Today is the time for change in the timber industry. New rules and laws dictate that wood processing and sawmilling enterprises adopt waste-free and environmentally friendly production, while having greater economic benefits.

And the main task of industrialists is the creation and development of import-substituting production.

Description and characteristics of various types of pellets

The remarkable thing about fuel pellets is that their production does not require specific raw material sources; they are made from anything. They do not require any high-tech raw materials. They can be produced from ordinary waste. These may be residues from wood processing: sawdust, wood chips. Or even agricultural waste, such as straw. They are also called fuel pellets. Essentially, these are small cylindrical granules. Their production includes the use of specialized equipment. They are made under high pressure without any adhesives. Their thermal properties are not inferior to dry firewood. They take up much less space.

To put it into perspective, we can say that one kilogram of such granules produces up to 4.5 kJ of heat, which corresponds to the calorific value of 15% dry wood.

When burning pellets, less carbon dioxide is produced, less ash is produced, and virtually no sulfur is formed. Purpose of pellets:

- heat houses that have a stove or fireplace;

- used in boiler rooms;

- used as litter for pets;

- used as absorbents for liquids.

Types of pellets

If you plan to produce pellets for sale, then you need to buy equipment for the production of pellets that meet the standards of the countries where you plan to supply them. For example, ash content for the USA should not exceed 1%, but in Europe it is half a percent higher.

Technological process for the production of pellet fuel

In order to produce pellets from sawdust, a whole list of technological manipulations must be performed with the source material, each of which solves specific problems.

The technological process for producing pellets from sawdust is a sequence of certain actions performed using appropriate equipment.

Such actions, in particular, are:

- cleaning sawdust from foreign impurities;

- preliminary grinding of the purified material;

- drying of raw materials for pellets;

- final grinding of already dried sawdust;

- bringing the moisture level of the prepared material to the required value;

- sawdust mass granulation process;

- cooling of finished products and their packaging.

Industrial scheme of pellet production

Since all of the above stages of the technological process for the production of fuel pellets are carried out for a specific purpose and are of great importance for obtaining quality products, each of them should be discussed in more detail.

Assessment of the quality of raw materials

The main influence on the quality of pellets is provided by the characteristics of the raw materials. Important in this case are such parameters as the type of wood from which the sawdust was obtained, the degree of contamination with foreign impurities, humidity and fraction size.

The sawdust storage must be dry, spacious and comply with fire safety standards

The qualitative characteristics of the material for making pellets and the degree of its preparation for the production process determine the technology for obtaining the finished product, as well as the choice of equipment. In this case, it is necessary to take into account the following nuances.

- If the humidity of the source material is high enough, powerful dryers will be required to bring it to normal levels. The use of such equipment in the pellet production process will lead to an increase in both energy and labor costs during the implementation of the technological process.

- If the feedstock contains a lot of large wood particles, then the production line for the production of pellets should contain not only a crusher, but also equipment for separating the crushed mass. The operation of such a production line will also be associated with increased energy costs.

- The efficiency of the technological process and the stability of the pellet production line largely depend on how uniform the source material is in terms of wood species.

- When assessing the quality of sawdust mass that is planned to be used for the production of pellet fuel, you should pay attention to the presence of tree bark, rot and waste from processing old wood in its composition. A large number of such inclusions in the total mass for the production of fuel pellets reduces their energy value and, accordingly, reduces the cost of the finished product.

- The feedstock may contain foreign impurities such as sand and stones. In this case, the pellet line must be equipped with special catching devices. Preliminary washing of the material also solves the problem with such impurities, but in any case this increases production costs and, accordingly, the cost of the finished product.

Thus, the characteristics of sawdust should be assessed before using it for pellet production.

To measure the moisture content of sawdust, moisture meters are used, consisting of an electronic unit and a sensor, the probe of which is placed on a conveyor or in a hopper

Sawdust pre-grinding process

In most cases, waste from wood processing enterprises is used for the production of pellets, which is supplied to pellet production without preliminary sorting. Naturally, such waste, in addition to the sawdust itself, also contains other components - tree bark, large chips, bars, slabs, etc.

The working parts of crushers used for coarse grinding of material are rotating hammers

In order to bring the raw sawdust mass into a homogeneous state in terms of the size of the fractions it contains, a grinder is used. As such equipment, at the stage of preliminary crushing of the raw material mass, hammer crushers of the deck type are used. A crusher of this type can be successfully used for sawdust, the humidity of which reaches up to 80%, and there is practically no sticking of it to the elements of the internal structure of the equipment.

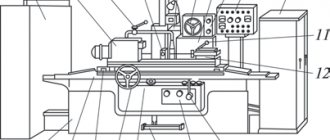

Hammer crusher device for wood

Drying process

Pellet production can receive raw materials with varying degrees of moisture, but directly during pressing, the value of this parameter should not exceed 8–12%. Thus, a pellet production line must include an installation for drying raw materials, which, as a rule, is a drying drum. Screw-type conveyors are used to feed wet raw materials into such equipment, which is the most economical option for solving this issue.

Diagram of a multi-circuit aerodynamic dryer

An aerodynamic sawdust dryer, which is based on a drying drum with the ability to regulate the rotation speed, includes several technical devices:

- source of generation and supply of hot air, running on natural gas or any other type of fuel;

- a cyclone into which the sawdust mass enters after drying;

- storage hopper from which sawdust is fed into the working chamber of the drying drum;

- cyclones, whose tasks include cleaning flue gases from dust, as well as capturing fine particles contained in the dried raw materials;

- a smoke exhauster that ensures the passage of hot air at a certain speed through the chamber of the drying drum and the air channels of the cyclones;

- screw conveyors - equipment that supplies wet raw materials into the chamber of the drying drum and transports already dried sawdust to the storage hopper.

Drying complex with a capacity of up to 1000 kg/hour with a furnace operating on wood, sawdust or wood chips

The process of drying sawdust, for which an aerodynamic dryer is used, is as follows.

- The sawdust mass that needs to be dried is fed into the chamber of the drying drum, the axis of rotation of which is located in the horizontal plane. When such a drum rotates, the uniform distribution of the loaded raw material mass in its working chamber is controlled. To ensure the safety of the sawdust drying process in the drum, its design includes a special explosion valve.

- Tedding of sawdust in the drying drum, which makes it possible to dry them more quickly and evenly in a stream of hot air, is provided by special blades attached to the walls of the working chamber of the device.

- After drying to the required moisture level, the sawdust from the drum enters the cyclone, where it is deposited and dosed into the storage hopper.

- Cleaning of used hot air from wood dust is also ensured using cyclone equipment.

- The automation unit is responsible for compliance with all operating modes of the drying equipment.

Crushing technology

The technology for producing pellets from sawdust provides that the raw material entering the granulator should not contain particles whose length exceeds 4 mm. Most modern models of equipment for the production of fuel pellets operate on raw materials whose particle sizes are no more than 1.5 mm, and the bulk mass is within 150 kg/m3. To achieve such parameters of the raw material, a grinder is used before feeding it into the pressing equipment. As a rule, this is a hammer-type crusher, which is capable of working with sawdust mass with a moisture content of no higher than 25%.

The grinder, which is used for finishing crushing of sawdust raw materials, must meet certain performance indicators both for the processed raw materials and for the air flow created.

This is explained by the fact that the grinder, which is equipped with a pellet production line, not only performs crushing functions, but also generates an air flow that removes crushed raw materials from the working chamber of the equipment. That is why, when choosing a shredder, you should focus on the characteristics of the control cyclone.

Rotary hammer crusher designed for grinding wood pulp in the process of producing fuel pellets

Supply of raw materials to the storage hopper

The supply of sawdust raw materials crushed in a hammer crusher to the cyclone equipment, as mentioned above, is ensured by the air pressure created when the hammers rotate in the working chamber. The task of the cyclone, which is equipped with almost any modern pellet production line, is to separate sawdust from the air flow transporting it from the grinding device. This installation works as follows.

- The air flow entering the cyclone along with crushed sawdust is twisted in a spiral.

- Under the influence of centrifugal force, sawdust, moving along with the air flow, is pressed against the walls of the equipment’s working chamber.

- Gradually losing speed, the sawdust, under the influence of gravity, is deposited in the lower part of the cyclone chamber, and the air with which it moved exits through the exhaust pipe.

- The sawdust that accumulates in the lower part of the equipment chamber is discharged into a storage hopper.

The pellet production line includes a cyclone for dry biomass removal

Bringing the sawdust moisture content to the required level

After several stages of preliminary preparation, the sawdust may become too dry, which will not allow them to be formed into granules with a dense and uniform internal structure. The production of pellets from sawdust requires that their moisture content immediately before pressing should be in the range of 8–12%. If this requirement is not met, the pressed raw materials must be additionally moistened.

Modern equipment for the production of pellets from sawdust is equipped with screw mixers, in which the moisture content of the raw material is increased using steam supplied to them under pressure. When performing such a technological process, you should constantly monitor the moisture level of sawdust raw materials in order to stop steam treatment in time.

Formation of fuel pellets

The main technological operation that the equipment performs for the production of pellets is the formation of granules with a dense and uniform internal structure from crumbly sawdust raw materials. To carry out this procedure, devices with round or flat matrices are installed on modern pellet production lines. Equipment equipped with round dies is more suitable for pressing materials that are not very hard. Such equipment, in particular, produces not fuel pellets, but pellets from more elastic and soft materials, which are used in the chemical, feed and food industries.

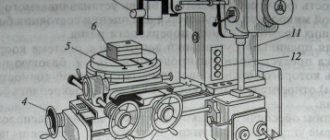

Ring type die pellet press

The production of wood pellets, the equipment for the production of which, according to the principle of its operation, is not much different from devices intended for pressing softer raw materials, is carried out using flat-type matrices. The production process for forming pellets, performed on equipment with both round and flat dies, is as follows. Rollers with a ribbed working surface, rolling over the surface of the matrix, presses crumbly raw materials through the holes in it, forming dense cylindrical granules from it. The length of the finished pellets coming out from the back of the matrix is adjusted using a special knife that makes reciprocating movements.

The thickness of the matrix wall depends on the diameter of the working holes

Manufacturing technology

The production of pellets takes place in several stages. At first, the raw materials are crushed into small parts. Next it is dried. After drying, it is crushed again into smaller fractions. Next, preparation is carried out using water, that is, the residual moisture should not exceed 10%.

This is important, since pressing raw pellets will require more effort, and they are not suitable for boilers, since they burn worse and generate less heat.

At the next stage, production involves pressing the pellets and re-drying. The finished product is packaged in one kilogram.

Particular attention should also be paid to the water content of the granules. Because too dry raw materials stick together worse. Some moisture dosage is needed. Pellets need to be cooled after the molding press. After which they are packaged.

Equipment for the production of pellets

Equipment for the production of pellets includes:

- crusher for grinding raw materials.

- Dryer;

- pellet press;

- cooling equipment for finished raw materials;

- packaging equipment.

Pellet production line

A fully assembled pellet production line will not be cheap. Its complete set includes drying drums, conveyors, scales, fans for blowing material, and hammer mills. The main role here is played, of course, by the pellet machine. You won’t be able to make it yourself, since you will need a milling machine to create the matrix. Pelleting equipment may vary in the quality of the pellets produced. Processing accuracy may vary from standards.

Homemade crusher

The production of pellets requires a crusher, which you can assemble with your own hands. If the raw material contains branches or other occurrences such as slabs, then additional equipment will be required to grind them. Of course, there are quite a few designs of such equipment. Some of them grind raw materials into not too large fractions.

Homemade crusher diagram

To make your own crushing machine, you will need one electric motor, quite powerful, and several circular saws. Such a machine will be a good helper to start your own pellet production. They are mounted on the same shaft. They are fixed in such a way that each subsequent saw tooth moves relative to the previous one. A pulley and a pair of bearings on the sides are placed on this shaft. The shaft is installed on the frame and fixed there. It should be borne in mind that the engine must have sufficient power to be able to crush branches and boards into the required sawdust size. The performance of such a unit is not the highest.

Sawdust dryer

Making pellets involves drying the raw materials. To prevent pellets from crumbling immediately at the exit from the pressing machine, it is necessary that the sawdust be of the required moisture content. In large production this is done in special chambers. At home, some craftsmen make drum dryers, since this design is the simplest.

Homemade sawdust dryer

Iron barrels are welded to each other. Next they are placed on the frame. Blades are welded to the inner walls, which interfere with the raw material during drying. Hot air is supplied from one side of the improvised drum, and this air leaves from the other. The drum rotates using an electric motor through gearboxes. The source of hot air can be a conventional heat gun.

You should know that this technological process is the longest and most energy-consuming. Therefore, expenses may exceed income.

Equipment for home production

During production, the selected raw materials (chips, sawdust, bark or agricultural waste) should first be crushed to a size of 3-5 cm, and then dried in a special dryer until the humidity reaches 15%. Then the raw material is placed in a special fine crusher.

As a result, a mass with a fraction size of up to 2 mm must be loaded into a press. After pressing, granules are obtained whose moisture content is up to 12%, and their size depends on the design of the equipment used. Next, the granules are collected in bags, sealed and used as fuel for stoves and boilers.

Equipment for the production of pellets at home will require the following:

- wood crusher. If you use husks or sawdust, there will be no need for crushing. It will be required when using branches, bark, scraps of lumber or substandard boards;

- drum or air dryer for raw materials. You can make it yourself from a barrel;

- a fine crusher, in which coarse raw materials are crushed into sawdust;

- granulator for pellets with a cylindrical or flat matrix. Its use will eliminate the process of fine crushing, since in the granulator the raw materials are simultaneously ground and pressed.

Granulator and its design

You can make a granulator yourself and do not buy expensive equipment for the production of pellets . If you have it, you will not need a crusher and shredder; a drying chamber will be required depending on the moisture content of the raw materials.

As mentioned, it can be equipped with a cylindrical or flat die . The cylindrical matrix is a perforated drum with rotating rollers from the inside. The dense mass is pressed into the holes of the drum (press channels) using rollers, and when the granules are already pressed, it is cut off by knives when exiting from the outside.

A device with a flat matrix works on a similar principle, but the matrix in it is a perforated disk that is rigidly fixed to the shaft. As it rotates, the rollers compress the raw material, then press it into the holes in the disk. The channels for pressing resemble a cone tapering towards the exit; this compacts the granules as much as possible. The holes have a diameter of up to 10 mm.

To make equipment for pressing pellets, you can prepare an existing matrix and rollers. They are often sold as spare parts for feed granulators; you can make them yourself using sheet metal at least 20 mm thick, as well as gears mounted on a shaft.

An electric motor with a power of at least 15 kW, as well as a gearbox, is usually used as a drive for a granulator . The rotation speed of the matrix should range from 60 to 100 rpm. The shaft for attaching the flat matrix can be oriented vertically or horizontally; this will require a container for loading raw materials and unloading finished granules.

Tips for choosing equipment

Equipment should be selected according to the volume of work that is expected to be performed. The largest units turn out to be more expensive in terms of cost and electricity consumption. If you intend to produce a small volume of pellets, from an economic point of view, medium-sized and low-productivity machines will be more profitable.

Dry raw materials in small quantities

Speaking of small volumes, it should be said that a cubic capacity of up to eighty cubic meters of sawdust is implied. Such pellet production is quite acceptable for private businesses. The cost of drying such raw materials is much less than for raw materials.

Basic equipment that will be needed first:

- hammer crusher for producing fine fractions of raw materials;

- unit for creating air flows;

- pressing equipment for pellets;

- cooling unit;

- separator;

- packaging line;

- transportation means;

- container or storage bin.

It is better to have equipment from one manufacturer, as this will save you from further problems if one of the components breaks down.

Raw sawdust in small quantities

Drying such wood processing waste is considered the most expensive, as it requires much more time and investment in terms of energy consumption. Although, with large volumes, the costs pay for themselves. Raw sawdust includes sawdust with a moisture content of up to fifty percent. Before making pellets, sawdust must be dried to a moisture content of approximately fifteen percent. To prevent your work from going to waste, after drying it must be stored in a dry and well-ventilated place.

Industrial pellet dryer

It is also necessary to provide for crushing the material after the drying apparatus. This will also help bring the raw material to the desired state, from which granules can then be compressed. For such tasks, powerful installations are more suitable, since small and cheap ones cannot always cope with the task.

A sufficient amount of raw materials with a moisture content of forty fifty percent

The volume sufficient for the production of pellets is considered to be from two thousand cubic meters. Such production will require. This also requires the availability of appropriate equipment:

- sieve for sifting out fine dust;

- dryer with electric heat generator;

- equipment for moving finished products;

- device for cooling finished products;

- pressing equipment;

- packaging machine;

- place for storage and warehousing of manufactured products;

- a place where you can store already dried raw materials. Warehouse or bunker;

- means for grinding initial raw materials.

Such volumes require serious preparation in terms of equipping workplaces. The most expensive item of all expenses is drying raw materials. In addition to the aerodynamic method, there are also other methods, for example, vacuum, infrared and microwave drying. This equipment is more expensive and requires more energy.

Dry raw materials in large volumes

To work with dry raw materials, you need the same equipment as for raw materials. The only difference may be the amount of pressing equipment.

When choosing equipment, you should take into account the performance of the equipment and the quality that the manufacturer is willing to guarantee for its equipment and final products.

Other materials

In addition to sawdust, other materials are used in the work:

- peat;

- agricultural waste;

- straw;

- branches.

All this must first be dried and crushed. The technology for working with this raw material is slightly different, since the composition is different.

Peat pellets

For example, peat needs to be dried, but does not need to be crushed. On the contrary, the husk will not need to be crushed, and depending on the condition, drying will most likely not be necessary either.

How to organize the production of pellets with your own hands

The fairly high cost of fuel pellets makes the question of how to make pellets yourself very relevant for owners of private houses and summer cottages who want to use this type of fuel. It should be said right away that it is possible to make a homemade granulator for making pellets. However, before embarking on such a project, you need to carefully assess your capabilities. The manufacture of such equipment, during the operation of which significant loads are created, requires not only quite serious technical training and the availability of appropriate skills, but also the use of turning, milling, welding equipment, as well as metalworking tools. All this presupposes the presence of high qualifications and sufficient experience in carrying out work of this nature.

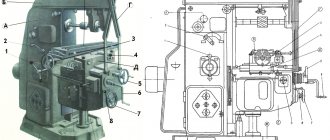

Homemade granulator device

The most important condition for the feasibility of self-production of fuel pellets is the availability of affordable raw materials, which must meet certain requirements for their quality characteristics. If you purchase raw materials for making pellets yourself, which will have to be pre-processed, the cost of the finished product may turn out to be such that it is simply unprofitable to use it for home heating.

When making pellets with your own hands, you should also take into account the fact that not all wood raw materials are suitable for production. Optimal in terms of obtaining high-quality fuel pellets, which have a dense and stable structure, are waste coniferous wood.

Drawing of the housing and matrix drive

What you need

In order to make pellets at home, as mentioned above, you will need a machine for the production of such fuel pellets. Let's consider the main elements of its design.

Flat matrix of round shape

It can be purchased ready-made or made independently using a sheet of metal for these purposes. The thickness of such a sheet must be at least 20 mm. The holes in the matrix in which the fuel granules will form must be conical. When purchasing or making your own matrix for a machine for the production of fuel pellets, you should keep in mind: the larger the diameter of such a structural element, the higher the productivity of the equipment will be.

The size of the granules depends on the diameter of the holes in the matrix

Operating principle of flat die granulator

Powerful rollers with serrated working surfaces

These elements, interacting with the surface of the matrix, press loose wood pulp through its holes, forming dense granules. Such rollers, mounted on a horizontal shaft through rolling bearings, are driven by a rotating vertical shaft. The degree of pressure of the gear rollers to the surface of the matrix is adjusted using a screw mechanism.

Gear rollers and matrix

Device case

It is made from a pipe of the appropriate diameter or from a metal sheet rolled into a cylinder. The inner diameter of the housing must ensure free rotation of the matrix installed in it.

Matrix with rollers inside the housing

Electric motor

The shaft of the electric motor is connected to a vertical rod that rotates the matrix.

V-belt drive

Bunker devices

These devices are necessary for loading feedstock and unloading finished fuel briquettes.

Powerful supporting frame

For the manufacture of the frame, rolled profiles are usually used.

Homemade installation for the production of fuel pellets

Before making a home-made installation for the production of pellets, it is necessary to develop its drawing, focusing on the technical characteristics that such equipment should have, as well as the parameters of the raw materials used and the fuel pellets themselves.

Requirements for pellet production

Since wood and the production of wood materials do not harm the environment, there are not many requirements for it. Wood is a combustible and flammable material, so the workshop where production is carried out must have fire extinguishing equipment. First of all, these are fire extinguishers and an automatic extinguishing system. It is also necessary to consider how raw materials and finished products will be stored. The room must protect them from sources of flame.

Pellet production workshop

Since all equipment for the production of pellets works with a large amount of water, it is reasonable to provide a water supply and drainage system.

Machine for the production of sawdust pellets: what do you need to know before buying?

Before directly purchasing everything necessary to create a wood pellet production business, you should calculate all the nuances of the future business, evaluate all its advantages, and carefully consider all its shortcomings and problems.

Equipment (mini machine) for producing pellets

You should carefully study all the equipment necessary for this task, calculate which one is suitable specifically for your premises, your future operating mode. In this case, it is necessary to prepare the room itself: its dimensions must be at least two hundred square meters, while the required height of this room should not be less than ten meters.

It must be possible to supply electricity and have a normal access road. It is also necessary to select future personnel in advance, so that after installation of the equipment there is no downtime. It should be taken into account that workers need time to study the principles of operation of this equipment.

It is necessary to consider the possibility of supplying raw materials: the best option for creating this business is the sawmill itself, in addition, you should think in advance about the markets for the finished product. In the case when pellet production is established at sawmills, the payback of the business occurs after six months of work.

Application of pellets

The main purpose of pellets is combustion in boilers as a heat source. Widely used in thermal power plants with a capacity exceeding 500 Megawatts. The specific heat of this product is not inferior to dry firewood or even peat. Depending on what raw materials the pellets were made from, their energy intensity may vary.

Application of pellets

The most commonly used raw material is sawdust, since it is available in sufficient quantities at all woodworking enterprises. The heat that can be obtained from their combustion is 4 kW/h/kg. This is enough to heat a small country house. In addition to heating, pellets are used as toilet fillers as a non-standard application. In fact, the scope of pellet application is very wide.