Business relevance

Despite the crisis, the pace of construction in our country continues to increase in both the private and public sectors. Along with them, the popularity of building materials is growing. It is known that almost no construction is carried out without bricks, among which Lego can be called in demand.

A business idea to open an enterprise for its production can lead to the construction of a successful and quickly profitable enterprise, giving high profits, since there are still few competitors in this niche. By properly planning your activities, you can find your niche in the construction market and increase production turnover.

How to start a Lego brick making business - where to start

Any business starts with an idea and financial calculations.

After that we open production.

Step 1. Register a business

Before starting a business, they choose the form of the new organization. LLCs and individual entrepreneurs produce products in the same way, but each type of business has its own characteristics.

Let's highlight the main ones:

- Individual entrepreneurs keep simplified records and pay less state fees. Such an organization is a company of one specific person. Other founders cannot be accepted into it. Personal savings or property of the citizen who organized the individual entrepreneurs are accepted to correct the financial mistakes of the organization.

- The LLC maintains full reporting. The time frame for registering a company is 2.5 months. The organization is owned by 1-50 people. The company is responsible for financial failures only with its property (authorized capital).

Please note: IP cannot be sold. With this form of organization, they sell only material assets (equipment, raw materials, finished products)

A business with a full package of documents for the company can only be sold by an LLC.

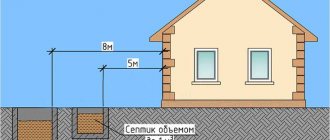

Step 2. Select a room

A big plus of Lego production is the minimum space requirements for the production line. Small machines are placed on a construction site, in a garage, in a personal garden, etc.

When launching a line with a capacity of more than 600,000 units/year, a workshop will be equipped.

Basic requirements for production premises:

- area more than 100 m² (including premises for storing raw materials and finished products);

- the height of the ceilings is calculated as the height of the equipment + the increase in loading (for overhead supply of raw materials);

- existing communications (electricity, water, heating);

- good ventilation.

Step 3. We purchase raw materials and equipment

Having determined the enterprise's budget, they proceed to the purchase of machines and additional equipment.

Basic parameters for choosing a machine:

- productivity (manufactured quantity per cycle/day/month/year);

- time of one cycle;

- pressure;

- number of matrices;

- mold thickness;

- operating mode (manual, automatic).

Without good equipment, the quality of products will be low. Study the offers on the market in detail and compare them with your requirements.

When choosing between a machine that presses bricks faster and compresses the mold more strongly, choose the latter. It is better to produce fewer products that customers will buy than to produce mountains of defects.

Environmentally friendly raw materials are available in all regions.

To select it, evaluate:

- customer preferences;

- price of the main material;

- the cost of binders, plasticizers and dyes;

- availability;

- quality.

The production line is designed for repeated changes of raw materials and recipes. At the preliminary stage, several options for the source material (filler) are selected: sand, clay, dolomite, marble chips, slag, etc.

Basic properties of the material

Lego brick is a high-quality facing material formed by hyper-pressing without firing. Outwardly, it is similar to a not little-known designer. This form makes the erected structures much stronger, and the masonry process simple and accessible to everyone. The peculiarity of using Lego bricks is their fixation thanks to a special adhesive mass (15 kg of such glue is enough for 1 m³ of brick). The use of standard mortars and cement is not allowed. The channels that are obtained through the holes of the materials can be used as highways for infrastructure nodes. Each brick has two holes protruding above the surface. During laying, the lower one is attached to the upper one. The result is a smooth surface that does not need to be plastered.

Raw materials

To produce this material, environmentally friendly substances are used. All components are widely used and available. There is no exact recipe for preparing raw materials - the ratio of ingredients depends on the required density and quality. One of the mixture composition options:

- filler – screening of crushed limestone (up to 90%);

- binder – cement (7-15%);

- water (up to 5%);

- plasticizers;

- dyes.

Video - composition of light brick concrete mixture:

Financial part

To calculate costs, we use approximate calculation data:

- personnel – 2 employees;

- working hours – 20 days a month for 8 hours;

- wage fund – 40 thousand rubles. per month;

- electricity for production – 1600 kW/hour;

- purchased equipment – 600,000 rubles.

Price for material and resources:

- cement M500 - 5 rubles/kg;

- screening – 0.6 rub./kg;

- electricity – 3.76 rubles.

The information provided in this article is only a brief introduction to the essence of the business. If you decide to move on to implementation, then you need to download a professional business plan for a brick factory with detailed calculations:

Profit calculation: In one shift you can produce 1,600 pieces of brick, in a month - 32,000 pieces. The cost of the finished product is approximately 12 rubles. Income with 100% sales of products will be 448,000 rubles.

To produce one Lego Creep, you need approximately 350 grams. cement (1.6 rub.), 3 kg. screenings (1.8 rubles), plasticizer and dye - 0.3 rubles, as well as 1.25 rubles. allocated for wages and 0.2 rub. for electricity. Other expenses (taxes, transport) – 0.75 rubles. The cost of one brick will be 6 rubles.

Net profit per month: (12 – 6) * 32,000 = 192,000 rubles.

Thus, the payback period of the project will be about four months.

How much can you earn

The most important question for an entrepreneur is how much money will the business bring in? The production of building materials is a promising business. When using cheap filler, the cost of the finished product will be about 4-5 rubles/piece.

The selling price of goods for wholesale sales fluctuates around 14-15 rubles/piece. Retail prices are even higher and depend on the method of sale.

If you sell goods only in bulk, then you can earn 10 rubles per unit of production. The more products are sold, the more money the entrepreneur will receive. Having sold 10,000 pcs. Lego he will earn 100,000 rubles. If sales are at the level of 50,000 units, his revenue will be 500,000 rubles.

When using waste (crumbs, dust, etc.), the cost of finished products will further decrease and profits will increase.

Business registration

At the first stage of implementing the idea, it is enough to register your activities as an individual entrepreneur. This form requires a minimum package of documents:

- application in form P21001;

- receipt of payment of state duty (800 rubles);

- copy of the passport.

Then you should choose the form of taxation. The most profitable option in this case will be a simplified system (15% of profit or 6% of revenue). To start working immediately on the simplified tax system, at the time of registration, add to your package of documents an application for the transition to a simplified taxation system in form No. 26.2-1.

It will take 5 working days to complete all permitting documentation.

If you are planning large-scale production at the start, it is better to register as a limited liability company.

Equipment

To start working, it is enough to purchase a machine (hyperpress), an industrial mixer and other things - molds (matrices), pallets, shovels, etc. The cost of equipment for brick production depends on productivity:

- machines with low productivity up to 1000 pieces per shift (manual or low power) - 90-300 thousand rubles;

- middle class - about 2000 bricks per shift, price from 350 thousand rubles;

- industrial equipment or a mini plant make it possible to produce more than 750 pieces per hour, but the cost is high - from 2 million rubles.

The brick machine consists of the following parts:

- bunker for bulk materials;

- dispenser;

- matrix for forming Lego bricks;

- pump;

- press;

- bed;

- electric motor (not available in manual units).

Video - budget machine for light brick:

Brick making technology

To understand the key intricacies of making bricks, pay attention to the key components of the machine. They include:

- dry mix hopper;

- dispenser;

- a chamber for the formation of bricks with a matrix that determines the future shape and size;

- electric motor (it is not available in manual models);

- oil pump and hydraulic press;

- the frame of the entire structure.

Design features may vary depending on the model and type of equipment, but the main components look exactly like this.

The production technology itself consists of using high pressure, which acts on the loaded mixture, while the filler is literally sintered with cement and water. This method is commonly called “cold welding”.

The production principle is as follows:

- The entire dry mixture is placed in the hopper and mixed thoroughly.

- Then the working mixture is transferred to a special container - a tray.

- After that, it falls on the matrix, and a press acts on it from above for several seconds.

- At the next stage, the platform with the brick moves up, and the press goes back.

- Now the worker can remove the finished product and transfer it to a tray for subsequent steaming or drying.

- The finished product must be placed in a separate room for several days, where strength will be gained. The exact drying time depends on the type of equipment.

At home

Making Lego bricks at home is beneficial in two cases - a lack of funds to purchase professional equipment or a desire to save on the purchase of building materials for your home.

In this case, you can purchase a manual machine for making bricks. Its cost varies within 40 thousand rubles. It does not consume electricity and can be transported in a regular car trailer. The scheme of its action is to prepare the mixture in a special matrix form. Manual mode is used. The machine has a loading hopper and a dosing unit. Small dimensions make it possible to work in a garage or small room and make bricks with your own hands. Video - Idea for a business in a garage. Making Lego bricks with your own hands:

DIY machine

On the Internet, there are many drawings available for various models of machines for making Lego, like this one.

Before starting work, study the drawings of the production machine, watch the video and prepare the necessary tools. You will need:

- Sheet of steel;

- Channel;

- Metal pipes for the piston, pipe for the handle;

- Corner;

- Accessory bolts and nuts;

- Welding installation;

- Bulgarian;

- Sandpaper;

- Dye.

Sequence of work:

- The stands for the machine are made of two channels approximately 1 meter long. The size of the brick produced will depend on the selected width of the cylinder.

- We connect two channels with blanks in the form of two steel rectangles, thus forming a section.

- We weld a channel on top of the resulting rack to create a running gear for the bunker. On one side, we weld a stop made of reinforcement. The channel will serve as a rail. We cut a hole in it according to the dimensions of the original cylinder.

- The bunker is welded from steel sheets according to the drawing. The dimensions of the hopper must correspond to the dimensions of the mold. The hopper is installed on a metal sheath, which is in the form of strips. It should move freely along the upper channel.

- The piston system is welded from metal sheets in the form of a rectangle, at the base of which two pipes are installed.

- To close and open the hopper lid, we make a handle from a pipe. It must be bolted to the hinge.

More details can be found in the video.

It is better to purchase the matrix separately, but if you wish, you can make it yourself, according to this scheme:

Technological production process

The main difference between Lego and ordinary ceramic is the exclusion from firing.

Thanks to this, the cost of bricks is significantly reduced and production is simplified. The “hyperpressing” process is used to make Lego bricks. The process of “hyperpressing” involves applying more pressure to the components of the future brick, as a result of which the constituent components are “welded” together. This method is also called “cold welding” because the result is a homogeneous, durable material. You can buy raw materials for Lego bricks in any area. The main raw materials are:

- Filler (the filler can be sand or a mixture of sand, slag or limestone);

- Binder (the main binder remains cement, the amount per 1 brick is 10-20 percent);

- Water (it is better to take purified demineralized water so that white stripes do not appear on the brick);

- Dyes (a variety of dyes are added to give a suitable color, has a purely decorative purpose).

The smaller the filler parts, the better the final product. Lego bricks are also made from clay. Take 9 parts clay to 3-4 parts Portland cement, mix and add 1 part water.

To understand the manufacturing technology, let’s consider what sequence is used:

- The dry mixture is poured into the hopper, it is thoroughly mixed in advance;

- After the bunker, the mixture passes through a dispenser, in which the required amount of mixture for one brick is separated;

- The dispenser pours the mixture into the matrix, where the pressing process begins;

- After pressing, a finished building material is obtained. It is placed on pallets and sent to a warehouse for further drying. The brick must dry for at least 20 days before it gains strength. The instructions for some units indicate the drying time for the brick.

Additional components

To simplify the work on the machine for the production of Lego bricks, many components are sold on the market. Among them:

- Additional molds (matrices) of various types, shapes and sizes. With their help, you can change the linear dimensions of the brick, as well as give it different decorative styles.

- Conveyor feeders. To automatically feed the dry mixture into the bunker, you can purchase a tape. They can deliver bulk mixture to a height; the cost of the belts starts from 90,000 rubles.

- For large production volumes, you can purchase a dry mixture mixing unit. It will make the work much easier.

In addition to the above, you will need pallets for storing finished bricks, shovels, buckets, empty containers, brushes for washing equipment.

Purchasing a machine for making Lego bricks or making them yourself can be an excellent business. Or a good way to save on bricks. Such a machine can be installed at a construction site and produce your own bricks at the site of use. The cost of Lego bricks is quite low compared to ordinary bricks purchased on the market.

In addition to the article, we are posting a video about the materials that are used to make Lego bricks on a machine: