1. 2. 3.

Profiled metal sheets or corrugated sheets are quite often used in construction. The material is both reliable and inexpensive. As a rule, corrugated sheeting is used when installing a temporary structure (for example, a warehouse hangar). The material is also used in the process of roofing installation and cladding work. The production of corrugated sheets does not involve large expenses. Some construction companies manufacture the material directly on site.

Types of equipment for the production of corrugated sheets:

- mechanical sheet benders;

- pneumatic;

- hydraulic;

- magnetic;

- semi-automatic;

- automatic production lines.

Mechanical sheet benders

To produce a profiled surface of a metal sheet, the cold stamping method is used. But first you need to select several sheets with a previously applied zinc or polymer coating.

There is a special machine on which corrugated sheets are made in piece quantities. In particular, it can be used to bend additional elements - ridges, valleys, aprons and small sheets of corrugated sheets.

To operate such a machine, human muscular strength is required.

Let's consider the technical capabilities of metals for processing:

- The thickness of the steel should not exceed 1 millimeter;

- The maximum length of the sheet should be about 2 meters;

- The bending angle should be 150 degrees.

Place the sheet on the equipped table, press it with a bar and use a lever to bend the desired profile. A manual machine for the production of corrugated sheets is relatively inexpensive and does not take up much space. This machine is not suitable for bending profiles on polymer sheets, as the protective layer can be damaged. Vulnerable areas will become covered with rust and the sheet will leak.

Features of semi-automatic production lines

Semi-automatic lines are more professional than manual machines. They produce high-quality products and can compete with industrial equipment. Semi-automatic installations are equipped with an electric drive, which eliminates the need for manual labor. Such machines are mobile because they can be moved to the desired location (for example, directly to the construction site).

The quality of the resulting profiled metal sheet will be high. In terms of its main characteristics, it is almost as good as products produced on professional lines.

Mechanized sheet benders

Mechanized equipment is represented by pneumatic, magnetic and hydraulic machines. The scope of application of mechanized equipment does not differ from the field of mechanical equipment. However, the reviews are much better. The sheet bender has an electromagnetic workpiece clamp. This allows you to bend steel, copper and aluminum profiles. For example, a manual machine for corrugated sheeting does not bend the workpiece along its entire length and does not automatically determine the angle of 360 degrees.

The pneumatic machine includes a punch. Using this device, a metal sheet is pressed into the matrix. Compressed air is required to operate the punch. The power of such a machine is significantly higher than that of a manual one. This allows for a 90 degree bend angle, as well as automatic calculation of length and thickness.

Using hydraulic equipment for profiled sheets, you can obtain various types of profiles (read: " "). At the same time, the production of large volumes of corrugated sheets is ensured. A hydraulic press operates on the same principle as a pneumatic one. Sheet bending for corrugated sheets can include numerical control. Presses vary in their performance. If you are using semi-automatic or automatic devices, you can select punch and die settings. This allows you to see the sheet model in the graph and set the work speed. As a rule, only large factories can afford such expensive equipment. A private company or individual entrepreneurs can rarely afford to purchase a press. Therefore, they use a manual machine to make corrugated sheets.

Technology and process of manufacturing profiled sheets

The first step is to draw up a design sketch and make mathematical calculations. After this, the color and thickness of the future material are selected.

Stages of corrugated sheet production:

- Installation of rolled steel into the unwinding device of the machine.

- Movement of corrugated sheeting along the machine to special scissors. They cut off the excess sheet.

- Adjusting the length and number of sheets using the control panel.

- Automatic rolling of steel sheets.

- Their further cutting in accordance with previously established parameters.

- Marking and packaging of finished sheets in film.

Corrugated sheet manufacturing technology

In order to produce a large batch of profiled sheets with different characteristics, the cold rolling method is used.

The production line includes:

- unwinder;

- rolling machine;

- scissors;

- receiving device;

- automatic process control system.

Using universal technologies for the industrial production of profiled flooring, it is possible to produce all profiles on one sheet.

The advantages of this method are:

- No rolls or errors in geometry.

- Exact geometry of each profile.

- Uniform metal tension along the length and width, as well as high quality work (profile lines do not crack).

Manual machine for the production of corrugated sheets, look at the video:

It is quite profitable to produce and sell corrugated sheets. That is why the machines are so popular among various enterprises.

The equipment is installed in separate workshops, in which certain requirements must be met:

- Using a lifting device that places the rolls on the unwinder. This process cannot be carried out manually.

- The minimum temperature in the workshop should be +4 degrees. This is due to the fact that polymer coatings crack at lower temperatures.

- Availability of space for rolls, manufactured orders and other materials.

If you decide to use profiled sheets for roof installation, then do not forget about sound insulation. Because when it rains, metal makes quite a lot of noise. Profiled sheets can be purchased directly from manufacturers. In addition, you can contact specialized stores that, in addition to selling the material, will provide free delivery. If you purchase corrugated sheeting at a factory, then most likely you will transport the material yourself. In any case, before purchasing profiled sheets, it is important to view photo and video materials on the Internet. From them you will learn, for example, how a manual sheet bender for corrugated sheets works.

Many products are made from sheet metal - drainage systems, shaped parts for cladding or metal tiles, flashings for bases, corners for structures made of corrugated sheets, etc. All this can be done by a special bending machine for sheet metal. We’ll talk about how to make a sheet bending machine with your own hands in this article.

Types of sheet bending machines and features of their design

Before you start assembling a manual unit with your own hands, you should accurately determine the volume and list of work that the new device will perform in the future. Indeed, depending on the purpose of this unit, the design diagram of the device may also change.

Of all the solutions available today, the simplest sheet bending machine in terms of design is a product that bends sheet metal using a special traverse. Such a device is useful if you are working with material no more than half a meter , allowing you to bend the metal at an angle of 90 degrees without additional devices using only the strength of your own hands.

The material is fixed in a vice or clamps, where bending is carried out due to the high pressure from the traverse.

Sometimes, due to the high elasticity of the material, it is quite difficult to achieve an angle of exact 90 degrees. A special spacer (in the figure on the right), which looks like an ordinary strip of metal,

helps to correct the situation

Simple manual

Shaped metal parts cost a lot of money. Even more than corrugated sheeting or metal tiles, therefore it makes sense to make a simple machine for bending sheet metal, and with its help make as many corners, ebbs and other similar parts as you need, and exclusively to your own dimensions.

Bending machine - side view

If you're worried about appearance, you shouldn't be. On sale today there is sheet metal not only galvanized, but also painted. In all designs, the sheet is fixed tightly, so that when working it does not slide on the table, which means that the paint does not rub off or get scratched. It is also not damaged in places of bending. So the products will look quite decent. If you try, they will look even better than what they sell on the market.

Powerful sheet bending machine from brands

This sheet bending machine will require a flat surface (table), preferably metal, three corners with a shelf width of at least 45 mm, and a metal thickness of at least 3 mm. If you plan to bend long workpieces (more than a meter), it is advisable to take wider shelves and thicker metal. You can use brands, but this is for bending metal sheets of large thickness and length.

You will also need metal door hinges (two pieces), two large diameter screws (10-20 mm), wings on them, and a spring. You will also need a welding machine - weld the hinges and make holes (or a drill with a metal drill bit).

For a homemade sheet bender, a 70 mm brand was used - three pieces of 2.5 m each, two bolts of 20 mm in diameter, a small piece of metal 5 mm thick (for cutting jibs), a spring. Here's the procedure:

- Two brands are folded, and grooves are cut into them at both ends for hinges. The edges of the recesses are beveled at 45°. The third tee is cut in the same way, only the depth of the recess is made a little larger - this will be the clamping bar, so it should move freely.

- Weld the loops on both sides (weld on the front and back).

- Two jibs on each side are welded to one of the brands (the one farthest from you, if you “open” them). They are needed so that you can install the clamping bar clamp bolt on them.

- Weld the bolt nut to the jibs.

- Install the clamping bar (third cut tee), weld metal plates with a hole in the middle in the upper part. The diameter of the hole is slightly larger than the diameter of the bolt. Center the holes so that they are on the same vertical line with the welded nut. Weld.

- Cut the spring so that it raises the pressure bar by 5-7 mm. Pass the bolt into the “ear” of the clamping bar, put on the spring, and tighten the nut. After installing the same spring on the other side, the clamping bar rises on its own when unscrewed.

- Weld two pieces of reinforcement to the screw head to serve as handles for tightening.

- Weld a handle to the movable (closest to you) brand. That's it, you can work.

This option is very powerful - you can bend long workpieces and sheets of considerable thickness. Such scales are not always in demand, but they can always be reduced. The video suggests a similar design of a smaller size, but with a different fastening of the clamping bar. By the way, no one bothers you to also install a spring on the screw - it will be easier to raise the bar. What’s interesting about this design is that you can make beading on it, something that such devices usually cannot do.

From a corner with a different type of clamping bar

This model is welded from a thick-walled angle, the frame is made like an ordinary construction sawhorse, which is welded from the same angle. The handle is from a luggage trolley. The design of the screws is interesting - they are long, the handle is curved in the shape of the letter “L”. Convenient to unscrew/screw.

This homemade sheet metal bending machine has many features:

Now let's move on to the design of the clamping bar (pictured above). It is also made from a corner, but is laid on the machine with an upward bend. To ensure that the bar does not bend during operation, reinforcement is welded on - metal jumpers. Small metal platforms are welded at both ends of the strip, in which holes are drilled for bolts.

Another important point is that the edge that faces the bend is cut off to obtain a sharper bend angle.

The clamping bar is placed on the machine, and a spring is placed in the place where the nut is installed. The handle is installed in place. If it does not press the bar, it is raised above the surface due to the elastic force of the spring. In this position, the workpiece is tucked under it, positioned, and pressed.

Place a spring under the hole, then a bolt

A good option for home use. It will not be possible to bend thick metal, but tin and galvanized steel can be bent without difficulty.

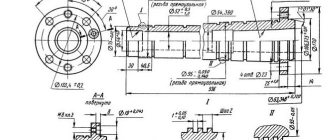

Bending machine drawing: introduction and improvement

From a design point of view, the manual sheet metal bending machine shown in the first drawing below can easily be improved. The diagram clearly shows that the metal bending device is assembled from the following components:

Initially, in the drawing, the traverse of the bending machine is made from a corner, but it is much better to make it from a channel . This solution will increase the endurance of the traverse many times over. Otherwise, at a certain point in time, the corner will certainly bend in the middle, which will noticeably reduce the quality of the bend in this place. At the same time, replacing it with a channel will make it possible to work longer on the machine without the need to replace components, providing more than 1300 bends instead of the usual 200, which is not much if you work actively!

The design of the presented sheet bending machine, made by hand at home, can be improved not only by changing the traverse, making the unit even more versatile and efficient.

The second drawing makes it possible to understand in more detail the design features of a homemade sheet bender:

We increase the reliability of machine mounts

A sheet bending machine, among other things, has another significant disadvantage, which is the layout of its placement on the working surface. The clamps themselves, namely they are designed as fasteners, are considered an unreliable fastening method. The situation is further aggravated by the fact that welds are characterized by rapid fatigue! Based on this, it makes sense to completely abandon the use of this fastening element, which will additionally eliminate cheeks and welded joints from the design of the device.

You can improve your sheet bending machine yourself in the following way:

But, if the new version of the sheet bending machine no longer has jaws, then how will the traverse be attached? This issue can be easily resolved this way: just use butterfly door hinges , which, as a rule, are used to secure heavy metal doors. The hinges themselves will provide the unit with greater accuracy, and fastening can be done using countersunk screws. In the second drawing this point is clearly demonstrated in the lower right corner.

Since butterfly door hinges are quite reliable, you can bend a lot of metal blanks on a homemade sheet bender with a traverse.

How to strengthen the pressure beam?

Next we will examine the issue related to strengthening the pressure beam. Although, if you use a fairly large corner for pressing, and do not plan to bend very thick sheets during the work, then you can skip this point, leaving the pressing beam from the corner. In other cases, we recommend strengthening!

To extend the operational period of the clamping beam, making it comparable to the traverse, you need to supplement the corner with a metal base with dimensions of 80 by 16 millimeters. In this case, it is worth making a 2 mm chamfer on the working edge of the complementary element. At the same time, the front edge of the metal strip must be given a 45-degree angle to align it with the plane of the clamping angle.

In the second sectional drawing this element is shown at the top right. Thanks to this solution, the metal will begin to work in compression, and not bending as before, which was extremely undesirable, significantly increasing the operating time of the machine without breakdowns.

Another 60th corner should be welded to the back flange of the main clamping corner. This will keep the latter from bending upward. In the second drawing this moment is more clearly presented at the top left.

Don’t forget about the bottom of the pressure beam, namely the milling of this part, because it is what forms the bend of the metal profile. According to generally accepted rules, the unevenness of this plane should not be more than half the thickness of the future workpiece, otherwise it will not be possible to make an even bend with your own hands - swelling will definitely appear along the fold line!

It is important to note that the beam can be milled only after installing all welds , because their implementation often causes changes in the geometric characteristics of the structure.

Sheet metal rollers or roller bender

This type of sheet bending machine can have three types of drive:

- manual;

- hydraulic;

- electric.

They make rollers for sheet metal with manual or electric drive with their own hands. Manual ones have 3 shafts, electric ones can have 3-4, but usually there are also three.

This machine needs a good solid foundation. This could be a separate bed or some kind of workbench or table. The basis of the structure is rolls. They are made the same size. The two lower ones are installed permanently, the upper one is movable, so that in the lower position it is located between the rollers. By changing the distance between the lower rollers and the upper one, the radius of curvature changes.

The machine is set in motion using a handle attached to one of the shafts. Then the torque is transmitted to other rollers through sprockets. They are selected so that the rotation speed is the same.

If the equipment is intended to produce pipes, the upper roller on one side is made removable, with a quick fixation system. Once the sheet is rolled into a pipe, there is no other way to pull it out.

Nowadays, all building materials without exception are constantly becoming more expensive, and corrugated sheeting, which is very widely used in construction, is no exception. The material is made from a sheet of metal, which is given a certain shape.

The main function of such a machine is cutting and rolling the workpiece, as a result of which it takes the form of a finished profiled sheet. Nowadays, a similar manual machine for making corrugated sheets can be made even with your own hands, if you know how to work with metal blanks and, preferably, have engineering skills.

Types of sheet benders

There are three types of sheet metal bending machines:

For bending sheet metal

To obtain radial bending of a metal sheet

All these devices are classified as sheet bending machines. The easiest way to make one with your own hands is the unit of the first group, a little more difficult - the third (rollers for sheet metal). So we’ll talk about them - from how to make a sheet bending machine with your own hands.

Automatic and manual machines for the production of profiled sheets

The main difference between corrugated sheets and other similar metal sheets is that the corrugation has a trapezoidal shape. At first glance, it may seem that it is impossible to make a machine for the production of such material yourself, but this is not so.

Production lines of such material represent a whole complex of mechanisms, each of which performs its own functions.

Thus, even the simplest automatic line for the production of profiled sheets consists of:

- unwinder of rolls of metal sheets;

- rolling mill, where the material is actually formed;

- scissors that look like a guillotine;

- receiving device.

It is clear that it is unrealistic to make such an automatic line on your own. But it’s quite possible to make a manual machine that can bend workpieces at the required angle so that you get a sheet of corrugated sheets.

It should be taken into account that a home manual machine will not be able to produce profiled sheets that are too thick - the maximum thickness of the workpiece is about 5 mm.

Assembled structure

In its finished form, the improved sheet bending machine consists of:

In the drawings you can see pressure flywheels, which, as a rule, few people have in stock. In most cases, for sheet bending, ordinary screws equipped with welded collars are used instead.

Important point ! Welding the knobs can have a negative impact on the threads, so after welding it is imperative to remove the threads on them.

Preparing supports and table for feeding workpieces

Self-production of a rolling machine begins with assembling a frame to accommodate all equipment components. In this case, it is enough to install reliable supports, securing them to the base: preferably a concrete floor.

Next, a table is assembled, along the surface of which the workpiece will be fed into the machine. Its length should be several times greater than the length of the finished product, since there will need to be free space on the surface to accept the finished product. The optimal table surface material is aluminum sheet.

There should be a special bar on the table that can secure the workpiece to the table using bolts. In the same way, a manual lever is secured, which feeds sheets of material along the table into the machine for corrugated sheeting, setting the required feed angle.

Installation of corrugated sheets

Installation of corrugated sheets has its own characteristics. In order for the roof to be of high quality, a sheathing is required, which is mounted perpendicular to the corrugated sheets. The frame, in the form of a lathing, is made in increments of no more than 60 centimeters. To install the sheathing, edged inch boards with a thickness of 25 mm are used. The sheets are laid in the direction from bottom to top, overlapping in one wave. When installing on the roof, you should pay attention to the size of the outer shelves. The shorter shelves should be at the bottom, and the longer shelves should overlap the shorter shelves. During the installation process, it is necessary to ensure that the sheets are installed without gaps. If you do not follow this factor, moisture may get into the gaps.

Installing a metal profile with your own hands - features that few people talk about

If the roof accommodates more than one row, then the sheets should be laid with an overlap, the magnitude of which depends on the angle of the roof slope. The greater the angle of inclination, the smaller the approach to the adjacent sheet must be made.

| Roof angle | The amount of horizontal overlap of the corrugated sheet |

| less than 12° | 200 mm + sealant |

| from 12° to 14° | 200 mm |

| from 15° to 30° | 150-200 mm |

| more than 30° | 100-150 mm |

Modern production of corrugated sheets makes it possible to order a sheet that will cover the entire roof from the ridge to the overhang. The maximum sheet length can reach a maximum of 12 meters. Despite these features, such sheets are difficult to lay, even with assistants, especially since the work has to be done at height. But one solid sheet performs protective functions 100 percent, compared to several sheets laid on the roof. As a rule, sooner or later, but such a factor will play a negative role.

Rules for fastening corrugated sheets

How to calculate the length of the self-tapping screw for installing corrugated sheets on the roof

Firstly, manufacturers made sure that the fastening of corrugated sheets was carried out not in the way everyone wants, but with special fasteners. Special fasteners are special self-tapping screws with rubber gaskets that are installed under the screw heads. These gaskets make the fastening area airtight, so moisture is unlikely to penetrate under the screw heads. As a rule, self-tapping screws are painted in the same colors as the corrugated sheets. For one square meter you need from 5 to 7 fastening points (screws). We should not forget that self-tapping screws will also be needed for attaching additional roofing elements, such as ridges, joints, etc.

The corrugated sheet is attached to the base of the sheathing due to the lower flange of the wave, which fits tightly to the sheathing. The length of the screws depends on the thickness of the material from which the sheathing is mounted. It is advisable that the sharp ends of the screws do not protrude from the back side of the sheathing. If a waterproofing film was installed on the back of the sheathing, the sharp ends of the screws can damage it.

The fastening technology involves connecting and fastening the joints, but in this case the fastening is carried out directly through the wave, so longer screws will be required: it all depends on the height of the wave. The main thing is that the manufacturer has provided for everything, and you don’t have to invent anything.

Sheet processing

As a rule, when arranging a roof, it is impossible to do without processing (trimming) sheets of corrugated sheets. In this case, the question arises, how to cut these sheets? You can use metal scissors or an electric jigsaw. Yes, it is slow and painful, but there are no other options. There is another option - this is a grinder, but it is better not to use it. Although it will allow you to cope with this process much faster, as a result of the high temperature at the cut sites, the protective layer is damaged. This leads to the sheets starting to rust in these places.

Installation technology

After all the preparatory work has been completed, they begin to install the elements of the drainage system, which includes an element of the roofing system - a drip line. The edge of the insulating film should be on top of the drip edge. The drip cap, together with the insulating film, is attached using self-tapping screws and sealing gaskets.

In general, the installation procedure depends on how the attic space will be warm or cold. If the attic is cold, then the installation sequence is as follows:

- First, a vapor-waterproofing material is installed on the rafters, which should not allow vapors to pass from the home to the roofing system, and moisture that has seeped under the roofing material should not enter the attic. This material is attached with sagging, starting from the bottom towards the top, with each strip overlapping by 15 centimeters. The joints must be secured to each other using tape.

How to install waterproofing on a roof - Wooden strips are used to attach the membrane to the rafter legs. The planks create the necessary gap, since the vapor-waterproofing membrane should not touch the roofing material.

- After this, the stage of installing the sheathing begins, using a 100x25 mm board. The board is nailed perpendicular to the rafter legs in increments of 50-60 cm. In the upper part of the rafter system, 2 boards are nailed in a row, since the ridge elements are supposed to be fastened here. The same must be done in the lower part, since this is where the droppers are attached.

- The final stage is attaching the corrugated sheets to the sheathing.

If you plan to have a warm attic, then the installation procedure is slightly different. The number of operations will be as follows:

- To insulate the attic, a sheathing is installed on the attic side to hold the insulation.

- A vapor barrier material is installed to the sheathing, also from the attic side, and then finishing materials can be attached.

- On the roof side, the space resulting from the installation of insulation between the rafters is also filled with insulation. It is desirable that it be a heat-insulating material that is not afraid of moisture.

Approximate composition of the cake for an insulated roof made of corrugated sheets - A waterproofing film or membrane is mounted on top of the insulation. The installation technology is the same as in the first option, when the attic is cold. The main condition is the formation of the necessary gaps: sagging - 2.5 cm and plus 2 cm of ventilation gap. If necessary, additional slats are nailed to the rafters to obtain the required clearances.

- The sheathing is installed.

- Corrugated sheets are attached.

Installation of corrugated roofing

Installation of rolling shafts and first start-up

The next component - rolling shafts - is very difficult to assemble with your own hands, so it is best to purchase them ready-made. Finding such devices on the market these days is not difficult.

Using brackets made from metal angles, the shafts are secured to the machine frame near the hand lever.

Having tightened all the bolts not to full strength, the almost completely hand-made machine for the production of corrugated sheets is ready for the first running-in of the material. If the manufactured corrugated sheet has the desired shape, the parts can be secured in place by firmly tightening all the bolts. Otherwise, adjustments are made to certain parts, and the procedure is repeated.

Where does the assembly begin?

To assemble a sheet metal bending machine, you will need drawings, photos, and videos demonstrating the assembly sequence with your own hands. In addition, before work, it is important to think through some points, namely the availability of components, the effort that will need to be applied for work, the cost of the device, weight and dimensions, which, in turn, will affect mobility. As a result, we obtain approximately the following set of initial data:

It is extremely difficult to find a drawing of a sheet bending machine that would fully meet the listed requirements, but this does not prevent you from using the closest solution, modifying it to suit yourself.

Features of working with a homemade manual machine

Even if you are an experienced craftsman, you should work very carefully on a machine you have made yourself, since any malfunction in any component of the mechanism can lead to injury during its use.

At the same time, we must not forget about safety precautions, working with extreme caution, especially if.

Thus, the self-assembled machine for corrugated sheeting is ready. The principle of its operation is very simple:

- the workpiece sheet is placed on the table;

- using a special bar, the workpiece is fixed on the table;

- using a manual lever, the optimal angle for feeding material into the rolling shafts is set;

- At the exit, the finished sheet should move freely on the table.

In order to avoid any work-related injuries, when working with such a machine, you must always adhere to safety regulations.

The machine on which corrugated sheeting is produced is a very dangerous piece of equipment, since it has many cutting and piercing components that can pose a danger to the operator. Therefore, working on the machine is only allowed in protective clothing and goggles.

Before each work with such a manual device, you should carefully check the functionality of all its components. It is highly not recommended to bend very thick metal sheets on manual machines.

Thus, having the skills to work with metal materials, even with your own hands you can make a mechanism for rolling corrugated sheets, which will ensure a fairly high quality of the resulting product. The main thing is not to make any mistakes when assembling it, and also remember the rules for safe use.

Do-it-yourself sheet bending: instructions and drawings for self-assembly

In fact, it is not difficult to make a sheet bending machine with your own hands, however, many specialists and self-taught craftsmen who use sheet steel in their households for some reason do not make such a machine for work. But it would help save a lot, featuring a long service life and high reliability.

At the same time, the features of the work and self-assembly of a sheet bending machine may be of interest not only to people who bend metal in large quantities every day; the article will also be useful for those who periodically do this!

Drawings for making a machine yourself

Today, corrugated sheeting is increasingly popular among those who build modern buildings, erect fences, reliably strengthen partitions, and renew the appearance of old buildings. Also, with profiled steel, wide possibilities for constructing an original roof for a residential building or office building become available. Due to the high quality of rolled steel, corrugated sheets can be used during the construction of structures such as warehouses and hangars.

Creating a high-quality building coating by rolling a strip through guide rollers is quite simple. Thanks to technology and equipment, it is possible to organize production in available areas.

Sheets of corrugated sheets can be used as a material for the following purposes:

construction of walls of various types of structures; roofing for buildings for various purposes; production of formwork; installation of partitions and fences.

Material calculation

Having learned what corrugated sheeting is, what it is made of, which one to use in a particular design, let’s move on to the main part, how to correctly install a roof from corrugated sheeting with your own hands.

Before starting the main work, you should calculate the amount of material. It also includes additional elements for corrugated roofing.

The simpler the roof, the easier it is to calculate the amount of material needed to cover it. You can do it yourself by performing simple calculations. If the design is complex, with many slopes, with different angles of inclination, then it is better to ask for help from specialists or try to calculate it on a computer.

Another known method is to make patterns of stingrays on paper to scale and calculate each of them separately.

Overlap of corrugated sheets on the roof

If several horizontal rows are arranged in the roof of the slope, then to calculate the length of the sheet it is important to take into account the amount of horizontal overlap. The size of the overlap depends on the angle of inclination of the roof slope (more details in Table 2). It is also important not to forget to take into account the length of the eaves overhangs.

Table 2. Dependence of the size of the horizontal overlap on the angle of inclination of the slope

| Tilt angle | More than 30° | From 15 to 30°. | Less than 15° |

| Overlap size | 100–150 mm | 150–200 mm | 200–250 mm |

When completing the calculations, be sure to add 10% to the result obtained, which will be spent on unforeseen situations (defects, damage, etc.).

Examples of corrugated sheet calculations

Sheets of corrugated sheets of one type of profile have the same width, and the length ranges from 0.5 meters. The width is indicated by two numbers: the larger one corresponds to the full size, the smaller one corresponds to the working (useful) width. When calculating the number of sheets, in order to correctly lay corrugated sheeting on the roof, you need to take the usable width, which takes into account the size of the vertical overlap between the sheets.

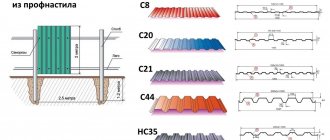

Table 3. Dependence of vertical overlap on the grade of corrugated sheeting

| Brand of corrugated sheet | NS35 | C8 | C10 | S20 | S21 |

| Vertical overlap | In one wave | In two waves | In two waves | In one wave | In one wave |

Corrugated sheets, made from sheets of 0.5–0.6 mm, are available in lengths from half a meter to ten meters. Typically, manufacturers cut according to the size agreed with the customer.

Experienced roofers recommend using metal profile sheets no more than 5–6 meters long; it is better to make 2–3 rows. This will facilitate installation (lifting, laying) and protect the corrugated sheeting from damage.

Calculation of the amount of corrugated sheets for a rectangular slope

Simple roofs can be gable or single-pitch, based on a rectangle.

For the calculation, the width of the slope (W) and the length of the slope (H) are taken. If the roof is not symmetrical, then each plane is measured and the calculation is carried out separately.

Table 4. Dependence of the width of the eaves overhang on the type of corrugated board

| Type of corrugated sheet | NS35, C44, N60, N65 | S8, S10, S20, S21 |

| Cornice overhang width | 200–300 mm | 50–100 mm |

To determine the number of sheets in a horizontal row (Ng), divide the width of the slope by the useful width (Bl) of the metal profile sheet. If the length of the slope is more than 5–6 meters, it is covered with two or more sheets, which corresponds to the number of rows.

Example: W = 8m - width of the slope;

H = 6m - length of the slope;

Grade of corrugated sheet C21, usable width Vl = 1 m.

Ng = W/Bl = 8/1 = 8 pcs - sheets in a horizontal row;

because H = 6m, we will install 2 rows;

L = H + Lк + Lн = 6 + 0.1 + 0.1 = 6.2 m - the total length of the ceiling in a vertical row, where Lк is the length of the eaves overhang (Table 4), Lн is the length of the horizontal overlap (Table 2 ). We divide into equal parts, i.e. by 2;

Lл = L/2 = 6.2/2 = 3.1 m - the length of one sheet, we accept the standard length of 3.5 m:

The total number of sheets 3.5 meters long on one slope is:

N = Ng*2(rows) = 8*2 = 16 pcs.

An example of calculating the amount of corrugated sheets for a hip roof

For roofs with a complex shape, the calculation principle does not change; sheets are calculated for each slope separately. To determine the amount of material, large-scale patterns of each slope or a detailed drawing of the roof are made, and roofing elements are graphically placed on them.

Hip roofs have a pair of slopes in the shape of an isosceles trapezoid and an isosceles triangle, which facilitates graphical calculations (see figure).

On a trapezoid, the calculation is carried out as follows.

- Divide the trapezoid into a rectangle and two right triangles.

- The amount of corrugated sheets in a rectangle is calculated as for a rectangular roof.

- In a right triangle, the underlying leg is divided into segments equal to the working width of the profiled sheet, and perpendiculars are built from points on the leg to the hypotenuse. The length of the first sheet is equal to the ascending leg, the length of the next sheet is determined to the point of intersection of the perpendicular with the hypotenuse.

The calculation for an equilateral triangle is identical.

- From the vertex of the triangle, lower a perpendicular, from the intersection point on the base in both directions, set aside segments equal to half the working width of the profiled sheet. Place perpendiculars from the extreme points of the segment - this will be the first sheet of corrugated board.

- Next, on the base of the triangle, make marks to the right and left of the boundaries of the first strip, equal to the working width of the sheet.

- From these marks we construct lines parallel to the height of the triangle until they intersect with its sides. The distance to the intersection point determines the length of the next sheet.

Everything that has been calculated is summed up, the number of sheets and their length are determined.

Additional elements

Additional elements for corrugated roofing are easier to calculate than the base material. You should determine which extensions are needed, measure the length where they are installed, add 100–150 mm to each joint for overlap, add up all the data and divide by the length of the element. You will get the number of extras in pieces. If you get a fractional number, you need to round it up to the nearest whole number.

There are quite a few types of additional elements for corrugated roofing, but not all are installed at once. It depends on the configuration of the roof and its purpose. The figure clearly shows which accessories are installed and where.

How to prepare supports and table for feeding workpieces

To make your own rolling machine, you first need to assemble a frame to accommodate all the equipment components.

In this case, it is enough to install reliable supports. They need to be secured to a solid foundation - preferably a concrete floor. Next you need to start assembling the table, along the surface of which the workpiece will be fed into the machine. The table should have a length that is several times the length of the finished product. There must be enough free space on the surface to accept the finished product. The optimal table surface material is aluminum sheet.

You need to place a special bar on the table, which will fix the workpiece on the table using bolts. A manual lever will also be attached in the same way, thanks to which sheets of material are fed across the table into the machine for corrugated sheeting and the desired feed angle is set.

Features and requirements for the material

There are several types of corrugated sheets, in the manufacture of which various raw materials are used. For example, metal corrugated sheeting is very popular.

It is made from steel using the cold rolling method.

For structures that will be used outdoors, for example, for a picket fence, you can make sheets coated with an additional protective coating - enamel, polymers, fiber.

Each type of raw material gives its own sheet thickness.

In the case of steel, we can get high-quality corrugated sheets, which can also be galvanized to increase strength and resistance to aggressive environments.

If you make sheets without any coating at all, the material will wear out faster. Therefore, we can say that not only the machine itself, but also the raw materials play a big role.

It is better to assemble a rolling machine for corrugated sheets indoors, where there is a flat concrete floor.

In this case, the temperature in the room also plays a big role: it must be heated, without sudden changes. We choose a temperature not lower than 4 degrees.

If you plan to constantly produce such material, then it is better to immediately prepare rooms for storing rolls, dry and warm.

How to install rolling shafts and run the device

It is quite difficult to assemble such a part of the structure as rolling shafts with your own hands, so the easiest way is to buy ready-made ones.

Today it will not be difficult to do this - you will find them at least in the market. Using brackets made from metal corners, the shafts are fixed to the machine frame near the hand lever. We do not tighten all the bolts to full strength - now our homemade manual machine for making corrugated sheets can be used for the first running-in of the material. If the corrugated sheet produced by the machine has the required shape, we fix the parts in place and tighten all the bolts firmly. If the shape of the corrugated sheet does not meet our requirements, we adjust certain details and repeat the procedure.

It must be remembered that a machine for producing corrugated sheets is equipment that is dangerous to operate. This machine is equipped with a large number of cutting and stabbing elements, which, if safety precautions are not followed, can cause injury to the operator. Therefore, it is allowed to work on the machine only in protective clothing and safety glasses.

The equipment necessary for the production of corrugated sheets is divided into three main groups:

- Manual machine for the production of corrugated sheets;

- Automated and semi-automatic production lines;

- Mobile equipment.

In the second case, all technological operations are performed with minimal participation of technological personnel or completely without requiring human participation.

Automatic and semi-automatic lines are also available in mobile versions. Such machines are convenient to use in the construction of modular buildings or arched structures at remote construction sites, when the cost of delivering finished profiled sheets is very high.

Example of a manual machine for corrugated sheeting

Finally, a manual machine for the production of corrugated sheets is driven by human muscle power. Typically, such machines are used for the manufacture of small products or various additional elements. This machine is extremely easy to use and it is on this that we will discuss in detail further.

Let's take on the sheet bending machine

Let's start making our own sheet bending machine by developing the simplest specifications. And we will calculate the latter, in addition to the longevity criteria described above, based on the expenditure of muscular energy that an average-sized adult man is able to produce day after day without deterioration in health. Of course, simplicity and low cost of design are also not in last place. Also, due to its weight and dimensions, the machine must allow transportation in a passenger car and use directly at the work site. It turns out:

- The width of the bendable sheet is up to 1 m.

- The thickness of the bendable sheet is up to 0.6 mm galvanized; up to 0.7 mm aluminum and up to 1 mm copper.

- The number of operating cycles without readjustment and/or repair is at least 1200.

- Bending angle – at least 120 degrees without manual adjustment; This is necessary for folds.

- The use of special steels or non-standard workpieces is extremely undesirable.

- Welding - as little as possible; parts/assemblies lead from it, and the welds are fragile and quickly tire from alternating loads.

- Metalworking on the side (turning, milling) is also as little as possible, it costs money.

Let's face it: drawings of finished structures that meet all these requirements are not found in publicly available sources. We will try to improve one, widely known, and, in principle, very successful.

Manual machine for corrugated sheeting - what are the advantages of such a solution?

Currently, many machine-building enterprises produce such equipment, and anyone can buy a manual machine for corrugated sheeting. Its main advantage is that such a machine does not require external energy sources to operate, since human physical strength is sufficient to operate it.

In order to set up the production of profiled sheets on a manual machine in a matter of hours, you only need a small room (although even this is not necessary, just an ordinary shed is enough) and two workers familiar with the structure of the machine.

A manual machine for making corrugated sheets is indispensable for a small construction company, which is often faced with the need to use a small number of products from profiled sheets. It is simply not practical to order them because the cost of delivery to the site is too high.

With the help of such a machine, it is possible to produce directly on the construction site various additional elements necessary, for example, when installing a roof. A manual machine for the production of corrugated sheets is so simple that it requires virtually no maintenance other than periodic lubrication.

The advantages of such a machine include its relatively low cost. A manual machine for corrugated sheets, the price of which is about 2000 US dollars, will pay for itself after producing 750-800 m² of profiled sheets, which is approximately its daily productivity. And this does not take into account the cost of delivering this corrugated sheet to the construction site if it is purchased. But you can also buy a machine that has already been used. It will cost several times less, and will last for many more years, since the forces acting on its main components are negligible and their wear is minimal.

Step-by-step instructions for assembling the machine at home

The main difference between corrugated sheets and other metal sheets is the trapezoidal corrugation. It seems that it is impossible to make such material at home, but this is not so. It is quite possible to make a machine for making corrugated sheets made with your own hands using a sheet bend. However, it is worth understanding that a home device cannot always help in the manufacture of products that are too thick. Thus, the maximum the thickness of galvanized steel that can be bent should not exceed 5 millimeters. With such a device, you can make not only sheets for picket fences, but also ridges, cornice strips, and so on. First of all, the frame of the machine is assembled. It is small in size and does not require complete closure of the walls. It will be enough to make good supports and secure them to the concrete floor with screws. Next, you need to prepare a table on which the sheet will be served.

Usually its length should be at least a couple of times greater than the expected length of the product, because there should still be room to receive the finished sheet. The table can be made from aluminum plywood.

The main thing here is to make a special bar that will allow you to secure the roll or raw material. It is pulled tightly to the table using bolts. The manual lever is secured in the same way. It is needed to move the sheets across the table and adjust the feed angle. For greater reliability, you can equip such a design with a control spring. It is worth understanding that some parts need to be purchased ready-made. For example, rolling shafts. It is impossible to make them at home from improvised means. But you can order them - today this is not a problem, and the cost for a home workshop will be very low. They are fixed to a frame and brought to the lever. The shafts should be secured using brackets made from pieces of metal corners. With this procedure, preliminary assembly must be carried out. The first running-in of corrugated sheets is also carried out on it. All bolts are not tightened to full strength, and the sheets are fed extremely carefully. You need to be guided by the fact that during operation the flange of the angle and the flange of the frame must be on the same plane. If you manage to give the corrugated sheet the desired shape, then all the parts can be secured. However, do not forget about safety precautions. This is especially true if guillotines are installed.

The work should be done extremely carefully, without haste, even if you are an experienced craftsman, as there is an increased chance of injury.

The mechanism of operation of the device is quite simple, which is why it is possible to make such a machine at home. First we place the sheet of metal on the table. It is fixed using claws or strips. You can also cover corrugated sheets with different compounds, but for this you need to equip a special table. At all stages you must wear protective clothing, gloves, and also use safety glasses. Today, corrugated sheets occupy a leading position among products that made from thin rolled steel. It is needed for the construction of fences, roofs and of course wall structures. Naturally, the production of corrugated sheets is increasing due to such great popularity. The corrugated sheet making machine is used to produce corrugated sheets from metal sheets. 2 - 2.5 meters - this is the length of the corrugated sheet that a manual machine produces. This machine is several times cheaper than the same rolling mill. It can fit in a very small area. In 8 hours, using a machine for the production of metal tiles, you can make 600 sq.m.. Probably, in our time, these are truly remarkable characteristics! This equipment is easily adjusted to the desired width of the corrugated sheet. In order to operate the machine for the production of corrugated sheets, 2 people are required. No electricity is required for production, since all the work is done by muscle power. You can organize your production at the construction site and this will bring the production of corrugated sheets closer to your end user. This device is relatively inexpensive and easy to use! The production of metal tiles and corrugated sheets can be made inexpensive and profitable. Before buying a machine, carefully weigh the pros and cons! By purchasing a manual machine for the production of corrugated sheets at the manufacturer’s price, you save your time and money! SHEET BENDING MACHINE “RG” AND “RG 3 IN 1”

A manual sheet bending machine with a rotary beam is used for the manufacture of additional roofing elements, the manufacture of ebbs, canopies and other various products from sheet metal up to 1 mm thick.

The advantage of our machine is its reliable rigid design, which ensures high-quality bending of the product along its entire length. For the manufacture of the main structural elements of our machine, high-quality steel with the required safety margin is used; the swivel joints are made of metal anti-friction materials with the possibility of periodic lubrication. All these conditions ensure long-term and trouble-free operation of the machine. The warranty on the machine is 1 year from the date of purchase. After the end of the warranty period, we provide qualified post-warranty service: supply and replacement of spare parts, repairs of varying complexity. A distinctive feature of our machine from bending machines from other manufacturers is the presence of a removable bending jaw, which is attached to the upper clamping beam of our machine. This makes it possible to replace it in case of damage, or by installing a sponge of a different configuration to be able to produce corrugated sheets of various heights or facade cassettes. 12 main technical advantages

- Increased rigidity of machine beams with the ability to adjust prestress.

- Strong, reliable and durable rotary joints of the machine with an improved lubricant supply system to the friction units.

- Removable upper bending jaw with the ability to quickly replace it with another tool for the manufacture of complex products: corrugated sheets, cassettes of facade systems, etc.

- The angle of inclination of the upper jaw is 20°.

- The width of the lower turning beam is 18 mm.

- The minimum width of an edge bent by 180º is 5 mm.

- Simple and convenient protractor stops for limiting the angle of rotation of the bending beam during serial bending of similar products.

- Receiving table with adjustable stops to support and position the sheet when performing the same operations.

- The maximum opening width of the clamping beam is 65 mm. The clamping beam is closed perpendicular to the sheet being processed, so that the steel sheet does not slip forward and dimensional accuracy is ensured. Compensator springs ensure easy lifting and safe lowering of the pressure beam.

- Simple and reliable devices for adjusting the clamping force of the upper beam allow you to quickly and accurately reconfigure the machine for different material thicknesses and install bending tools of different heights.

- The use of cutting rollers of increased diameter in the cutting device to obtain a better edge of workpieces.

Scope of delivery (standard equipment):

Roller knife RG

Designed for cutting metal sheets directly on a bending machine.

The cutting rollers are made of hardened tool steel, which guarantees an accurate and high-quality cut and a long period of operation (the possibility of repeated sharpening). It is possible to adjust the position of the cutting rollers in relation to the sheet being cut (re-adjustment is used when there is a significant change in the thickness of the metal being cut). The operation of the knife is designed for approximately 25 km of cutting metal with a thickness of 0.5 mm. Designed for visual determination of the bending angle of the product. Bending angle limiter

Installed on both sides of the machine.

Used to limit the angle of rotation of the bending beam when producing identical products. Receiving table with stops.

Used to support and position sheet metal during bending and cutting operations.

Additional handles

Additional handles on the edges of the rotary beam provide more comfortable work on the machine.

Additional equipment at the customer's request:

Corrugated sheet sponge and corrugated receiving table (allows for the production of corrugated sheets with a capacity of up to 300 sheets per shift);

— segmented sponge (makes it possible to produce cassettes); — additional rolling machine (makes it possible to evenly press the metal 180 degrees along the entire length of the product). Technical characteristics of RG sheet benders:

Please check the availability of machines and production time at our warehouse. Profiled metal sheets or corrugated sheets are quite often used in construction.

The material is both reliable and inexpensive. As a rule, corrugated sheeting is used when installing a temporary structure (for example, a warehouse hangar). The material is also used in the process of roofing installation and cladding work. The production of corrugated sheets does not involve large expenses. Some construction companies manufacture the material directly on site. Types of equipment for the production of corrugated sheets:

- mechanical sheet benders;

- pneumatic;

- hydraulic;

- magnetic;

- semi-automatic;

- automatic production lines.

At Metinvest-Service you can select according to the type of protective coating:

Profiled metal sheets or corrugated sheets are quite often used in construction. The material is both reliable and inexpensive. As a rule, corrugated sheeting is used when installing a temporary structure (for example, a warehouse hangar). The material is also used in the process of roofing installation and cladding work. The production of corrugated sheets does not involve large expenses. Some construction companies manufacture the material directly on site. Types of equipment for the production of corrugated sheets:

- mechanical sheet benders;

- pneumatic;

- hydraulic;

- magnetic;

- semi-automatic;

- automatic production lines.

Disadvantages of a manual machine for corrugated sheets

A manual machine for the production of corrugated sheets also has some disadvantages. First of all, this is the short length of the resulting corrugated sheet. It is usually 2.0-2.5 m. With large sizes of the working plate, uneven bending of the profile in the form of an arc is possible, which occurs due to different compression forces in different parts of the pressure lip.

In addition, it is worth noting that on a manual machine for corrugated sheets it is possible to produce only one brand of corrugated sheet. However, machines with a replaceable matrix are now being produced, which makes it possible to produce corrugated sheets with different shapes and trapezoid heights. In this case, the bending dies must be replaced manually.

And the main disadvantage is that using a manual machine you can only make profiled sheets from galvanized steel. When deformed, the polymer coating of the metal may become covered with small cracks, which will subsequently lead to premature corrosion of the corrugated sheet.

This problem is solved with the help of special modern manual machines for processing thin sheet steel with a polymer coating. However, they cost significantly more than standard options. In addition, galvanized profiled sheets can be painted. At the same time, modern technologies for applying paint and varnish coatings, such as, for example, powder painting, create a decorative and protective layer that is in no way inferior, and maybe even superior in quality, to a polymer protective and decorative coating.

How to choose a sheet bending machine?

To correctly select a device for creating bent elements from metal profiles, you should adhere to the following rules:

If you plan to use a homemade sheet bending machine to work on a constant flow, then get ready for the fact that at some point in time your “shop” may suspend its activities for a while due to a breakdown. This is due to the fact that home craftsmen, as a rule, use steel to assemble a sheet bending machine, which simply cannot withstand heavy loads!

For less intensive household use, a do-it-yourself machine is ideal, allowing you to save some money and become an excellent assistant in your work. It is important to take this nuance into account and not hope that a homemade unit will show miracles of performance and endurance!

Before you start assembling a sheet bending machine with your own hands, it is recommended that you not only carefully familiarize yourself with the various options for drawings, but also watch special videos. It is likely that the dimensions of the described solution will be too small for some, then you can take a closer look at larger models that will no longer act as a mobile device, becoming a choice in favor of a private workshop.

Properties of corrugated sheets

Corrugated sheeting, which is available in several main varieties on the modern market, can be made from various materials. However, the main raw material for the production of corrugated sheets is cold-rolled sheet steel, on the surface of which a thin layer of zinc is applied. To give a steel sheet the required configuration, a rolling method is used, which can be done in a hot or cold state. The production of corrugated sheets, in which the steel sheet is preliminarily subjected to significant heating, is carried out only by large metallurgical plants. At home or on the scale of a small manufacturing enterprise, corrugated sheets are produced by cold rolling.

Main types of profiled sheets

Depending on the conditions of further use and the loads that the corrugated sheet will experience, steel of various thicknesses can be used for its manufacture. Instead of a zinc coating, a layer of paint or other material can be applied to the surface of the corrugated sheet, which can provide reliable protection of the metal sheet from the negative influence of the external environment. Considering the fact that structures made from corrugated sheets are used primarily outdoors, the presence of a coating that protects them from intense wear due to corrosion makes it possible to provide such material with the required durability.

The conditions in which equipment for the production of corrugated sheets is operated also affect the quality of the finished product. Thus, it is advisable to install both a manual machine used for the production of corrugated sheets and an automated line for the production of such material in a dry and heated room in which sudden changes in temperature are not observed. The conditions in which the raw materials for the production of profiled sheets - sheet steel rolls - are stored also play a role. The room in which such storage is carried out must also be dry and heated.

Preparation and important information

The calculations are completed, the material has been calculated, now it is necessary to prepare the roof for laying corrugated sheets.

Any roof, regardless of covering, is a complex structure. Each individual roofing device made of corrugated sheets performs its intended functions, ensuring reliability in operation.

Laying corrugated sheeting on the roof is the final part. Before this, it is necessary to prepare the rafter system, “layer cake” (vapor barrier, waterproofing, thermal insulation, sound insulation) and ventilation.

To install corrugated sheets, you need to purchase a special tool.

Tools for work

During installation, you can get by with a small number of special power tools designed specifically for working with corrugated sheets - cutting (cutting).

It is not advisable to cut sheets with a grinder or a similar machine, since the disk becomes very hot during operation and burns the protective coating. Later, corrosion forms at the cut site, rapidly progressing throughout the entire sheet.

Electrical tools you should have:

- electric nibblers;

- drill or screwdriver.

Various drill attachments:

- for cutting metal;

- for screwing screws (“magnetic bit”).

You should purchase specialized hand tools:

- corrugated pliers;

- hand scissors for metal;

- manual cutting shears for metal.

The rest of the tools (hammers, mallets, measuring devices, markers, knife, stapler, rope, etc.) that are needed when performing roofing work should be prepared at your own discretion and need.

Manual machine for profiled sheets - technical characteristics

The manual machine for profiled sheets has the following main technical characteristics:

- the length of the resulting corrugated sheet is 2.0-2.5 m;

- the largest bending angle of the workpiece is 150°;

- initial workpiece material: carbon sheet steel 1.0-1.2 mm thick, stainless steel sheet 0.5 mm thick, copper sheet 1.3 mm thick and aluminum sheet 1.5 mm thick;

- productivity: about 120 sheets of corrugated sheets measuring 1000x2500 mm per shift.

Useful article? Save it on social networks so you don’t lose the link!