Types of machines for Lego bricks and selection criteria

The Lego machine can have a manual, hydraulic or electric drive. Manual machines are cheaper, but can only handle a limited output. In addition, the quality of their products is somewhat lower than that of electrified ones.

Based on productivity, machines are divided into three types:

- Small. Around 1000 bricks in a standard eight hour shift. Available with manual and electrified drives, they cost from 80 to 200 thousand rubles.

- Average. 2-3 thousand bricks per shift, electrified, cost from 200 thousand rubles.

- Industrial. Up to 800 bricks per hour, cost from 2,000 thousand rubles.

Hydraulic Lego machine

The hydraulically driven machine, designed for small production volumes, is quite compact. Its dimensions:

- height: 2 m;

- width and length - 1.5 m each;

- weight - up to a ton.

A space of 10 m2 is enough for operation.

Comments:

- kadyr 04/2/2015 10:33

Send to Kazakhstan by mail

Yes, you can by EMS service - 125 USD, delivery time is 3-5 days or by mail - delivery time is 2-3 weeks, delivery cost is 65 USD

Kadyr, good evening. What city do you live in? It will be cheaper for me to come for the matrix than EMC delivery. I'm interested in a set for $160 which will be next in line.

Kadyr, what city in Kazakhstan do you live in? It’s cheaper for me to get there than EMC costs. I'm interested in $160, when will it be my turn?

Read also: Types of diodes and their applications

Good afternoon Mikhail! We are located in Alexandria, Kirovograd region. Ukraine, location map here: //msd.com.ua/img/map.php Lego matrices are produced almost to the warehouse (there are no queues, i.e. they are in stock now). In Ukraine, delivery is by cash on delivery, abroad - by full prepayment.

Can you send me by bus to Volgograd?

Unfortunately, we do not have representatives at the border, we can send cash on delivery to any city closest to the Ukrainian border to the Nova Poshta warehouse, for example, look for the nearest branch here: https://novaposhta.ua/office

We don't have a bus to Volgograd. We have a representative in Russia (Stary Oskol) - you can make an official prepayment for it 20% more, after the prepayment the matrix will be sent to you within 3 working days.

Hello Rashid, I’m interested in a kit for 160 dollars, how much should I send to Stary Oskol and how will it be sent? I live in Kazakhstan in the north and you make matrices with steel and there are drawings for a hydraulic machine

Good afternoon There is no drawing for hydraulics, we are not ready for a manual one yet, but you can take as a basis a brick machine, which we have been producing for more than 7 years (there is no strong demand for it): //msd.com.ua/zip/kirpichnitsa.zip If you want to Stary Oskol, send money 20% more, if there is no trust, send it to me. Can you please contact me: Shakhidov Rashid Sultanovich ind. 28000, Ukraine, Kirovograd region. Alexandria Any translation system, preferably one of these: Golden Crown PrivatMoney Unistream WesterUnion Contact Coinstar MoneyGrim With delivery to Kazakhstan, the Lego matrix set, welded box and void boxes cost 285 USD (i.e. delivery by EMC service - 125 USD, it takes 3- 5 rubles, you receive it at your address customs-free and duty-free!)

Hello. I would like to buy a matrix set for 120 and an additional upper and lower punch. How much will it cost with delivery to Almaty. Kazakhstan.

I want to purchase a die set and an additional upper and lower punch. Please tell me how much it will cost with delivery to Almaty?

With delivery to Almaty it will cost 210 USD

A matrix with a box is available in Sevastopol for 160 US dollars, with delivery to Almaty it will cost 170 US dollars, i.e. GlavDostavka shows that delivery is only 10 dollars. We will not disassemble the matrix in Sevastopol.

Rashid give me your Crimean phone number. number, I live in Crimea, I want to purchase one set, we need to talk on the phone. I'm waiting for the phone. numbers on email mail.

Rashid assalam alaikum I want to buy a matrix for Lego I live in Chechnya how to contact swami

Here is my number 89604416568

In Chechnya (or the North Caucasus of Russia) you can contact my close relative and make an advance payment through him: +7 928 7893104 Ilyas The cost of a complete matrix with a box and cylinders is 160 US dollars, the cost of delivery to Chechnya or Russia is 120 US dollars total - 280 USD

I want to purchase a die set and an additional upper and lower punch. Please tell me how much it will cost with delivery to Belarus

Good afternoon. Is the kit available in Sevastopol? Or do I need to order it? What is the price of the matrix today? And is it possible to purchase the machine itself?

I want to order a matrix with cylinders and shipping throughout Ukraine, how much will it cost?

Great. I wanted to ask how much delivery will be in Kyrgyzstan and how we will buy manual machines

My number is 702257562

A manual machine with delivery to Kyrgyzstan costs 970 USD

two side plates on a Lego brick with milling and a matrix, top and bottom, with delivery to Belarus, how much will it cost?

220 USD with delivery to Belarus

HELLO ONE ONE LEGO BRICK MACHINE HOW MUCH IS IT IF WE BUY HERE FOR RUSSIA I AM MAADANBEK

I HEARD THE MOST DISH 40 THOUSAND RUBLE THAT'S CORRECT

How much does a ready-made matrix cost from welded boxes in Kyrgyzstan?

How to contact you?

Good afternoon, I am interested in the cost of the matrix with delivery to Perm.

Hello. We are engaged in the manufacture of matrices for Lego bricks and more. The matrix is made on professional CNC equipment from wear-resistant, hardened steel, characterized by increased strength (45 steel is not suitable for the manufacture of matrices used for pressing.) For mechanical and hydraulic presses. Delivery throughout the Russian Federation and the CIS The price is lower than the market price, the quality is higher.

Read also: Diameters of inch pipes in millimeters

There are ready-made matrices available.

+79688639475 WhatsApp or Viber [email protected]

approximately how much the machine will cost with delivery to Uzbekistan

answer if possible in a telegram to the number +998919861701 or in VK Jurabek Khafizov

We don’t use telegram, we have WhatsApp, Viber +38 050 4571330. Matrix with box and cylinders with delivery to Uzbekistan - 360 US dollars

Rashid primerno skolko videt ruchnoy stanok s dostavkoy v Turkmenistane…

1150 US dollars If only the matrix is 480 US dollars

Good afternoon, I am interested in the cost of the matrix with delivery to Scotland where I live.

Good afternoon A complete set of molds for Lego bricks, such as in the video:

Cost US$180, delivery to Scotland – US$150, total US$330 with delivery to your address.

Good day! A complete set of a Lego brick form, such as on the video:

costs $180, delivery to Scotland - $150, a total of $330 with delivery to the address.

Any site materials can be published with a link to the source Website promotion © 1999–2018 Site map

Lego bricks appeared on the construction market not long ago and quickly gained popularity. While retaining the advantages of ordinary brick, it also has its own advantages. You can buy such bricks ready-made, or you can purchase or independently make a machine for their production. It will be cost-effective for large production volumes of Lego bricks.

Operating principle

The method of operation of the Lego brick machine is simple.

The prepared working mixture should be poured into the hopper. A dispenser supplies the required amount of it into the molding matrix. Then the mixture is compressed using a lever.

The manual drive allows you to achieve a force of up to 2 tons, hydraulic - 5-12 tons.

After the end of the lever stroke, several (depending on the capacity of the matrix - from 3 to 15) ready-made Lego bricks are obtained in the working compartment. Next, open the working compartment and remove the molded Legos. The manual drive is driven by the operator’s muscular strength; the pressure in the hydraulic system is pumped up by a hydraulic pump driven by an electric motor.

Specifications

The main indicators by which different machine models are compared when choosing are given below:

- Resource. Expressed in the guaranteed number of operating cycles. For manual machines, the figure must be at least 500,000. For models with electric drives - from 1,000,000.

- Operating pressure. The higher the indicator, the stronger the product. Lego bricks, formed on manual machines with a force of 2 tons, are best used for the construction of one-story sheds and for decoration. Bricks compacted with a force of 20 tons are suitable for load-bearing walls.

- Production rate. Expressed in the time it takes to produce one Lego. Usually from 10 to 40 seconds. Depends on the number of cells in the matrix.

In addition to the indicated indicators, the Lego machine is characterized by operating modes.

How to make molds

To make molds, a matrix is required; it is a stationary part. The matrix looks like a box; the part has no bottom or lid. The punch is a necessary part. This is a movable bottom with which the form is equipped. As the mold contracts, the force is transferred to the mixture, creating a brick.

The installation is controlled by the operator. The punch moves up and down, you can control it yourself or entrust this work to an assistant. You will quickly assemble the machine; you can start making bricks right away.

When the processing process is completed, the product is ejected from the matrix. A removable cover covers the matrix; it is fixed to the structure with latches.

On the machine you can produce products of different configurations. This is possible because you can change the surface of the punch. It is worth noting that the quality of the brick directly depends on what material you are going to use.

The compression force also matters. It is also influenced by the quality of the mixture you put into the brick press.

Operating modes

Lego brick machines can operate in manual and semi-automatic mode. In the first, the operator performs all operations – loading the mixture into the hopper, feeding it into the working chamber and increasing the force to the required value – independently.

In semi-automatic mode, all he has to do is load the mixture and take out the finished product - the device will do the rest itself. This mode increases productivity by one and a half to two times and significantly increases the stability of the strength characteristics of the product.

Industrial machines also implement an automatic mode, in which all operations occur without the participation of an operator, but under his supervision.

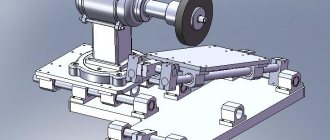

Industrial equipment for the production of Lego bricks

The machine can operate in manual and semi-automatic modes.

Brick making mixture

The production of clay bricks is based on the use of soils that contain no more than 10-14% clay. Silty soil and vegetation layer are not suitable for the mixture. If thin soils are used, then clay is added to them. In addition, you need to pay attention to the moisture content of the mixture. To check this, you need to take a handful of earth and squeeze it in your fist. In this case, the mixture should form a lump without leaving marks on your hands. Fatty soils are those that contain a lot of clay. If they are used, they include additives in the form of sand, slag and ash.

If the lumps of earth rolled up in a fist do not fall apart or smear, this means that such soil can be used. To increase resistance to moisture and strength, 16-18% hydrated fluff lime can be added to the raw material. By adding cement to the mass for making bricks, the strength of the product can be increased almost threefold. With this additive, the mixture must be used within one hour.

Consumables and tools

The high performance of the final product of the Lego machine is largely determined by the correct selection of the components of the working mixture.

It includes:

- cement grade 300-400, from 5 to 15%;

- filler - screening fractions of crushed stone - 80-90%;

- water;

- pigment to give a specific color.

You will also need tools and auxiliary equipment for Lego production:

- concrete mixer;

- containers for mixture components;

- vibration compactor;

- loading and unloading equipment;

- transport.

Equipment and inventory

Don't think that all this is expensive equipment. On the secondary market all this is sold at low prices. For example, a used concrete mixer with a volume of 180 liters can be found for 5,000 rubles. A new deep vibrator can be purchased at a cost from 2000 to 5000 rubles. You can also make a concrete platform yourself, spending 7,000-10,000 rubles.

The simplest concrete mixer is suitable for home production.

You will also need auxiliary tools: bayonet and scoop shovels, trowel, buckets, plastic container, hacksaw, hammer, set of keys and screwdrivers, garden cart. Another cost item will be cellophane film, which will be needed when drying finished products. Most of the listed equipment is available in almost every home and the purchase of these items does not need to be included in the overall budget.

The deep vibrator can be selected in any modification

Advantages and disadvantages of Lego bricks

Compared to fired ceramic bricks, Lego has the following advantages:

- perfect shape, not distorted by firing;

- low moisture absorption;

- environmentally friendly production;

- simplicity of technology and low energy consumption;

- frost resistance;

- the ability to conduct communications through holes in Lego.

Application of Lego bricks

Lego brick has its own disadvantages:

- little experience in operating buildings does not allow us to accurately estimate the service life of the material;

- The lack of standards and mention of the material in SNiPs delays its widespread use in the construction market.

Convenience and practicality of innovative production

An exact or universal recipe for the mixture from which Lego bricks can be made has not been established. The composition of each mixture is selected individually, taking into account the characteristics of the components used for its production.

The basis of the mixture is PC500 cement and filler in a ratio of 15:85. As for the filler, it could be:

Which one to choose is decided at the place of production, taking into account the climatic characteristics of the region. In addition, it is necessary to take into account that clay reduces the frost resistance of the mixture, and, consequently, of the manufactured brick.

DIY machine

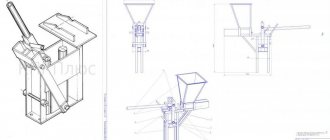

There are many general diagrams and detailed drawings of machines for producing Lego bricks on network resources.

To make a simple DIY brick machine you will need:

- steel sheet 2-3 mm;

- channel 10 cm, thickness 4-5 mm;

- 89 mm pipe for the piston;

- 50 mm pipe for lever;

- fasteners;

- primer and paint.

Equipment you will need:

- welding inverter;

- Angle Grinder;

- abrasive paper.

General view drawing of a machine for Lego bricks

Assembling a machine for producing Lego bricks with your own hands is quite possible for a home craftsman with experience in welding and metalworking operations.

Types of equipment for brick production

Bricks are usually made in a factory using special equipment. However, there is a technology that allows you to make this building material from clay at home with your own hands. To do this, you only need a special brick press. Today it can be purchased from companies specializing in such equipment. Although no one forbids making such a press with your own hands. For this purpose, you will need very little: a sufficient amount of material (this could be, for example, sheets of steel) and a welding machine.

Before revealing the secrets of creating a homemade brick machine, we will tell you about their structural elements. Thus, this installation is a press equipped with a rotating base. Rotation occurs like a revolver. At the base there are receiving forms into which a special mixture is supplied. While the base rotates, the material is pressed in one cell, and the mixture is poured into free molds. On the other side of the installation, the finished product comes out. Using such a brick machine, you can quickly produce a batch of medium-sized products.

A screw press is often used to make bricks. In this equipment, almost all processes occur automatically. The body of such a press is usually made of cast iron. In addition, the design has a screw shaft and a supercharger. To obtain a product, the clay mass must first be loaded. Moreover, it is important that it has a humidity of 19 to 24%. The output is a product in the form of pressed timber. It is cut into several identical pieces to make bricks. Sometimes the timber is not divided into parts, but is used entirely as a separate building block.

There is also special equipment for the production of hyperpressed bricks. This press allows the raw material to be compressed as much as possible, resulting in a very durable brick. This technology can be used to produce hollow and solid (solid) blocks. The last of them are considered the most popular.

A variety of additives can be mixed into the clay. In general, slag is the most commonly added material. But recently, when pressing bricks, they also began to include components such as reeds or straw into clay. This makes production cheaper, and the bricks acquire some useful qualities.

Sequence of work

Carefully studying the machine drawing before cutting the material will help save time on correcting errors. The sequence of manufacturing operations is as follows:

- Cut two meter racks from the channel.

- Connect them with crossbars into a frame.

- Weld the chassis for the bunker on top. On the one hand, it is necessary to provide a limiter. Make a hole along the diameter of the piston.

- Cut the steel sheet and weld the parts into a bunker. Its dimensions correspond to the dimensions of the working chamber. The hopper must move along the upper channel.

- The piston is assembled from a sheet rectangle and reinforced with stiffeners.

- Weld a handle for opening/closing to the hopper lid.

All that remains is to clean, prime and paint the machine.

Technological production process

The Lego production technology is based on the super-compression operation. Under high pressure, the material is compacted, and its particles are sintered together without heating.

The technological process is divided into the following stages:

- The thoroughly mixed working mixture is poured into the hopper.

- The dispenser measures the volume of mixture required for one working cycle.

- This volume enters the matrix, where the Lego is molded under pressure.

- Molded bricks are stored on pallets and dried under natural conditions for 2-3 weeks. At this time, the mixture finally hardens and gains strength.

Drying times may vary depending on the ingredients used. It must be selected in accordance with the user manual.

Types of material

Based on production technology and material composition, bricks are divided into:

- ceramic,

- pressed,

- silicate.

Ceramic bricks are made from clay that has been formed into briquettes, after which the required strength is given to it by firing. This type of material is used most often, because it is suitable for almost any stage of construction. Such a brick can be either solid (or solid), or it may have technological holes that make it lighter in weight. This material is often used for laying stoves and fireplaces.

Special machines are used to make pressed bricks. After pressing, they are dried so that they acquire the necessary strength.

As for sand-lime bricks, they are made from a mixture of 8 parts sand and one part lime. After pressing, they are processed in a special apparatus (autoclave), where they are exposed to hot steam supplied under pressure. This treatment gives the material the necessary strength. Today, sand-lime brick m150 is becoming increasingly popular. Its dimensions allow you to save on construction time. In addition, it uses less masonry mortar.

Additional components

To make work easier and provide additional opportunities, manufacturers offer a wide selection of components:

- Press forms. Allows you to obtain Lego elements of non-standard sizes and shapes.

- Feeding belt devices for loading the mixture into the hopper. Useful for large production volumes.

- Specialized mixer. Designed taking into account the parameters of the mixture and ensures greater homogeneity compared to general purpose concrete mixers.

- Sets of pigments for obtaining various shades of products.

Shovels, measuring buckets and other containers and tools are also available.