Surface grinding machine device

To construct sanding equipment for wood processing, you will need the following components and available tools:

- This mechanism forms the working surface on which the performing organ is mounted. The table can be mounted relative to the tabletop in any position, depending on technological needs.

- The machine is equipped with a drive, the purpose of which is to move the work table in the required direction.

- Above this table there is a working belt. Its location is determined by a screw mechanism.

- The grinding process is carried out using the transverse movement of the table and the possibility of longitudinal movement of the iron.

- The belt moves by an electric motor.

- The machine is also equipped with a dust collector, where waste generated after grinding is transported.

When setting technical characteristics for grinding, you need to proceed from the properties of the material being processed and its roughness. Thus, the following parameters are adjusted:

- speed;

- “roughness” of the working skin;

- the force with which the surface of the workpiece or semi-finished product must be pressed against the sandpaper.

The choice regarding the grain size of the skin is made based on the desired end result. The force used to adhere the belt and the speed are the fundamental indicators. If the belt is not pressed sufficiently and the speed of the grinding process is significant, then there is a possibility of fragmentary (incomplete) processing.

This means that certain areas will not be treatable. If we simulate the opposite situation, with significant pressure and weak feed, the semi-finished product will most likely turn black.

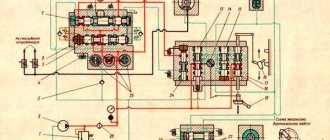

Homemade surface grinding machine for metal

Sanding the surfaces of metal products can be done in several ways. The manual method does not provide adequate accuracy and uniformity of processing. Factory models of equipment are quite expensive. Therefore, in some cases it will be advisable to make a surface grinding machine with your own hands.

Operating principle of surface grinding machines

Belt Surface Grinding Machine

The main difference between this type of equipment and electric emery is the degree of processing of the workpiece. It is intended not only for sharpening cutting parts, but also for removing a certain layer of material.

Structurally, the machine consists of a power unit (electric motor), which is located in the main body. With the help of transmission mechanisms (belt or gear), the grinding shaft rotates. To fix the workpiece, a frame is provided, which is most often connected to the body of the unit.

Depending on the design, metal processing units can be of the following types:

- spindle location – vertical or horizontal. This affects the processing technique of the part;

- accuracy of metal layer removal. This depends on the hardware settings. For factory models it is tenths of microns. In homemade installations, achieving such results is problematic;

- moving element. To process large workpieces, the position of the grinding part or the workpiece itself may change. In the latter case, a moving table is required.

One difference is the type of sandpaper used. Grinding wheels or an abrasive belt can be used for these purposes. In the latter case, the design must provide for the presence of two shafts with different diameters. This will increase the total processing area.

To make a surface grinding machine with your own hands, use circuits with manual parameter settings. Despite the relatively large errors, they are easy to implement for working on metal and wood.

Making a machine yourself

General view of a homemade surface grinding machine

The main component of the equipment is the power unit. For this, it is best to use an asynchronous electric motor. The number of revolutions should be from 800 to 2000. But it all depends on the parameters of the workpiece.

The problem is the lack of any diagrams for making a machine with your own hands. Experts recommend proceeding from the characteristics of the manufacturing materials that are at hand. The optimal household model is designed for processing small steel products. An abrasive tape is used for this.

Recommendations for making components yourself:

- main shaft It can be made of wood, usually the diameter is 25-30 cm;

- tension mechanism. Installed on the motor housing. Designed for belt tension, must have vertical adjustment;

- Desktop. The most important component that a surface grinder should have. Since changing the location of the motor shaft is problematic, the degree of impact of the abrasive on the workpiece can be adjusted by raising or lowering the work table.

The last component should include a steel plate and a flat part. Its position can be changed using adjustable legs. This is the best option for a homemade design.

To increase the processing area, you can install a shaft system. But you need to take into account that the dimensions of the entire unit will become larger.

For safety reasons, it is necessary to install a protective shield. It is made of plexiglass and attached using a regular loop. To ensure stability, a steel plate can be used as a base. The electric motor and work table are fixed to it. It is also recommended to install the on/off button in a convenient location for the operator.

To process parts made of carbide steels, corundum wheels can be used instead of an abrasive belt. They are installed on the motor shaft, the grinding procedure remains the same.

In the video you can see how a disc surface grinding machine was made with your own hands:

Surface grinding machines for metal

Surface grinding machines are designed to give metal, wood blanks, and plastic pipe cuts the necessary smoothness, remove burrs, scale and other defects that inevitably appear during cutting, soldering, welding and other types of mechanical and heat treatment. The accuracy of professional ones (with manual debugging and CNC) is 0.16 microns. A do-it-yourself surface grinding machine assembled from scrap materials has a large error and requires more time than similar processing on a CNC machine.

Taking into account that at home you will hardly need to process metal parts weighing half a ton, the weight of the machine itself will be significantly lower.

More often in home and automotive workshops, processing is carried out manually, rather than by placing the part on a table, which is explained by the low weight of the parts. The accuracy of surface grinding machines, where the part requiring processing is held in a canopy, directly depends on the fidelity of the master’s hand.

The grinding quality is far from the level that a CNC surface grinder provides, but this is not required when processing household parts.

Making your own grinding machine

The most common homemade grinding machine is the grinder. Its assembly diagram is simple:

- engine;

- frame made of thick metal corners;

- 4 rollers;

- sanding tape;

- 2 springs.

The grinder circuit is simple, but it is not very convenient for constant use. Often repairs are required for the tape, which can stretch. It is to adjust the tension of the tape that springs are installed vertically on the frame, the length of which is adjusted with a handle.

The handle itself serves as a bar for lifting one roller. Thanks to this device and crossbars, the belt is replaced less frequently. Rollers made from durable steel or titanium require no repairs. The roller bushings are attached to the frame with strong bolts until they are completely immobile.

The rotating part of the roller is made according to the principle of a bearing.

A small belt grinder is suitable for processing metal and wood products. If it is necessary to use the machine for materials of different densities, special attention must be paid to selecting the engine power. The motor of a washing machine is quite suitable for woodworking.

Metal processing when choosing this type of unit can lead to insufficient speed. Grinding and sharpening of home tools on such a machine is possible. If the work requires careful adjustment, then you need a professional, factory-assembled unit.

Greater accuracy is provided by surface grinding machines that are not hand-assembled, but factory-made.

In addition to massive manual and CNC machines, manufacturers produce factory and mini versions for installation in repair shops and garages. Their circuits are not so complicated, and work on the production of household metal elements does not require complex equipment.

Although, for the manufacture of metal decorations for interiors and in a home workshop, a CNC machine may be required. The device of a surface grinding machine that has a certain accuracy must necessarily have a rigid fastening of the metal being processed.

Principle of operation

The main difference between this type of mechanism and emery machines is the level of processing of the workpieces. It is suitable not only for sharpening cutting devices, but also for removing unnecessary layers of material.

Physically, the machine is equipped with a power mechanism (electric motor). Due to transmission elements (belt or gear drives), the grinding shaft rotates. To securely fix the workpieces, a base is provided, often attached to the mechanism body.

Depending on the design features, processing mechanisms can be of the following types:

- position of the working body - vertical or horizontal spindle. This directly affects the processing technique;

- accuracy when removing unnecessary layers. For production modifications this is tenths of a micron. In homemade machines, it is very difficult to obtain such parameters;

- mobile organ To process large parts, the location of the grinding element or the part itself can be changed. In the second case, there is a need to equip it with a moving table.

To make a surface grinder with your own hands, techniques with manual settings are used. Despite the rather significant errors, they are distinguished by ease of execution.

Types and features

Three modifications are offered for consideration, most applicable to home needs.

Surface grinder JET 16-32 Plus. This machine has excellent technical parameters, which are more than enough for household use and for minor repair work. The accuracy of surface finishing of a part can reach 10 fractions of a micron.

The machine consumes power at the level of 2 kilowatts, which is also acceptable for home working conditions, because not every electrical network can support the operation of a 10...15-kilowatt unit. Small dimensions and weight (61 kg). The characteristics of the main work are as follows:

Surface grinder PROMA RVR-400A. This is already the level of professional equipment, equipped with CNC. There is a working surface that is designed for a fairly significant load (350...380 kg), which will allow processing large-sized semi-finished products. The power of such a machine is 10 kW. Has the following operating parameters:

- 1100 mm – maximum possible longitudinal feed;

- 240 mm – possibility of cross feed;

- 550 mm – maximum lift of the “working body” above the bed.

This example is given more as an example, because equipment weighing almost 4 tons is needed in a production environment, and not in a home workshop.

Surface grinding mechanism LSh-322. The manufacturer of this equipment presents it as a machine for small repair rooms. Just what we need. The machine has small dimensions - 1050 × 1000 × 1800 mm, weight 700 kilograms. Significantly more compact than the previous model.

It has excellent characteristics regarding processing accuracy - maximum deviations are in the region of 3...5 microns, and roughness is 0.16 microns. Still, for household needs, this mechanism is expensive (its price is about $15,000) and also massive.

Video: homemade surface grinding machine.

Do-it-yourself universal inclined table for a sharpening machine

Hello, dear readers and DIYers! Many of you often use a sharpening machine, and know very well how important it is to maintain the required sharpening angle. It is not very comfortable to even sharpen a knife blade while holding it suspended. In this article, the author of the YouTube channel “DENDEN TV” will tell you how you can make a special table with an adjustable angle and height.

This homemade product is very easy to make and does not require complex machines or welding.

Materials. — Sheet plywood — Steel stud, washers, M8 wing nuts, wood screws — M8 lock nuts — PVA glue, spray paint, linseed oil — Sandpaper.

Tools used by the author. — Mini drilling machine — Slotted drill-saw — Carpenter’s machine vice — Screwdriver, bits — Countersink drill — Grinder, cutting disc — Belt sander — Orbital sander — Clamps — Circular saw, carriage, pusher — Band saw — Vise, rasp - Square, ruler, pencil. Manufacturing process. So, the main material for this attachment will be plywood. First of all, the master cuts out a block measuring 100x45x45 mm. It will serve as the basis for the entire structure.

Next, a rectangular blank for the platform measuring 100x80 mm is cut out. For it, the master uses sheet plywood 20 mm thick.

Two pieces for the hinge joint are also cut out. Holes are drilled in them for attaching the platform, as well as the base. Moreover, the lower holes have an oval shape. For ease of work, the master uses a homemade machine vice. You can make them yourself by reading the following article.

The edges of the hole are smoothed with a rasp, and the surfaces of the workpieces are sanded manually using sandpaper.

Both ends of these parts are rounded using a band saw.

A through hole with a diameter of 8 mm is drilled in the base block.

All surfaces of the parts are sanded using a belt machine.

Now a hole for the pin is drilled in the platform.

All parts are painted with spray paint.

So, all the parts are ready, and the hinges are attached to the base first. A lock nut is installed on one side of the stud, and a wing nut on the other. Washers are placed under the nuts.

The master decided to use a large sheet of plywood as the base for the machine. Both surfaces are sanded with an orbital machine, and the edges are also slightly rounded.

Having marked the contours of the machine, the author drills holes for fastenings. After this, the platform is covered with a layer of linseed oil. This will help protect the wood from moisture.

Pilot holes are drilled from the bottom of the platform using a countersink drill. Then the base of the attachment is screwed with self-tapping screws.

I thank the author for a simple but useful tool for a sharpening machine!

Good mood, good health, and interesting ideas to everyone!

The author's video can be found here.

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.