Home > Products > Reinforcement products > Reinforcement bending and production of reinforcement products

Category:

Reinforcing products

In stock:

Yes

Today, reinforcement is often used for the production of metal structures of a wide variety of shapes, as well as in other areas of construction. Accordingly, there is often a need for various reinforcement configurations, rather than just straight rods. This can be realized by bending the reinforcement using special equipment.

This is what a machine for bending reinforcement looks like:

Reinforcement bending machine

Rebar bending

Reinforcement is a strong and ductile connection of metal elements that ensure the stability of building structures, frames, foundations, fences, gratings and other structures. It can be made of soft and hard metals, which is determined by its purpose. The most commonly used reinforcement is made of steel, which is capable of withstanding large mechanical (weight) loads for a long time.

We can produce the following fittings products according to your order:

Reinforcement products according to customer drawings

There is fittings:

- working;

- distribution;

- construction or installation, which is available with a ring and spiral pattern.

Each of its types corresponds to the specific features of solving specific production and construction problems.

When carrying out construction work, not only straight reinforcement bars are used. For installation at the ends of buildings, bent reinforcement is used, shaped like the letter “P” or a closed clamp. To obtain rods of various curved shapes, a method such as bending reinforcement is used. In this process, the workpiece, wholly or partially, is given a curved appearance. This technology can also be used for straightening reinforcing bars.

Bending metal reinforcement is a fairly common operation. It is carried out with the aim of giving the product any shapes that may be necessary to create a specific object or structure.

provides bending and cutting services for reinforcement, as a result of which the customer receives metal parts with the most accurate parameters specified in the drawings.

We will help you calculate all permissible bending angles of your metal product, depending on the material from which the reinforcement is made, as well as the purpose of the finished product. In addition, we will calculate the possible load force on the finished structure and, if necessary, advise on the correct choice of reinforcement for such a product.

Technology for the production of reinforcement products

Bending of reinforcement is carried out only in a cold state on a special bending machine with several steel shafts and a rotating disk. The workpiece is fixed between the central and thrust shafts. After this, a horizontal disk with a bending shaft is activated. With its help, the reinforcement bar is rounded to the desired degree (maximum 180°).

There are two types of machines designed for light bending (workpieces with a diameter of 6-20 mm):

Light reinforcement bending machine

and heavy steel reinforcement (20-40 mm):

Heavy steel reinforcement bending machine

Heavy steel reinforcement bending machine

Types of machines

There are two types of machines for bending reinforcement:

- Manual. Relatively simple devices that do not require an electrical network, since they work using muscle power.

- Electromechanical. The mechanism is driven by an electric drive.

Each device is suitable for fittings of a certain diameter. As a rule, the size is indicated on the label. For example, DR-12 is for rods with a thickness of up to 12 mm, DR-20 is for rods with a cross-section of up to 20 mm. For some models this size is indicated in inches. When choosing, the scale of the work to be done is also taken into account. For one-time use or in private construction, a manual machine can also be used, but for large volumes it is more advisable to use an electromechanical device.

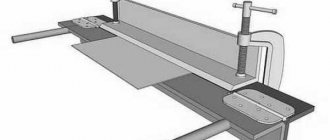

- Manual machines . They are usually made of alloy steel. The device consists of a support base with a lever and rollers attached to it. The welded plate that acts as the base usually has holes for bolts for attaching to a table or workbench. By rearranging the bending pins, the machine is adjusted to a specific rod diameter. A number of device options are supplemented with limiters for the bend angle and length of the reinforcement bar. These parts ensure bending accuracy. The advantages of a manual machine include: light weight, mobility, ease of control, independence from electrical power sources. The downside is low labor productivity.

- Electromechanical machines . On a mechanical machine, you can bend several reinforcement bars at the same time. When you press a pedal or other switch, the disk begins to rotate (clockwise) and sets the mechanism in motion. The device can be controlled manually or automatically: using buttons or a remote control pedal.

Using an electromechanical bending machine, a rod can be bent in any direction at an angle from 5 to 180° without significant loss of strength. The bend angle is adjusted with a stopper. Mechanical machines have relatively large weight and dimensions. There are two types of devices - stationary and mobile. Mobile models are used directly on the construction site under a canopy, while stationary ones are used in production; they are attached to the floor with anchor bolts. The device is supplied with an electrical cable, exhaust ventilation and grounding. Some models have special holes with which the machine is moved by a crane around the workshop or construction site.

Characteristics that you should pay attention to when purchasing a machine: disk rotation speed, power, maximum diameter of the bending rod. The drive can be hydraulic or pneumatic. There are models suitable for double folding, making staples and loops.

Bending machines and devices

With the development of construction technologies and metal processing methods, various bending machines for reinforcement were created. The operating principle of all such devices is the same, but the differences are in the design features and the maximum diameter of the rod that needs to be bent.

Bending machines, both factory-made and home-made, work on the principle: a rod is fixed between a central and thrust roller, and with the help of a third roller, the bending roller, the reinforcement is bent at the desired angle. The machine bends metal reinforcement to the left and to the right. A given radius provides a thrust shaft that prevents deformation of the reinforcement along its entire length.

There are two types of machines for bending reinforcement:

- with mechanical drive;

- manual.

The main working body of mechanically driven machines is a rotating disk with bending and central fingers attached to it. There is a gap between the fingers where the rod to be bent is placed. The reinforcement in the gap rests at one end against the roller, which is rigidly fixed to the body. When the disk rotates, the bending pin acts on the reinforcement and bends it around the central shaft.

A specific machine, depending on its purpose, may belong to one of the following groups:

- lightweight (rods Ø3−20 mm bend);

- heavy (Ø20−40 mm);

- extra heavy (Ø40−90 mm).

Mechanically driven machines can be used to bend several rods at the same time.

Nowadays machines are produced that can be used for bending rods whose diameter is 3−90 mm. When reinforcement needs to be bent at different angles, it is better to use a machine with a hydraulic drive. This universal equipment will allow you to obtain a bend surface without folds and cracks, which can cause internal stresses. This equipment allows you to increase the bend angle to 180°.

The modern market also offers portable machines. They are easy to use and not expensive. Bending can be performed using special equipment and using a pipe bender installed on ordinary workbenches.

Homemade machines of this type are used for rods with a diameter of no more than 14 mm and are not intended for high productivity. More often, such devices are used in private construction.

When choosing equipment for fast bending of reinforcement, two main factors are taken into account: the largest diameter of the rod to be bent and the volume of work. During bending, parts of the processed rod are subjected to different loads: the outer surface is stretched, and the inner surface is compressed.

Application of reinforcement products made by bending method

Products produced by bending reinforcement are used for constructing various reinforcement cages, reinforced concrete products for monolithic and prefabricated construction, and reinforcing stone masonry.

In addition, such products can be used as gratings, fencing elements, gates, etc. Using ready-made staple bending products, the client can quickly and accurately install parts in the design position, which can significantly reduce time and labor costs, as well as eliminate the cost of waste reinforcing bars in the production of the corresponding parts.

How to create a homemade machine?

You can create a primitive machine yourself. To do this, you will need any pieces of pipe (thick) - they will act as a support and central roller.

Further:

- pipe sections are fixed in the soil or in a vice at the required distance;

- on the reinforcement that is to be bent, a larger piece of pipe is placed on top;

- begin to bend the rod, placing it between the “support” and “central” rollers.

It is necessary to additionally control the bend angle.

Important! To avoid injury during bending, work should be carried out in overalls and protective work gloves. You should not use adjustable wrenches or pliers to bend the rod, or perform jerking actions - this can lead to injury and damage the structure of the steel.

Advantages of bending reinforcement

Bent products made from reinforcement are distinguished by high strength and reliability due to the cold deformation method - the metal does not become thinner and does not collapse at the bend, as when the workpiece is preheated. Automated CNC machines allow you to perform any number of bends with a minimum error of only ±0.5 degrees.

Technical characteristics of reinforcement bending

Reinforcement with a diameter of 6 to 40 mm is subject to bending - for example, rods 12, 16, 20 mm. The extreme values of the length of bent straight sections (between adjacent bends) are from 1000 to 12000 mm. The maximum bending angle is 180°, and the accuracy is ±0.5°.

Equipment for bending and cutting reinforcement

Bending reinforcement is a complex process that can be performed by a specialist either manually or using special equipment. In order to bend the reinforcement at the desired angle manually, you need to apply great physical force and have the necessary devices for correct bending, but such bending may not be of high quality, and the process itself is quite traumatic.

That is why it is worth ordering a reinforcement bending service from a specialized company that has not only professional craftsmen on staff, but also specialized equipment and high-tech CNC machines.

CNC machines for bending reinforcement and producing reinforcement products

We regularly update and improve our technical base, increase the level of professional training and qualifications of our personnel, because we stand by our reputation for what we do! We guarantee all our customers high precision cutting and bending of reinforcement for their metal structures.

The modern machines with which our company is equipped allow us to produce high-quality staples, clamps, and hinges in small and large batches in the shortest possible time without losing the quality of the finished product. Bending of reinforcement with a diameter of 6-40 mm is easily done on our equipment.

Reinforcement products at Madis company

Order batches of bending parts from us, and you:

1. Get fast delivery of high quality products; 2. Avoid unnecessary labor costs; 3. Accelerate the pace of your project; 4. Eliminate costs that may arise from the generation of waste reinforcement when manufacturing parts directly on site.

Production of products from reinforcement. Madis Company.

The price for the production of products from reinforcement depends on the volume of work, as well as on the complexity of the configuration of the ordered metal product. The cost of cutting depends on the diameter of the reinforcing bars. Apply now and our managers will advise you on the price of bending and cutting of reinforcement.

Advantages of bending reinforcement and circles in our company

Our customers include construction companies of various levels: from those taking their first steps in the market to companies with many years of experience and an excellent reputation. Both of them note the main advantage of our bending fittings - the price of the service. In addition to affordable prices, we guarantee:

- quick application processing,

- cooperation on a contractual basis,

- processing of your rental strictly within the established time limit,

- compliance with technical standards and taking into account your wishes,

- undeniable quality of order execution.