What does a slotting device consist of?

The problem of metal chiselling can be solved with the help of homemade and professional modifications of this equipment.

Moreover, they will work on a similar principle. Next, the design features of this machine and the technology of its operation will be considered, which will help make it easier to use it to perform the tasks you face. Regardless of the version of the slotting machine, it always has an identical design , which provides it with the ability to perform a particular task.

The structure of slotting machines is represented by the following elements:

- A bed that provides support for the table.

- A cutter with sharp teeth.

- A rocker mechanism with a box, the main purpose of which is to ensure rapid feeding of the tool.

- The drive, which can have three design options - hydraulic, mechanical and electric.

Homemade slotting machines have a much simpler design, in contrast to professional hydraulic modifications. At the same time, the latter are characterized by a more advanced device and, in addition to this, they create fewer problems when using them manually.

Hydraulic slotting machines are equipped with several components:

- hydraulic system;

- cooling system;

- bed;

- slotting cutter;

- feed box and table;

- control system;

- equipment whose functions include monitoring the operation of the system.

For efficient operation of the hydraulic drive, the latter must be placed in the frame. The device works according to an algorithm that controls the back and forth movements carried out by the slider.

Using such slotting machines, you can create keyways , splines and grooves that are fixed on shaped or flat surfaces.

Its other purpose is to process flat or shaped surfaces, to make cuts and grooves for holes made in the form of a cylinder and a cone. Often, such equipment is used to perform chiselling with the required slope.

Such equipment is suitable for processing the external surfaces of workpieces, the height of which does not exceed 320 mm, and in addition, the internal space, whose height should be limited to 250 mm.

Such devices have become widespread for the manufacture of products on a small scale, as well as as devices included in the arsenal of a home craftsman.

This machine has the ability to feed three types of tables, due to which you can perform the necessary operations on a machine with several surfaces, choosing only one necessary installation option to solve a specific problem.

Such equipment has the possibility of multi-machine service , which is provided by the capabilities of the table, a stopping system that provides a list of algorithms, as well as remote control.

Rating of the best models

Let's look at several current models of slotting machines available on the Russian market.

JET JBM-5 708580M

Compact model designed for processing small volumes of wood. Ideal for those for whom furniture making is a hobby and not a professional activity. One of the cheapest options.

You need to understand that due to its compact size, the unit is not suitable for processing voluminous parts, and due to its low power, it does not penetrate the groove too deeply and interacts poorly with hard types of wood.

Therefore, the model is the best option for those who make small-sized wood products (for example, small crafts or souvenirs).

The unit is small in size. It does not have its own full-fledged frame with a base. But at the bottom of the device there is a clamp that allows you to secure it to a carpenter's table.

There is also no moving block for the workpiece. You will have to move it by hand. Hold it too - since there is no block for the workpiece, there are no clamps that fix it.

For more precise movements of the chisel, a U-shaped guide is attached to the frame holding the electric motor.

The average cost of the model in Russian retail stores is 25,000 – 26,000 rubles. It is unlikely that you will be able to find a slotting machine at a lower price.

| Options | |

| Power, W) | 700 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 120 |

| Dimensions (mm) | 370x350x800 |

| Weight (kg) | 20 |

JET JBM-4 10000084M

A more “advanced” model from the same manufacturer. It also attaches to the carpenter's table. However, the unit has its own base, a movable holder for the workpiece.

Thanks to this, making grooves in wood is much more accurate. This model can already be called “semi-professional” - it is suitable for the full assembly of furniture, although not in production, but in domestic conditions.

The cost of the unit is higher than its simpler counterpart and amounts to 35,000 rubles.

| Options | |

| Power, W) | 550 |

| Speed (revolutions per minute) | 1420 |

| Penetration depth (mm) | 110 |

| Dimensions (mm) | 275x440x640 |

| Weight (kg) | 39 |

Corvette 92

The unit is of domestic production. It has everything necessary for professional woodworking, making it ideal for small furniture production.

The lower part of the device is a metal cabinet in which you can place a chisel or tool. The base of the frame is attached to it with four bolts. Thanks to this, the unit is quite stable. If necessary, the frame can be mounted on another base (for example, on a carpenter's table).

The workpiece area is quite large (40x15 cm) and has its own clamps. This allows you to fasten even a large part, securing it securely.

A massive block with a motor can move along the workpiece. Its location is changed using two rotating knobs. There is also a lever that can move the bit not only from right to left, but also forward and backward. This allows you to hollow out grooves of almost any geometry.

The workpiece platform can also be moved from place to place if desired. Another rotating handle is responsible for its movement.

Thanks to the maximum chiselling depth of 76 mm, it is able to process even fairly large workpieces.

The machine costs from 55,000 to 60,000 rubles. This is not a very high price, so the unit can also be purchased for use on a personal plot.

| Options | |

| Power, W) | 1500 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 155 |

| Dimensions (mm) | 650x550x2030 |

| Weight (kg) | 220 |

720HD

Professional unit. Designed for processing large-scale workpieces. It has good performance, so it can be used in furniture production.

The block with the workpiece moves in any direction horizontally. The frame with engine and bit has hydraulic shock absorption. This allows you to move it very smoothly and thereby achieve high precision chiselling.

The model costs about 150,000 rubles.

| Options | |

| Power, W) | 750 |

| Speed (revolutions per minute) | 1400 |

| Penetration depth (mm) | 76 |

| Dimensions (mm) | 560x480x830 (without cabinet base) |

| Weight (kg) | 108 |

STALEX B5013

Professional level slotting machine. Ideal for medium-scale furniture production. It has great power and the ability to process large workpieces. Thanks to this, it has high performance and is practically universal.

The unit has an electric motor with a chisel at the end, which can only move in a vertical plane. But the workpiece board can also move horizontally. And not only left and right, but also back and forth.

You can change its location very quickly - just make a few turns of the rotating knobs that are responsible for it. The bit is lowered and raised using a spring-loaded lever.

The device has a powerful steel base, which makes it as stable as possible. If desired, the unit can be fixed to the floor. For this purpose, there are holes in the base for bolt fastening.

The cost of the machine ranges from 180,000 to 200,000 rubles.

| Options | |

| Power, W) | 1100 |

| Speed (revolutions per minute) | 1650 |

| Penetration depth (mm) | 125 |

| Dimensions (mm) | 1090x1120x790 |

| Weight (kg) | 330 |

Functions of metal slotting machines

Often, with the help of this equipment, they perform the chiselling of internal parts of flat and shaped types, as well as grooves and grooves of various workpieces .

These machines are also suitable for working with different types of stamps that are placed on a table or fixed in specialized devices. Using this equipment, you can process workpiece surfaces at the required angle while maintaining the initial position of the part. This result makes it possible to rotate the frame, which serves as a location for the cutter.

The position of the table can be changed manually or mechanically. The possibility of circular feed of the table allows you to perform operations on the processing of gears or round-shaped workpieces.

When feeding, the workpiece enters the table through a movable cylinder, which is attached to the hydraulic transmission. The bed provides three options for feeding movement:

- Circular.

- Longitudinal.

- Transverse.

It is possible to change the position of the table in three directions simultaneously:

- Vertical.

- Horizontal.

- Round.

A slotting machine of any design is characterized by the presence of only two planes, which are used for feed movement. This reveals all the advantages of a hydraulic device : the user has fewer problems during the work process, and in addition to this, higher quality machining of parts is ensured.

Principle of operation

During operation of a slotting machine, two types of movements are performed: reciprocal and translational .

Despite the fact that the equipment is designed to work in vertical planes, the movements it makes are rectilinear, which makes it similar to planing machines. The key role when using such a machine is given to the slotting cutter , which is fixed in the slider. The feed is provided by a table on the surface of which the workpiece is rigidly fixed.

During the use of slotting equipment, the mechanism performs reciprocating actions with some interruption. At such moments, the movements of the slotting cutter can have a curved or circular trajectory.

Slotting machines of any design are designed to operate in two slotting modes: simple and complex . In the first case, chiselling is carried out point-blank, while the cutter seems to jump to a certain area and, as a result, it is possible to obtain holes of identical size and shape.

The essence of the second mode of operation of the machine is to create an impact performed at an angle with inclined surfaces . Typically, a homemade machine is not suitable for performing such operations, so it is advisable to use a hydraulic one to solve these problems.

Such equipment is in demand in situations where there is a need to process hard-to-reach surfaces of parts. Here we are talking about surfaces located inside the part, which are used in different types of structures.

Equipment of this type is most widespread when performing work with blind grooves and grooves of various shapes . Homemade slotting machines are in demand for private workshops or small-scale production.

In large-scale industry, sophisticated processing methods have to be used. For this reason, in such situations it is necessary to use a special device designed for CNC metal processing.

If we talk about private production, workshops or service centers, then here slotting equipment is in demand for processing metals, cast iron and other metal alloys .

Among the commercially available modifications of such equipment, the most popular is the “GD” model. It can be presented in several series - 200, 500. However, each of them represents the class of devices under consideration and has the corresponding characteristics.

Design and operating principle

The slotting machine is designed for processing hard-to-reach places, mainly located inside the limited space of the workpiece being processed, where other metal-cutting tools cannot reach. Gear teeth are also often cut using slotting machines.

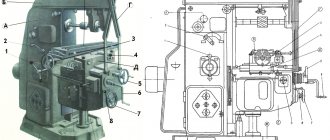

A slotting machine, in general, consists of several main elements (Fig. 2).

Figure 2. Layout of slotting machine components.

Figure 2. Layout of slotting machine components.

1. Bed. The bed is the base of the machine and is intended to accommodate all other components and elements on it. Slotting machines are usually installed on a pre-prepared concrete platform with the level set to zero. At the bottom of the frame there are holes for mounting bolts that secure the machine to the floor. Sometimes the bed has the ability to adjust the machine level, which allows it to be installed on an uneven area with subsequent adjustment.

2. Lateral movement flywheel. Serves to ensure feed of the workpiece in the transverse direction. Each model of slotting machine has its own scale division price.

3. Handle for ensuring rotational movement of the workpiece. Impact on this control causes the table with the fixed workpiece to rotate. Basically, the rotational movement of the workpiece is required in the process of gouging out gear teeth or ring gears. Slotting machines are also often used to create internal spline surfaces, provided that the milling machine for some reason cannot carry out this operation.

4. Longitudinal feed flywheel. Provides longitudinal movement of the table with a fixed workpiece.

Modern slotting machines are equipped with an automatic feed system with adjustable parameters. This allows you to automatically create the required profile on the workpiece. The use of automation of the slotting process is especially widespread when creating parts with circular cyclic surfaces, such as gear wheels, gear rims, parts with splined surfaces, etc. In this case, the work of the machine operator is reduced to setting the feed speeds of the part, the speed and depth of penetration of the cutter and control part processing process.

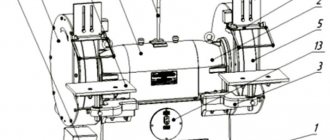

5. Table (Fig. 3). Serves to place the workpiece. Often has removable holding elements that change depending on the specifics of the work being performed. It is often equipped with a chuck modified for a planer, which is used on lathes.

Figure 3. Slotting machine table.

Figure 3. Slotting machine table.

6. Preparation. Depending on the direction of the machine, the workpiece can be wooden or made of non-ferrous or ferrous metal.

7. Tool holder. Serves to secure the cutter in it. The tool holder is designed in such a way that when a cutter is secured in it, one of the surfaces of the cutting edge passes through the center of the rotation axis of the table located at the zero point. This allows you to snap to a reference point when setting up automatic processing parameters.

8. Crawler (dozer). The main working body of a slotting machine. In the drive block of the slider, the rotational motion transmitted from the electric motor is converted into translational motion using a crank mechanism.

9. Gearbox. Serves to transmit rotation from the electric motor to the drive flywheel of the slotting mechanism. It has the ability to switch speeds, which allows the cutter to operate at different cutter feed frequencies. The gearbox gears operate in an oil bath. There is a safety friction clutch, which serves to protect the kinematic chain from destruction in the event of an emergency jamming of the slider.

10. Handle for switching the speed of the cutter. Using this handle, gears are changed and the frequency of the working movements of the slider is changed. The frequency changes in steps.

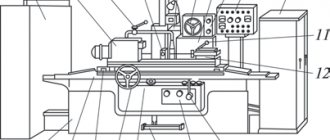

11. Vertical column. It is a stand on which the elements of the slotting mechanism are fixed.

12. Control panel. Contains buttons to start and stop the machine, and, depending on the model, is also used to configure automatic part feeding.

Selection of metal slotting equipment

When choosing a slotting machine, there are a number of factors to consider. By acting in this way, you can guarantee a long service life of the equipment and its uninterrupted operation for a long time.

First of all, you should consider such a parameter as the permissible height of the parts for the device. It can have different values, which are determined primarily by the type of surface being processed.

Along with this, the declared power of the machine , the size of the cutter and the possibility of its regulation also deserve attention. It would be useful to inquire about the presence of transverse and longitudinal stroke of the device and the value of the permissible angle of inclination.

An important characteristic that determines the quality of work of a slotting machine is the speed of movement of the working tool. Only products that are equipped with a massive cabinet can demonstrate stability during operation. This makes it possible to significantly simplify the processing of parts.

At the stage of choosing equipment, you should also take into account the size of the table , since this directly determines the ease of working with the device.