Since melting iron at home requires a heat source with a high temperature, the design of a homemade furnace is chosen based on this condition. It must meet environmental safety requirements and not take up much space in the workshop or garage. These requirements are fully met by installations in which even refractory metal is melted by electric current.

Making a furnace for melting metal

If there is free space for placement, make a stationary diesel or coal stove from fireclay bricks. A fan will be required to supply air. The compact electric furnace creates temperatures of up to 3000⁰C due to the flow of current between two electrodes through a layer of carbon-graphite powder. It melts small portions of any metals. The disadvantage is the long period of heating to the melting temperature and the need to manually turn the metal for uniform heating.

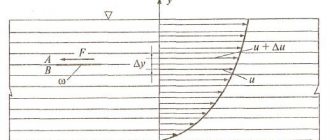

An induction furnace heats the metal throughout its entire volume due to the induction of eddy currents in it by the magnetic field of a coil (inductor) connected to the generator. The advantages include:

- uniform and rapid heating of the metal;

- high efficiency, since only the melting object is heated, and not the installation parts;

- no evaporation of alloying additives:

- mixing of the metal during smelting occurs naturally;

- heating temperature regulation;

- due to high productivity, it is possible to melt small portions of molten metal in short periods of time;

- Melting is carried out in accordance with environmental safety requirements.

Among the disadvantages it should be noted:

- lower temperature of the slag compared to the metal, since eddy currents are not induced in it;

- During melting, it may be difficult to remove sulfur and phosphorus impurities from some types of metal.

Depending on the location of the heated object, induction installations are:

- Channel, when the containers where the metal is melted are made in the form of channels that are installed around a coil with an internal core. They are used in industrial enterprises when large volumes of cast iron, steel, and non-ferrous metals need to be melted.

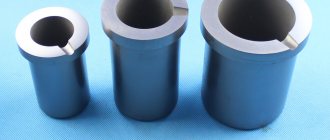

- Crucible with a removable container made of heat-resistant material - a crucible, which is placed inside the coil. This design is compact and convenient for home use.

You can buy a ready-made induction furnace or, if you have the skills to work with electronics, make it yourself.

A homemade crucible installation will cost an order of magnitude cheaper.

The generator is assembled using a transistor or tube circuit, or an inductor is connected to a welding inverter. When making a homemade installation, it should be taken into account that the duration of metal remelting is affected by:

- generator power and frequency;

- magnitude of eddy current losses;

- interference from nearby metal objects.

Induction furnace from a welding inverter

This option is easy to make yourself and is safe to use, since the inverters are equipped with protection against short circuits, overloads, and overheating. To assemble the stove, it is enough to make an induction coil. It is wound with a copper tube with thin walls with a diameter of 8 - 10 mm on a cylindrical template with a pitch of 5 - 8 mm. The number of turns, from 7 to 12, is selected depending on the parameters of the inverter. It should be taken into account that with low inductor resistance, melting will often be interrupted due to overload protection.

Melting metal in an induction furnace from a welding inverter

The finished coil is installed on a heat-resistant surface or placed in a housing made of graphite or textolite. If you use a conductive material, melting will take longer, since part of the magnetic field energy will be spent on the passage of eddy currents through the walls of the housing. To connect the welding inverter, install a socket that can withstand the maximum current consumed by the equipment.

Important!

The inverter frame must be grounded.

Transistor induction furnace

A furnace for melting metal using transistors that is simple in design can be assembled from available parts:

- two field-effect transistors IRFZ44V;

- pairs of UF4007 diodes (can be replaced with UF4001);

- two resistors with a nominal value of 470 Ohm, 1 W;

- several film capacitors with an operating voltage of 250 V, so that the total capacitance is 4.7 μF;

- copper wire with enamel insulation with a diameter of 1.2 and 2 mm;

- two ferrite rings for chokes (bought at a radio store or removed from old computer power supplies).

Transistor induction furnace

Assembly is carried out in the following order:

- Since the transistors will get very hot when melting is in progress, they are installed on radiators. The larger the cooling area, the better. When placed on a common radiator, the transistors are isolated from the surface with plastic gaskets with high thermal conductivity.

- The chokes are wound with 1.2 mm wire on ferrite rings. 7 - 15 turns are evenly laid around the circumference at the same distance from each other.

- Film capacitors are soldered in parallel into a battery;

- The induction coil is wound with a 2 mm wire on a template with a diameter slightly larger than that of the crucible. After 7 - 8 turns, the ends are left for connection to the generator.

- The prepared parts are installed on the board and connected to each other as shown in the diagram:

Transistor oven circuit

Voltage is supplied from a 12-volt battery with a capacity of 7.2 A/h. With a load of 10 A in operating mode, the charge will last for 30 - 40 minutes of melting. The battery can be replaced with a power source connected to the mains, with an output voltage of 10 - 20 V and a current of at least 10 A. If desired, a housing is made of heat-resistant dielectric material for installation. To regulate power, change the number of turns of the coil and/or its diameter. But it’s easier to make several replaceable inductors with different parameters.

Step-by-step instruction

How to make a melting furnace at home - read the following instructions:

- A high-frequency alternating current generator is installed.

- Spiral winding. Made from copper wire.

- Crucible.

All these elements are placed in one housing. The melting cup is placed in the inductor. The winding is connected to the power source. When the current is turned on, an electromagnetic field appears. The resulting eddy currents pass through the metal in the cup and heat it. Melting occurs.

Homemade muffle furnace

The positive properties of an induction furnace are that when melting metals, a homogeneous melt is obtained, alloying components do not evaporate, and melting occurs quite quickly. In addition, the installation of such a stove does not harm the ecosystem and is safe for the user.

Cooling can be done using a fan. Only the latter should be located as far as possible from the furnace, otherwise its winding will serve as an additional closure of the vortex flows. This will reduce the melting quality.

Wheel furnace

How to melt metal at home

The metal is placed in a cup or crucible and transferred to the furnace. First, large pieces are melted, then small ones are added. Fill the entire container with small shavings and sawdust at once. To obtain castings without harmful impurities and reduce losses, you need to know how to melt different types of metal. Precious metals are placed in glass ampoules of medicinal solutions and melted together with them. The glass crust that forms on the surface of the castings cracks and crumbles after cooling with water. Non-ferrous metals are melted in iron containers, and steel, cast iron, and iron are melted in graphite crucibles.

Methods of obtaining and mining

Mining and processing takes place in natural mines. Then the consumable raw materials are delivered to the foundry, where they are processed into the final material. Methods of obtaining:

- Powder. In the manufacture of alloys, powders are used - a mixture of the main components of the alloy in accordance with GOST. Using special equipment, the powder is compressed and given a certain shape. After this, the consumable material is sintered in an industrial furnace.

- Foundry method. All components of the future alloy are first melted and then mixed. The mixture should harden.

Natural springs

The largest amount of metals is found in the earth's crust. Their compounds can be found in various foods, water, air, and chemicals.

Natural compounds

Natural compounds:

- sulfides - cinnabar, zinc blende, sulfur pyrites;

- chlorides - rock salt, sylvinite;

- sulfates - gypsum, Glauber's salt;

- carbonates - magnesite, dolomite, limestone, marble, chalk;

- oxides - red, magnetic, brown iron ore;

- nitrates - Chilean saltpeter.

The main natural compounds are ores, which are found in different areas of the globe.

Ore mining (Photo: Instagram / dikomnw)

Extraction methods

There are two ways to mine metal ores:

- Open. It involves the development of a huge quarry that goes deeper towards the center. From its depths, ore is transported to the top using mining dump trucks, where it undergoes further processing. The average depth of the quarries is 300 meters. Large excavators, dredgers, and quarry equipment are used for development. The quarry method of extracting metal ore is used only if, after testing the soil, more than 57% ore is found in it. The main disadvantage of the quarry is the shallow depth of development.

- Closed. It involves the development of mines that can go down to a depth of several hundred meters. Applicable when less than 57% of useful ores were found on the surface after inspection. Externally, the mine resembles a well, which branches out to the sides at great depths. The main disadvantage is the danger for workers (frequent collapses, gas explosions, great health hazards).

One of the modern methods of mining metal ore is SGS. It is a hydromechanical method of ore mining, which involves the creation of a deep shaft equipped with a pipeline with a hydraulic monitor. A stream of water under high pressure is fed into the pipeline. With its help, rocks are broken off and float to the top of the mine. The effectiveness of this method is low, but it is completely safe for people.

Mine (Photo: Instagram / subcities)

rich mines

Rich iron mines:

- Bakchar iron ore deposit.

- Abakan iron ore deposit.

- Abagaskoe iron ore deposit.

- Kursk magnetic anomaly.

The Kursk magnetic anomaly is the largest iron ore deposit in the world. According to rough estimates, there are about 210 billion tons of useful ore here, which is 50% of the total reserves on the planet.

The richest deposits of aluminum ores are located in

- Hungary;

- France;

- India;

- South Africa;

- Kazakhstan;

- Russia;

- Yugoslavia;

- Kola Peninsula;

- Siberia.

Rich deposits of copper ore are located in the USA, Sweden, Canada, Russia, Finland, and South Africa.

Copper ore (Photo: Instagram / alex_tango1910)

Hydrometallurgy

A technique that is based on chemical reactions. They occur in various solutions. The most common materials obtained in this way are nickel, zinc, and gold.

Pyrometallurgy

Metal is extracted from consumable raw materials under the influence of high temperatures. To carry out this method, furnaces and smelters are used. This method produces cast iron, lead, steel, nickel, copper, and chromium. For the production of active metals, it is important to use reducing agents.

Electrometallurgy

Involves processing consumable raw materials with electric current. The current strength varies depending on the predominant components in the ore. With the help of electrometallurgy, various metals are obtained - alkaline earth, alkaline. The main ones are aluminum and magnesium.

Recovery

Recovery methods:

- Using metals. This process is called metallothermy.

- With the help of hydrogen. Using this technique, it is possible to obtain a material with the least amount of foreign inclusions.

- Using carbon or carbon monoxide. This technique is called carbothermy.

Security measures

When starting to operate a homemade furnace, you should take into account the threats that arise during smelting:

- Splashes of molten metal and heated parts of the installation often cause severe burns.

- In case of fire, there should be a bucket of cold water near the workplace.

- The lamp circuit must be placed in a housing to prevent accidental contact with parts that are supplied with high voltage.

- The range of the electromagnetic field is not limited by the dimensions of the housing. Therefore, before melting begins, you need to remove all metal jewelry and put electronic devices away. If you are near the oven, a mobile phone, digital camera, or MP3 player may be damaged. People with an implanted pacemaker are not recommended to be near the induction unit while melting is in progress.

In a home furnace, not only melting is performed, but also parts are heated before tinning, molding, and hardening. Despite the simplicity of the considered circuits, homemade induction installations are not inferior in basic characteristics to factory-made models for domestic use. If necessary, they can be easily configured to solve a specific problem by changing the parameters of the induction coil and the output signal of the generator.

Ore, coke and blast furnace = cast iron

We all know well from school that any metal is mined from ore. Ore is nothing more than a rock with a high content of the metal we need. However, in nature, only gold and rare earth metals are found in their pure form, which do not oxidize and can be preserved in the form of pure metals for unlimited periods of time. All other metals are found in the ore in the form of various compounds. Most often these are oxides.

Iron ore is no exception. It consists almost entirely of iron oxide Fe2O3 with the addition of foreign impurities and waste rock. In essence, it is dirty rust. And pure ore cannot be sent to a blast furnace. The resulting metal will be of very low quality, and the main product of the furnace will be slag.

In order for the ore to become suitable for loading into the smelter, it is enriched at a mining and processing plant. In the old days, the ore had a high iron content. Today we are practically forced to recycle old dumps and process ore with low iron content, which, of course, affects the cost of steel.

During beneficiation, ore goes through many stages of purification from foreign impurities. At the exit from the mining and processing plants, pellets with a high content of iron oxide are obtained, ready for loading into the furnace. Typically, the mining and processing plant and steel mill are located in the same location to reduce the cost of transporting pellets.

The second component necessary for metal smelting is coke, which is a solid fuel and a source of carbon monoxide, through which iron is reduced from oxide in two stages. Coke is coal that has undergone pyrolysis. Initially, charcoal was used as fuel and a source of carbon monoxide. It is obtained by pyrolysis of wood, but charcoal is too expensive and unsuitable for industrial metal production. Although charcoal is devoid of foreign impurities, which are saturated with ordinary coal. In order to clean coal from gases and impurities, it was also subjected to pyrolysis - that is, heating without air access with removal of the resulting gases. The result is coke, a clean fuel suitable for smelting metals. Not all brands of coal are suitable for producing coke, but only so-called coking coals. Coke can arrive at a steel mill thousands of kilometers away, since it is almost never the case that coal and ore are located in the same place.

The third element necessary to obtain metal is a blast furnace. This grandiose structure was invented back in the 14th century, but then it did not have the same dimensions as it does now. However, the principle of operation of the ancient furnace and the modern one is the same - the reduction of iron from oxide under the influence of carbon monoxide at high temperature.

A blast furnace can operate continuously for as long as desired. In any case, as long as charge and coke are loaded into it, and its lining is not damaged to such an extent that it requires repair. This structure is a shaft furnace with a minimum height of about 35 meters, in which there are several zones. The lowest zone is the furnace in which liquid cast iron is collected, with shoulders located above it. This is the high temperature part of the oven. Above is the steam - the FeO reduction zone, where iron is released from iron oxide under the influence of high temperature and carbon monoxide in the form of drops of liquid metal and flows into the furnace, where it is finally melted. Even higher is the Fe2O3 reduction zone - this is the so-called mine, in which the temperature is lower, but under the influence of carbon monoxide the first stage of the reduction of iron from oxide to oxide occurs. At the very top of the blast furnace there is a top - a device in which blast furnace gases are separated and through which the charge is loaded. Loading of the charge - a mixture in certain proportions of ore, coke and various auxiliary additives in modern furnaces occurs automatically, but previously manual labor was used for this. It is important to understand that even the smallest blast furnace can hold at least 300 tons of charge. And loading them manually is quite problematic, but this mass must be constantly maintained so that the oven does not cool down. Modern blast furnaces have loading volumes of more than 12 thousand tons. Naturally, it is impossible to load such a mass manually.

At the bottom of the furnace there are tap holes for releasing molten metal and draining slag, as well as tuyeres for supplying heated air. To ensure normal operation of the furnace, the air must be heated to a temperature of 1100 - 1200 degrees. At this temperature, it is important that the tuyere nozzles do not lead. To do this, coolant circulates inside them.

The hearth part of the blast furnace has a multilayer lining, which is also cooled by a circuit laid inside. And the furnace itself rests on a reinforced concrete foundation 4 meters thick. The furnace is supported in a vertical position by steel columns.

As a sufficient amount of liquid metal accumulates in the forge, it is drained by knocking out the plug in the forge tap hole. The metal is removed from the furnace through channels and enters thermostated containers for further transportation along the technological chain. Blast furnace slag can be discharged both through a metal taphole and through special slag tapholes. The slag in molten form is transported to a specially equipped site and drained there. The slag is subsequently processed into mineral wool, since it is mostly a mineral base.

Pig iron comes out of a blast furnace. Its properties are far from required, since it contains too much carbon, inclusions of phosphorus and sulfur. To obtain steel from it, you need to burn off the excess and introduce alloying additives. Then you will get steel with the required characteristics. All this happens in the open-hearth or oxygen-converter shops.