Home |Technique and materials |Homemade machine for the production of building blocks with your own hands

Date: October 6, 2018

Comments: 0

The modern building materials market offers a wide range of wall blocks. But not everyone knows that it is quite possible to reduce the cost of building a private house, cottage, garage or utility room. Instead of buying bricks or cinder blocks, it’s enough to start making them yourself. To do this, you need to use a machine for producing blocks, and if the budget does not allow, you need to make a vibropressing machine yourself.

Inexpensive factory models of vibrating machines are not characterized by high productivity, but for private use this is not required. True, buying a machine to build a small house, which will require about a thousand standard-sized blocks, will not be entirely profitable. Therefore, as an option, you can consider renting equipment for a certain period. This will be enough to procure building materials for future use.

Factory machine for making building blocks with your own hands

In settlements with a small population, you may not be able to find a company that provides machines for the production of building blocks, but there are craftsmen among your friends who are ready to offer homemade equipment or share the secrets of its manufacture.

Types of building blocks

Brick is still the main material in the construction of high-rise buildings, but for low-rise construction it is cheaper to use other building materials. If you exclude wood, which is now expensive, the choice will still be varied. Modern wall materials are made from:

- foam concrete;

- slag concrete;

- aerated concrete;

- expanded clay concrete.

Block characteristics comparison table

As a filler for cinder blocks, a variety of and sometimes exotic materials are used, which are industrial waste: screenings, broken glass and bricks, sawdust, wood chips.

Let's first consider how expanded clay blocks and cinder blocks are made independently, as the most budget-friendly among all the above building materials.

[testimonial_view id=”4"]

What is the best way to fill the forms?

If you are setting up the production of cinder blocks at home, know that there is no universal composition; each master selects his own unique recipe, which is more suitable for a particular bathhouse and which depends on the existing slag. But the standard cinder block recipe is as follows: 7 parts slag, 2 parts sand and 2 parts gravel, 1.5 parts good cement (grade M400) and from one and a half to 3 parts water. The accepted dimensions of a cinder block are 39x19x20 cm, but dimensions of 40x20x20 cm are also used in private construction.

In addition to the slag itself, ash, other coal combustion waste, gravel, processed sawdust, perlite, stone and granite screenings, gypsum, broken bricks and the like are used as fillers for such blocks. For greater plasticity of the blocks, a plasticizer is also added - this is 5 grams per block, during vibration casting. For what? It is this substance that significantly increases the strength of the block, its frost resistance and water resistance, and eliminates cracks.

You need to measure the amount of water especially carefully: the blocks should not spread during removal. You can conduct the following test: if the solution crumbles when it falls to the ground, but comes together in your fist, this is what you need. By the way, concrete for the construction of a small bathhouse can be prepared manually, but for a more serious structure it is better to initially acquire an electric concrete mixer designed for a volume of 0.2-0.5 cubic meters.

DIY expanded clay blocks

If there are no problems with expanded clay in your region, you can consider yourself lucky: expanded clay concrete, despite its cheapness, is rarely found on sale, but this building material is characterized by a whole range of positive properties. To make expanded clay blocks you will need:

- expanded clay itself;

- cement;

- sand;

- water.

The main material for creating the mixture will be fine expanded clay

When mixing the solution, it is important to adhere to a certain sequence: expanded clay is added to the water, then cement, and finally sand. The proportions of the solution are as follows: for nine liters of water, use 54 kg of expanded clay, 9 kg of cement and 27 kg of sand. The result will be a mixture weighing about 100 kilograms, with the yield of finished blocks in the amount of 9-10 pieces.

Manufacturing technology of expanded clay concrete blocks

If it is not possible to use a specialized machine (such equipment is not cheap), expanded clay concrete can be produced on a non-industrial scale using special matrices. You will also need an appropriate container for the solution, a flat area and formwork made of wood or metal in the shape of the letter “E”.

A concrete mixer, a standard piece of equipment in a builder’s arsenal, will help reduce time losses and reduce labor costs. If there is a shortage of time, the problem can be solved by using a vibrating machine; a simple model of such a machine can be made independently.

To do this, it is enough to attach a low-power but high-speed electric motor to the mold, which is converted into a full-fledged vibrator using an eccentric. The vibrations of the matrix force the mixture to be distributed in the mold as densely and evenly as possible, improving the strength characteristics of the finished products. Factory-made brick presses have maximum productivity: professional machines are equipped with additional equipment that allows you to automate the process, eliminating heavy manual labor. But such vibropressing machines also cost a lot.

Making a mold for cinder blocks - drawings

To make the mold you will need sheet metal 5mm thick, a corner and pipes with a diameter of 8cm. The frame of the mold is made of metal. Its dimensions must correspond to the standard parameters of a double cinder block.

In the form itself, pre-prepared pipes are fixed on plates, which will serve as a filler for technological voids. The pipes are cut to the height of the mold and welded on both sides with plugs. The pipes are attached using plates, which are welded to the mold frame from the outside using corners. These same plates will serve as limiters for the lid when vibrating.

To make a lid for the mold, blanks are used with holes made that are slightly larger in diameter than the pipes used. Handles are made on both sides of the lid for gripping. You will find all the dimensions of our cinder block production machine in the pictures below.

Do-it-yourself cinder block production

Expanded clay is an excellent and inexpensive material for making building blocks, but an even more economical way to conduct construction is to use cinder blocks. Having comparable sound and heat insulation characteristics, slag concrete is made from materials whose cost is an order of magnitude lower.

The industry is not interested in producing cinder block building materials - it is more economically profitable to produce expensive analogues (building blocks made of foam concrete, aerated concrete, brick). But special equipment for forming cinder concrete blocks is on sale, and quite a lot. The range of prices for such vibrating machines is enormous: from simple models with a static matrix, which can easily be assembled in a garage from scrap materials, to fully automated lines.

Cinder block: manufacturing technology

A modern cinder block has dimensions of 188x190x390 mm, a solid building material is characterized by sufficient strength for arranging foundations and multi-story construction, hollow ones are used in all other cases. The voids can be round, rectangular or square, the number varies from one to 8-10 voids, the voidness rate ranges from 25-50%. Almost equal in strength to monolithic products, hollow cinder blocks allow you to save expensive cement by almost half.

For quick and high-quality mixing of the mixture, it is advisable to use a construction concrete mixer

The following can be used as filler in production:

- coal slag;

- fine gravel;

- crushed stone screening;

- sand;

- brick waste;

- broken glass;

- ash;

- perlite;

- gypsum;

- sawdust;

- wood chips.

When mixing the solution, the proportions will depend on the composition of the filler. The main condition is that the finished solution does not spread. Cement in the production of slag concrete is used at a grade no lower than M400; to improve the performance properties of the finished product, plasticizers can be added to the solution.

Portable machine for making cinder blocks with your own hands

A guideline for self-production of a solution for cinder blocks can be the factory recipe: for seven parts of blast furnace slag - two parts of coarse sand, one and a half parts of cement and up to three parts of water. The way to check that the consistency of the solution meets the requirements is simple: throw a handful on the ground, it should crumble. If you collect the solution and squeeze it in your fist, it should return to the shape of a ball.

It is not necessary to focus on standard dimensions: making blocks with your own hands is an individual process, and many prefer to set up production using multiple mold sizes (for example, 200x200x400 mm), which simplifies interfacing with other structural elements of buildings under construction.

Conclusion

From everything described above, it follows that making equipment for the production of cinder blocks with your own hands, which will make your life easier, will not be difficult. Moreover, the drawings for the cinder block machine can be modified depending on your needs, which will lead to even greater productivity and lighter design.

We hope that this instruction helped you answer most of the questions, and once again convinced you that if you want it done conscientiously, do it yourself. In the video presented in this article you will find additional information on this topic.

Preparation of cinder blocks without special equipment

If you have free time and are unable to make a simple vibrating machine for the production of slag concrete, it is advisable to use a mold with boards or sheet metal as the walls and bottom. It is preferable to use one matrix for the manufacture of several blocks of slag concrete, at least in order to save materials. To create voids in the mold for pouring the solution, you can use bottles, scraps of metal pipes, wooden cylinders or bars.

Manual machine for making cinder blocks and expanded clay blocks at home

The procedure itself is simple: prepare the solution, pour cinder concrete into the molds, level it, removing excess. After a day, the blocks can be carefully removed and laid out to dry on a horizontal surface. To protect the finished material from cracking and getting wet during drying, cover the cinder concrete stacks with plastic film.

You can use homemade cinder blocks a month after they are made. This point should be taken into account and the production of building materials should be started in advance.

How to do it yourself

Knowing the dimensions of the desired block, we proceed to manufacturing the matrix:

- Blanks are cut from sheet metal with a thickness of 3–5 mm.

- To make voids in a block, you will need a void former, which can be made from pipes of the required diameter. It is advisable to use tapered pipes to facilitate removal from the finished block. At your discretion, you can use not only pipes, but also rectangular void formers, the main thing is not to forget to make them cone-shaped.

- We connect the workpieces using tacks, since a continuous seam can lead to metal leaking.

Note! Seams are made only on the outside of the mold, otherwise the block will not have the correct geometric shape.

Please note that all welding irregularities remain on the outside

- The height of the form should be 5 cm higher than the dimensions of the finished block. This is due to the fact that during vibration the mixture tends to be compacted, and also for installation on top of a pressure sheet.

- The next stage is the frame. To make it easier to move the machine, the base is placed on wheels, which allows you to move the machine without disturbing the finished block. It is recommended to make the racks on which the form will walk a little longer, so to speak with a margin, because you will always have time to cut it off - for convenience. All mechanisms and parts are made according to individual preference, and based on your height.

- Block making machine

- Bathhouse projects with a swimming pool under one roof

Stages of work

Advice! Don’t forget about the simple principle: the larger the shoulder, the less the effort. You can verify this by studying the diagrams of machines for pouring cinder blocks.

Step-by-step manufacturing sequence: 1-2-3 – binding of the base and connection of all mold elements, 4-5 – installation of void formers, 6-7 – connection to the frame, 8 – finished machine

All that remains is a small matter: connecting the electric motor to the network and bringing the power switch to a place convenient for you, and, of course, making test material.

Connecting electrical wires, if you are not an electrician, is better to entrust to professionals

Making a vibratory pressing machine

Adding a slag concrete vibrator to the above-described production scheme provides the opportunity to significantly improve the quality of products and at the same time speed up the process.

It is not difficult to assemble such a machine; if you follow all the recommendations, this equipment will work no worse than its factory counterparts. The simplest version of a vibrocompression machine involves the use of a homemade matrix, a vibrator and a hand press. To reduce physical stress, the manual press can be improved by using a lever system.

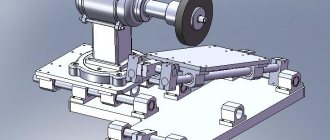

Drawing of a homemade machine with a vibration motor for making cinder blocks and expanded clay blocks

A set of tools and materials necessary for the manufacture of a vibration machine with a metal mold:

- welding machine;

- Bulgarian,

- a set of keys;

- vice;

- sheet metal with a thickness of at least 3 mm;

- pipes for creating voids with a diameter of 8-10 mm;

- channels, strips of metal;

- low-power electric motor (up to 1 kW);

- connecting elements (bolts, nuts, cotter pins).

The main element of the machine for making blocks with your own hands is a matrix, the dimensions and shape of which are selected based on production needs.

The sequence of actions when making a homemade vibrating machine:

- Using a grinder, we cut out the walls of the matrix from sheet material. If the mold is intended for the manufacture of several block products, we provide for the presence of the corresponding number of partitions in the matrix.

- We cut off the required number of blanks from the pipe (at the rate of 3 pieces per brick), the height of which should be 3-5 mm less than the height of the matrix. The taper of the pipes is achieved using the following technique: cut the pipe in half and crimp the workpiece in a vice (for thick-walled pipes you can use a lathe).

Drawing for the manufacture of a machine with lightweight extrusion of building blocks

- Each pipe section is welded tightly on both sides.

- We weld the plates to the pipes, connecting them together. For fastening to walls, it is better to provide a removable connection, which will allow, if necessary, to remove the limiters for the production of monolithic cinder blocks.

- Using welding, we attach bolts for attaching the electric motor to the long outer wall.

- We weld a metal apron on top of the form.

- We make a press in the form of a thick-walled plate, provide for the presence of holes with a diameter slightly larger than the smaller diameter of the limiter pipes (so that the press enters the matrix at a distance of no more than 50 mm).

- We weld the handles to the press.

- We install the motor. We weld an eccentric onto the electric motor shaft (ordinary bolts are suitable as material for the eccentric; they are welded parallel to the shaft and leave room for screwing on the nuts, which will allow you to adjust the amplitude of vibrations).

- We thoroughly clean the device, polish the surfaces, and paint the homemade unit for the blocks.

Manufacturing of the machine

Machines for cinder blocks are sold in a wide range, their prices vary from 3-4 thousand rubles to several tens.

But, since today we are talking about self-production, we will start by determining for what scale you need such a machine:

- If you need to make a small building, then a machine for the simultaneous production of one or two blocks is perfect for you.

- If you want to put this on the conveyor belt, then you need to make a matrix of four or even more blocks.

What does the equipment consist of?

Having decided how many cinder blocks you want to produce per day, let's look at the structure of this machine:

- The most important part in the machine is the matrix, so you need to pay special attention to this stage of manufacturing. After all, the shape, accuracy and dimensions of future cinder blocks will depend on it in the future.

Note! All other components of the unit are intended only to simplify the use of such a machine, these are filling, compaction, extraction, movement. Although each process is important in its own way for a positive final result.

- There are several methods for compacting the solution, the most suitable and easiest to manufacture is an electric motor with a displaced center of gravity to create vibration. The motor is attached directly to the mold (matrix) and must be covered with casings. A shift in the center of gravity can be achieved by welding a bolt and nut perpendicularly to the engine shaft.

For your information! To understand how this all happens, look at the photo below. They show drawings of a vibrating machine for cinder blocks.

Compliance with dimensions is the basis for a positive result