Principle of operation

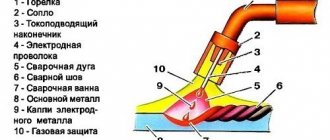

The included gas torch for the semi-automatic machine is an actuator for producing a welding seam in a shielding gas environment.

Gas burner for semi-automatic machine

The operating principle is as follows:

- The torch is placed to the base metal at the arc formation distance.

- Before the arc starts, shielding gas is supplied to the welding zone for a few seconds.

- Voltage is supplied to the current-carrying tip, and accordingly to the electrode wire.

- In the welding arc, the electrode wire melts and drops with the gas flow into the weld pool.

- When the torch moves along the elements being connected, a weld seam is formed.

- The protective gas environment ensures a high-quality and clean seam.

During welding work, torch elements are exposed to high temperatures. Particularly affected are the gas nozzle, the current carrying tip and the electrode holder, also called the diffuser and gas divider.

Burner device for semi-automatic machine

- burner base;

- insulating ring;

- electrode holder;

- current carrying tip;

- gas nozzle.

Failure of, for example, the current-carrying tip prevents the supply of welding wire to fill the pool.

Some repair features

Many years of experience show that in some cases the weld is weak due to the poor quality of the shielding gas.

Or due to its unstable supply to the arc burning zone.

In such cases, it is necessary to inspect the entire gas supply path and the burner, which the welder holds with his own hands during work.

This tool should always be kept in working order. Protect it from damage and contamination.

All preventive maintenance prescribed in the operating instructions must be carried out strictly.

If these requirements are met, the semi-automatic welding machine will operate flawlessly.

Source

↑ Diagram and details of the welder

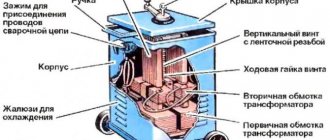

A single-phase 16A type AE circuit breaker is used as a power and protection switch. SA1 - welding mode switch type PKU-3-12-2037 with 5 positions.

Resistors R3, R4 are PEV-25, but they don’t have to be installed (I don’t have them). They are designed to quickly discharge choke capacitors.

Now for capacitor C7. Paired with a choke, it ensures combustion stabilization and arc maintenance. Its minimum capacity should be at least 20,000 microfarads, optimal 30,000 microfarads. Several types of capacitors with smaller dimensions and higher capacity were tried, for example CapXon, Misuda, but they did not prove to be reliable and burned out.

Power thyristors for 200A are taken with a good margin. You can install it at 160 A, but they will work at the limit, and you will need to use good radiators and fans. The used B200s stand on a small aluminum plate.

Relay K1 type RP21 for 24V, variable resistor R10 wirewound type PPB.

When you press the SB1 button on the burner, voltage is supplied to the control circuit. Relay K1 is activated, thereby, through contacts K1-1, voltage is supplied to the electromagnetic valve EM1 for acid supply, and K1-2 - to the power supply circuit of the wire drawing motor, and K1-3 - to open the power thyristors.

Switch SA1 sets the operating voltage in the range from 19 to 26 Volts (taking into account the addition of 3 turns per arm up to 30 Volts). Resistor R10 regulates the supply of welding wire and changes the welding current from 30A to 160A.

When setting up, resistor R12 is selected in such a way that when R10 is turned to minimum speed, the engine still continues to rotate and does not stand still.

When you release the SB1 button on the torch, the relay releases, the motor stops and the thyristors close, the solenoid valve, due to the charge of capacitor C2, still remains open, supplying acid to the welding zone.

When the thyristors are closed, the arc voltage disappears, but due to the inductor and capacitors C7, the voltage is removed smoothly, preventing the welding wire from sticking in the welding zone.

Prevention measures

To avoid many breakdowns of a semi-automatic welding machine, it needs proper care and proper operation. The device often operates in difficult conditions (high room humidity, dust or smoke in the working area, low or, conversely, high air temperature, long welding operations with short pauses, and so on). All this leads to a decrease in the uptime of the unit.

Experts and manufacturers of welding equipment recommend optimal timing for carrying out preventive measures with machines, aimed at preventing the most common malfunctions.

It is necessary to carry out a technical inspection of all equipment at least once a month, including in this event not only the identification of obvious (or possible) malfunctions or irregularities with the equipment, but also the following work:

- mandatory cleaning and tightening of terminal blocks, contacts, screws and clamps;

- replacement of burnt insulation of wires and cables;

- blowing air or inert gas under pressure on internal and external devices to remove dust and other dry contaminants;

- cleaning the electronic control board with a neutral solvent;

- checking the correct operation of the fan and refrigerators.

How to repair?

Before you begin diagnosing and repairing semi-automatic welding machines, you should take care of the safety measures necessary when working with electrical equipment. The basic rule in this case is to completely de-energize the device with a visible break in the connection to the power source. In addition, it is necessary to prepare tools for work, including equipment for testing electronic parts and consumables, such as insulating tape, thermal paste, available spare parts and parts.

You also need to be prepared for the possible costs of purchasing other materials and spare parts, since it is extremely difficult to foresee the condition of a faulty device in advance.

As mentioned earlier, you should first take steps to diagnose and eliminate possible causes of malfunctions in the mechanical part of the equipment. To do this, the welding machine is inspected, all contacts, bolted and screw connections are cleaned and tightened, and the insulation is restored. You need to understand that most problems arise from loose and dirty contacts in electrical connections. This includes overheating of the equipment, an unstable arc or its complete absence, and increased buzzing of the device.

Overheating of the welding unit is often caused by violations of its operation: exceeding the permissible values of the welding current and the time of continuous operation. As a result, parts wear out quickly. Worn parts of the equipment should be replaced in a timely manner, and the welding current should be adjusted according to the instructions.

Problems with the wire feeder are solved according to the reasons. If the channel is worn out or is too narrow, then it is completely replaced with a new one. This is done like this: they simply push out the faulty one with a new channel. It turns out that the old channel is being dismantled and a new wire feed line is being installed at the same time. You just need to choose a suitable channel (both in length and diameter), which should be smooth inside.

If the tension mechanism is faulty or the rollers are worn out, the tension is adjusted and the rollers are replaced.

Repairing the welding current regulator involves disassembling the mechanism, cleaning it from dust and dirt, removing foreign objects, tightening the terminals and replacing the insulation. It happens that the regulator does not work due to the rotating handle rod becoming disengaged. In this case, the engagement must be restored.

The electronic control board is cleaned of dust and dirt, faulty parts are replaced with spare parts or purchased from an electronic goods and spare parts store. In case of short circuits in coils, cables, wires, transformers, measures should be taken to isolate exposed sections of windings (or completely replace faulty elements), cable cores and wires.

Troubleshooting other problems

Problems with the piezoelectric element are the most common “disease” of gas burners, but they are far from the only one, since other parts can also fail. This is especially true for devices that are used for a long time and “mercilessly”. In any case, the structure will have to be completely disassembled and then carefully inspected.

Do-it-yourself gas burner repair may be required if a malfunction is detected in the operation of the nozzle. There are two options here.

- Heavy pollution. This trouble occurs if gas was used to refuel the burner, the quality of which is far from ideal. The best option is to use lighter gas. Due to the accumulated dirt, fuel will not be able to enter the burner, which means there will be nothing for the device to work on. Cleaning the nozzle is a method that is quite accessible at home.

- The second problem inside the nozzle is the ring falling out. A common reason is the appearance of cracks in it due to strong heating. The consequence is the impossibility of igniting the burner, since the spark will fly in different directions. In this case, repairing a gas burner will consist of making a homemade element. For example, a similar ring can be made from copper wire.

How do you repair a gas burner yourself if the source of the problem is the nozzle? In both cases, the technician has the opportunity to fix the problem himself.

Cleaning the nozzle yourself

Checking the nozzle for blockage is quite simple. You need to remove this element, then look through the hole into the light. If the white “spot” is not visible, then the “diagnosis” can be considered confirmed, so cleaning is necessary. However, there is one big obstacle to this operation. This is a small hole for which it is very difficult, almost impossible, to pick up a needle or thin wire.

Therefore, it is not always possible to mechanically clean the nozzle. Another disadvantage of “violent” actions is the risk of widening the hole. Such a defect will inevitably affect the operation of the burner - the flame will burn incorrectly: its height cannot be predicted. For this reason, experts recommend using two other methods.

- Blowing out dirt. This method is suitable if the contamination is not yet too serious. The nozzle is removed, then pressed against the gas cartridge with the side with the hole, and begin to blow through. There is a chance to get rid of the interference in such a simple way. Instead of compressed gas, you can try using a powerful jet of water.

- The nozzle gets very hot. It should be noted that this option refers to cardinal, even brutal decisions. Craftsmen use it at their own peril and risk, since a possible outcome is destruction (burning) of the part. A wire is attached to the removed nozzle and then heated red-hot using a second burner. After this, the part is dipped in cold water.

If you choose the best option, then it can be called the first, more gentle one. But it is also not always effective. Therefore, many consider it optimal to search for a thin wire and then sharpen its tip. One of the places where you can “get” a super-thin needle is a tattoo parlor (art tattoo studio). In this case, there is a chance to guarantee both the result and the safety of the part.

However, there are times when even these methods are powerless. Then, instead of cleaning or heating, they use a solvent wash, which is distributed with a soft brush. Some owners, after treating with gasoline, blow out the part using a pump. They say that this “tandem” always helps to get rid of blockages. Another rescue option is a product designed for cleaning carburetors.

Replacing the nozzle ring

When a gas burner is used intensively, the ring operating at high temperatures falls out after a certain period of time and is then completely lost. Due to damage or loss of such a part, it is unlikely that anyone will decide to buy a new gas burner. Finding a suitable replacement is also not the best solution, so the owner is left with the only option. This is making a ring with your own hands.

The material of the original element is brass, but purchasing it is not advisable, since such a ring will be equal in cost to the price of a new gas burner. Copper, or rather ordinary copper wire, can become a full-fledged replacement for this expensive alloy. Its cross section is 2.5 mm. To create a new part, first cut a piece to the required length. Then the wire is bent, focusing on the diameter of this nozzle element.

Repairing a gas burner with your own hands will be a quick process only if the diagnosis is carried out correctly. How to distinguish between a ring falling out and a clogged nozzle? You need to try lighting the burner with matches. If the operation is successful, then you can exclude the “plug” from the dirt and come to the conclusion that the ring is to blame.

Sequence of repair actions

Any repair begins with cleaning the device from dust, oil, and dirt. After this, the integrity of cables, hoses, and insulation is checked.

Electrical circuit malfunction

Electrical repair begins with checking the contacts.

The electrical circuit is wired completely using special devices. If a non-working part is found, it is soldered off and a new one is put in its place. Usually the technical passport contains a diagram and consumables - a list of diodes, rectifiers and other angles used.

5th category mechanic for repairing welding equipment Timofeichev N.G.: “Inverters produced by German and Czech companies are small in size, durable and reliable. They have one drawback. All nodes are located on one board. If one part fails, it is difficult to replace it at home. You should install a new board, which makes up the lion's share of the cost of the device. Basically, such electronics are found on household equipment. If there is a lot of work at home, it is better to take a semi-professional semi-automatic machine with separate control units.”

Wire feeder malfunction

The wire may move jerkily if the channel for feeding it has already been worn out or the rollers of the feed mechanism do not press it well . An incorrectly selected tip insert can cause jerking.

The hole must match the consumable exactly. When the cable length is more than 4 m, a pulling mechanism or a combined one should be used. The channel is selected with an internal diameter of 4 mm.

Preliminary inspection

The preliminary inspection includes cleaning all internal components and checking the integrity of the insulation. All contacts should be immediately cleaned of oxides and tightened well. There should be no even spots of short circuits anywhere.

Troubleshooting

Regular proper care of the equipment and operation of the welding machine in modes appropriate to its characteristics will ensure its long-term operation. It is easier to inspect every month and, if necessary, change the insulation than to replace broken capacitors.

Important! Once a year, the device should be completely disassembled and the fan motor should be cleaned and the bearings lubricated.

When moving from the cold to a room, the unit must stand for 2 - 3 hours to warm up. All consumables must exactly match those indicated in the passport.

Some repair features

For a good semi-automatic machine, the manufacturer tries to supply various components, accessories and spare parts with a minimum working life. When replacing a part, you must carefully unsolder it and select a similar one using the datasheet list. It shows all the characteristics and different designations of the same parts.

The frequency of repair of a semi-automatic welding machine completely depends on its operating conditions. If the basic requirements are met and regular care is taken, the device will last much longer.

Wire release and ejection

The quality of the weld is affected by the length of the consumable material extending from the tip, as well as the size of the gap between the wire and the working surface. The discrepancy between the diameter of the wire and the size of its exit from the tip leads to excess spatter, metal burning, lack of fusion and warping.

Some designs of semi-automatic machines provide the ability to change the location of the burner tip relative to the nozzle. They are located at the same level, but the contact tube in relation to the nozzle can be extended or, conversely, recessed. The adjustment amplitude is 3.2 mm.

Short overhang is used to form welds on low alloy structural steel. As the distance increases in this case, the effectiveness of the protective gas cloud decreases. In order to increase the melting point, you can lengthen the flux wire slightly.

Release and overhang directly depend on the diameter of the filler wire:

Externally, it consists of the following elements:

1 Welding sleeve

2 Handle with button

The welding sleeve is a cable connecting the handle to a semi-automatic machine, inside of which there is:

1 Twisted channel for feeding welding wire from the feed mechanism to the torch handle.

2 Channel for supplying shielding gas to the welding zone.

3 Power cable.

At the other end of the sleeve there is a connector for connecting it to the feeding mechanism.

Such cables are supplied in lengths from 2.5 to 7 meters. This allows you to comfortably perform welding work at a remote distance from the semi-automatic machine. When using long hoses, there is a risk of wire jamming in the twisted channel.

Inside the nozzle there is:

1 Insulation ring

2 Electrode holder

3 Current carrying tip

4 Tip nozzle

The current-carrying tip is made of copper. This allows welding current to pass through without loss and excess heat to be removed when heated.

Burner device with sleeve

The diagram below clearly shows what elements they consist of:

There are also water-cooled burners. The diagram below shows one of them:

How to choose a burner and sleeve for a semi-automatic machine

Before making a choice, you first need to decide on the type and scope of work. If the work involves welding small components in small quantities, then purchasing an expensive torch will be unnecessary.

Therefore, you should pay attention to the following factors:

1. Maximum operating current of the welding machine;

2. Wire channel diameter;

3. Cooling method;

5. Connector for connection;

6. Strength and wear resistance of the burner with a sleeve

Maximum operating current of the welding machine

Selected depending on the maximum operating current of the power supply. If welding is performed with a current of 250A with a torch designed for a current of 200A, this can lead to overheating and melting of cables with wire channels inside the sleeve. If you do not plan to exceed the maximum permissible current, in such cases it can be used.

Wire channel diameter

There are two types of channels for wire passage: steel and Teflon. Each of them is used for a specific type of wire.

The steel channel is used for wires intended for welding carbon and alloy steels.

Teflon channels are used for aluminum wire.

There are different channel diameters - 0.6 - 3.0. The channel diameter is selected depending on the diameter of the welding material.

Burner cooling method

There are two types of cooling: non-cooled and water-cooled. To perform work at home and in small industries, where the welding process occurs intermittently, cooling is not necessary. If the welding process continues continuously for 10 - 15 minutes, then water cooling is required.

Repair of semi-automatic welding machines

The semi-automatic welding machine is designed on the basis of a welding inverter, the repair of which we discussed in the article “Repair of inverter welding machines.” Therefore, we recommend starting your acquaintance by reading the previous article.

To troubleshoot the problem, you can contact a workshop. If you feel strong and have the desire, then you can try to repair the welding machine with your own hands. We would like to warn you: if you do not have the appropriate experience and knowledge, then it is better (for the welder) and cheaper (for you) to take the device directly to a specialized workshop (see contacts in different cities here).

Inverter semi-automatic welding machine “Kontur-165”.

Preliminary inspection

Before disassembling the welding machine, check its settings. Poor operation of the device can be caused by the following reasons:

- electrode incorrectly selected in terms of material or diameter;

- incorrectly selected current value or voltage polarity;

- there may be no arc due to poor contact between the cable clamp and the part being welded;

- Temperature protection may well be triggered if the time of continuous operation of the welding machine is simply exceeded. You should just let it “rest” and cool down;

- Often the cause of failure is a cable break. Check its integrity.

If none of the above helped restore the functionality of the welder, then only then should you start repairing it.

Troubleshooting

Any repair begins with fault diagnosis. Malfunctions of this type of welder are divided into 2 groups:

- mechanical;

- electronic.

Checking the serviceability of the resistor.

Troubleshooting mechanical problems

Mechanical problems are caused by delayed wire feeding or excessive friction in the wire feed channel. The clamping mechanism should be checked and, if necessary, adjusted. If this operation does not give a positive result, then the canal is completely replaced.

It is recommended to install the new part simultaneously with removing the old one. This is done as follows:

- connect the end of the failed channel with the beginning of a new one;

- By pulling and removing the old channel, a new one is inserted in its place.

Checking modes with a tester.

Electronics Troubleshooting

It is recommended to check and troubleshoot in the following sequence:

- Check the fuses on the control board. If the fuses are working or you have replaced them, but the welder does not start working, then move on to the next point. Note that we will move on to each next point of the action plan proposed below after the negative results of the check for the current one;

- remove the control board and inspect it carefully. If you visually identify a faulty element (the housing has burst, the leads have melted, etc.), then replace it, put the board in place and check the functionality of the welder;

- carry out a “test” of all elements using a tester (ampere-voltmeter, multimeter, etc.). To prevent them from bridging each other, they should be desoldered and, after checking, replaced or replaced with serviceable ones. To avoid confusion, it is recommended to select the direction of the check (for example, left - right and top - bottom). In this case, the risk of missing any element will be minimized.

- After eliminating the malfunction, it is recommended to change the thermal paste on the radiators for cooling semiconductor elements.

If all the measures do not lead to a positive result, then the welder will have to be taken to the workshop.

In conclusion, we recommend watching a video about repairing the electronic part of a semi-automatic welding machine - an inverter. We wish you success!

Typical faults

The semi-automatic welding machine is convenient and reliable during operation.

IMPORTANT TO KNOW: Selecting a semi-automatic welding machine

However, there are also situations when it requires repairs.

If the device does not cook at all, then repair work must begin with a careful inspection of all components and parts.

Most often, failures and malfunctions arise as a result of non-compliance with the operating rules of the device.

It often happens that contact is lost in the electrical circuit and the welding process is interrupted.

In order to determine the malfunction with a high probability, the operating instructions contain common breakdowns and methods for eliminating them.

Unauthorized cycle interruption

The semiautomatic welding machine turns off for no apparent reason when the short circuit protection circuit breaker is triggered.

A short circuit can occur in the high voltage circuit between the wires of the transformer winding. Or between the wires and the metal case.

Video:

The protection also works when the capacitor is broken. When performing repairs, you must first turn off the power to the device. Then find and fix the problem.

This may require replacing the insulation or soldering in a new capacitor.

Strong rattling and humming noise

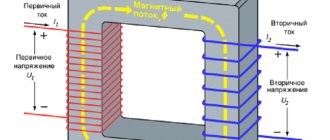

Very often, the humming of a semi-automatic welding machine is accompanied by overheating of the transformer.

If this happens while the welder is welding another seam, then you need to stop work and inspect the machine.

Such troubles can be caused by loosening of the bolted connections that tighten the sheets of the magnetic circuit or core.

For a similar reason, the unit that moves the coils may rattle.

A short circuit between welding cables is also accompanied by a strong hum.

To fix such a malfunction with your own hands, it is enough to tighten the fastening bolts, check the integrity of the insulation and, if necessary, strengthen it.

Device overheating

If a semi-automatic welding machine welds, but at the same time gets very hot, then it is urgent to carry out a preventive inspection, repair or replacement of worn parts.

Most often, welding violations lead to overheating of the device. If the welding current is set above the permissible values, this leads to overheating of the main elements.

Video:

And first of all - the secondary coil of the transformer. The same reaction will follow if the diameter of the electrode is chosen larger than it should be.

IMPORTANT TO KNOW: Tips for choosing a semi-automatic welding machine

Or when welding is performed for a long period of time without interruption. For large volumes of welding work, it is necessary to take technological breaks.

Welding current is not adjustable

If, when choosing the operating mode of a semi-automatic machine, the welding current value is not set to the required value, then you need to carefully inspect the regulator mechanism.

Incorrect adjustment may be caused by worn screws or a short circuit between the regulator terminals.

If foreign objects get inside the casing, the mobility of the secondary coils is disrupted.

This kind of malfunction can be easily fixed with your own hands, without resorting to the services of specialists from a service center.