Design of edge trimming machine

Before you start making an edger with your own hands, you need to familiarize yourself with the specifics of its layout and design. This woodworking equipment is mandatory for completing specialized production lines and is intended for pre-processing of lumber before sanding.

Edge trimming machines have standard equipment. They consist of a frame that performs two functions. It houses mechanisms for sawing, and can also serve as a conveyor for feeding workpieces. An alternative option is to rigidly fix the wooden part to the surface of the working frame.

Depending on the design features, the following types of woodworking edge trimming machines are distinguished:

- method of supplying materials - manual, automatic or semi-automatic. Manual models are simple in design, but have a low performance indicator. They are the best option for self-production;

- by the number of saw blades – single and double saw blades. The former are intended for one-sided processing and are used extremely rarely. The optimal result is achieved after using two-saw models, since trimming occurs simultaneously along two edges of the workpiece;

- movable or stationary carriage with saw blades. To make homemade woodworking equipment, it is recommended to make a subcutaneous carriage. This will allow you to control the processing process. But factory models are made with a fixed carriage. This helps improve productivity.

Additionally, a manual woodworking machine can be equipped with a system for removing cutting products - chips and wood dust. To do this, you can use a standard chip vacuum cleaner or its equivalent.

The optimal power of the power plant should be 4 kW or more. This is necessary for simultaneous processing of workpieces using a manual two-saw woodworking machine.

How to make a manual edging machine with your own hands

Woodworkers, as well as small entrepreneurs who repair or modernize a variety of furniture products, often have to perform operations on processing the ends of wood. You can purchase a specialized edge banding machine (the price of which will pay for the unit only if it is used multiple times), or you can make an edge bander yourself using suitable spare parts and equipment (most often a hand-held electric drill) and drawings.

Is it justified to make a homemade machine?

The expediency of high-quality processing of the ends is undeniable, although veneering requires less time. In addition to heat treatment, an alternative to an edge banding machine is the use of a do-it-yourself chisel (the handle is removed, the shape of the cutting blade is adjusted). However, such a process is tedious and advisable only for a single application. The advisability of using edging equipment arises in the following cases:

- For high edge heights.

- To ensure a stronger bond (the durability of the adhesive depends on external conditions - vibrations, changes in ambient temperatures).

- The need to prepare not only straight, but also curved edges.

- To obtain decorated edges.

- If there is free space in the workshop necessary for the work of the edge maker.

In this case, the equipment used must be compact, easy to move, stored in any cabinet, and be able to connect to a single- or three-phase power supply. The peculiarities of investments in industrially produced models are also taken into account: they, even used ones, cost 3-4 times more than the total cost of producing a machine with your own hands.

So, if you do not need shaped design of end surfaces, and have skills in repairing and upgrading mechanical equipment, then it is quite possible to independently make a small homemade machine designed for processing edges.

The initial data for the design/manufacturing of the machine are:

- The largest edge thickness in practice: with an increase in this parameter, the power consumption will also increase;

- Availability of a stationary power supply source in the workshop (it is unsafe to use an extension cable);

- The home craftsman has a reliable clamping device at his disposal, which allows him to process several workpieces of the same type at the same time.

You will need to carefully read the numerous step-by-step video instructions and recommendations for using such equipment.

Recommendations for DIY production

At the first stage, it is necessary to draw up a design diagram of the equipment. It must include an accurate drawing indicating the location and main characteristics of the constituent elements. Without this, it will be impossible to make a high-quality and reliable edge trimming machine.

The best option for self-production would be a design with a movable carriage. To implement it, you can use a two-saw or four-saw cutting unit controlled by a manual mechanism. The latest edge trimmers will be able to form two workpieces in one pass. But at the same time, they will require a powerful power plant to operate.

Structural elements of manual woodworking equipment:

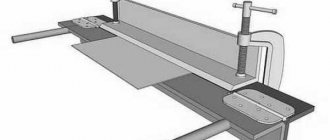

- support frame. The workpiece will be fixed on it. It is best to make it welded from square profile pipes. The upper ones will be designed to move the carriage. Roller guides are attached between the side machines. With their help, you can feed workpieces with a large mass. Clamps or similar devices can be used to secure wooden parts;

- movable carriage. A power unit is installed on it, which is connected to the drive shaft using a belt drive. To mount the disks, a special shaft must be made with the ability to change the position of the disks. The carriage moves along the frame guides using wheels.

Additionally, a lifting block should be provided to adjust the cutting depth. In this way, the maximum thickness of the workpiece can be significantly increased.

The control unit should be located on the side of the equipment. To increase the safety of operation of the woodworking machine, it is necessary to install a shield on the carriage. This way you can avoid chips getting into the electric motor.

How to make an edge trimmer with your own hands - ooo-asteko.ru

» Machine » DIY edge trimming machine

The edge trimming machine is designed for removing edges from the surface of wooden blocks and boards. This operation can be done on an ordinary band saw. But at the same time, it is difficult to achieve precision processing and create a product with the required geometry parameters.

Design of edge trimming machine

Edger with two saws

Before you start making an edger with your own hands, you need to familiarize yourself with the specifics of its layout and design. This woodworking equipment is mandatory for completing specialized production lines and is intended for pre-processing of lumber before sanding.

Edge trimming machines have standard equipment. They consist of a frame that performs two functions. It houses mechanisms for sawing, and can also serve as a conveyor for feeding workpieces. An alternative option is to rigidly fix the wooden part to the surface of the working frame.

Depending on the design features, the following types of woodworking edge trimming machines are distinguished:

- method of supplying materials - manual, automatic or semi-automatic. Manual models are simple in design, but have a low performance indicator. They are the best option for self-production;

- by the number of saw blades – single and double saw blades. The former are intended for one-sided processing and are used extremely rarely. The optimal result is achieved after using two-saw models, since trimming occurs simultaneously along two edges of the workpiece;

- movable or stationary carriage with saw blades. To make homemade woodworking equipment, it is recommended to make a subcutaneous carriage. This will allow you to control the processing process. But factory models are made with a fixed carriage. This helps improve productivity.

Additionally, a manual woodworking machine can be equipped with a system for removing cutting products - chips and wood dust. To do this, you can use a standard chip vacuum cleaner or its equivalent.

The optimal power of the power plant should be 4 kW or more. This is necessary for simultaneous processing of workpieces using a manual two-saw woodworking machine.

Recommendations for DIY production

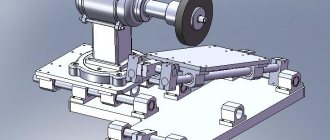

General diagram of an edge trimming machine

At the first stage, it is necessary to draw up a design diagram of the equipment. It must include an accurate drawing indicating the location and main characteristics of the constituent elements. Without this, it will be impossible to make a high-quality and reliable edge trimming machine.

The best option for self-production would be a design with a movable carriage. To implement it, you can use a two-saw or four-saw cutting unit controlled by a manual mechanism. The latest edge trimmers will be able to form two workpieces in one pass. But at the same time, they will require a powerful power plant to operate.

Structural elements of manual woodworking equipment:

- support frame. The workpiece will be fixed on it. It is best to make it welded from square profile pipes. The upper ones will be designed to move the carriage. Roller guides are attached between the side machines. With their help, you can feed workpieces with a large mass. Clamps or similar devices can be used to secure wooden parts;

- movable carriage. A power unit is installed on it, which is connected to the drive shaft using a belt drive. To mount the disks, a special shaft must be made with the ability to change the position of the disks. The carriage moves along the frame guides using wheels.

Additionally, a lifting block should be provided to adjust the cutting depth. In this way, the maximum thickness of the workpiece can be significantly increased.

The control unit should be located on the side of the equipment. To increase the safety of operation of the woodworking machine, it is necessary to install a shield on the carriage. This way you can avoid chips getting into the electric motor.

Tips for equipping your equipment

Model with two electric motors

To reduce the design, two power units can be mounted on a homemade edge trimming machine. This will make it possible not to make a belt drive system, which will greatly facilitate the manufacturing process.

To move the carriage along the guides, you can make a long handle. Next to it there are usually buttons for activating/deactivating electric motors. This will make it possible to control the processing process from a safe distance.

In addition, the following additional components can be installed on edge trimming machines:

- ruler;

- cut depth indicator;

- a protective mechanism that prevents motors from overheating.

Most often, improvised components are used to make this. Therefore, it is impossible to give clear recommendations for assembly. The technology directly depends on the characteristics of the constituent elements.

For example, you can look at the design and operation of a homemade woodworking edge trimmer:

stanokgid.ru

Edge trimming machines

The production of lumber from logs is accompanied by the formation of rounded waste. On large equipment with a circular saw, it will not be possible to process them into products suitable for further use.

For such needs, it is advisable to have a through-type edge trimmer with one or more saws.

You can get your own assortment of building blanks with a thickness of 0.5 cm and higher: bars, thin edged boards, laths, lamellas, glazing beads.

Tips for equipping your equipment

To reduce the design, two power units can be mounted on a homemade edge trimming machine. This will make it possible not to make a belt drive system, which will greatly facilitate the manufacturing process.

To move the carriage along the guides, you can make a long handle. Next to it there are usually buttons for activating/deactivating electric motors. This will make it possible to control the processing process from a safe distance.

In addition, the following additional components can be installed on edge trimming machines:

- ruler;

- cut depth indicator;

- a protective mechanism that prevents motors from overheating.

Most often, improvised components are used to make this. Therefore, it is impossible to give clear recommendations for assembly. The technology directly depends on the characteristics of the constituent elements.

For example, you can look at the design and operation of a homemade woodworking edge trimmer:

The operating principle of an edge banding machine and some device options

This device is widely used both in private workshops and on an industrial scale. The following can be used as working material for decorating wooden products:

The typical width of the cladding is approximately 2-5 centimeters, and the thickness can vary between 0.4-3 millimeters.

Next, the desired wooden part is brought to the device and the prepared tape is glued along its edge. This happens very simply - you just need to move the device along the tree, pressing it lightly.

Of course, if we are talking about making an edge banding machine with your own hands, then it is unlikely to have some of the advanced functions of a factory product, for example, heating the glue. Although it is quite easy to organize even this mechanism - it just takes a little more patience and time.

As for the types of the device in question, the following options are distinguished:

- For working with curved edges. Usually, manual feeding of material is used here, since the master needs to adjust in time to the next bend on the part and rushing for an automatic belt will definitely not work.

- For straight cutting. Such products, as a rule, have automatic feeding. They are most often used in the mass production of furniture or other things made of wood.

Making an edge banding machine with your own hands

Finishing the edges of furniture parts is an important stage in its production. High-quality edges help protect the material, be it wood or plywood, from various negative impacts, and also give it a beautiful and finished look.

Any normal enterprise engaged in the manufacture of furniture is required to have equipment for edging. There is a special unit for this, which is called an edge banding machine.

If you have your own small production or you are just a single craftsman making various wood products, then you do not have to waste money and buy such a device. It is relatively easy to make with your own hands, spending a little time and effort. A homemade edge banding machine will perform its task no worse than a factory unit, but will cost the owner significantly less.

The operating principle of an edge banding machine and some device options

This device is widely used both in private workshops and on an industrial scale. The following can be used as working material for decorating wooden products:

- Paper.

- Veneer.

- Melamine.

- PVC.

The typical width of the cladding is approximately 2-5 centimeters, and the thickness can vary between 0.4-3 millimeters.

The essence of the device is that a facing material is passed through it, onto which glue is applied using special rollers. It is important to choose the normal temperature at which the glue will set at its best.

Next, the desired wooden part is brought to the device and the prepared tape is glued along its edge. This happens very simply - you just need to move the device along the tree, pressing it lightly.

Of course, if we are talking about making an edge banding machine with your own hands, then it is unlikely to have some of the advanced functions of a factory product, for example, heating the glue. Although it is quite easy to organize even this mechanism - it just takes a little more patience and time.

As for the types of the device in question, the following options are distinguished:

- For working with curved edges. Usually, manual feeding of material is used here, since the master needs to adjust in time to the next bend on the part and rushing for an automatic belt will definitely not work.

- For straight cutting. Such products, as a rule, have automatic feeding. They are most often used in the mass production of furniture or other things made of wood.

In order for the manufacture of an edge trimming machine to be successful with your own hands, you need to become familiar with the typical design of such a unit.

The cladding supply system consists of a roll, a guillotine and special rollers. There is also a special magazine where the beginning of the tape is fed. It is pulled by rollers to the very part that needs to be processed, along the way being covered with a layer of suitable glue, heated to the desired temperature.

The mentioned rollers must have an adjustable speed; this is the only way to organize the optimal tape feed speed. A guillotine is needed to cut the material to the required length. Trimming occurs both automatically and manually, depending on the type of device and its tasks. The trim is adjusted so that approximately 25-30 millimeters of allowance remains.

There are some types of facing materials that immediately come with glue applied to them. In this case, it is enough to warm them up before use. If this is not the case, then the glue is contained separately in a special tray. Its temperature takes typical values of 150-200 degrees Celsius.

The pressure between the wooden part and the cladding is performed with a special support roller, although there may be several of them. When making a homemade edge banding machine, you can get by with just one such element, adding the necessary force with your physical strength.

: Homemade edging machine.

How to make the device yourself

Since the units in question have a fairly high price on the market, many craftsmen are willing to spend some time making them themselves. In principle, this option will also be quite sufficient for normal operation, but here you will have to pay more attention to safety precautions and use the device very carefully.

First, you need to acquire the necessary components. The standard package includes:

- Automatic trim cutting unit.

- The rotation control unit for the rotation of the rollers feeding the tape is good if it is equipped with a special indicator.

- A place for heating the glue, some kind of thermostat.

- Adhesive tape supply unit.

- Guides that will help to properly fix the workpiece.

Typical design

In order for the manufacture of an edge trimming machine to be successful with your own hands, you need to become familiar with the typical design of such a unit.

The cladding supply system consists of a roll, a guillotine and special rollers. There is also a special magazine where the beginning of the tape is fed. It is pulled by rollers to the very part that needs to be processed, along the way being covered with a layer of suitable glue, heated to the desired temperature.

There are some types of facing materials that immediately come with glue applied to them. In this case, it is enough to warm them up before use. If this is not the case, then the glue is contained separately in a special tray. Its temperature takes typical values of 150-200 degrees Celsius.

The pressure between the wooden part and the cladding is performed with a special support roller, although there may be several of them. When making a homemade edge banding machine, you can get by with just one such element, adding the necessary force with your physical strength.

Video: Homemade edging machine.

How to make the device yourself

Since the units in question have a fairly high price on the market, many craftsmen are willing to spend some time making them themselves. In principle, this option will also be quite sufficient for normal operation, but here you will have to pay more attention to safety precautions and use the device very carefully.

First, you need to acquire the necessary components. The standard package includes:

- Automatic trim cutting unit.

- The rotation control unit for the rotation of the rollers feeding the tape is good if it is equipped with a special indicator.

- A place for heating the glue, some kind of thermostat.

- Adhesive tape supply unit.

- Guides that will help to properly fix the workpiece.

If you have stocked up with everything you need, you can start assembling. Of course, nothing prevents you from moving a little away from the accepted configuration and adding some of your own additional components that will help make the device more convenient and functional.

As a conclusion, it is worth noting that any person who has experience working with mechanisms, basic electronics and tools will be able to make an edge banding machine with their own hands. A little imagination - and you will get what you want.

Features of the manual machine

A manual machine has a relatively low cost, however, it is characterized by a low productivity indicator.

If, when operating a stationary device, it is enough only to set the parameters of the product, set the characteristics of the tape, and feed the workpiece, then the process of applying an edge when using a manual device requires full participation and control.

An important feature is that a manual edge banding machine has a certain period of continuous operation.

If it is exceeded for a long period, the heating unit or the tape transport mechanism of the device may fail.

Various solutions in machine design

Depending on the intended purpose and installation location, an edge-edging woodworking machine can combine the following design solutions:

- internal combustion engine or electric;

- the carriage with cutting elements is driven automatically/manually;

- number of saws making simultaneous cuts (1, 2, 3...).

Common to the edge trimming machine are a frame with guides for moving the carriage, clamps - clamps for the workpiece, a control unit, and optionally - a laser ruler, which simplifies positioning operations.

Models for industrial production are distinguished by an automatic device for feeding wood under a stationary carriage. They are equipped with systems for removing sawdust, dust, and waste.

Features of work

If a single-saw unit is installed on the edge trimming machine, then cut one side of the board first, and the other in reverse. This option is suitable for small processing volumes. A multi-saw edge trimming machine, which, if necessary, has up to 14 simultaneously operating saws, can reduce time and costs. The cutting is performed in 1 pass of the carriage.

Circular saws on the Taiga edge trimmer are installed with rotation in opposite directions.

A two-saw (or more) edge trimmer is adjusted manually, setting the gap between the cutting discs. Later models of two-saw edge trimming machines are equipped with electronic controls; there is no need to mechanically reconfigure the machine yourself. The rotation speed is changed by a switch, and a laser ruler is used to accurately position the board on the table.

Principle of edge trimming

Servicing of this type of equipment during operation is carried out by 2 people.

Do-it-yourself edge trimming machine drawings

The edge trimming machine is designed for removing edges from the surface of wooden blocks and boards. This operation can be done on an ordinary band saw. But at the same time, it is difficult to achieve precision processing and create a product with the required geometry parameters.

Various solutions in machine design

Depending on the intended purpose and installation location, an edge-edging woodworking machine can combine the following design solutions:

- internal combustion engine or electric;

- the carriage with cutting elements is driven automatically/manually;

- number of saws making simultaneous cuts (1, 2, 3...).

Common to the edge trimming machine are a frame with guides for moving the carriage, clamps - clamps for the workpiece, a control unit, and optionally - a laser ruler, which simplifies positioning operations.

Models for industrial production are distinguished by an automatic device for feeding wood under a stationary carriage. They are equipped with systems for removing sawdust, dust, and waste.

Features of work

If a single-saw unit is installed on the edge trimming machine, then cut one side of the board first, and the other in reverse. This option is suitable for small processing volumes. A multi-saw edge trimming machine, which, if necessary, has up to 14 simultaneously operating saws, can reduce time and costs. The cutting is performed in 1 pass of the carriage.

Circular saws on the Taiga edge trimmer are installed with rotation in opposite directions.

A two-saw (or more) edge trimmer is adjusted manually, setting the gap between the cutting discs. Later models of two-saw edge trimming machines are equipped with electronic controls; there is no need to mechanically reconfigure the machine yourself. The rotation speed is changed by a switch, and a laser ruler is used to accurately position the board on the table.

Principle of edge trimming

Servicing of this type of equipment during operation is carried out by 2 people.

How to make a hand loom

You can make an edge trimmer yourself after some preliminary preparation. It is necessary to determine the main parameters of the future equipment, develop drawings of the edge trimming machine, and provide for the main and auxiliary equipment. It is useful to take into account the technical solutions of standard analogues from well-known manufacturers. Each homemade version finds wider application if it is unified in terms of raw materials and products.

The technical characteristics of taiga installations can serve as initial data:

- engine power from 5.5 kW for a single-saw k1 to 15 kW for a two-saw k-2m;

- circular saws ø 450 – 500 mm;

- rotation speed – 3000 rpm;

- adjustable distance between saws 50 – 340 mm;

- cutting depth 85 – 105 mm;

- permissible board dimensions 6.5 × 0.6 m.

The frame for placing the workpiece is welded from a channel to fit the size of the workpiece inside the passage of the cutting element. The main criterion is stability and lack of vibration during operation. Height 1 m. Guides for the carriage rollers are welded on the longitudinal sides.

It is better to make a homemade unit with a movable saw unit. This will allow you to control the feed speed and quality of the cut, and reduce defects.

We assemble the moving part from 2 U-shaped posts connected by a crossbar. This is a frame for mounting powered edge trimming saws.

As the number of disks increases, performance improves. A three-saw edger will allow you to effectively cut timber, glazing beads, and slats with a minimum of costs.

, please select a piece of text and press Ctrl+Enter.

Edge trimming machines: double-saw, single-saw

Any wood processing enterprise, from small to large, faces the problem of a large amount of waste when processing logs. The sawmill produces a rough cut of the log, cutting it to a square beam, and then, if necessary, cutting it into bars or edged boards of the required size. It is not rational to process rounded waste on a sawmill.

Wood edger

However, this waste can bring a lot of benefits and additional profit. Edged boards of small thickness, glazing beads and many other useful products are made from them. It is for this purpose that an edge trimming machine is installed at every woodworking enterprise.

How to make a hand loom

You can make an edge trimmer yourself after some preliminary preparation. It is necessary to determine the main parameters of the future equipment, develop drawings of the edge trimming machine, and provide for the main and auxiliary equipment. It is useful to take into account the technical solutions of standard analogues from well-known manufacturers. Each homemade version finds wider application if it is unified in terms of raw materials and products.

The technical characteristics of taiga installations can serve as initial data:

- engine power from 5.5 kW for a single-saw k1 to 15 kW for a two-saw k-2m;

- circular saws ø 450 – 500 mm;

- rotation speed – 3000 rpm;

- adjustable distance between saws 50 – 340 mm;

- cutting depth 85 – 105 mm;

- permissible board dimensions 6.5 × 0.6 m.

The frame for placing the workpiece is welded from a channel to fit the size of the workpiece inside the passage of the cutting element. The main criterion is stability and lack of vibration during operation. Height 1 m. Guides for the carriage rollers are welded on the longitudinal sides.

It is better to make a homemade unit with a movable saw unit. This will allow you to control the feed speed and quality of the cut, and reduce defects.

We assemble the moving part from 2 U-shaped posts connected by a crossbar. This is a frame for mounting powered edge trimming saws.

The cleanliness of the cut can be improved by setting the overdrive gear to 5000 rpm. The engine for a homemade cutting unit is from 4 kW (single saw) and above, the Ø of the disc for a single saw edger is from 250 mm.

As the number of disks increases, performance improves. A three-saw edger will allow you to effectively cut timber, glazing beads, and slats with a minimum of costs.

If you find an error, please select a piece of text and press Ctrl+Enter.

Do-it-yourself edge trimming machine drawings

DIY wood copying machine

Depending on the intended purpose and installation location, an edge-edging woodworking machine can combine the following design solutions:

- internal combustion engine or electric;

- the carriage with cutting elements is driven automatically/manually;

- number of saws making simultaneous cuts (1, 2, 3...).

Common to the edge trimming machine are a frame with guides for moving the carriage, clamps - clamps for the workpiece, a control unit, and optionally - a laser ruler, which simplifies positioning operations.

Models for industrial production are distinguished by an automatic device for feeding wood under a stationary carriage. They are equipped with systems for removing sawdust, dust, and waste.

Features of work

If a single-saw unit is installed on the edge trimming machine, then cut one side of the board first, and the other in reverse. This option is suitable for small processing volumes. A multi-saw edge trimming machine, which, if necessary, has up to 14 simultaneously operating saws, can reduce time and costs. The cutting is performed in 1 pass of the carriage.

Circular saws on the Taiga edge trimmer are installed with rotation in opposite directions.

A two-saw (or more) edge trimmer is adjusted manually, setting the gap between the cutting discs. Later models of two-saw edge trimming machines are equipped with electronic controls; there is no need to mechanically reconfigure the machine yourself. The rotation speed is changed by a switch, and a laser ruler is used to accurately position the board on the table.

Principle of edge trimming

Servicing of this type of equipment during operation is carried out by 2 people.

How to make a hand loom

You can make an edge trimmer yourself after some preliminary preparation. It is necessary to determine the main parameters of the future equipment, develop drawings of the edge trimming machine, and provide for the main and auxiliary equipment. It is useful to take into account the technical solutions of standard analogues from well-known manufacturers. Each homemade version finds wider application if it is unified in terms of raw materials and products.

The technical characteristics of taiga installations can serve as initial data:

- engine power from 5.5 kW for a single-saw k1 to 15 kW for a two-saw k-2m;

- circular saws ø 450 – 500 mm;

- rotation speed – 3000 rpm;

- adjustable distance between saws 50 – 340 mm;

- cutting depth 85 – 105 mm;

- permissible board dimensions 6.5 × 0.6 m.

The frame for placing the workpiece is welded from a channel to fit the size of the workpiece inside the passage of the cutting element. The main criterion is stability and lack of vibration during operation. Height 1 m. Guides for the carriage rollers are welded on the longitudinal sides.

It is better to make a homemade unit with a movable saw unit. This will allow you to control the feed speed and quality of the cut, and reduce defects.

We assemble the moving part from 2 U-shaped posts connected by a crossbar. This is a frame for mounting powered edge trimming saws.

The cleanliness of the cut can be improved by setting the overdrive gear to 5000 rpm. The engine for a homemade cutting unit is from 4 kW (single saw) and above, the Ø of the disc for a single saw edger is from 250 mm.

As the number of disks increases, performance improves. A three-saw edger will allow you to effectively cut timber, glazing beads, and slats with a minimum of costs.

, please select a piece of text and press Ctrl+Enter.

Edge trimming machines: double-saw, single-saw

Any wood processing enterprise, from small to large, faces the problem of a large amount of waste when processing logs. The sawmill produces a rough cut of the log, cutting it to a square beam, and then, if necessary, cutting it into bars or edged boards of the required size. It is not rational to process rounded waste on a sawmill.

Wood edger

However, this waste can bring a lot of benefits and additional profit. Edged boards of small thickness, glazing beads and many other useful products are made from them. It is for this purpose that an edge trimming machine is installed at every woodworking enterprise.