Properties of plasma spraying

When working with metal structures, sometimes it is necessary to supplement them with additional properties so that they can be used in any field.

This way the surface will become even more resistant to moisture, high temperature and chemicals.

Diffuse metallization has many features that make it unique among other types of metal processing.

- Due to exposure to high temperatures (five to six thousand degrees), the surface treatment procedure is greatly accelerated. The process itself takes place in a fraction of seconds, and the result is excellent.

- The result is a combined ball. You can apply not only metal elements, but also gas particles from a plasma jet. Thus, the metal surface is coated with atoms of certain metal elements.

- If you carry out classical metal spraying, then the application occurs unevenly, takes a very long time and involves oxidative processes. But with the help of hot plasma, the correct temperature and pressure are obtained, due to which a high-quality coating is formed.

- The plasma jet transports particles of metal and gases at the speed of light, so you won’t even understand anything. Thus, welding occurs with powders, rods, rods and wires. Afterwards, a layer of several microns to one millimeter is formed on the base of the structure.

“To carry out diffuse metallization, complex equipment is used, in contrast to gas-plasma equipment. To carry out plasma metallization, you need to use gas and electric devices.”

Applying plasma coatings to granules of bulk materials

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

It is used for spraying coatings from metal powders, oxides, carbides, nitrides, borides and other refractory compounds, from composite powders and mechanical mixtures of various powders and wires.

The advantages of the plasma-arc spraying method

coatings include:

- the ability to obtain coatings from most materials that melt without decomposition;

- relatively low thermal effect on the substrate (usually heating the latter in the range of 50-150 ° C), which makes it possible to apply coatings to the surface of a wide range of materials, including plastics, wood, cardboard, etc.;

- the thickness of the coating can vary from 15 microns to 6 mm or more with an average thickness variation of ± 10%;

- the possibility of using various types of gases to form an arc plasma jet: inert (argon, helium), reducing (hydrogen) and oxidizing (air, nitrogen), as well as ammonia, natural gas, water vapor and other gaseous substances, which in combination with the use of chambers with a protective environment (vacuum) or protective attachments allows you to regulate the properties of the environment in which the particles of the sprayed material heat up and move;

- the possibility of flexible regulation of the electric and gas operating modes of the plasma torch, including during the spraying process itself, allows you to control the energy characteristics of the sprayed particles;

- fairly high process productivity, amounting to 3-11 kg/h for burners with an electrical power of 25-40 kW and 11-25 kg/h for burners with a power of 80-120 kW;

- the possibility of applying coating to open surfaces with virtually no limitation on their size, provided that the necessary mechanization and safety equipment are available.

Disadvantages of the plasma-arc spraying method

coatings are:

- in some cases, the level of adhesion strength of coatings to the substrate is insufficient (usually 15–50 MPa when tested for normal peeling);

- the presence of porosity (usually in the range of 2-15%), which prevents the use of many plasma coatings in corrosive environments without additional treatment;

- low efficiency of plasma jet energy when heating the powder (2-8%).

Volchenko V.N. “Welding and welded materials”, vol. 2.

Plasma spraying is based on the use of the energy of a plasma jet for both heating and transfer of metal particles. A plasma jet is produced by blowing a plasma-forming gas through an electric arc and compressing the walls of a copper water-cooled nozzle. Plasma coatings have the following properties: heat resistance, heat and erosion resistance, thermal and electrical insulation, anti-seize, corrosion resistance, cavitation protection, semiconductor, magnetic, etc.

Areas of application of plasma coatings: rocket, aviation and space technology, mechanical engineering, energy (including nuclear), metallurgy, chemistry, oil and coal industries, transport, electronics, radio and instrument engineering, materials science, construction, machine repair and restoration of parts.

If the cost of flame spraying with wire materials is taken as one, then the cost of plasma and flame spraying of powders will be 1.9 and 1.6, respectively, and electric arc spraying will be 0.85.

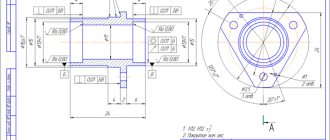

The plasma jet is produced in a plasma torch, the main parts of which (Fig. 3.34) are the electrode-cathode /, a water-cooled copper nozzle-anode 4, a steel housing 2, devices for supplying water 3, powder 5 and gas 6. Parts of the housing interacting with the cathode or anode, isolated from each other. Powdered material is supplied to the feeder using a transport gas. It is possible to introduce powder with plasma-forming gas. The sprayed material (powder, wire, cord, or a combination thereof) is introduced into the plasma torch nozzle below the anode spot, into the plasma arc column or plasma jet.

High temperatures and jet speeds make it possible to spray coatings from any materials that do not dissociate when heated, without restrictions on the melting temperature. Plasma spraying produces coatings of metals and alloys, oxides, carbides, borides, nitrides and composite materials.

The necessary physical and mechanical properties of coatings are explained by the high temperature of the plasma and its flow rate, the use of inert plasma-forming gases, and the ability to regulate the aerodynamic conditions for the formation of a metal-plasma jet. There are no structural changes in the material of the part, it is possible to apply refractory materials and multilayer coatings from various materials in combination of dense and hard lower layers with porous and soft upper ones (to improve the running-in properties of the coatings), the wear resistance of the coatings is high, and full automation of the process is achievable.

When alloying through a wire, surfacing is carried out using high-carbon or alloyed wire under fused flux. This ensures high precision of alloying and stability of the chemical composition of the deposited metal over the coating depth.

Alloying of the deposited metal through flux is performed by surfacing with low-carbon wire under a layer of ceramic flux. The high hardness of the coatings excludes their subsequent heat treatment. However, this alloying method has not found wide application due to the large unevenness of the deposited metal in chemical composition and the need to strictly maintain the surfacing regime.

The combined method of alloying simultaneously through wire and flux has become most widespread.

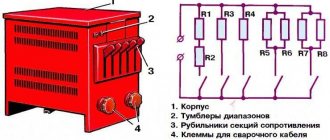

Rectifiers VS-300, VDU-504, VS-600, VDG-301 and converters PSG-500 with a flat-sloping or rigid external characteristic are used as power sources. Special installations are used as part rotators (UD-133, UD-140, UD-143, UD-144, UD-209, UD-233, UD-299, UD-302, UD-651, OKS-11200, OKS- 11236, OKS-11238, OKS-14408, OKS-27432, 011-1-00 RD) or decommissioned turning or milling machines. For wire feeding, heads A-580M, OKS-1252M, A-765, A-1197 are used.

The main technological parameters of surfacing: composition of the electrode material and flux, arc voltage U, current strength / and polarity, surfacing speed vH and feed vn of the electrode material, surfacing pitch S, electrode displacement from the zenith e, diameter d3 and electrode stickout. Approximate modes of surfacing under a layer of flux for cylindrical parts are given in Table. 3.52.

Surfacing under a layer of flux has the following varieties.

Surfacing with a lying electrode (rod or plate) made of low-carbon or alloy steel is used to restore planes. Part of the flux is poured onto the surface to be restored (3...5 mm thick), and part - onto the electrode (the thickness of the flux layer reaches 10... 15 mm). Flux mixtures are used. In one place, the electrode is connected to a part to excite an arc, which, when burning, wanders in the transverse direction. The current density is 6...9 A/mm voltage 35...45 V. To carry out the process there is an OKS-11240 GosNITI installation.

Increased productivity and a higher content of alloying elements in the coating are provided by multi-electrode submerged arc surfacing on parts with significant wear over a large area (Fig. 3.23). A stray arc burns between the part and the electrode closest to it.

What equipment is used for diffuse spraying?

To perform sputtering with metal ions, high-temperature technical plasma is used - a combination of many quantum particles of light, positive ions, neutral elements, and electron gas.

Due to the high temperature, electrical gas discharges create strong thermal ionization of elements that are connected to each other and the external environment. Therefore, there is a simple plasma, weakly, moderately and strongly ionized (in turn divided into low-temperature and high-temperature).

In order to perform plasma ionization of metal structures, specific equipment is used - plasma equipment.

As a rule, an arc, pulse or spark electric discharge is used.

To implement all this, you need to use:

- High-frequency generator (or welding modifier) to create a discharge.

- A sealed chamber (it contains elements for treating the base with diffusion spraying).

- Gas container. Under the influence of electric discharge, ionization of elements occurs.

- A gas pressure device (vacuum or pump equipment is suitable).

- A system for changing current, pressure, voltage and increasing or decreasing the thickness of the metal surface.

The order of plasma ionization occurs in the following order:

- Fixing the part in a sealed chamber and generating an electrical discharge.

- The working atmosphere is pumped up with pressure and powder particles (a high-temperature plasma is obtained that transfers powder elements to the base of the workpiece).

- With vacuum spraying, in conditions of inert gas or low pressure, it is possible to accelerate the movement of elements, resulting in a more dense coating with good adhesion.

Distinctive Process Characteristics

- coating of thin-walled small-sized products

- effective control of the energy characteristics of sprayed particles and coating formation conditions due to the flexibility of adjusting the parameters and operating modes of the plasma torch;

- high coefficient of powder utilization (up to 85%), adhesion strength of the coating to the base (up to 60 MPa), low porosity;

- versatility due to the production of coatings from most materials without limiting their melting temperatures;

- coating of products made from almost any material;

- low thermal impact on the sprayed base, which avoids deformations, changes in product dimensions, and also eliminates undesirable structural transformations of the base metal;

- coating local surfaces;

- obtaining regulated uniform porosity of the coating for use in working conditions with lubricated sliding surfaces;

- positive effect on the fatigue strength of the base, due to the formation of a layered coating structure during PT, in contrast to the columnar structure formed during deposition from the gas or vapor phase, diffusion saturation;

- coating with minimal allowances for subsequent machining;

- the possibility of use for additive technologies or the shaping of parts (PN is produced on the surface of a mold-mandrel, which is removed after the end of the process, leaving a shell of sprayed material);

- reduced noise and radiation levels;

- reliability and stability of the equipment, high service life of plasma torch elements, by optimizing cooling conditions and ensuring a smooth increase and decrease in current;

- low argon consumption;

- maneuverability and the ability to automate the process.

Areas of application of diffusion metallization

Due to the fact that any metal or metal alloy can be subject to plasma spraying, this type of diffusion treatment is used on an industrial scale, as well as for restoration work.

The powdered metal is transferred to plasma equipment, where the high temperature plasma melts it and absorbs it into a thin ball of metal.

Next, let's look at where spraying is used:

- production of aircraft, space and rocket launchers;

- mechanical engineering and energy;

- metallurgy and chemical production;

- oil production, oil refining and coal mining industries;

- in the field of transport and equipment production;

- in the field of restoration of machines, installations and obsolete elements.

After the plasma-powder jet passes through the electric arc and settles on the base, it is enriched with the following properties:

- resistance to elevated temperatures;

- corrosion resistance;

- electrical insulation;

- thermal insulation;

- resistance to erosion;

- cavitation protection;

- magnetic attraction;

- semiconductivity.

“Plasma powders are filled using plasma-forming or transported gas. Due to metallization, various coatings are obtained, regardless of the melting point (metal, combined alloy, carbide, oxide, boride, nitride, composite). After processing, the material will not suffer one bit in appearance, but rather will be enriched with additional properties. Hard and soft balls, refractory materials, and media of any density are subject to spraying.”