Purpose of the machine for cylindering

The woodworking machine completely prepares the log for installation in the wall structures of log houses. Functions of woodworking machines:

- production of grooves for installation;

- rounding of logs (including final);

- production of edged boards from gun carriages;

- production of parquet dies;

- milling smooth wood;

- cutting unedged boards;

- preparing the crown cup;

- timber production;

- sawing timber into carriages;

- adjustable log rotation speed;

- making a compensation groove using a circular saw.

The movement of the carriage is controlled by a laser pointer. An important property of rounding machines is the ability to perform any manipulation with one set of tools without reinstalling the log. The combination of cutters and techniques makes it possible to produce complex products with different diameters, for example, balusters. You can process a log up to 7 m long with your own hands.

Types of rounding equipment

Depending on the technology, the log rounding machine is divided into:

- Passage – carries out wood processing while moving, without stopping.

- Cyclic – when processing wood, the movement of the log is interrupted. The movement pattern is a cycle of operations.

- And also cyclic installations are classified into two subtypes:

- Cyclo-positional - material processing occurs in the process of advancement relative to the tool

- Cyclo-passing - wood is subjected to woodworking with a tool that itself makes the necessary movements.

According to the mechanism of operation, the machines are divided into:

- Mechanical - require the presence of an operator who adjusts modes, configures, loads and unloads equipment.

- Automatic - the entire processing scheme is carried out by a machine. There are models where a person only needs to load the material.

- Semi-automatic - the installation automatically performs only one cycle of operations, and then the person must start the mechanism again.

A machine for rounding logs in the case of a separate type gives different productivity. Pass-through equipment is more productive, but inferior in terms of correct processing and the formation of pronounced roughness of the material.

The device of the machine for cylindering

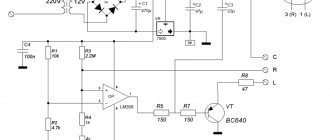

The log processing machine drawing includes:

- a metal frame, usually made of rectangular rolled pipe;

- guides for moving saw and power devices;

- headstocks for fastening the log and twisting it. The front one is equipped with a dividing head, with which the barrel is fixed. The spindle head is also installed there;

- Wood is processed using cutters. The shape cutter selects the groove for installation. The universal cutter is designed for cutting crown cups, processing planes, and rounding;

- knives for cutters are removable. Made from good steel, they can be replaced and sharpened without touching the cutter;

- levers for placing logs;

- stop roller to prevent logs from sagging;

- mechanical brakes are installed at both ends of the carriage and are used during removal of the crown bowl;

- the carriage lock stops it while removing bowls;

- device for manually rotating the barrel: used when cutting a longitudinal groove.

What affects performance

To determine the basic parameters of the material, there is a set of regulations. In our country this is GOST 2708-75, in the west ISO 4480-83. There is no big difference between them, the main parameters are identical. It is on this data that a program such as a calculator for rounded logs of volume, weight, density and other characteristics is based.

Array volume table.

Advice: it is desirable that the table of volume of rounded logs be original, that is, taken from the above-mentioned regulatory documents. Since now there are many corporate tables compiled taking into account the commercial interests of some corporations and containing inaccuracies that are beneficial specifically for those who compiled them.

Machines and equipment

Even 50 - 100 years ago, every carpenter or just a good owner knew how to round a log at home. Due to the fact that this occupation is long and very labor-intensive, with the development of woodworking production there are not many real specialists left.

Of course, in the debate about whether a log or a rounded log is cheaper, an ordinary unprocessed trunk wins. But building a good house or a high-quality bathhouse from “wild” material is almost impossible. Apart from the time spent on handicraft cylindering and labor-intensive installation, you will not be able to seal the seams and joints hermetically. Accordingly, the room will be cold and will not last long.

A machine for cylindering logs is, in fact, a symbiosis of milling and turning functions. Such equipment has impressive dimensions and includes a common metal frame on which they are based, a power unit, which can consist of several power units.

The main work is done by the headstock. It is on it that cutters for stripping the top layer and figured cutters for finishing the log are installed. The tailstock, as in most similar equipment, serves to fix and feed the workpiece itself.

If you want to know how long it takes to make a rounded log, then in this case it depends on the quality and functionality of the equipment. Modern automated lines are capable of turning a high-quality calibrated product from natural logs in a matter of minutes, according to specified parameters.

All such units come in two types - continuous and cyclic. The first ones are designed for large production volumes and have a minimum of functions. In them, the material moves in a continuous flow and, passing through the working area, is cylindered and milled.

Installing the workpiece on the machine.

Aggregates of the cyclic type perform a given algorithm of actions, after which the cycle is repeated. They, in turn, are divided into cyclo-pass type, where the barrel moves and the carriages are in a fixed position. And cyclo-positional, where the log is motionless and the carriages move around the workpiece.

As a rule, a do-it-yourself machine for a cylindrical log is made on the basis of a sawmill, where a stop is installed instead of the front cone, and the tailstock is replaced with a bearing or a rotating cone. The workpiece secured in this way rotates due to an additional drive or with your own hands, which is very difficult and inconvenient.

Processing is carried out by a milling head mounted on separate guides. The very principle of operation of such a handicraft unit is reminiscent of the operation of a wood milling machine. A rotating workpiece is gradually processed by a milling cutter moving along guides.

Advice: due to the serious weight of the workpieces themselves, experts recommend rigidly mounting such equipment exclusively on a concrete base. If this is not available, as an option, you can lay a reinforced concrete slab for the floor.

General diagram of the machine.

A few words about the characteristics

Domestic production is more focused on the so-called lunar profile of rounded logs. It contains a mounting cup for connecting the crowns and a compensation cut.

This cut serves to compensate for the natural internal stress of the array, as well as temperature and humidity expansion. Such a product is cheaper to manufacture, plus it does not require careful preliminary preparation of the material.

The Finnish profile provides a tighter connection of the crowns; therefore, less sealing materials are needed, but the log requires careful drying and preparation, as a result the price of the Finnish profile is higher.

The working height of the rounded log is 6 meters. This does not mean that products cannot be larger or smaller.

It’s just that most technological lines are oriented towards this size. An increase in height entails an increase in cost. The price of smaller barrels depends on the quality and complexity of processing of a particular product.

Storing goods in stacks.

As for the diameter, the working range here ranges from 160 to 320 mm. Rounded logs of 400 mm or more are processed on special machines. Such non-standard goods are used to equip the main crowns of the building, as well as other important load-bearing units. In addition, the walls of the first floors for multi-storey cottages are sometimes erected from logs with a cross-section of 400 mm.

The cost of the product is greatly influenced by the method of drying the massif. Natural drying takes place for about six months under open sheds in natural conditions. Such a product costs less, but its shrinkage is higher.

Chamber drying involves processing the material in special high-temperature chambers. Such a log shrinks less and is considered to be of higher quality.

Important: glued rounded logs appeared on the market relatively recently. The price for such products is much higher. But, according to experts, they are of exceptional quality.

The video in this article contains materials on this topic.

Types of machines for cylindering

Mechanisms for cylindering are divided into the following types:

- checkpoints.

- cyclic.

Pass-through machines ensure constant advancement of the barrel. During processing, the log is advanced through the tool.

Cyclic machines move and process wood in cyclic movements and are divided into:

- cyclo-pass: the log is motionless, the cutter moves;

- cyclo-positional: the tool is stationary, the material moves.

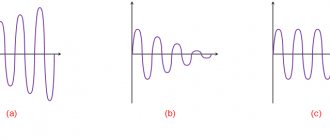

There are two types of movements used in woodworking: linear and rotational. The shape of the final product depends on the combination of movements. With a cyclo-pass mechanism, the logs move in a straight line and the tool rotates. During positional movement, the barrel rotates and the cutter moves along its axis.

An industrial rounding machine sharpens or mills wood. The turning process is possible with rapid rotation of the log. As a result, a lot of sawdust is formed. During milling, waste is generated periodically; in this case, the tool rotates.

Rounding equipment is divided into three categories according to the level of automation:

- mechanized machines. The worker loads the material, he also monitors and adjusts the mechanisms.

- automatic machines. The worker only controls all processes. Loading and processing occurs automatically.

- semi-automatic machines. Only one stage of woodworking is automatically controlled, then a worker is connected.

Comparison of woodworking machines

- Continuous rounding machines are productive, but they allow errors in processing and surface roughness;

- cyclic positioning equipment processes wood very efficiently and carries out all operations, but is significantly inferior in productivity.

Due to its compact size and stable base, cycle positioning equipment is widely used in woodworking.

Classification

Experts propose to classify rounding machines according to five parameters:

- type of mechanism;

- the method of moving the log;

- level of automation;

- drive power type;

- diameter of the workpiece used (minimum – 80 m, maximum – 500 m).

Two types of mechanisms are used in installations. The first is a pass-through (rotary) one, which allows you to continuously move the wood through the cutter. The second is cyclic (turning), in which processing is performed by repeating a cycle of actions.

If cyclic actions are performed by a cutting tool, the machine is classified as a cyclo-pass type, and if a log moves, it is classified as a cyclo-positional type. In the mechanisms, logs have the ability to both rotate and move rectilinearly along the guides.

Homemade rounding machine

sawmill at the base of the machine

The easiest way to make a machine with your own hands is from a sawmill. Instead of the front cone, a stop is installed. The headstock located at the rear is equipped with a thrust bearing. An additional electric motor or handle is used to rotate the log.

The most difficult thing to make is a cutter, so it is made up of parts. You should choose the most durable material possible. The cutter moves on an additional rail. The device is similar to a conventional milling machine: a log is placed in the grooves, its rotation is started, and the cutter moves along.

A homemade rounding machine must be placed on a strong concrete base. You can prepare a frame of sleepers or thick timber, installed on compacted soil.

Installation progress:

- The frame is being assembled. A building level is used, an error of up to 0.5 mm per 1 m is allowed. The frame is installed at a height of 20 cm.

- Installation of the power mechanism, headstocks.

- A cable for the electrical cable (mobile) is attached to the installed racks.

- The power mechanism is equipped with a stopper.

- Grounding is provided.

- A motor is connected to the power supply to rotate the log. When connecting, check that the phases correspond to the modes. If the phases are connected incorrectly, when pressing the buttons the head will move in the other direction. This means the phases need to be changed.

- The direction of rotation of the log is checked. It changes by changing the phases on the electric motor. Before checking the phase connections, it is strictly forbidden to start the rotation motors and the machine.

It is important to firmly and rigidly secure both headstocks, installing them parallel to the guides. The axes of the headstocks must match! The machine will quickly fail if the cutters are not balanced. The final stage of machine installation is the installation of cutters. The figured one is fixed to the shaft and attached to the conical part with a bolt. A universal one is screwed into its body and tightened tightly.

If it was kept in a damp place between starts or the interval between uses was more than 8 weeks, the machine should be kept in a dry shed to dry out the motors.

A rounding machine with a movable carriage in action:

Creating a machine yourself

To produce a universal device that works with wood, you will need:

- Vala;

- Bed, which is adjustable in height;

- Drill chuck;

- Electric motor.

This mechanism can easily sand, sharpen and cut wooden components.

When choosing an engine, do not lose sight of the following characteristics:

- Power in the range from 0.6 to 1.5 kW;

- Synchronicity;

- The average shaft rotation is about 2500 rpm.

The shaft must have a device for fixing the drill chuck. If there is none, then you will need to sharpen the end part of the shaft using a file. The diameter of the fastening must be slightly larger than the diameter of the cartridge. Then start the engine and sharpen the cartridge so that it is firmly attached to the shaft. Using lapping paste and a file, adjust the chuck to the required shaft size. If you do not have such a paste, you should rub the sandpaper and dilute its abrasive with oil.

Be sure to drill a hole and tap an M5 M6 thread in the center of the shaft, this will prevent you from accidentally slipping off the chuck. Also, don't forget to secure it with a countersunk head.

You can position the wood piece in different positions in relation to the machine.

Features of work

The frame is fixed to the table with two bolts, and the slats are secured using fixing brackets.

To build a frame, you will need six iron corners, the cross-section of which should be 2.5 by 2.5 cm, and one corner with a cross-section of 4 by 4 cm. Their length is 30 cm. Use a welding machine to connect

Pay attention to the quality of the welds, as the machine vibrates noticeably during operation

To make a countertop, you can use plastic, metal, plywood or boards.

To install parts on the table space, you will need to make brackets and strips. To install a cutter, saw or pulley into the chuck hole, you need to additionally make transitional bushings, as well as mandrels.

Review of factory models

KEDR OS-100

OTSS-4A

WOODVER OSV-2

| KEDR OS-100 | OTSS-4A | WOODVER OSV-2 | |

| Log length (mm) | 6200 | 8000 | 8000 |

| Minimum diameter (mm) | 160 | 160 | 140 |

| Max Diameter(mm) | 240 | 500 | 360 |

| Power, kWt) | 7,5 | 20 | 15 |

| Price, rub) | 210000 | 750000 | 670000 |

Recommendations before purchasing

For the chosen level of productivity, it is important to consider the degree of automation of the rounding machine.

In mechanized models, the operator loads and unloads logs, configures and adjusts the mechanisms. He also monitors the quality of work performed at all stages of operations.

In automated rounding machines, the specialist servicing it is assigned the role of process controller.

In semi-automated installations, the master joins the process after the machine has completed one cycle of operations.

Note! To create optimal and uninterrupted operating conditions, it is important to select the appropriate type of drive power supply.

Electric can work without interruption, provided that the power lines are reliable or there is an additional power generator. Gasoline requires constant refueling, but does not depend on external factors.

But the main choice is between pass-through and loop types. The pass-through will provide high productivity, sometimes at the expense of the quality of processing. Most models of such machines do not have the ability to make the surface of the log smooth, without burrs and roughness. Cyclic installations work much slower, but at the same time they have a number of advantages:

- provide very high quality processing;

- perform the entire set of operations;

- have compact dimensions;

- The design is stable and easy to maintain.

Why exactly a log?

What is the significance of the curvature of a log when sawing ungraded wood on a multi-rip machine?

Why does a thread-like strip form on its surface when rounding a log?

Why is the Kedr rounding machine cheaper? Question from Boris from Krasnoyarsk.

I bought a rounding machine that looks the same as OTSS-1M. Is it possible to buy a new cutter for it?

There is a need to purchase a laser cut indicator for a sawmill. Will your laser work in such conditions of -40C? What is the line length of a line laser?

Hello! Do you have machines for sale for rounding logs, where the natural consistency of the log is preserved? We build handmade houses. You have to cut and chop by hand, but I would like to try to get a similar result using a machine. Best regards, Evgeniy.

Hello, we purchased an OS1-400 machine from the Izhkomstanko company, started production and came across one very interesting point, the essence of the question is whether it is necessary to make a raw round log larger in diameter by about half a cm, so that when it dries, we get required diameter? And does a dry log absorb moisture after assembly? If it absorbs, does the part increase in diameter? Or not? Thank you very much in advance for your help.

How to set knives on the OS1-400 cylinder machine?

How do you solve the log vibration problem?

Tell me, how do Svyatogor and Sherwood machines differ from Pilteh machines?

Why does a wave form when sawing on a band sawmill?

What is the difference between the OTS-4A rounding machine and the OTS-2A?

... I recently learned that the yield on circular sawmills is much more than 78-80 percent, after I also read about it on the Internet, is it true? After all, on disc wheels the thickness of the cut is greater, so why is the output so large?

How to check the geometry of a band sawmill?

What is better to specialize in production: only cylindering of logs, production of house kits, production and assembly of houses from cylindered logs?

How does the height of a wall made of rounded logs depend on the width of the mounting groove?

The principle of processing the surface of a log during rounding.

How to join a cross-cutting machine and a cup cutting machine in a line?

What to do if instead of a cylindrical log you get a cone (carrot)? The difference in the butt and apex reaches 5 mm.

How long does it take to round one log, what is the real productivity?

Why does the conveyor belt move to the side?

What are the types of rounding machines?

What is the difference between the OTS-2A rounding machine and the OTS-3A?

How to make a rounding machine with your own hands? I don’t see anything complicated except the rounding cutter. Is it possible to order from you a cutter for a rounding machine and a cutter for a cup cutter with a diameter of 220 mm?

The complete set of the OTS-3A rounding machine, what else will be needed to organize the production and assembly of houses from rounded logs?

What is the difference between houses made from rounded logs and those assembled from hand-cut logs?

Is it possible to additionally order a milling cutter for the OTS-1 rounding machine?

Is it possible to purchase your machine on credit or lease?

Where can I see your equipment in action?

I saw your machine in our region.

But I can’t find it in the photo on your Pilteh website?

Can I pick up the OTS-2A machine in my car?

I'm interested in a corner disc sawmill. Deadlines?

I want to order a machine with certain parameters.

Category: Tips Created 02/06/2014

With their help, you can quickly cut the desired piece from a board or log. To calibrate the product you will need a thickness planer.

Thanks to it, it is possible to produce a wooden part of the required thickness with an accuracy of literally up to a millimeter.

Circular saws are different. Nowadays, manual and stationary units are produced that are designed to work with various types of wood products.

This equipment is a powerful electric tool, the main part of which is a durable disk with very sharp teeth.

This unit will easily cut boards, laminate, slats, and wood boards. It's even suitable for cutting metal.

Circular saws come in different models. Therefore, their technical characteristics may differ.

To choose the power tool you really need for production, you should familiarize yourself with the following characteristics of the equipment when purchasing:

- cutting depth. One of the most important indicators of the unit. It depends on the diameter of the disk. The larger its size, the deeper the cut will be;

- Engine power is also an important indicator. It affects the speed of the equipment. The more powerful the unit, the more productive it will be. Circular saws used in production can have a power of 2500 W. This is a very high figure;

- equipment safety. Since circular saws will be constantly used by workers at a woodworking enterprise, they must be completely safe to use. Therefore, you need to choose units with a protection system, a lock that prevents their accidental activation.

To calibrate wood blanks, a thickness planer is required.

Most often it is used in furniture production, since manufacturers of interior items require professional equipment that would allow them to produce neat and beautiful products. When choosing a thickness planer, you need to pay attention to its technical capabilities:

- how often the shaft rotates. The faster it rotates, the smoother the surface of the workpiece will be;

- depth and width of the cut made by the thickness planer. Depth is an indicator that means how much wood the unit can cut in one pass.

- Width – what width of parts the machine can process.

It is customary to call a rounded log from which the top layer of wood is cut off on a special woodworking machine.

As a result of this processing, the diameter along the entire length of the log will be the same, i.e., a cylinder is obtained from a cone-shaped tree trunk.

Houses made of rounded logs look not just beautiful, but elegant. They are warm, durable, and, most importantly, environmentally friendly.

The rounding machine is designed to give the correct shape to logs used for the construction of log houses.

The use of machines makes it possible to speed up and simplify the preparation of wood.

Hand-processed logs come out the same diameter, with a groove, planed surfaces and prepared mounting bowls.

Wood processing has been carried out for several centuries. Since ancient times, rounded logs have been used to build houses, bathhouses and other structures.

The process of giving the correct shape to logs is quite complex and involves the use of special rounding machines.

Many people who often work with logs decide to create a rounding machine with their own hands. It is almost impossible to carry out high-quality processing manually, and it requires quite a lot of time.

We invite you to familiarize yourself with the Bathhouse with a gazebo under one roof

Let's look at the features of how to make a cylinder machine with your own hands, what types of such equipment there are and many other points.

Modern machines make it possible to carry out rounding so that the prepared log is suitable for installation in wall structures without finishing. The functionality can vary significantly, depending on the design features of the rounding machine and its cost.

When considering all drawings and models of equipment that is used for rounding logs, attention should be paid to the following points:

- Creation of grooves that can be used during installation to solve various problems.

- Production of edged boards, parquet, dies.

- Carrying out cylindering work, including the final stage of the task under consideration.

- Milling the surface of wood to achieve the desired roughness.

- Creating a crown cup.

- Production of gun carriages by cutting wood.

- Creating an expansion groove using an installed circular saw.

One should take into account the fact that a self-made rounding machine may not have all the functions, since for this purpose complex projects must be used in its production. The easiest way is to create non-universal equipment that is designed to solve specific problems, for example, rounding workpieces.

The main feature of machine models produced by well-known manufacturers today is the use of a laser pointer to control the movement of the carriage.

This point determines high processing accuracy and the ability to carry out the entire process without reinstalling the workpiece.

Thus, a CNC-controlled carriage with a set of tools moves along guides and performs various types of operations.

Log rounding machine

As practice shows, you can make a model with your own hands that will have manual control and the ability to process workpieces up to 7 meters long.

When considering what kind of homemade rounding machine drawings may have, we note that often the design has the following elements in one form or another of their implementation:

- The main and most cumbersome element is the frame. It is on it that stress is concentrated and all other elements are attached. When making the frame, it is recommended to use rectangular pipes. The connection of all elements is often carried out using welding, which allows you to speed up work and create a truly durable structure. However, it is possible to create a frame using a combination of a bolt and a nut. Collapsible frames are more mobile, but have less rigidity.

- Guides along which the power saw and sawing device will move. The length of the logs can reach several meters and weigh tens of kilograms. In order to significantly simplify the processing task, you should create a homemade rounding machine on which the tool moves, and not the workpiece.

- Pasterns: front and back, in some cases, only one. They are necessary to twist the logs during processing. Note that the front one quite often has a dividing head and a workpiece fastening system. Using the dividing head, you can set the rotation angle at each stage of processing, which is necessary to improve the quality of the workpiece.

- As a rule, a milling cutter is used as a cutting tool. There are quite a lot of types of this cutting tool. When considering how to make a cutter with your own hands, we note that the work is complex and involves the use of rolled tool steel, which has increased strength and a low degree of machinability.

- A high-quality cutter has replaceable knives that can be sharpened and replaced if necessary. The cutter itself does not wear out over time.

- To correctly place a log that has a lot of weight, special levers are installed.

- The rollers, acting as a stop, do not allow the log to sag during processing, thereby significantly increasing the quality of the resulting material.

- Almost all models have mechanical brakes that are installed on both sides of the carriage. They are necessary to perform the work of selecting the crown bowl.

- A device that allows you to rotate the steel manually at the time of cutting a longitudinal groove.