Craftsmen of different professions and specialties have different tools and devices in their arsenal. But almost all masons, carpenters, lumberjacks and even road workers, despite their different functions and tasks, have a tool that they cannot do without - a measuring tape. And although this type of measuring instrument has different shapes and purposes, the main thing for which a tape measure is needed is to accurately determine the sizes of various objects.

Description and purpose

From time immemorial, different quantities have been used to measure length - cubit, fathom, arshin or span, these are only Russian names for quantities. But as practice has shown, along with a large number of names, there was little order, because it was not without reason that the saying said that “everyone measures to his own yardstick.” The discrepancy in quantities and means of measurement was resolved by the introduction of two main measurement systems - metric and English with its inches and miles.

After the reference system was simplified and standardized, measuring instruments were developed for its implementation. And if the tailor's centimeter measuring tape found its use literally immediately, then in construction, geodesy and even in military affairs, measuring instruments for a long time had a bulky and clumsy appearance.

At the same time, the invention of a steel tape with scales and divisions printed on it became one of the breakthroughs in the introduction of standardization of the metric system.

The ease of use of such a convenient device for measuring distances literally revolutionized construction, making it possible to measure distances with millimeter accuracy and make building plans. Unlike a regular ruler with a scale printed on it, the steel strip has become more convenient, both in terms of working with it and in terms of storage. Unlike a construction meter, which can also be folded for convenience, the tape measure gave more freedom in use and significantly saved time. There was no need to constantly move in order to measure the dimensions of the building - just stretch the tape and measure. Indeed, in a folding carpenter's or construction meter the length is only 100 cm, while construction tapes can be 3, 5 or even 10 meters long.

And the dimensions of this measuring device have become much more compact - instead of wooden sections with a relatively large case, this measuring instrument fits into a compact case, which also has several additional functions that make work easier.

Where is a measuring tape used?

If the student’s main tool is a ruler, then masters of various professions use tape measures. Moreover, even office workers may need to use a tape measure, which allows them to find out the size of the room, the height of the ceilings, or measure the diagonal of the computer screen. The device in question is used in various fields, but it is used exclusively for measuring length or distance:

- When carrying out repair and construction work, markings are applied, the area is calculated, and the required amount of building materials is calculated

- When making furniture, blanks are measured and then cut to the required dimensions.

- When installing electrical wiring and electrical equipment, use a tape measure to measure the length of the required amount of wire, as well as the distance when installing sockets and switches

- In geodesy, distances of land plots are measured

- Petrochemical industry - measurements of the level of the remaining amount of petroleum products in tanks are carried out

Due to the use of the tool in different areas, the tape measure is also called a universal device. Its advantages include low cost, which is based on the length of the fabric used. Before we find out what types of roulettes there are, let’s understand the principle of operation of the device.

This is interesting!

Using a measuring tape, you can carry out not only linear measurements, but also angular ones. When taking angular measurements with a tape measure, it is important to understand that the larger the angle, the less accurate the measurement readings. In addition, when performing angular measurements, the metal sheet is deformed, which negatively affects the operation of the instrument and its service life.

Main design elements

Despite its small size and obvious purpose, the roulette device, especially its highly professional models, has a complex design. In a tape measure, the main element is a measured piece of steel strip made of another, durable but elastic material. In professional instruments used for field measurements, these can be strips of carbon fiber, fiberglass sheets, or thickened stainless wire with a meter scale printed on it. There are instruments with a fabric measuring tape with a centimeter scale printed on it. All of these devices use a different scale, so when measuring, the accuracy class of the tape measure is taken into account, because the error when working with a steel tape will be less than with a tape made of fabric or tarpaulin.

The measuring tape, like other structural elements, is located inside the housing. In most modern devices, the housing is made of impact-resistant plastic. But there are also copies with a metal case made of stainless steel. Cases are compact, open or closed. The compact size of the case is used for tape measures of 1 and 3 meters in length. The open case is used for special geodetic tape measures, the length of which is 50 and 100 meters.

For operation, it is important that the device includes a mechanism for winding up the measuring strip or simply a tape measure mechanism. In older models, this role was played by a rotating drum on which the tape was wound. And such a drum was driven using a folding handle. For construction tapes with a length of 1, 3, 5, 7.5 and 10 meters, the mechanism is most often spring-loaded today - when unlocked, it automatically winds the tape back into the body.

A hook is installed at the end of the measuring strip. In different models it has a special appearance. For ordinary construction tapes, this is a metal tip in the form of an angle with one or more slots. There are tips in the form of a metal bracket or even with an installed carabiner, and professional logger tapes are also equipped with a hook for fixing in the wood.

There are several buttons – latches – installed on the body of automatic roulettes. They are used to block the mechanism for rolling up the measuring tape so that during operation the tape does not uncontrollably wind up into the housing. If you remove the strip lock, it will automatically go into the housing.

The hitchhiking device is designed for quick but controlled rolling of the web to the desired length. This is very important especially when one person operates the device.

The design of a measuring tape, especially modern models, has a number of additional components that make working with it easier.

First of all, additional equipment includes:

- Built-in flashlight is an indispensable feature for working in dimly lit areas;

- Clip – a device that allows you to install it on a belt, quickly remove and put it on;

- Strap – allows you to hang the instrument on a hook for storage or carry it on your wrist.

- Laser pointer - allows you to use a bright beam to form a point on an object so that the tape measures the shortest distance in a straight line, and not the relief;

- Pencil holder - allows you to use this measuring device to draw circles without using a compass;

- Magnets on the hook and body - allow you to fix the tape on metal objects and free your hands for other work.

How to use a measuring tape correctly to extend its service life

There is nothing supernatural when working with a regular tape measure, and even more so when all the features of this tool are known

However, to increase the service life of the measuring device, it is recommended to pay special attention to a number of factors:

Initially, you should check the instrument for accuracy. How to do this is described above. It is strictly contraindicated to lubricate the belt with oils or other liquids. This leads to the accumulation of dust particles on the surface, which get inside, accelerating the failure of the tool. Do not bend the steel strip at an angle of more than 90 degrees. Although the tape is flexible, only such kinks negatively affect the service life of the equipment. The device should be stored in a dry place, avoiding exposure to moisture and high temperatures. When carrying out measuring work on your own, you should initially secure the end of the tape with a hook. If the size of the workpiece being measured is larger than the length of the tool tape, then measurements should be taken in parts, making appropriate marks

Only in this case is it important to take into account the presence of error, so it is recommended to use a device with a blade of the appropriate size

Operating a tape measure with a metal sheet at subzero temperatures helps to reduce the expansion coefficient, which is important to consider. By reducing the expansion coefficient, the tool error increases

As the temperature increases, the expansion coefficient increases. Plastic, fiberglass and wooden sheets are free from this drawback. When the operating temperature increases by 10 degrees on an 8-meter tape measure, the steel sheet stretches by 1 mm, and when the temperature decreases by 10 degrees, the tape decreases by 1 mm. Below is a table that can be used to guide deviations at different temperatures for tape measures from 2 to 100 meters.

Table of changes in the length of the tape measure depending on temperature

Areas of application of roulette

Accuracy in measurements is required for representatives of many professions and specialties. Where you need to know the linear dimensions of objects, a tape measure will be the most important measuring tool, even if the measurements are taken by non-professionals.

Typically this tool is needed:

- When carrying out design work - to measure areas, distances from the site of proposed construction to stationary objects;

- In construction, none of the operations can take place without it, from marking the pit to measuring the walls for installing electrical cables and sockets;

- In carpentry work, special precision is required here

- In the work of experts and real estate appraisers, most often it is with the help of a tape measure that both the length of the car’s braking distance and the height of the ceilings in the premises of the house are measured;

- In geodetic and cartographic work - when drawing up site plans, checking the correctness of interpretation of aerial photographs, developing land allocation projects;

- It is a mandatory measuring device for coaches and physical education teachers - meeting many standards is impossible without knowing the exact results of students’ exercises.

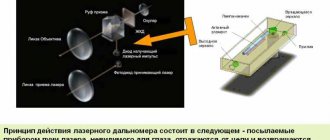

Which is better - a tape measure or a rangefinder?

A tape measure can be used to measure length, width and height.

The main disadvantage of the instrument is that it is problematic for one person to carry out measurements with this device. This is due to the fact that the tape bends when it is pulled out, so measurements of the length of the room will need to be taken along the base of the floor or by hooking the tape onto a hook. To take measurements with a laser rangefinder, you will need to place the instrument against the wall and press the laser button. The corresponding readings are shown on the instrument display. If it is necessary to perform simple mathematical operations, the device automatically makes calculations, for example, the area of the room.

As a result, we can say that if you independently perform a large number of measurements, it is better to use a laser rangefinder. If single measurements of linear distances are carried out, then you should use a regular tape measure. Even if you prefer to use a laser rangefinder, you cannot avoid using a regular tape measure, with which you can determine curved distances.

Types of roulettes and their features

For many professions, both ordinary universal measuring tapes and highly professional measuring instruments are used. Professional roulettes are developed taking into account the peculiarities of its use by qualified workers and working conditions. Thus, to measure terrain, both traditional geodetic instruments and new types of measuring instruments are used - electron-optical rangefinders. And although the accuracy of electronics is higher, the distance can only be correctly measured taking into account the terrain using a geodetic tape measure with a scale division of 0.5 or 1 meter.

For lumberjack work, a special lumberjack tape measure is used. Its design provides an additional carabiner on the body for fixing it on a worker’s belt. And at the end of the measuring tape there is a special metal tip, which makes it possible to quickly fix the edge on the log.

Construction tapes usually have a double scale - in centimeters and millimeters and in inches. The tape is usually 2 cm wide and the scale is printed in bright contrasting colors to make it easier to find the value on the scale.

How to repair an instrument

Despite the general simplicity of the design, sometimes situations arise when it is necessary to determine the cause of the breakdown and eliminate the malfunction. In this case, users begin to think about how to repair the tape measure quickly and without much effort. Of course, you can buy a new device, but there is no point in doing so if you can easily fix it yourself.

Tape measure with spring Source drive2.com

Usually, it is the winding mechanism that breaks down in the device. In this case, the tape can freely exit the housing, but it cannot return back. This problem occurs due to certain reasons:

- When the web is torn away from the spring;

- If the spring is broken or the plate is damaged;

- Separating the spring from the holder;

- Tape deformation.

Measuring tape body Source drive2.com

How to use roulette

To measure small distances and objects, when both edges of the object are at arm's length, you can work independently. With one hand, the end with the hook is attached to one edge of the object being measured, and with the other, the tape is unwound and, upon reaching the desired point, the latch is pressed and the length of the object is determined according to the scale on the tape.

The principle of working with large objects and distances is slightly different - first the line along which the measurement will be taken is determined, and then the distance is divided into segments, the ends of the segments are marked. After this, these segments are measured one by one. At the end, the results obtained are summarized.

When measuring diameter, the mark method is used - a mark is placed at one end of the circle, to which the beginning of the tape is applied, and the measuring tape is gradually stretched so as to find the point with the highest indicator on the reverse side. If possible, then find the center of the circle and measure the diameter through it perpendicular to the first measurement.

It is necessary to measure all linear dimensions with maximum tape tension, otherwise the accuracy of distance measurement will be questionable.

What to consider when choosing and purchasing a tool

If a home craftsman needs a tape measure for occasional use, then it is not at all necessary to consider expensive options. For such purposes, a cheap Chinese tape measure is suitable, with which you can take any measurements around the house or apartment.

When choosing a roulette, you should pay attention to a number of important factors:

- The length of the canvas is the most important parameter. It all depends on how long the workpiece or objects are planned to be measured. For home use, devices with a tape length of 3-5 meters are quite sufficient.

- Durability of the case - it is not at all necessary to choose metal devices, since impact-resistant plastic is no worse in quality

- Type of tape - you don’t have to choose for a long time here, since fiberglass tape is often supplied on tape measures of 10 meters or more. Conventional hitchhiking tape measures are equipped with metal tapes, which are more durable and efficient.

- Measurement accuracy - devices have errors, so when performing high-precision measurements, you should pay attention to options with an electronic display or laser rangefinders

- Manufacturer and price - to avoid falling for a fake, you should choose devices from popular brands that will never be cheap

It makes no sense to purchase tape measures with different functions if the tool will be used occasionally.

Types of roulette malfunctions and ways to eliminate them

With constant use, most tape measures show similar faults - a broken spring or a broken measuring tape. In the first case, you need to disassemble the housing and replace the spring with a new one, or, after removing the broken edge, simply insert it back into place.

If the measuring tape breaks, you can remove the first meter with the scale and attach the hook to 0 of the second meter. However, when working with such a tape measure, you need to be careful and remember that the measurement starts at 100 cm.

The measuring instrument and the secrets hidden in its design

Many masters use tape measures for a long time, and do not know all the secrets of this tool. To improve the quality and convenience of the manipulations, we will consider the main structural elements that have a dual purpose.

- Hook - at the end of the metal blade there is a steel tip that limits the possibility of winding up the tape. The tip is attached to the canvas using several rivets, through which a movable connection is provided. The hook serves not only as a limiter, but also as a hook, by means of which the edge of the tape is fixed to the part, making it possible to measure large items or objects independently. As for the play in the hook, which is why many people think that the tape measure is defective, it is designed specifically to increase the accuracy of measurements. How is this achieved? When the tape hooks onto the protrusion of the part, it is pulled back. As a result, the measurement is made from the zero mark, without taking into account the thickness of the toe. If it is necessary to measure not the outer surface, but the inner one (for example, a window or doorway), then the hook is recessed into the canvas due to the backlash, which also makes it possible to measure from the zero mark. The tip can be magnetized, which also simplifies the operation of the device when working with metal workpieces

- Cutout at the toe. A special cutout on the metal plate is designed to secure the blade to the head of a nail or self-tapping screw. However, this cutout can be used to draw circles of different sizes. The principle of using a cutout is based on the fact that you should initially screw a screw into the center of the future circle. A hook with a cutout in a circle will move along the head of the screw. After this, we determine the diameter of the future circle, and extend the tape to the appropriate distance, followed by fixing it with a button. A pencil is inserted into a special mount (if there is no mount, the pencil can be fixed with adhesive tape or electrical tape, or you can use part of a compass), and a circle is drawn. A full-fledged compass cannot replace a tape measure, but when it is necessary to obtain a circle of large diameter, then it is quite possible to do this with this device

- Indication of the length of the device body. When examining several models of tape measures, you can see that on some devices only the total length of the tape is indicated. On other models there are additional designations represented by a digital value in millimeters (with additional arrows in both directions). This designation means that it is possible to orient not only by the total length of the tape, but also by the distance of the housing. The convenience of such a designation on the body is manifested by eliminating the need to bend the tape to take readings. When the tape bends, its wear accelerates, so the presence of a housing length designation is a great advantage that can increase the service life of the tool

- Teeth on the toe. In addition to the protrusion at the beginning of the measuring blade, the metal plate has two teeth (if they are missing, you can make them yourself using a triangular file). Few people think about what they are intended for. Their purpose is quite simple and very convenient. The teeth are used to make scratches or marks, which is especially convenient when measuring long distances with a short tape measure

- Dividing the workpiece into parts - very often, after measuring with a tape measure, it becomes necessary to divide the part into two or more parts. Many do this by dividing the resulting value by 2, or however many equal parts you need to get. However, roulette simplifies the implementation of this procedure. To do this, you need to position the tape so that it ends with a whole number, that is, if the length of the workpiece is 18 cm, then you need to position the tape diagonally so that the 20 cm mark is adjacent to the edge. After this, a mark is made at the value of 10 cm, allowing you to divide the workpiece in half

The presence of a built-in flashlight allows you to take measurements at night or in low light, thereby increasing the accuracy of measurements. A flashlight or backlight illuminates the tape, so the technician can only record the readings.

This is interesting!

The design of roulettes can use built-in displays that display the length of the extended blade from the instrument body. Such instruments not only increase the accuracy of measurements, but are also very convenient to use, since the need to read readings is eliminated.

Tips for use

Using a tape measure involves its gradual wear and tear. Some problems may be caused by non-compliance with operating instructions, or too frequent use. In order for the tape measure to continue to be a working tool, you need to comply with some standards.

Avoid working outdoors in rainy weather. The metal sheet will begin to rust faster when exposed to moisture. A wet tape rolled into a casing may show signs of corrosion. Literally rust, which will hide the measurement scales. Corrosion on the spring will also make it difficult to use the measuring tape. It will become more difficult to pull it out, and jerking will lead to loosening of the spring.