Read and see reviews about the PyroPrinter CNC burning machine in this section. And also send your feedback to the manager by email. mail or to a group on VK https://vk.com/chpy_vuhigatel. We are interested in what you burn on the machine and what additional materials for the machine you would like us to write down. All materials that are provided with the machine are the wishes of the same customers who purchased the machine. Therefore, do not be shy, but say what you would like to add to the materials.

We also now have a section in our group - “Sharing my experience”, where you yourself can directly talk about some of your thoughts, how to improve the quality or what else interesting you can burn.

Reviews from Avito and other sites

[Show slideshow]

Materials and tools for making a CNC machine from a printer

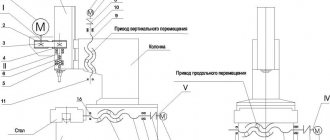

A simple homemade CNC machine from a printer is shown in the photo. It has a working area measuring 16 × 24 × 7 cm. It is capable of processing textolite (up to 3 mm thick), plywood (up to 15 mm), plastic and wood. The main purpose is engraving.

To manufacture such a machine, you will need the following materials, parts and components:

- The basis is the printer. A matrix type machine is recommended, for example, HP, Epson, Xerox, Ricoh, Canon. Its important elements are stepper motors.

- Plywood with a thickness of 15 mm. It is necessary for the machine body.

- Duralumin corners measuring 20 mm.

- Bearings: 606 or 608 in the amount of 3 pcs. and linear (4 pcs.).

- Self-tapping screws.

- M8 bolts 25 mm long and M8 nuts (2 pcs.).

- Construction pin M8.

- Rubber hose.

- Dremel.

- Bracket for fastening boards 80 mm wide.

- PVA and epoxy glue.

You should prepare the following tool in advance:

- electric drill;

- jigsaw;

- vice;

- hacksaw;

- pliers;

- files of several sizes;

- side cutters;

- screwdrivers;

- spanners;

- thread cutting tool.

For measurements and markings you will need a metal ruler and a square.

What useful things can you get from a printer?

From a matrix printer you can take many parts to assemble a CNC machine:

- The most valuable are stepper motors for moving the head and sheets of paper. Controllers are removed along with them.

- Hardened steel guides provide increased strength. They are made with great precision.

- Printing head sliding unit. Old type devices are especially good. Here you can find convenient copper bushings that can replace bearings.

- Toothed drive belt. It is quite suitable for assembling a machine belt drive.

- Limit switches. They will be useful for assembling the control circuit.

Important! The device should be disassembled as completely as possible. Almost all the parts are useful for assembling the machine - screws, nuts, studs, etc.

Reviews from our VK group

(the reliability of reviews can be easily checked here: https://vk.com/topic-120762264_33678006)

[Show slideshow]

1

You can read more reviews about the machine in our group on VK - https://vk.com/album-120762264_247190613

https://vk.com/topic-120762264_33678006

Setting up and debugging a CNC burner

Setting up a CNC burner is quite simple; even a beginner can cope with this task. First, a control program is installed on the computer that will control the machine. The Pyroprinter program, designed for installation on a PC running Windows XP and older, is popular among Russian specialists.

Working with the software is also easy. You must upload an image in one of the special formats: DXF, Exeilon, HPGL or Gerber. The program creates a list of commands for the machine in the form of G-codes and M-codes. The controller based on Arduino Nano V3 provides a stable speed of movement of the nichrome thread: up to 10 m/min at 20 steps/mm.

Source: pyroprint.com

Using CNC burners to create souvenirs and merchandise is a convenient business that can be organized even at home. Compact pyroprinters are designed to be placed on tables. However, it should be taken into account that when burning wood, smoke appears, so it is necessary to provide high-quality ventilation of the room. The ease of operation of the devices and the relatively low level of required investment also belong to the list of advantages of this business.

When using laser machines, the investment is higher, but it is possible to use the equipment not only for burning images, but also for laser cutting and engraving.

Other reviews that were emailed to us

Selection of laser engraving machines and operating principle

Laser engravers allow you to engrave and mark on various surfaces, for example, a memorable inscription on a leather wallet or a logo on a wooden flash drive case.

A laser engraver is a compact machine that fits on a desktop and does not require any special skills to operate. The working area is small and lies within a square with a side of 40...80 mm.

Common brands: Neje, Kkmoon, Decker, as well as all kinds of copies. A typical layout is a cube case with guides made from a floppy drive (cheaper, made from acrylic sheets), or a portal case without a bottom. Top models of engravers have Bluetooth connectivity and a built-in battery for autonomous operation.

The main purpose of such engravers is burning and cutting for hobby purposes, and is also suitable for study and small business.

The laser diode sends a powerful pulse with a certain shutter speed, and the optical system (lenses) focuses it to a point. In this way, the top layer of the material of the object is burned out; depending on the exposure time, a deeper and darker dot is obtained.

The piercing depth also depends on the properties of the material being processed. Available materials for engraving: cardboard, wood, bamboo, leather. You can burn on plastic (select modes so as not to char the edges).

Materials such as paper, cardboard, foamiran, felt, foam plastic are cut through (with a thickness of no more than 2-3 mm). You can cover the material with black paint and burn the paint itself - this way you can engrave on aluminum or copper (for example, you can try on other materials), that is, if you want to prepare printed circuit boards, then you can process boards coated with a layer of varnish / marker or expose them photoresist (video). It will not evaporate the copper between the tracks. It won't even heat up.

Please note that a laser engraver does not have the ability to burn on transparent materials (plexiglass), or on metals (not on copper either).

Review of Pyroprinetr from Maxim Ilyushin

“Hello, dear friends - future pyrographers and businessmen! Yes, yes, this text is just for you, those who have not yet decided to purchase a machine and who have many unanswered questions! I want to say right away that this post is not an advertisement, the Administration simply asked me to talk about the machine as an independent person. I will describe some frequently asked questions absolutely honestly, without any embellishment, and you can decide for yourself whether you need it or not. Well...let's get started shall we? The first and most important question that I get asked is how difficult is it to work on the machine?….the answer is not as simple as it seems. Working on it is not difficult and generally requires minimal movements from the operator, but the cooking process…. The first and most important thing I ask you to remember is that the machine is a VERY thin tool. Just imagine that to burn out a shade of black, the tip moves in the plane by a fraction of a millimeter, so it is important to follow all the manufacturer’s recommendations. I'll try to explain it in my fingers. If there is a draft in the room, you will get a damaged drawing, if the board is not processed properly, you will get a damaged drawing, if carbon deposits are not removed from the tip, you will get a damaged drawing, and so on. Initially, I myself thought that all these were little things, but as I wrote above, absolutely everything is important, which is why the process of preparing for burning is the most labor-intensive. Don’t be lazy, go over the board with sandpaper one more time, lubricate the machine, change the tip and don’t forget about the ruler. Question number two is also very important. Is it difficult to launch your own business (I hate this word, to be honest, but everyone is used to it)? Yes, it’s difficult, yes, it’s labor-intensive, but who has it easy now? Understand one thing...water does not flow under a lying stone; having bought a machine, crowds of people will not run to you to order portraits. To do this, you need to try hard, especially in big cities where there is competition. Before purchasing, consider where you will place the machine. Although it is not large, do not forget that it also needs a computer (preferably a stationary one, a laptop is simply not very convenient in terms of image adjustments), preferably a place for a small warehouse of boards (I always have 15-20 blanks for every need), Well, and space for small things, such as skins, etc. I have all this equipment at home. I just bought another computer desk (500 rubles on Avito, and in Moscow, in the regions, I think it’s even cheaper), kicked the cat out of the corner and put everything there. It turned out quite tolerably, that’s enough for me. Now to the clients themselves. All this is well described in the materials that come with the machine, but I’ll still tell you in two words. I advise you, first, to sit down and think over your advertising budget, and from there you can decide what and where to spend. If the budget is small, then start with friends, acquaintances, social networks. If it allows, then feel free to buy hosting and make a website (although, again, it’s in the materials, but still). Be sure to come up with a catchy name for yourself, Vasya Pupkin pyrograph, no one will remember