the body will be made of. 3) There’s probably no need to talk about ruler/calipers and wrenches

Well, or instead of a nozzle, you can cut it out with a jigsaw. 2) A jigsaw with a file according to what the body will be made of. 3) There’s probably no need to talk about ruler/calipers and wrenches

Manufacturing

Marked the plywood, drilled holes, cut it out. Using sandpaper (not to be confused with sandpaper!!!) I removed the burrs. Oh, by the way, another instrument... Well, God bless him. Inserted the bolts into the holes and installed the bearings. Be sure to install washers on both sides of the bearing so that the center of the bearing is stationary and the outer part rotates freely. Tightened the bolts. At first I thought that the fact that the diameter of the bolt did not correspond to the inner diameter of the bearing would be a problem (the required bolt was not on the market), but it turned out that this was even better: you can set the position of the bearing before tightening. Although I can’t say that it’s very necessary: the device is self-centering. The final touch is to insert the bolts that will hold it all in place.

Application

In this case, I was balancing the rear wheel, which has a constant axle, so I simply leveled both parts. Using straps to secure the load turned out to be quite convenient. The width of the structure is adjusted by moving the straps along the beam. And, in fact, the balancing process itself: insert the wheel, it turns with its heavy point down.

Using straps to secure the load turned out to be quite convenient. The width of the structure is adjusted by moving the straps along the beam. And, in fact, the balancing process itself: insert the wheel, it turns with its heavy point down.

Attach the load from above, turn it 90 degrees, release it, it turns again with the heavy point down, etc. My balancing is done by attaching weights to the spokes; they are quite convenient to rearrange, so as soon as there are 3 of them, you can rearrange them all and play with the position of the common center of gravity. As soon as the wheel remains in place when turning to any angle, the result is achieved. This photo clearly shows why it is advisable to make the structure thinner and without bolt heads protruding towards the wheel. The sensitivity of this miracle device was tested with silicone fish and is about 16 grams at 18 radius, which is also the diameter. The balancing result seemed sufficient to me. I don’t feel any beats at speeds up to 160; I usually don’t drive any higher. I hope it is useful to someone

Structure of the apparatus

The basis of a balancing machine is the supports on which the workpieces and sensors are installed to determine their balance. During testing, the level of imbalance is determined, and based on this information, further actions are taken.

Depending on the type of support, balancing machines are divided into soft and hard. The first measure the parameters of the wheel, taking into account the vibrations of the supports. At the same time, the device is additionally configured for each detail, which allows for fairly accurate testing.

In both the first and second versions of the device, the speed sensor plays a special role. No less important for such a machine is the sensor that measures the rotation angles. Depending on the information input option, balancing devices can be manual or automatic.

Balancing methods

Using the advice of experienced drivers, you can carry out balancing yourself the old fashioned way without using a special machine. This will take more time than a service technician would spend, but it will help save money.

If desired, wheel balancing can be done independently in a garage.

To perform the procedure yourself, you will need the following equipment and materials:

- jack;

- balancing weights;

- chalk or marker;

- a set of keys.

Interesting! To balance wheels on cast or forged wheels, it is advisable to purchase self-adhesive weights. But in winter, such weights can come unstuck due to temperature changes.

Balancing weights are required for balancing

Without removing the wheel

The self-balancing process consists of the following steps:

- Preparatory. The wheels are cleaned of dirt and stones stuck in the tires, the caps are removed, the pressure in the tire is reduced, and old weights are removed. The jack is installed on one side of the vehicle, freeing 2 wheels. Check the free rotation of the wheels. If the wheel is difficult to spin, you need to undo the cotter pin and loosen the hub nut.

- Determination of an easy point. The wheel is turned counterclockwise and waited for it to stop. Mark the top point. Then turn the wheels clockwise and mark the top point again. The midpoint between the two marks is the light point.

- Installation of weights. Using a hammer, weights weighing from 10 to 45 grams are placed on the found point, starting with the light ones. After this, they spin the wheel and wait for it to stop. The weights should be at the bottom. If it turns out wrong, the light weights are removed and heavier ones are added. It is not recommended to use more than 60 grams of weight on one wheel.

- Static balancing. As soon as the weights are at the bottom after stopping, they begin to move them apart in different directions. The wheel begins to rotate and the weights move apart. The goal of the process is to ensure that the wheel stops in a different position each time. Once this starts to happen, the weight is distributed evenly, that is, static balance is achieved.

The procedure is carried out in this sequence with each wheel. To check the correctness of the balancing, you need to drive the car at least ten kilometers at a speed of more than 90 km/h. If you don’t feel any jolts or tapping while moving, it means everything was done correctly. If the procedure is performed incorrectly, specific shocks to the steering wheel appear.

For your own confidence, at the first self-performed balancing, you can undergo diagnostics at a service station. If the specialists confirm that everything was done correctly, in the future you can carry out the procedure yourself.

Important! Self-balancing in the garage is only permissible if there is a static imbalance. Eliminating dynamic imbalance requires the use of equipment. Experts recommend contacting a service center if your car has worn tires and old bent wheels. Without special equipment, it is impossible to balance such wheels yourself.

At a homemade stand

You can make the balancing process easier by making a homemade stand in the garage. In this case, you do not have to remove the brake pads from the wheel and loosen the step nut.

A homemade stand simplifies the process of wheel balancing

The stand is mounted from an old hub with a working bearing. The hub is installed on the frame so that the wheel rotates freely and the entire structure is firmly held on the surface. It is convenient to use vertical metal posts as a frame, between which the wheel is attached. Further balancing actions coincide with the previous method of performing the procedure.

On the machine

Even an experienced motorist in a garage carries out balancing “by eye”. Therefore, there can be no complete confidence in the correctness of the process. In specialized workshops, balancing is performed on computer-controlled machines.

Modern service stations are equipped with CNC balancing machines

The machine consists of a cone-shaped support for mounting a wheel, a rotating electric motor and sensors. The wheel rotates when performing tire mounting, and at the same time the computer detects vibration and pressure. Sensor readings help to accurately calculate the weight and location of weights.

The workshops are equipped with two types of machines:

- Manual - in which the master measures the wheel with a ruler and manually enters the data.

- Automatic - information is read by sensors and displayed on the monitor in digital or graphical form.

Based on the type of supports used, machines are divided into:

- Soft, measuring wheel parameters, taking into account the vibrations of the supports.

- Rigid, measuring pressure and rotor phase.

Interesting! On rigid machines you can test various parts, but the quality and accuracy of measurements is reduced for this reason.

Most modern services are equipped with automatic balancing machines. The master puts the wheel on the shaft, tightens it with bolts and unscrews it. Sensors determine the points of axial runout. The computer determines the intensity of the push and calculates the mass of the load that must be attached to the calculated point. The computer will also inform you if the wheel cannot be balanced.

Balancing with granules

One of the newest methods of wheel balancing is the use of special granules instead of weights. The essence of the technique is to pour special granules into the tire, which slide while driving in the internal space. This free movement eliminates imbalance when driving at speed.

Modern wheel balancing techniques involve the use of microbeads

The advantage of this method is that the granules are poured once, and they perform their intended function throughout the life of the tire. The disadvantage of this balancing method is the high cost of the granules. Therefore, balancing in this way has not gained popularity at present.

Video: DIY wheel balancing

Principle of operation

The main task of the balancing machine is to determine the balance of the geometric center of the wheel with its mass. An unbalanced part makes any job difficult and can lead to serious damage. Eliminating imbalance allows you to:

- Increase the service life of bearings.

- Prevent premature wear of tires.

- Increase the service life of suspensions.

There are several options by which you can correct imbalance of wheels or other parts:

- Balancing rings - used in the process of repairing metalworking machines.

- Adjusting screws - special pins are screwed into the unbalanced part, through which it is adjusted.

- Drilling is the most popular balancing option. This is done by creating holes that change the weight of the parts being processed.

Read also: Do-it-yourself sandblasting

Homemade balancing machine for car wheels. Do-it-yourself wheel balancing

Not only the comfort of the driver and passengers, but also their safety, as well as the serviceability of other components and mechanisms of the car depend on the condition of the car’s wheels. In addition, it significantly affects fuel consumption.

One type of vehicle chassis maintenance is wheel balancing. Why this procedure is needed, how it is performed and with what frequency, we will explain in this article. We will also consider the possibility of implementing it on our own in a garage.

Wheel balancing: what is it for?

Several thousand years have passed since the invention of the wheel, but even today, in the age of high technology, it is not possible to make it ideal. In addition, during movement it is constantly affected by many factors leading to mechanical deformation.

This applies to both the disk and the tire. The slightest flaws associated with the uneven distribution of their mass around the circumference lead to imbalance. This, in turn, leads to vibration, which has a destructive effect on the wheel bearing and other elements of the chassis.

But is wheel balancing necessary if the car is quite reliable? Here's a simple example: at a speed of 100 km/h and an imbalance of 15-20 g on a 14-inch wheel, the load on the disc will be similar to hitting it with a three-kilogram hammer at intervals of 800 times per minute. Now imagine that you drive 100 kilometers this way. What do you think will happen to the chassis of your most reliable car?

To prevent such situations, the wheels are balanced. We figured out why it is needed. Now let's look at what imbalance is and what types there are.

Making a stand

After prolonged use, individual parts of the device may malfunction. Conventionally, the origin of the breakdown can be divided into mechanical disorders and problems with electrical components. In the latter case, problems with the sensors are detected. Mechanical problems most often occur after falls or strong impacts.

Problems with the machine can be detected by the following signs:

- Normal balancing requires several cycles of operation.

- The parameters of the tested disks are determined incorrectly.

The main task of the balancing machine is to determine the balance of the geometric center of the wheel with its mass. An unbalanced part makes any job difficult and can lead to serious damage. Eliminating imbalance allows you to:

- Increase the service life of bearings.

- Prevent premature wear of tires.

- Increase the service life of suspensions.

There are several options by which you can correct imbalance of wheels or other parts:

- Balancing rings - used in the process of repairing metalworking machines.

- Adjusting screws - special pins are screwed into the unbalanced part, through which it is adjusted.

- Drilling is the most popular balancing option. This is done by creating holes that change the weight of the parts being processed.

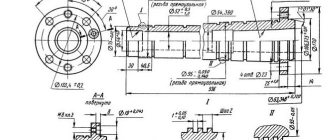

A do-it-yourself balancing machine is made so as not to remove the pads and not touch the hub nut. The work takes place with the wheel removed. To assemble the machine you need:

- Turn the shaft. A thread is applied to one end of it and a place for the cone is prepared. At the other end of the shaft, places for bearings are machined

- The stand is made from a pipe with a diameter of 52 mm. A support table is installed in the middle to support the wheel while being mounted on the shaft.

- Indicators are installed on the side and top of the rack to record wheel runout.

A homemade wheel balancing machine is used as follows:

- Place a clean wheel and tire on it, use a nut and a cone to secure it.

- Check both types of runout with old weights

- Remove the weights, spin the disk

- Mark a heavy place with a plus - it will go down, mark a light place with a minus - it will go up

- Rotate the dial 90 degrees

- In the place where there is a minus mark, install weights on the rim

- Turn the disk 45 degrees - if it remains in this position, then the balancing is complete

- Check the results of the procedure again, secure the weights

There are several options for making machines with your own hands, with the help of which the wheels on a car are balanced. If you have the necessary parts and knowledge of electronics, you can make an automated device. An electric motor is used to spin the disks.

Read more: Film on a car: choosing a coating and how to apply it yourself

Currently, the majority of stands carry out the balancing procedure automatically. The wheel is put on the shaft, clamped with bolts and unscrewed, while the end runout is measured automatically. As a result, the computer identifies problem areas and shows the weight of the weight that needs to be attached to the specified point.

It should be noted that due to the use of a high-tech stand, the process is significantly simplified.

A sketch of the wheel is displayed on a special display and the area where the weight needs to be attached is shown; the technician just has to follow the recommendations and avoid making serious mistakes.

But there are also exceptions; in particularly serious cases, it is not possible to balance the wheel with the help of weights, then the corresponding inscription is displayed on the display.

By attaching a weight of suitable weight, the master thereby gets rid of the uneven distribution of weight, due to which the eccentricity is reduced and the moment of inertia is significantly reduced, and as a result, the runout disappears.

The concept of imbalance and its types

Imbalance is a violation of the normal balance of a wheel caused by tire wear or deformation of the wheel rim. There are two types of this phenomenon: static and dynamic.

In the first case, the axis of rotation takes a parallel position with respect to the axis of inertia, shifting the center of gravity in a certain direction. Visually, static imbalance can be determined by lifting one side of the car, spinning the freely rotating wheel and observing it.

Before it stops rotating, it will make several pendulum movements in different directions and stop when its center of gravity is at the lowest point. Such symptoms are not critical for the car, but are fraught with uneven tire wear and increased fuel consumption.

Whether it is necessary to balance the wheels in this case is, of course, up to you to decide, but over time, a static imbalance can develop into a dynamic one, and then fuel and tires alone will not do the trick.

Balancing machine repair

After prolonged use, individual parts of the device may malfunction. Conventionally, the origin of the breakdown can be divided into mechanical disorders and problems with electrical components. In the latter case, problems with the sensors are detected. Mechanical problems most often occur after falls or strong impacts.

Problems with the machine can be detected by the following signs:

- Normal balancing requires several cycles of operation.

- The parameters of the tested disks are determined incorrectly.

Homemade device

It is possible to make a calibrating machine at home, but only the mechanical part. Electrical equipment and measurement sensors should be purchased ready-made. The device drawings should be selected in accordance with the features of the future use of the machine. The best option for creating a balancing machine is presented in these step-by-step instructions:

- We create a shaft. It should be turned so that at one end there is a ready-made place for mounting bearings, and at the other there is a thread for installing a washer.

- We install bearings. It is best to use those that have already been used, but have not yet used up the main resource. Such parts will create minimal resistance.

- We form the apparatus stand. For these purposes, it is best to use a pipe with a diameter of 5.2 centimeters. At the upper end of the support we mount it from above and from the side.

- For convenient placement of the part, we recommend creating a support platform.

Video: DIY wheel balancing machine.

Nuances of operation

To start working with the machine, you need to fix the disk. This can be done using a nut and a cone. After checking the reliability of the fastening, you can begin measuring procedures. The disk is spun up, and then its performance is compared with the reference ones. Deviations should be in the range of 2 and 1.5 g. The first indicator is horizontal, the second is radial.

After the initial testing, all weights should be removed and repeated measurements should be taken. The disc under test stops at the heaviest point downwards. Be sure to take this information into account when measuring disk parameters. After this, the wheel must be twisted 90 degrees and a load is hung on the opposite side. If the wheel stops rotating when turned 45 degrees, it means that the do-it-yourself calibration was done successfully.