We make pendants with our own hands from metal using a machine

If you have access to a metal lathe, then try making such beautiful pendants with your own hands.

As a child, I collected all kinds of semi-precious stones and other things like them. There was this pearl in my treasure box I made a pendant out of it as a Valentine's Day gift for my wife.

Making pendants with your own hands

Before making the pearl pendant, I experimented with different pieces of iron.

Step 1: Initial Polishing

To start, I cut a piece of 12mm tubing.

You can buy such a tube in a store. 1.50 m for 60 rubles. I put it in the lathe and polished it first with 200, then 800 and 2000 sandpaper.

Doing this will make it easier to polish at the end.

Step 2. Cut

The pearl is attached inside a metal trench. I measured the pearl and it was about 6.5mm.

First I labeled the tube. I made a cut along this mark with a pipe cutter. I then used a carbide drill bit to cut the groove.

I widened the groove with a file.

Step 3. Improve the ring

After I cut the ring, I filed down all the rough edges.

Safety first: Use extreme caution when operating a lathe.

Step 4. Open the ring

I cut the ring with tin snips. Then I flattened it a little with a hammer. Do not beat it too hard so as not to spoil it.

I formed the letter U from a metal strip. I did this using a vice and a metal pin with a diameter of 0.63 mm. See photos.

I pressed the ends of the strip together, but they weren't pressed tightly together yet. I heated them on the fire until they were hot. Then he placed them in water. After this, the structure remained closed.

The last two photos are “before” and “after” heating.

Then I drilled a hole for the chain. I used a diamond blade to sand down the edges.

Step 7: Polishing and Installation

To quickly polish I made an improvised grinding machine. I covered the drill bit with sandpaper and inserted it into the drill press.

To process the inside, I also used a drill, but a smaller one.

To insert the pearl, I placed a flathead screwdriver between the two ends of the loop, widened the gap, inserted the pearl, and removed the screwdriver.

I then hung the pendant on a chain and placed it in the box.

DIY - How to make a TRIDENT from A4 paper with your own hands?

Instructions on how to make a trident from A4 paper. Required materials: 11 sheets of A4 paper, glue, scissors. Approximate time to create 1 paper craft: twenty-six minutes. Reference: A trident is a bladed weapon consisting of a single shaft and a tip of three sharp teeth. It was often used in close combat as a piercing weapon, and thanks to its design, it could easily disarm your enemy. It was especially widely used during the Roman Empire in gladiator battles. They were worn by retiarii, this is a special type of gladiator warrior, literally translated, it sounds like “a fighter with a net”, their weapons consisted of a trident and a net, their armor consisted of one shoulder pad that covered the shoulder or the left side of the chest. gladiator The tactics of the retiarii was to throw their net at the enemy, if he was lucky enough to do this, then he would attack him with his trident. In Greco-Roman culture, it was a symbol of lightning, and was the weapon of the most important Greek god Zeus (Jupiter). Also, the trident is a symbol of power over the seas and oceans and the entire water element. It was a permanent personal attribute of the ancient Greek god Poseidon (Neptune). In Christianity, the trident is a symbol of the Trinity. But it has gained fame as a satanic weapon; it is with it that the devils torment sinners in hell. In Hinduism, it is already a weapon of the Hindu god Shiva; it was often depicted as a mark on the foreheads of his followers. In other cultures• It is a sign of the Maserati company.• It was a personal sign (tamga) of the great Genghis Khan. • The trident is a symbol of the princes of the times of Kievan Rus. Today, the Trident is the coat of arms of Ukraine.• Also depicted on the flag of the Crimean Tatars and Barbados. ——————Weapons made of paper: https://www.youtube.com/playlist?list... Subscribe to the YouTube channel “Origami and crafts from A4 paper”: https://www.youtube.com/channel/UCQRY ... Link to this video: https://www.youtube.com/watch?v=FzTWh... And most importantly, remember that every origami you make with your own hands ennobles you a little, and the folding process itself teaches attentiveness and patience. Thank you for watching our DIY video. Just don’t forget to rate this video about a paper trident later!))) The composition “BTS Prolog” belongs to the performer Kevin MacLeod. License: Creative Commons Attribution (https://creativecommons.org/licenses/…).Original version: https://freepd.com/Unclassified/BTS%20….Artist: https://incompetech.com/Composition “Faceoff” » belongs to the artist Kevin MacLeod. License: Creative Commons Attribution (https://creativecommons.org/licenses/…).Original version: https://incompetech.com/music/royalty-….Artist: https://incompetech.com/

Read also: What does copper consist of?

Crafts on lathes

Lathes have been operating for many decades as the most reliable way to process and artistically decorate any homemade product made of wood or metal. Electrical processing gives the product an elegant and completely finished look. Crafts should have a smooth surface and smooth shaped transitions.

To make wooden crafts with your own hands, soft wood species are used, such as:

Products required for hardwood are made primarily from oak or birch. For beauty and picturesqueness, various decorative elements, tinting or paint can be applied to crafts.

To make crafts with your own hands, you don’t have to be a turner or carpenter by profession and be able to make professional drawings. With a lathe at your disposal, you can learn a lot at home.

DIY metal machine

Thanks to metal lathes, people have the opportunity to make some parts themselves. It is not always possible to buy a part for a car or special equipment.

And most often, not because there is not enough money, but if we are talking about old Soviet special equipment or automobile industry products, many models are no longer produced. But nevertheless, this does not deprive the user of the opportunity to use them. Do-it-yourself metal lathes make it possible to do everything you need at home.

Wood turning

Most crafts require processing by turning. To make a craft on a lathe in the shape of a vase, plate or glass - objects that have the transverse shape of a circle, the workpiece must be secured in a special chuck of the machine. To fasten long parts, a trident is used, which presses them in with the center of the tailstock.

By moving the chisel along the axis of rotation, the part will be sharpened. This type of turning is called longitudinal. If the homemade product is small, it can be secured with screws to a faceplate or flat disk.

Features of the design of a do-it-yourself screw-cutting lathe

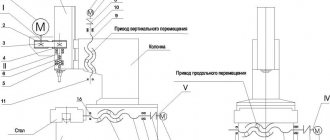

General view of a homemade machine.

It is not difficult to make a homemade lathe at home. The main thing is to follow a number of rules that will help you do this. The first step is to replace the driven and driving centers of the equipment on the same axis. In this way, the user removes vibrations that may occur during the processing of metal workpieces.

Important! When using equipment with one leading center, you need to install a special jaw chuck or a faceplate.

Thanks to these elements, the user will be able to secure the part for further processing with cutting tools.

Important! Under no circumstances should motors be installed as commutator-type electric drives.

If such a unit is not provided with additional counter-load, the torque will be too strong. It will not be possible to grind anything at such speeds. In addition, the part may simply fly out of the clamps, which do not provide sufficient gripping force.

In this way, you can not only damage the workpiece itself, but also suffer badly if it hits a person. For this purpose, use an asynchronous motor. The essence of its work is that even with an increase or decrease in load, the rotation frequency transmitted to the shafts will not change.

Such a unit will allow the operator to process parts of the following dimensions:

- Thickness - 10 cm;

- Width - up to 70 cm.

Before installing such a bolt, lubricate it with machine oil for better and more comfortable sliding. Only then is it permissible to insert it into the thread, which is designed to move the tailstock of the installation.

To work on creating a machine from improvised means, you will need several simple tools that every person can find

- Electric welding;

- Bulgarian;

- Grinding machine;

- Drill with a set of drills;

- Spanners;

- Measuring tools - a caliper along with a tape measure or ruler;

- Pen, pencil or marker for marking.

The first step is to think over the drawing, and then proceed with installation.

Making a wooden box

The recommended wood for making the box is acacia, which, when sanded, gives a beautiful light green color. To make crafts with your own hands, you will need various turning tools made of good steel.

- First of all, the workpiece must be rounded and the edges removed from it. First, you can use a semicircular cutter, then a smoother jamb cutter, which is used to make indentations, a kind of decorative grooves.

- Then both sides of these indentations are cut off, which creates bulges on the box.

- Then we round off the resulting edges.

- Now you can move on to creating the internal cavity. We move the support bar to the end of the workpiece and start making a recess from the center to the edge with a straight narrow cutter.

- Then you need to smoothly expand the cavity to the very bottom. To do this, we use the tip of a triangular cutter.

- Using a wide cutter, we level the bottom, give it the required thickness and make a groove for the lid.

- Let's move on to sanding. We clean the bottom and walls with sandpaper.

- When everything is ready, use a hacksaw to separate the part from the machine.

The lid of the box should be dome-shaped, the size matching the dimensions of the box itself. For this we need a semicircular cutter.

Purpose of the machine and what can be done with it

A lathe is a device for making wooden products in the shape of bodies of revolution. With its help, you can sharpen the material, cut it, and also sand it with sandpaper. The machining process itself is a combination of two types of motion: rotational and translational. The machine directly rotates the workpiece itself, and the turner manually, using a chisel, regulates the pressure on the workpiece to obtain the desired shape.

And it’s not only construction blanks that can be turned on a machine. It all depends on the imagination and qualifications of the master. These can be souvenirs and decorative items. For example, a beautifully made beech wine glass or unusual apple tree spoons will be a worthy decoration for any kitchen. In the hands of an experienced craftsman, any log will become a masterpiece!

Metal crafts

You can make quite a lot of different intricate crafts from metal, including jewelry elements. Before you start working, you can put the drawings on paper. One of the interesting decorative elements is the figurine “Two people playing checkers.”

We take two nails, no more than 5 cm long, several small nails and four nuts. We bend the nails with pliers, following the contour of the sitting people. Two nuts are “chairs” on which the little men will sit, the other two are the gaming table on which miniature checkers should be placed. The board can be made from a small piece of cardboard, and bitten off nail heads are suitable for checkers. To secure all these figures, use special glue or spot welding.

Owning a lathe, a craftsman with a rich imagination will always be able to decorate his home with his own hands and make a worthy gift to his loved ones in the form of an elegant homemade product.

Video instructions for making the “Dodecahedrons in a Ball” craft on a metal lathe

If you find an error, please select a piece of text and press Ctrl+Enter.

What you can do with a homemade metal lathe with your own hands

Compact equipment will not take up much space in your home workshop

Using a tabletop metal lathe, you can perform various work operations efficiently and quickly:

- processing of ends and grooves with the required level of accuracy;

- expansion of existing conical and cylindrical holes (countersinking);

- accurate cutting of workpieces according to the length established by the plan;

- creating a relief surface by rolling;

- cutting standard and special threads (external/internal).

Complex and unique products can be created without errors using a metal lathe for the home

Please study the materials in this article carefully. If implementing the project with your own hands will be difficult, the knowledge will be useful for an objective assessment of the assortment of specialized stores. Separate sections contain information about operating rules that will help extend the service life of process equipment and ensure a high level of safety.

Metal turning products

How to make bodies of rotation: bushings, flanges, shafts, axles? Only on a lathe. Turning is one of the areas of metal cutting. Of course, there are now many modern methods for shaping parts, but turning is still successfully used in small-scale production.

The supply of metalworking usually exceeds demand. You can consider potential performers for a long time. But it’s better to contact us and save time and money.

Our company will produce custom-made products in Moscow at an affordable price, in a short time and with high quality.

- long-term cooperation

- technical support on any thematic issues

- flexible pricing policy

- discounts for bulk and repeat orders

Making a metal lathe with your own hands: step-by-step instructions with comments

First stage: selection of a metal lathe device, preparation of design documentation

The following drawings show the completed project. Such a relatively simple metal lathe for a garage (workshop) is not too difficult to make on your own. Belts and some other components are standard products. You can make other parts yourself or order them from a specialized workshop.

Design, main parts, dimensions

Headstock and Tailstock Components

Travel mechanism and support

Components of the carriage, assembly drawing

To select the required accuracy of movement of the caliper, change the thread pitch of the lead screw. It is cut with a die on a screw cutting machine. To strengthen the structure, connections are made using welding. The headstock bodies are made from channel bars (No. 12/14).

How to choose the right motor for your lathe

The project presented above is designed for the use of a power unit with a power of 450-600 W with a maximum operating shaft speed of 2500-3500 rpm.

In order to save money, some project authors use old electric motors from broken household appliances

Such solutions are quite suitable if you choose an existing engine of sufficient power.

The reasonable cost of products in this category makes it easy to find an acceptable option in the retail chain. In this case, you can count on the manufacturer’s official guarantees

To avoid mistakes, you can study examples of factory-made metal machines and successful homemade products. Based on such a mini-research, it is easy to draw a conclusion about the following proportions: to process parts with a diameter of 8-12 cm and a length of 60-80 cm, electric motors with a power of 600-800 W are used. Standard air-cooled asynchronous type models are suitable. Manifold modifications are not recommended. They sharply increase speed when the load on the shaft decreases, which will be unsafe. To prevent such situations, you will have to use a gearbox, which will complicate the design.

Electrical circuit of a metal lathe

One advantage of belt drive should be emphasized. It prevents direct mechanical impact on the shaft from the tool in the transverse direction. This extends the life of the support bearings.

Assembly order

This algorithm explains the sequence of actions when working with the above drawings. The use of other design documentation implies making appropriate changes to the assembly process.

Start with the front headstock. Install the spindle into it. Next, the entire assembly is connected to the running pipe using bolted fastening. First, threads are cut on the fastening parts. When performing this operation, the alignment of the parts is carefully monitored.

At the next stage, a power frame is assembled from channels. When the frame is made, the headstock is installed on it. Here you also need to pay special attention to the parallelism of the running tube and the long parts of the frame. They make the markings accurately. The holes are drilled sequentially with an additional reamer boring, checking each fastening unit. One or two mistakes will not unduly affect the strength of the channel, so it is better to make a new precise hole in a different place, if necessary.

Factory tailstock of a metal lathe

When assembling this unit, special attention should be paid to the accuracy of the placement of the central axes of the spindle (1) and quill (2). If a mistake is made, conical surfaces will be obtained instead of cylindrical when processing workpieces. They also check that these elements are parallel to the running pipe. The support bar (3) prevents the tailstock from unfolding. To adjust the height, you can use steel spacers.

The caliper parts are installed sequentially in accordance with the assembly drawing diagram. Here, particularly high precision is not needed, since numerous adjustments are provided. If intensive use is expected, make individual components detachable in order to replace wearing parts without extra costs.

At the final stage, the electric motor is installed and connected to the electrical network according to the selected circuit. Check the functionality of a metal lathe with your own hands in practice. To improve appearance and protect against corrosion, some parts are coated with primer and paint.

This photo of a metal lathe clearly demonstrates the high quality of the homemade product.

Metal turning products to order

If you have a need to manufacture metal parts, then you should not continue looking for a contractor. Consider that you have already found it in us. We are aimed at long-term and mutually beneficial cooperation with you. is located in Moscow, but we will be happy to fulfill orders from other regions.

We are always in touch

We perform with high quality and on time

We work all over Russia

CNC equipment

Our specialization is not only turning, but also drilling holes with subsequent countersinking and reaming, milling, and metalworking. We produce metal bushings, rods, hardware and other rotating bodies.

Turning is divided into the following main types:

- Grinding of external surfaces (cylindrical, conical, shaped) with a cutter, thread cutting.

- Boring. This includes machining internal blind and through holes.

- Trimming (trimming) and cutting.

- Cutting threads in holes with a cutter or tap.

Our workshop has the necessary equipment: universal screw-cutting lathes, semi-automatic machines, modular machines with adjustable units. We strive to reduce the cost of production; in the end, products produced on a metal lathe are not too expensive. The most profitable manufacturing technology is being developed, combining affordable cost and high quality.

Types of turning equipment

Types of machines are divided depending on the following parameters:

- purpose of the machine;

- the accuracy of the work he performs;

- its mass;

- the maximum length and diameter of the part that can be processed on the machine, as well as its position in relation to the processing tool installed in the machine.

In fact, it is possible to divide machines into woodworking and metalworking, and then allocate their own subgroups in each group, depending on the specifics of the equipment, focused on performing specific tasks assigned to the machines.

Woodwork

Woodworking machines usually have a slightly smaller size and power compared to their “colleagues” working on metal; in addition, they do not require a coolant supply system, since working with wood produces significantly less stress. There are quite a large number of varieties of machines for woodworking, let’s look at them in more detail.

Sawing

Equipment of this type is used to shape selected wooden elements, as well as for sawing blanks; the equipment requires a minimum level of worker training to perform the work. This type of machines is divided into:

- sawmills, which, using linear saws, provide transverse or longitudinal sawing of wood, they provide general preparation of the material for further work;

- band saws, which cut wood material during the linear movement of the saw, are used for preliminary preparation of material and its processing;

- circular saws, which cut wood in vertical or inclined planes using circular saws, are most often used in shaping due to their higher operating accuracy compared to other devices in this group.

Planing

Planing machine equipment performs tasks related to removing the top layer of the processed material and is divided into:

- single-sided surface thicknessers, with the help of which the upper surface is processed, most often on large workpieces, are simple both in design and in maintenance;

- double-sided surface planers, which can process both planes, lower and upper, significantly increase work efficiency, but are more difficult to maintain;

- jointers, the main advantage of which is the ability to chamfer at the desired angle, while the surface treatment function is also available.

Assembly

Assembly machines are automated devices used to assemble a number of elements into a finished product or semi-finished product, which is used for subsequent processing and/or assembly with other elements.

Gnutarnye

As can be understood from the name of this group of machines, the main function of this equipment is to give elements a certain shape by bending them, for which hydraulic presses equipped with locking clamps are used.

Grinding

These machines are usually used in the final stages of manufacturing parts, they are used to do finishing work by removing the top layer of material using an abrasive-coated tool. Grinding machines are divided into several groups:

- cylindrical grinders, for processing bodies of revolution;

- surface grinding, for appropriate surfaces;

- edge grinders, for processing the edges of shaped elements;

- special grinding machines for complex surfaces.

Milling

Milling machines are needed for processing shaped and flat surfaces. Depending on their configuration, they are divided into:

- vertical milling, with the tool positioned perpendicular to the table and the part;

- horizontal milling, with a horizontal spindle;

- universal, on which you can change the location of the workpiece in relation to the processing unit without reinstalling it.

Drilling

Machines of this type are used for drilling and reaming holes in parts or for processing them. They are also divided into several types:

- vertical, working exclusively in the vertical plane;

- horizontal, similar processing parts, but horizontally;

- radial, on which you can change the angle of inclination of the tool to process a fixed part.

Turning

Woodworking lathes are used for turning body parts and fasteners, and manufacturing decorative elements. They are divided into groups depending on the degree of automation of the device:

- manually controlled devices that are completely dependent on the worker;

- automated equipment, which contains units that ensure copying of a number of processes without human intervention, but under his control;

- fully automatic equipment in which all processes are controlled by a computer program specified before starting the machine.

For metal work

Machines for working with metal have fewer varieties, but slightly different specifics.

Based on the degree of accuracy of the work performed, the equipment can be:

- ultra-precise;

- increased accuracy;

- especially accurate;

- accurate;

- normal accuracy.

Based on the type of work to be done, you can select equipment taking into account its specifics.

Lobototurny

These mechanisms work with metal parts of large or uneven diameter, turning heavy cylindrical workpieces, and they work in the horizontal plane.

Carousel

Using such machines, you can perform simple preparation of parts (turning) or create blanks for the manufacture of more complex objects, for example, gears, since they can be used both for conventional turning and for:

- drilling;

- boring;

- trimming ends;

- thread cutting;

- countersinking;

- creating grooves.

Lathe-screw-cutting

Perhaps the most common type of device for metal processing due to its versatility, in addition, there are models of really small sizes that can be installed in any small workshop.

This machine allows you to work with non-ferrous metal and ferrous metal, sharpen cones, cut different types of threads: inch or metric, pitch.

Turning and turret

Turret lathes are also widespread, especially in CNC format, with a turret head for several tools at once. Multi-position rotary head, a design element that significantly increases the efficiency of the device, reducing the time for processing the part.

Top class turning and milling

If you need to produce metal parts, but do not have machines and specialists, then contact our company. Let us note that the Moscow region is also included in our area of interests. Provide the drawings, and our engineers and technicians will develop the optimal technical process.

The cost of services provided is determined individually.

The price of the service depends on the complexity of the work and is negotiated on terms favorable to you.

The price is calculated from the moment we receive your application (drawings, sketches, samples).

Turning work – from 10,000 rub.

Milling work – from RUB 20,000

Manufacturing of equipment – from RUR 30,000

Batch from 100 pcs – from 30r/part

When executing an order, we use modern equipment and tools with high cutting capabilities. If you have any questions, call our manager, he is always in touch.

Work examples

By clicking on the photo below you can see examples of parts that were manufactured in our production.

Parts kit

Custom parts kit

Sleeves

Housing 12x18n10t

turning works to order

Parts kit

Four-piece set

Shafts

Rotor base

Making supports

Glasses from AISI 304

PTFE spacers

Black polyamide bushings

Pistons

Housing and covers

Turning order No. 407

Aluminum axles

Turning order No. 408

Turning order No. 214

You can view other metalworking works by clicking on the button below.

All our works

Making the Steering Wheel as an interior item with a secret, part 2

- home

- Master Classes from “Master Class Direction” by tag: turning

A new project on Rubankov TV from the Moscow Rubankov Carpentry School. Uncle Vanya, the head of the workshop, started an interesting design project for the interior with a real steering wheel, see the details for yourself) In the video we will do a lot of planing, sawing, gluing, turning on lathes and much more. Enjoy watching and see you at our craft school courses.

The steering wheel, like an interior item with a secret, part 2

1:09 Japanese drills - https://goo.gl/yr7JR2 4:25 Sorby turning cutters - https://goo.gl/QuXyth 5:33 PETROGRAD awl - https://goo.gl/Zn74YX 7:00 Drills Japanese - https://goo.gl/yr7JR2 8:11 Hegner jigsaw https://goo.gl/5mwLWx 10:03 Borma Holzfabre stain https://goo.gl/VRyUJR 14:09 piher quick clamps - https: //goo.gl/vuLi6x 15:15 Japanese saws, abutment saws - https://goo.gl/Dkx4F5 13:25 Glue brush - https://goo.gl/yRqPg6

DIY helm Part 1 - https://rubankov.ru/workshop/master_classes/delaem-shturval-kak-predmet-interera-s-sekretom-chast-1/

How to make money on tabletop lathes and what you can produce on them!

How to make money on tabletop lathes and what you can produce on them!

bad idea. doh…. you can't make money that way

How to make money on tabletop lathes and what you can produce on them! We must start with something else. See what is in demand in your area. Is it possible to establish sales? You study the technology thoroughly, if you are not a professional. And then you try. I know only one group of artisans nearby, more or less successful. This is a copper alloy casting for church needs. Everything else is far from metal. They transport meat to Moscow... They transport plastic windows. But this is again a temporary phenomenon... Etc. How to make money on tabletop lathes and what you can produce on them!

Of course you can earn money, but a little only for the soul. I sharpened fishing equipment, reel floats, etc. Fishing stores will gladly take YOUR goods, homemade products are always in demand, in some cities there are no markets, only for pennies, Add to This is due to the cost of the material. So don’t expect to make a lot of money, but sales if the item is made with high quality are constant. Yes, you can come up with a lot of things if you have free material.

How to make money on tabletop lathes and what you can produce on them! IMHO. Here you need to do something very exclusive/unique. Not in terms of accuracy, of course... but, so to speak, artistic value. And one more question for TS. What does it mean to make money? What amounts are implied? You don’t have to answer out loud, it’s a personal matter... but do the math for yourself. How much needs to be done and at what price, say per month.

PS. Another IMHO - it won’t work

Post edited by Dmitry43: 12 January 2014 — 13:01

How to make money on tabletop lathes and what you can produce on them!

Dmitry43 (12 January 2014 - 13:00) wrote:

TS gets a two-week break for cross-posting. How to make money on tabletop lathes and what you can produce on them!

Asklepiadot (12 January 2014 - 13:01) wrote:

View message Dmitry43 (January 12, 2014 - 13:00) wrote: And another question for TS TS for cross-posting is on rest for two weeks. It's a pity... Well then, let it be just advice on how to make money on tabletop lathes and what can be produced on them!

victor7 (12 January 2014 — 12:32) wrote:

Good morning everybody. Sorry, but the topic is completely different. I asked, but did not receive an answer from you. I ask the question again: 1) Is it possible to produce something to earn money on tabletop lathes, such as TV-4, TV-6, TV-7, TV-16. as well as desktop milling machines 2) If it is possible to make it, then I ask for advice and ideas. 3) Or this is not for making money and you won’t make money on it. If you ask about this on the forum, then you probably can’t. You can create a workshop and take orders, but you probably won’t get by with small machines to make serious money. And qualifications are needed. And so, indeed, as a part-time job you can do something to order, but as a main source of income it is not effective. Yes, and here you need qualifications and a get-together among those who are interested in your work (something for modellers, auto/motor parts for restorers, all sorts of things for historical reconstruction, some devices for jewelers, artists, I don’t know what else). Making hundreds of simple parts in series on such machines is most likely unprofitable, and not very convenient. You can come up with your own unique product and release it. This refers to a device or device for something, and not just one part. But not everyone can do this anymore. If you want it simple, it’s better to make the keys on a special machine. They are always needed. How to make money on tabletop lathes and what you can produce on them! Once upon a time we made a batch of bushings for the clothing industry; it’s quite possible to do it on a small machine. A friend made brass nuts, supposedly for furniture. Inside there was a hexagon on a home press. Then he made a device for quickly cutting threads. He made these nuts in large quantities, and earned very good money. How to make money on tabletop lathes and what you can produce on them!

himgr (12 January 2014 — 13:13) wrote:

A friend made brass nuts, supposedly for furniture

It was probably a long time ago. Nowadays there are plenty of furniture fittings available for pennies. And other furniture makers have become How to make money on tabletop lathes and what can be produced on them!

Even a small lathe is very necessary. Place it in the garage, open the gate wider (so that everyone can see how you work and what) and start sharpening anything for your loved one. The handles for the files are beautiful, canopies for gates, copper slip rings for car generators, grind the commutators of drills, grinders, starter commutators, etc. In half a year, a stable clientele will appear and people themselves will begin to suggest what can be done on your equipment. You will begin to acquire tools and machines. Those who want are looking for opportunities to use the knowledge and skills they have, and those who don’t want are looking for reasons to refuse. Our people have sooo many problems, you will not be useful.

How to make money on tabletop lathes and what you can produce on them! Stop turning the chipmaker into a branch of the Hansa. Let technologies and designs live here, and let’s leave the squabbles about legality there. If you are afraid to make bullets, then you can make bullets. Die-cuts for wads. Matrix for twisting. Purlin rings. If you have access to heat treatment and grinding, then the calibers are for rifle owners. There is a lot to offer modellers. But here it is highly advisable to stew in their environment. How to make money on tabletop lathes and what you can produce on them!

As one of my friends said, you can’t make money on individual parts. You need to produce at least some kind of ready-made unit.

How to make money on tabletop lathes and what you can produce on them! How to make money on tabletop lathes and what you can produce on them!

victor7 (12 January 2014 — 12:32) wrote:

Good morning everybody. Sorry, but the topic is completely different. I asked, but did not receive an answer from you. I ask the question again: 1) Is it possible to produce something to earn money on tabletop lathes, such as TV-4, TV-6, TV-7, TV-16. as well as desktop milling machines 2) If it is possible to make it, then I ask for advice and ideas. 3) Or this is not for making money and you won’t make money on it. This can be done. https://cazac.ucoz.co...t_stirling/0-14 And if you do this, that’s already good money. https://cazac.ucoz.co...ex/delavan/0-13 How to make money on tabletop lathes machines and what can be produced on them! Unfortunately, there are no finished products left. But I gave a lot to friends, everyone is happy. This is what I abandoned. As I wrote earlier, you can do whatever you want, the main thing is that this production satisfies YOU. How to make money on tabletop lathes and what you can produce on them!

donut (12 January 2014 - 13:32) wrote:

You can do whatever your heart desires, the main thing is that this production satisfies YOU.

If it's a hobby. The topic was about making money, which means it’s more important that they BUY it. How to make money on tabletop lathes and what you can produce on them!

If making does not bring joy, then there will be no income.

How to make money on tabletop lathes and what you can produce on them!

You need to make something yourself (finished product) that requires small turned parts

How to make money on tabletop lathes and what you can produce on them!

donut (12 January 2014 - 13:32) wrote:

Dear, what was that? How to make money on tabletop lathes and what you can produce on them!

Slava9 (12 January 2014 — 13:17) wrote:

.Put it in the garage and open the gate wider (so everyone can see how you work and what)

We periodically walk along the garages and see what you are doing. I think it's the same everywhere. Can you initially give a certain amount, and then cover it and become a plus?

Post edited by Leon10: 12 January 2014 — 14:02

www.chipmaker.ru

Choosing a location for a turning workshop

A well-located turning workshop will be provided with orders without high advertising costs. If potential customers are nearby or constantly pass by, they will find the workshop themselves. The most successful location for the workshop would be:

- in a garage cooperative;

- next to a busy road;

- near a construction supermarket;

- on the market territory.

The main customers at first will be technicians involved in the repair of various equipment, installation of heating systems, and car enthusiasts. While searching for spare parts, they will find a lathe shop located in a prominent location.

In villages with a small population, orders will have to be sought externally and metal imported from afar for work. Transportation costs will eat up most of the profits. In remote villages and on the outskirts of large cities, you can open workshops if the business is expanding, there are constant orders in batches, and the existing equipment cannot cope with the load. Renting premises on the outskirts will cost less for a branch. Local workers do not aspire to Moscow-level salaries, but recruiting personnel will be more difficult.

A large space for a developing business should not be rented; for the first time, a garage or container will do.

8–10 sq/m is enough, on which there will be a compact layout:

- a lathe is the basis of the business;

- auxiliary equipment;

- tool storage location;

- area for blanks and rolled products;

- table or shelf with finished products;

- washbasin with water;

- fire extinguisher.

When choosing a location for a workshop, you should pay attention to the presence of:

- electricity;

- water supply and ebb;

- availability of a bathroom.

It is difficult to install a toilet in a small room. It’s easier to locate your business in a market or next to a supermarket. In this case, a public toilet will be within easy reach.

During cold weather, it is necessary to equip the room with heating and ensure the air temperature established by sanitary standards. This possibility must be foreseen in advance when choosing business premises.

When locating a turning workshop in a permanent building, you will need to equip:

- separate entrance;

- a major partition from the rest of the room;

- bathroom with water and low tide;

- wash basin;

- ventilation;

- fire shield.

The requirements of the Fire Department and the Sanitation Station in such cases are much higher. Considering the noise and vibration of operating equipment, and the odors from evaporating coolants, it is impossible to rent premises in residential buildings. A place for eating and a shower should be provided for workers.

In the turning shop it is necessary to equip general lighting and local lighting for each machine. Wiring must comply with fire safety requirements.

Equipment selection

In an enterprise of any size, regardless of the product being manufactured, lathes are the busiest and most in demand. Most of the cutting work is done on them. You should start your small business by purchasing a tabletop machine. Small equipment for a turning shop has significant advantages:

- connected to the household power supply network;

- do not require a special foundation for installation;

- space under the table and drawers can be used.

The equipment of a turning shop cannot be limited to units of the same type. A sharpening machine for cutters, drills and other tools is a must. A set of circles is purchased for it, taking into account the work performed on it. In addition to tools for the machine, it can be used to sharpen garden tools, knives and axes.

Tools for turning business

A machining business is impossible without cutting tools. Need to purchase:

- set of cutters;

- carbide plates;

- drill;

- taps and dies.

A place must be provided for storing tools. It should be near the lathe. Equipment is also stored there. A tabletop lathe allows you to use the cabinets and drawers of the table on which it stands.

Tools are bought in large quantities from hardware vendors on the market. Many old workers sell tools made in the USSR. When purchasing, you should choose cutting, scoring and through cutters.

Drills are useful in two types: with a diameter that is a multiple of an integer mm, and for threading. In addition to dies and taps for metric threads, you will need a tool for cutting pipe threads near the hardware store.

Basic universal equipment is sold complete with the machine. Special devices are made and purchased as needed when needed for work.

Optional equipment

The next purchase for your lathe business should be a benchtop drill press. It will not have a full load, but will significantly expand the list of manufactured parts. Having received a machined pulley, the customer will not look for where to make a hole for the mounting bolt.

A turning and milling business does not require a large area of premises. Even desktop equipment with a 230 W power supply will allow you to make keyways, splines, and selections. On shafts they are necessary for fastening and transmitting torque.

The milling unit will allow you to make parts with a complete configuration, grind hexagons on bolts and nuts, when manufacturing from round bars, make crackers and dowels.

To work, you will need cutters of different types and replaceable carbide inserts. From the equipment, adapter cones for the spindle, fasteners.

Equipment for business expansion

It is necessary to expand production using floor-mounted lathes such as VT and TVSh. Large units are not needed because they:

- expensive;

- take up a lot of space;

- require a foundation for installation;

- consume large amounts of energy;

- will not be fully loaded.

Large parts are made in production. The population and small entrepreneurs - potential customers - are interested in small things.

When expanding your turning business, you need to focus on the specifics of the region and what orders you receive most often. Having regular customers who regularly need the same parts, it is good to purchase a CNC turning and milling machine. It will completely replace a whole range of machines and will be justified in batches of 20 pieces or more.

Purchasing a welding machine transforms a business from small to large. Such production requires a spacious room with a fenced welding area, several lathes and a cable supply with a voltage of 380 W. To effectively operate the equipment, it is necessary to hire several turners and workers of other specialties.

To operate, the welding machine requires a step-down transformer that changes operating modes. From the tool you will need electrodes of different brands. To clean up welding and finished seams, you need a grinder and circles.