Sawing wood with a chain saw leads to wear on the cutting edge of the saw link, that is, to dullness. This happens quite quickly. Hard knots, remains of earth, and small stones not only dull the chain, but can also lead to deformation of individual elements.

As a result, there is a decrease in productivity, an increase in the load on the saw’s gasoline or electric engine, and increased fuel consumption. Indicators of a dull chain saw are:

- shredding;

- increasing the applied load;

- appearance of dust;

- the cut darkens from overheating;

- the smell of burnt wood.

Chain sharpeners

To restore the functionality of the chain saw tool, a device for sharpening the saw chain links is required. Devices are classified as follows:

- By installation method: mobile;

- stationary;

- factory;

- manual;

Stationary models of sharpening equipment have a rigid mount and are placed in close proximity to the workplace or on a workbench. They are mechanically driven by an electric motor. Mobile devices are distinguished by the fact that the work is done manually, they can be taken with you to a place of work remote from a source of electricity, and also by their small size and weight.

Which is better to choose, manual or automatic?

Owners of chain saws often ask the question of which machine to choose, manual or automatic. It is impossible to answer this unequivocally, because they are completely different, although they are intended to perform the same task.

Alternatively, you can have both machines. Install the electric one permanently in the garage and use it to sharpen chains with serious damage to the cutting edge, for example, those that occur when the chain hits a nail. The manual machine can be taken into the plot, which will make it possible to correct the chain in the field.

Chain teeth

Before considering methods for sharpening chain elements, it is necessary to familiarize yourself with the structure of the link, the shaping and the angles necessary for easy sawing of wood.

Link elements:

- base;

- cutting edges (blade);

- depth limiter.

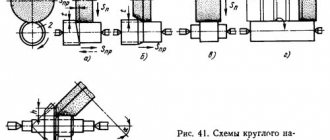

The link blade is equipped with two cutting edges that cut in horizontal and vertical planes. It tapers towards the rear, allowing for miter sawing. The back angle, which reduces energy costs, is set by the back of the tooth.

Proper sharpening creates the necessary angles that form the upper corner, and guarantees increased chain life and the impossibility of its jamming:

- the angle of the edge end relative to the surface being cut is 65° – 85°;

- back angle – 55° – 60°;

- cutting edge cutting angle: for cross cutting - 25° - 35°;

- for longitudinal cutting - 10°.

When turning there are certain rules that must be followed:

- The sharpening angles must correspond to the parameters specified by the manufacturer.

- The overall dimensions of the links after sharpening should not differ.

- The sharpening angle when working in winter or with dense wood should be reduced in order to reduce runout.

Technical parameters of chainsaw chains

It should be noted that the chain pitch directly affects the performance of the sawing tool. Therefore, to perform a large amount of work, it is recommended to choose a chain with the largest possible teeth .

Using a tool like this, the work can be done with less effort and quickly.

Technical characteristics that are important to pay attention to when choosing chains for chainsaws:

- step interval;

- number of links;

- their thickness;

- planned type and scope of work.

The smallest step is 1/4. If a chainsaw is equipped with a chain with this pitch, then it is suitable for performing simple household tasks . She will do an excellent job of cleaning fruit trees, but at the same time she will not be able to cut firewood.

Products from many European and Chinese manufacturers most often have a chain with a pitch of 0.325 and 3/8. A chain with a similar interval can cope with a wide range of work , including the removal of fairly thick trees reaching a diameter of more than two meters.

Steps 0.404 and 3/4. Chains with such an interval are usually equipped with tools for industrial use . Choosing a chain with a pitch within this range is advisable if the sawing tool is needed for frequent sawing of forest, as well as harvesting thick logs or performing tree cutting work.

As the number of links increases, the process of sawing wood becomes easier. Thus, a parameter such as the number of links also needs to be taken into account. However, a more important characteristic is their thickness, which can have the following values: 1.1 mm; 1.3 mm; 1.5 mm; 1.6 mm.

If the tool is intended for domestic use, it is recommended to choose a chain whose teeth have a thickness of 1.3 mm . If a buyer is looking for a tool for logging, it is recommended to choose a chain with a tooth size of 1.5 mm.

In cases where the chainsaw meets the tasks that need to be solved in all respects, however, there is a drop in performance, we can conclude that the reason for this is a dull chain . If poor performance is due to other problems, then the only correct solution is to buy a new chain.

Turning machines

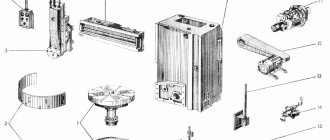

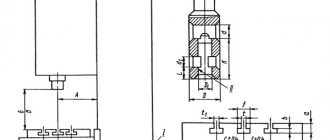

A manual machine for sharpening chainsaw chains consists of:

- a set of round files (2 pieces) of the appropriate diameter;

- template;

- chain clamp on the bar;

- flat file.

The operating principle of the handheld device is similar to a bow saw. Only instead of a blade, the working element is a file. Before starting work, the clamp is attached to the chainsaw bar. All angles along which the file will move are manually set.

The saw blade is locked using the lock. After sharpening, the link is replaced by the next one. Using a rotating mechanism, the position of the file changes. Among the disadvantages of this sharpening method are the long duration of work and the inability in some cases to correct a link defect.

A universal machine for manually sharpening chainsaw chains is preferred by those who work a lot with wood. Such models are compact, operate from a 220 V household electrical network and are equipped with a rotating mechanism designed for several positions.

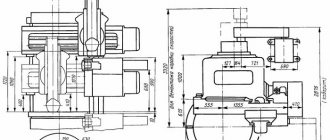

The design includes:

- base;

- Desktop;

- chain holder;

- rotary mechanism with graduated scale;

- electric motor;

- abrasive wheel;

- shield;

- feed handle;

- guide grooves;

- installation and mounting screws;

- setting wedge;

- switch.

Depending on the model of the sharpening machine, fixing and tightening the saw chain can be done manually or automatically. Expensive models have automated feed of the abrasive wheel and sub-adjustment of the feed of links.

Design and main characteristics of the product

Any device must have a base on which a clamping vice is located; in these places the chain is located and secured. There is a special tool on the working surface, through which the material is sharpened. At the same time, it is adapted taking into account the height of each specific tooth.

Saw sharpening device

The device contains a round and flat file, a template for calibration, and a hook for removing sawdust. The first type of file is used for the inner surface of the tooth.

This machine has the following main parameters:

- Power – the optimal indicator is 220 W. You should not pay attention to lower power.

- Dimensions of the working circle - the diameter of the tool ranges from 105–400 mm. It all depends on the material being processed.

- Large circles are installed on industrial devices.

- Additional properties - if the device provides rotation of the grinding head. In this case, sharpening is done with better quality.

- Spindle rotation speed – you need to consider where exactly the machine will be used.

If you choose it for a home workshop, then a device that provides 3 thousand revolutions per minute is enough. This is not enough for industry. In this case, you will need devices with a speed of 4.8 thousand revolutions.

Such equipment is not needed in every household, but if it is required, then it is important to choose the right machine. It all depends on the needs of production or individual farming.

How to make a sharpening machine with your own hands

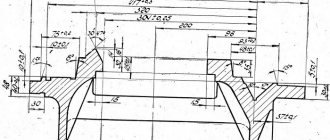

A stationary machine for sharpening chains with your own hands is quite expensive. And some craftsmen are trying to build a self-propelled unit. Making a homemade machine is a troublesome task. To machine and center the adapter between the motor shaft and the abrasive wheel, you will need a lathe.

To make the base (bed), you can take the base of metalwork yews. It already has holes for attaching to a workbench. A rotating mechanism with an adjusting wedge is fixed to the base. A degree scale is applied. The rotating mechanism for fixing at the required angle is equipped with a screw clamp.

An electric motor with an abrasive wheel is mounted on the bracket. For ease of inclusion, the design can be supplemented with a power button. As an abrasive wheel, you can use a grinding wheel with a thickness of 2-3 mm.

To protect against electric shock, metal parts are exposed and not insulated; the design should be equipped with a plastic handle. Use an LED flashlight to illuminate your work area. Since homemade machines are rarely equipped with protective screens, work on sharpening chains should be carried out wearing safety glasses.

On a do-it-yourself chainsaw chain sharpening machine, it is enough to install an 80 W electric motor. The power cable is selected based on the load. It is enough to take a three-core cable with a cross-section of 0.75 mm².

Choosing a good machine, making it yourself or using hand tools is everyone’s business. If you use a chain saw on occasion, then there is no point in purchasing a machine. If you have experience working on a lathe, milling, or drilling machine, then making a simple design for sharpening chains will not be difficult.

How to sharpen teeth with a grinder

If an automated sharpening machine seems expensive, then a grinder can replace it. This tool should be used as a sharpening machine if you have extensive experience working with angle grinders. If you work with an angle grinder incorrectly, it can not only harm your health, but also the chain itself, the teeth of which will be incorrectly sharpened.

The principle of sharpening with an angle grinder is as follows:

- The chain remains on the tool

- The sharpening angle is visually selected

- The tool is turned on at half power using a connected voltage regulator

Each tooth must be sharpened with a grinder. If the angle is chosen incorrectly, it will be possible to determine this already at the first launch of the tool.

Advice from professionals

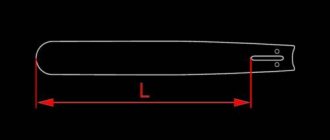

The new chain must be run in so that the mating parts get used to it. At low speeds for a minute, the lubricant will fill the channels on the tire.

Particular attention should be paid to chain tension. Weak tension leads to collapse and the load increases, which can lead to link rupture.

Monitor the level of oil intended for lubrication of the chain, bar, and sprockets. The lack of lubricant leads to increased wear of the chainsaw elements.

After work, clean and generously lubricate the chain with clean oil.

Useful recommendations from experts

To prevent premature chain wear, you need to follow the advice of experts. Experienced professionals advise:

- break in the chain before sharpening. To do this, you will first need to run the headset at low engine speeds. After complete cooling and restoration of the chain, you will need to adjust it on the bus;

- regularly inspect the saw element, paying attention to its tension and condition. When sawing wood, when the chainsaw is tilted to one side, the saw set takes on increased loads. Due to poor tension, the cutting teeth may become unusable;

- remove shavings and other wood waste from the cutting set in a timely manner;

- try to prevent the chain teeth from getting on nails and other hard objects;

- sharpen the saw element on time - if the chainsaw is not used regularly at home, the operator will only need one procedure per 3 months of use. If the tool is intensively used in forest felling, then the headset will need to be restored at least once every 2–3 weeks;

- Do not use the chain immediately after sharpening it. The headset needs time to cool completely. If necessary, the process can be accelerated by using compressed air cylinders. Before installing the part back onto the tire, it will need to be dipped in clean oil. This will make the cutting element more mobile and significantly extend its service life;

- Use only high-quality branded oils for lubrication. Filling with used lubricants is not allowed.

The owner of a chainsaw needs to remember that the condition of the cutting element largely depends on the storage conditions of its operation. If the headset is stored in a damp room, this will lead to rapid wear of its cutting teeth and the formation of rust on them. To prevent this, you need to choose only dark and completely dry rooms for storage.

How can you tell if a chain is dull?

There are several signs by which you can understand that the chain is currently not suitable for operation:

- You need to put in more physical effort for the same action.

- Feeling of vibration when working with a tool.

- The unevenness of sawdust, which, moreover, becomes more like dust.

Chain stretching.

The chain can also become dull for several reasons:

- Mishandling.

- Contact with objects that are too hard, such as stones.

- Too voluminous and long-term work.

Review of popular sharpeners

There are a large number of chain sharpening machines on sale, which, in fact, differ only in name and manufacturer. From a technical point of view, most of the machines that can be found on sale are practically no different. This applies only to household models, in the price category up to 4000-5000 rubles.

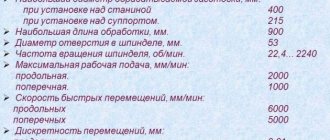

Kraton CSS-180

Main characteristics of the machine:

- power 180 watts;

- rotation angle of the chain guide, 35 degrees to the left and right;

- operating voltage 220 volts;

- disc mounting hole diameter 10 mm;

- maximum circle diameter 100 mm;

- rotation speed 3000 rpm.

The machine is equipped with a transparent plastic protection. The base is stable, cast from aluminum alloy.

It is characterized by small dimensions and weight. Assembled in Russia, but parts are supplied from China. This model is classified as a household model, which means it is not intended to perform large volumes of work. The cost is within 3000 rubles. Similar machines can be found under the brands Caliber, Vikhr, Rezer, Oregon.

ANAB X1

The professional automatic device ANAB X1 has the following characteristics:

- sharpening motor power 0.3 kW;

- pneumatic 6 bar;

- power supply 220 volts;

- sharpening angle 35 degrees;

- rotation angle 28 degrees;

- pitch of sharpened chains 1/4″, 325″, 3/8″, 404″.

Below you can watch a video of how the ANAB X1 machine works.