performs laser cutting and bending of sheet metal to order using high-precision equipment. We produce parts of complex shapes from steel of any grade and alloys based on copper, aluminum, black steel, and stainless steel. We perform laser cutting of pipes and sheet materials. The technology makes it possible to obtain high-quality products at minimal cost in a short time. This will help our customers increase the pace of production and project implementation.

We offer metal laser cutting services in Moscow and the Moscow region at the best prices in the region. Finished products are delivered to customers by leading transport companies. CNC machines, which are characterized by high productivity and precision of operations, help us reduce the cost of work per linear meter. The absence of defects increases the profitability of equipment operation. The cost of laser cutting depends on the material being processed, the configuration of the final product, and the order volume. Our company offers transparent pricing for each client. You can find out the price of the service by phone or using a convenient application form.

Laser cutting is a material cutting and cutting technology that uses a high power laser and is typically used on industrial production lines. Laser metal cutting is one of the latest, modern and high-quality types of metal cutting. The company provides ]laser cutting of pipes[/anchor], sheets and other materials - profitably, efficiently and quickly.

How does the process work?

The cutting beam is formed using an electromagnetic field and carbon dioxide molecules. It has high power, and, leaving a resonator with a diameter of 12 mm, is focused, concentrating the energy into a beam with a diameter of only 0.15 mm. This allows you to instantly burn through metal and cut it at high speed. This achieves high cutting precision and a perfectly smooth edge.

Laser cutting technology consists of the following stages:

- The sheet of metal being processed is placed on the work table.

- The pipes are secured in a special clamp.

- The cutting laser head is directed to the desired point.

- The temperature parameter is set to begin the melting process.

- The metal heats up, boils and evaporates at the desired point.

Types of laser cutting

Laser equipment used in modern metalworking has different classifications. Depending on the type of working fluid used in the machine, units are divided into solid-state, gas and gas-dynamic. Their power is 6, 6-20 and 20-100 kW, respectively.

Important! In installations of the first type, ruby plays the role of a solid body.

As an alternative, it is possible to use special glass with additives.

Such lasers are capable of creating a powerful pulse literally in a matter of moments, and their operation is possible not only in a pulsed mode, but also in a continuous format. The operation of devices of the second type is carried out through the use of a gas mixture, which is preheated to the required level through the action of electric current. Due to the energy obtained in this case, the directed flow of gases acquires its directionality and becomes monochrome. The mixture itself includes nitrogen with helium and carbon dioxide.

If we talk about the third type of equipment, then such units are also gas lasers operating under carbon dioxide conditions. Once heated, it passes through a narrow passage with rapid cooling and expansion at the same time. It is at this moment that a powerful energy flow is released, which ensures cutting of even the thickest workpiece. This laser cutting of metal to order allows you to obtain the highest cutting precision. The equipment is characterized by high power, but at the same time it is quite economical.

Areas of use

- The absence of mechanical contact allows the processing of fragile and easily deformable materials;

- Materials made of hard alloys can be processed;

- Processing of round and square stainless steel pipes;

- High-speed cutting of thin sheet steel is possible;

- When producing small batches of products, it is more expedient to laser cut the material than to make expensive molds or casting molds for this;

- Manufacturing of fittings, equipment, ventilation grilles, profiles;

- Production of decorative parts of small architectural forms, doors.

Laser cutting of metal is the company's most popular service. A professional approach will allow you to complete your tasks quickly and reliably.

Selection of gas medium

High-quality artistic laser cutting of metal requires careful selection of the optimal gas environment.

Experts advise carrying out the work process in an oxygen or nitrogen-filled environment. Oxygen is successfully used when processing low- and medium-alloy steel. The only exceptions are parts that require further staining along the sections. When oxygen hits the base of the workpiece being processed, it begins an oxidation reaction of the metal with the simultaneous release of a certain amount of heat. Due to this, the overall cutting temperature increases. This makes it possible not only to increase the processing speed of products, but also to increase the thickness of the workpieces themselves. Also, in a number of situations, this technology promotes partial evaporation of the metal (its sublimation). The presence of impurities in the composition significantly complicates cutting and slows down its speed. Therefore, whenever possible, it is worth using the purest possible oxygen.

Laser cutting of metal using nitrogen is just as popular in Moscow. It is indispensable when working with stainless steel alloys and high-alloy steel. After all, these cutting materials require exclusively inert gases. And nitrogen is best suited for this.

Also, the choice in favor of such a gas is relevant for further staining of the formed sections. This can be not only powder painting, but also finishing with other paints and varnishes. If increased demands are placed on the accuracy of the profile being formed, then the use of nitrogen is useful when working with workpieces thicker than 2.5 cm. But it is worth remembering the need to increase the nitrogen pressure in the system as the thickness of the workpiece increases.

Processed materials

Any steel of any condition, aluminum and its alloys, and other non-ferrous metals are suitable for laser cutting. Typically used sheets and pipes of the following metals:

| Black steel | Stainless steel | Copper | Brass | Aluminum |

- Steel from 0.2 mm to 30 mm

- Stainless steel from 0.2 mm to 12 mm

- Aluminum alloys from 0.2 mm to 20 mm

- Brass from 0.2 mm to 12 mm

- Copper from 0.2 mm to 15 mm

Laser cutting of metal at the Nateko company's production is performed on a CNC machine LM 3015SR.

Laser cutting complex LM 3015SR (cutting sheets 3000*1500mm and pipes 6000mm, ⌀ 20-220mm)

Features of cutting different metals

The processing process for different metals has certain differences.

Here it is important to take into account all the advice and recommendations of the equipment manufacturer to obtain a finished product of the highest quality with minimal time and labor costs. If we talk about copper, then this material is characterized by fairly high thermal conductivity, and cutting should be performed exclusively at low laser speed. But with the maximum permissible power of the radiation generated in this case. If these rules are not followed, the edge being formed may be seriously damaged.

Laser cutting of aluminum, which is so often used today, is characterized by the greatest complexity of the production process. It's all about the uniqueness of this alloy. Cutting requires quite serious energy costs and the mandatory addition of gas equipment to the laser installation. Only in this case can you count on a smooth and maximally clean edge without the least damage and defects.

Important! Processing stainless steel requires the mandatory use of nitrogen as a protective medium.

This is the only way to guarantee a perfectly clean cut without any traces of scale.

But it is worth remembering that the power of the generated energy beam depends on the thickness of the workpiece. The larger it is, the more powerful the radiation should be. Accordingly, the overall cost of laser cutting of stainless steel increases. The use of lasers when working with brass is becoming increasingly popular today. And not only at large production facilities, but also when producing small batches of products. It is not surprising that the demand is so high. After all, this material is characterized not only by increased resistance to corrosion processes, but also by a relatively low cost. Moreover, brass does not require the use of overly powerful equipment or specialized settings of the laser unit. A standard configuration and a correctly loaded drawing are sufficient to obtain the required result.

You also can’t ignore titanium. Its processing is carried out in a protective environment based on inert gas. Although the gas environment eliminates the slightest possibility of metal ignition. The specific technology does not in any way affect the cutting efficiency or the quality of the resulting profile.

Ferrous metal and galvanized steel are cut using an oxygen environment.

Prices for cutting black steel

| Thickness, mm | Contour length up to 100 m, rub. | From 100 m, rub. | Cost of one plunge, rub. | Special prices |

| 1 | 40 | 26 | 5 | call |

| 2 | 54 | 40 | 5 | call |

| 3 | 68 | 54 | 5 | call |

| 4 | 82 | 68 | 5 | call |

| 5 | 96 | 82 | 5 | call |

| 6 | 110 | 96 | 5 | call |

| 8 | 138 | 124 | 5 | call |

| 10 | 198 | 184 | 5 | call |

| 12 | 258 | 244 | 5 | call |

| 14 | 318 | 304 | 10 | call |

| 16 | 378 | 364 | 10 | call |

Stainless steel cutting prices

| Thickness, mm | Contour length up to 100 m, rub. | From 100 m, rub. | Cost of one plunge, rub. | Special prices |

| 1 | 44 | 28 | 5 | call |

| 2 | 60 | 44 | 5 | call |

| 3 | 76 | 60 | 5 | call |

| 4 | 92 | 76 | 5 | call |

| 5 | 108 | 92 | 5 | call |

| 6 | 124 | 108 | 5 | call |

| 8 | 156 | 140 | 5 | call |

Aluminum cutting prices

| Thickness, mm | Contour length up to 100 m, rub. | From 100 m, rub. | Cost of one plunge, rub. | Special prices |

| 1 | 48 | 30 | 5 | call |

| 2 | 66 | 48 | 5 | call |

| 3 | 84 | 66 | 5 | call |

| 4 | 102 | 84 | 5 | call |

| 5 | 120 | 102 | 5 | call |

Prices for cutting brass

| Thickness, mm | Contour length up to 100 m, rub. | From 100 m, rub. | Cost of one plunge, rub. | Special prices |

| 1 | 52 | 34 | 5 | call |

| 2 | 70 | 52 | 5 | call |

| 3 | 88 | 70 | 5 | call |

| 4 | 106 | 88 | 5 | call |

| 5 | 124 | 106 | 5 | call |

Copper cutting prices

| Thickness, mm | Contour length up to 100 m, rub. | From 100 m, rub. | Cost of one plunge, rub. | Special prices |

| 1 | 50 | 32 | 5 | call |

| 2 | 68 | 50 | 5 | call |

| 3 | 84 | 68 | 5 | call |

| 4 | 104 | 84 | 5 | call |

| 5 | 122 | 104 | 5 | call |

Dimensions of the table for cutting sheets are 4760*4048*1950mm.

Favorable terms of cooperation for large customers. The company offers laser cutting services for various metal structures, profiles, sheet metal, pipes, etc... The work is carried out quickly, efficiently and at an affordable price.

Comparison of laser and plasma cutting

There are major differences between laser and plasma cutting.

- Metal thickness.

This is the main parameter that distinguishes the two cutting methods. Laser cutting has no competitors when working with metals up to 6 mm thick. With greater thickness, the speed of work slows down, and laser cutting is rarely used for cutting metals thicker than 20 mm. Plasma cutting is effective for material thicknesses of 20–40 mm. Can be used for cutting copper up to 80 mm thick, cast iron up to 90 mm, aluminum and its alloys up to 120 mm, alloy and carbon steels up to 150 mm. - Taper of cut.

When laser cutting metal with a thickness of more than 6 mm, an edge taper of about 0.5° appears. For this reason, the lower part of the resulting holes has an increased diameter. For plasma cutting, this parameter is larger – 3–10°. When making holes in this way, their output diameter is smaller than the inlet diameter. - Temperature effect.

Laser cutting is characterized by a small temperature affected zone. Plasma cutting exposes metals to high temperatures, and sheets up to 0.5 mm thick can warp. - Cutting quality.

The leader in this parameter is laser cutting. It is characterized by a stable and precise cut, as well as excellent edge quality. When using plasma cutting, scale is formed and the edges need to be reworked.

Comparative characteristics of both methods of cutting metals are given in the table below:

| Parameter | Laser cutting | Plasma cutting |

| Cutting width | Stable from 0.2 to 0.375 mm | Varies due to arc instability ranging from 0.8 to 1.5 mm |

| Cutting accuracy | High ±0.05mm | Varies depending on equipment wear ranging from ± 0.1 to ± 0.5 mm |

| Cutting taper | No more than 1° for metal thickness more than 6 mm | From 3° to 10° |

| Cut perpendicularity | Provided | The cut tapers at the bottom, so the edge is smoothly rounded |

| Edge quality | High | Scale needs to be removed |

| Temperature effect | Low in a limited area | High. Thin metals may warp |

| Performance | High for metals no thicker than 6 mm. Decreases with increasing sheet thickness | High for metal thickness up to 40 mm. Decreases with increasing sheet thickness |

The price for laser cutting is from 26 rubles/linear meter.

The minimum price for work is 5,000 rubles. The cost of cutting is determined according to the drawing and depends on:

- complexity of the part;

- circulation of parts;

- type of metal;

- thickness of the metal sheet.

For ease of use of our resource, we provide a metal laser cutting calculator. It will easily allow you to estimate the approximate cost of manufacturing the products you need.

You can order a service by contacting our company by phone, sending a request by email, or filling out a request form on the website by clicking the button below.

This is interesting:

“How laser cutting works” “Types of laser cutters” “Laser engraving and marking”

Laser cutting technology

The workflow itself is not particularly complex and consists of only a few fairly simple intermediate steps. Here they are:

- The laser source is directed to the starting point of the cutting line;

- The metal is heated to the required temperature level with its subsequent melting;

- At the border of the melted zone, a small depression is formed;

- After a certain period of time, the material begins to boil and local evaporation occurs at the site of exposure to the emitter.

After this, the beam moves to a new area and everything repeats from the very beginning.

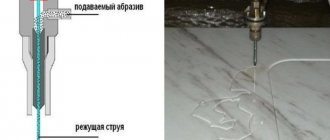

But there is one important aspect. The described technology is effective only when the thickness of the workpiece being processed is insignificant. When working with thicker steel products, a pressurized gas supply is required to remove any remaining melted material.