Purpose and benefits of home installation

The machine is manufactured for your own economic purposes. Both the complexity of the design and the engine power depend on this. In general, it can perform the same work as professional installations:

- turning of different surfaces (in the form of cylinders, cones);

- thread making;

- pruning work;

- end metalworking.

Thanks to such a wide functionality, this device can be used to sharpen knives, repair some car parts, cut metal structures, etc.

At the same time, making a lathe with your own hands is a more profitable option because:

- such a product will cost less;

- it is not as bulky as many industrial installations;

- it can be designed and performed for specific tasks required by the owner;

- It can be easily placed in a garage, shed and mounted on any hard surface.

Features of a homemade lathe

A homemade metal lathe, as a device assembled with your own hands, has a number of operational features that are important to consider when working on it:

- Since work with workpieces is always accompanied by large vibration vibrations, it is important to ensure the same location of the driving and driven installations - they must be along the same axis.

- The use of commutator electric motors is an undesirable option, since often in these mechanisms the speed of revolutions per minute can arbitrarily increase; This is dangerous because the workpiece may fly out.

- If it is impossible to install another electric motor, then in the case of installing a commutator motor, it is necessary to equip it with a reduction gearbox - this will compensate for the uneven running of the mechanism.

- The optimally suitable electric motor is an asynchronous one, whose speed does not deviate significantly.

- The driven center may consist of a static or moving structure; in any case, it is made from an ordinary bolt, which is processed so that the barrel takes the shape of a cone - it is with its help that it can rotate.

Tabletop lathe, main components

A do-it-yourself mini metal lathe is made on the basis of what was done in production conditions, but for one reason or another it no longer serves its intended purpose. This means that the main components and assemblies will have to be taken from other devices that are completely unsuitable for this, adapt them and use all your ingenuity.

So, the main parts of a turning-screw-cutting or turning-milling machine should be:

- frame, a durable metal structure that ensures the stability and strength of the entire structure;

- guides for a lathe are a real headache for a DIYer, because they must have accuracy and stability, guides both longitudinal and transverse;

- lathe drive;

- working body - cutting part, system for fastening and adjusting the feed of cutters;

- spindle and tailstock - for fastening and holding the part during processing;

- Safety features - protection against spontaneous activation, protection against chips.

Actually, these are only the main parts that have to be made or selected from what is at hand.

Preparatory stage: design and drawings

At the preparatory stage, it is important to understand what components the future metal lathe will consist of. Based on this, suitable units and parts are selected from available materials. It is important to consider what specific tasks the mechanism will be focused on and what it will be used for.

In principle, the installation should consist of the following elements:

- Electric motor with transmission to the drive mechanism. Working units from old washing machines are often chosen. Usually the power is selected in the range of 1000-1500 W. This is enough for household work.

- Connecting parts (metal corners, bolts).

- Housing and metal base (pipe, channel).

- Running gear – handle for longitudinal movement, bearings.

- Supporting part (frame structure).

- Thrust mechanism with cutters.

- The tailstock and the front headstock – ideally, can be taken from another machine.

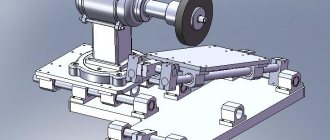

The diagram of the finished device is shown in the photo.

When all the parts are available, you can draw up a schematic drawing of the product. You can take the following drawings as a basis.

The assembled lathe, its main elements can be seen here.

NOTE. It is best to make a metal lathe with your own hands from metal products (pipes, angles, etc.). Any wooden structure is short-lived, and working with the part will be much more difficult.

What does a lathe consist of: main components

For the most part, industrial and household lathes are similar. The difference lies in functionality, power and weight. The figure below shows the structure of a typical screw-cutting lathe. The main nodes are:

- bed;

- caliper;

- headstock (placement of the gearbox to adjust the rotation speed and change the amount of torque);

- tailstock (for more stable and reliable support of the workpiece or part clamped in the chuck (spindle), as well as for installing drills, taps and other tools);

- tool holder

bed

One of the main elements is the frame - a massive metal base on which all the main components and parts of the equipment are mounted. It must be strong enough, and the mass must be such as to prevent the machine from tipping over during operation. For the floor version, massive supports (pedestals) are added.

Lathe bed

Lathe support

The lathe support is designed to move along, across and at an angle to the spindle axis of the cutters fixed in the tool holder. The device has a cross design, consisting of three main elements: a carriage, a transverse and a cutting slide.

Read also: Melting point of all materials

Making your own lathe headstock

The headstock is one of the most difficult components of a lathe, especially for DIY production. It houses a gearbox with a spindle and a control unit. Under the headstock casing there is an electric motor, which is connected by a belt drive to the gear pulley.

Homemade headstock assembly with chuck

This unit contains a block consisting of replaceable gears designed to transmit and change the spindle rotation speed and torque from the feedbox shaft. You can buy a lathe headstock or make one yourself.

Lathe tailstock

The tailstock of a metal lathe is movable and is designed to press the workpiece to the center of the spindle. One of the elements of this unit is a quill, on which a stationary or rotating center is installed, the tip of which rests on the workpiece. The workpiece is installed in a chuck on the spindle and supported by the tailstock. This ensures reliable fastening of the part for high-quality processing.

Metal lathe tailstock

Drills, taps, countersinks, etc. can be installed in the tailstock. When installing and moving on the skids of the frame, it is necessary to avoid sharp and strong impacts on the body of the unit in order to prevent displacement of the centers.

Tailstock detailing

Making your own tool holder for a lathe

The tool holder is designed to attach a metal processing tool to the support of a lathe and moves both in the longitudinal and parallel directions relative to the workpiece. There are two types of tool holders: two- and four-position. In the first case, you can simultaneously install two cutters using screws, and in the second - four, which allows you to quickly change cutters if necessary without stopping the lathe. A special handle is provided for quickly changing cutters.

Tool holder for metal lathe

Making a bed: step-by-step instructions and video

Further actions consist of manufacturing the support unit (frame), installing the working equipment, connecting it to the electric motor and direct commissioning. The sequence of actions is as follows:

- First you need to make a frame, which can be cut from steel pipes (profiles) in accordance with the dimensions in the drawings. All joints must be made only at right angles, so you can check the correctness of the connection using a regular square. The bed is made of guides. which can be used as long shafts.

- The side posts of the frame should be given special attention, since they are load-bearing elements. Consequently, the immobility of the entire structure largely depends on them. It is best to make the stands on a professional lathe.

- Next, you need to assemble the entire support installation: the side elements go along the edges, between them there are 2 guides. Bushings are mounted on the guides at a certain interval, as shown in the photo.

- Next, the bushings are fixed, with the help of which the tailstock and tool holder will be attached. In this case, it is better to make sure that the bushings are of different sizes, since the movement of the mechanism in this case will be greater.

- The surfaces for mounting the caliper are made of ordinary steel sheets. It is important that they are free from defects and even. The optimal sheet thickness is within a centimeter.

- Next, the lead screw is installed. You can make a carving on a metal stick, but there are simpler options - for example, use the leg from an old swivel chair

- When installing the screw, it is important to ensure that the side posts are equipped with bushings. A steering wheel is attached to the propeller itself to allow rotation, as well as a vernier.

- After this, the surface is mounted on which the headstock will then be installed.

NOTE. The holes on these sheets are also made on a professional machine. They need to be made with particular precision, since even small errors will not allow the device to function normally - the working parts will periodically get stuck.

After this, the frame is completely assembled. It is important to take into account that all elements are tightly connected - the slightest slack is unacceptable, since during operation vibration swings will increase the fragility of the mechanism and can lead to damage.

Visual instructions for installing the frame are in this video.

Assembling the mechanism with your own hands: step-by-step instructions and video

Further work is aimed at installing the mechanism itself and fixing it on the working surface. The algorithm is as follows:

- If it is not possible to take a headstock from an old machine, you can also make it yourself. To do this, take the shaft and install it on the support using bolts.

- Similarly with the tailstock: if it is not ready-made, it can be made using a screw, profile and bushing. A handle from any mechanism is also selected and mounted into a single mechanism.

- The next stage is to assemble the caliper, similar to the technology for assembling the frame.

- The tool holder, which is manufactured next in line, is based on a regular plate, which should preferably be at least 10 mm thick. Fastening to the caliper using bolts.

- The subframe can be welded from profile pipes. Its dimensions must exactly match the finished product, since otherwise it will be quite difficult to change the position of the belt.

- The final stage is to install an electric motor with a belt drive.

Video: DIY mini lathe. Headstock

It is important to first do the first start at idle speed, and then check the operation of the entire device on a rough metal part.

Design Features

The task of making a lathe is not as difficult as it seems at first glance. Important design elements are simply copied from industrial designs. At the same time, the scheme of a homemade lathe does not require the implementation of all assembly units present in factory models. You will need to make a frame, a support and a spindle. Other nodes will be needed only to solve specific problems.

Bed design

The basis of the working part of most machines is the bed. The massive base is intended for the installation of all mechanisms, and also serves as a damper for vibrations that inevitably arise during machining. Many characteristics of the finished product will depend on the correct choice of frame. Classic cast iron designs are not used in homemade machine tool construction due to the high complexity of the technology. Practical applications have been found for frames of monolithic or welded type. The monolithic version provides high rigidity and vibration damping characteristics. Its main drawback is its heavy weight. A metal plate 10-20 mm thick is perfect for such a base. Depending on the purpose of the machine, it is possible to use other materials. Monolithic bases can also be obtained using other technologies, for example, polymer concrete casting.

Bed for a homemade lathe

The welded frame is made in the form of a rectangular frame. For its manufacture, various metal profiles are most often used. The welded frame of the lathe is easy to manufacture and lightweight. But the apparent simplicity of this solution turns into the need for additional processing of the seats for installation of equipment. A compromise can be achieved by choosing a regular channel. The necessary elements are installed on the horizontal edge of the channel; the side ones are used as a stand and a place for attaching auxiliary devices.

Machine support

To make a homemade lathe support with your own hands, you will need guides along which longitudinal and transverse movements will be performed. Industrial equipment traditionally uses dovetail slide guides. It is impossible to make such a unit in a high-quality manner at home. Therefore, when choosing, preference is given to ready-made cylindrical or profile rails with linear bearings. The best option for constructing a movement system is to install rails with rolling bearings. They allow you to obtain high accuracy, no backlash, reliability and long service life. It’s no wonder that such rails have become very popular among machine tool manufacturers all over the world. Their main disadvantage is considered to be only their high cost.

There is also a cheap solution. It involves the use of polished rollers from old printers or other equipment.

Movement in the longitudinal and transverse directions is created using running pairs of the screw-nut type. In mechanical engineering, mechanisms are used that are based on threaded rods, trapezoidal screws or ball screws (ball screws). The choice of standard pins is justified only for very simple machines, as it does not provide adequate accuracy and durability. The trapezoidal screw is more reliable and resistant to heavy loads. The best, but expensive, option involves the use of a ball screw. They are installed in precision industrial equipment. Fastening the lead screws requires the use of bearing blocks that ensure free rotational movement and the impossibility of reciprocating movement. You can make such a block yourself, but it is better to use mass-produced models.

To connect the caliper components together, steel plates 8-10 mm thick are suitable. It is enough to process them according to the dimensions of the guides and drill the required holes.

Assembling the caliper will be reminiscent of working with a children's construction set, and the result will be no worse than that of factory models.

Spindle and feed box

The spindle head is used to fasten the spindle axis, install the gearbox and feed switch box (Gearbox). The working part of the device of any box requires a large number of gears and is difficult to implement at home. A simple solution to the spindle problem would be to use a variable speed drive based on an asynchronous motor with a frequency inverter. This kit completely replaces the classic gearbox.

Lathe from a drill: assembly algorithm

To use the device in a city apartment, it is quite possible to create a homemade metal lathe from an ordinary drill in a few hours. It will serve both as an engine and a rotating mechanism. The design is not so powerful, but it is quite suitable for performing small tasks.

It is advisable to attach the drill to a metal structure - an old stand is ideal.

The manufacturing algorithm is as follows:

- First, as always, the frame is made. Moreover, if you have a reliable workbench with a smooth surface, then it can serve as a support, and then the bed will not be needed.

- Then the wooden bases of the structure are created or a ready-made metal stand is selected. It is important to securely fasten the drill head to the base. This can be done using a regular clamp.

- The emphasis on the other side can be made using bars of the appropriate size. They are fixed to the surface with self-tapping screws. All other assembly stages do not differ fundamentally from conventional devices.

Video: do-it-yourself lathe from a drill

The installation can also handle wooden products - with its help you can apply simple relief carvings to a wooden workpiece, as shown in the video.

HELPFUL ADVICE. Working on a drill lathe is not limited to just cutting parts and sharpening. You can install a copier on it, with which you can create perfectly similar parts at home in a matter of minutes.

Mini-machine: manufacturing video

Often, for household purposes, you need a small homemade metal lathe - here is a video with clear step-by-step instructions for making it.

Tools, materials and drawings

It is best to manufacture a tabletop lathe and assemble it using serious equipment. Access to milling and drilling equipment allows you to avoid some problems. If there is no such access, then all that remains is to use what is at hand. Not only lathes, but also other complex homemade products are made using a limited set of metalworking tools and an electric drill. Of course, “direct” hands must be attached to all this. Materials for the future design are chosen from what is at hand, trying to limit financial costs. In demand will be a metal profile for the frame, sheet metal parts, fastening units for spindle bearings and lead screws, and fasteners. You will need to purchase rail guides, drive screws, and a frequency converter. Fortunately, today there are many companies offering their supply.

There are many possible options for how to make a mini lathe. To select a specific solution, you must clearly define what the machine will be used for and what workpieces will be sharpened on it. Processing steel requires a different design approach than soft feedstocks. The technical specifications include the dimensions of the final product, the maximum parameters of the workpieces being processed, available resources, methods of transporting the machine and other necessary wishes. After analyzing all the wishes, they carry out the drawings of a homemade lathe.

Drawing for assembling the machine

The necessary detailing is developed to match the available components and capabilities. If this stage seems difficult, ready-made drawings for lathes are freely available.

Safety precautions

Compliance with certain rules when working on a machine is mandatory, especially if we are talking about a product made by hand.

Preparatory stage

Immediately after assembly, you should run the machine at idle speed for a few minutes and listen to the sounds of the engine: they should be uniform, without extraneous noise. Preparation for work consists of the following steps:

- Appropriate clothing is worn, all buttons are fastened and protruding parts are removed.

- Before starting work, the workplace should be in complete order so that only the necessary tools are on it - then you can consistently implement the entire plan without unnecessary fuss and waste of energy.

- Before each session, the homemade machine must be checked for the integrity of all parts and the reliability of their connections.

- It is also important to take care of sufficient lighting of the working surface and the correct location of the source so that your own shadow does not interfere with your work.

Safe work rules

During work, you must adhere to the following rules:

- Removal of parts, as well as cleaning and lubrication of the working mechanism is not carried out during operation.

- When processing a part, you need to be on the correct side and at a safe distance from the installation itself.

- Do not pass any objects or place your hands over the operating mechanism.

- If you are working on cutting a part, then the part being cut cannot be supported by hand - it is unknown in which direction it will move at any given time.

- It is unacceptable to lean even on stationary parts of the machine or lean on the working surface.

- All chips from parts are carefully removed after each working session.

A visual illustration is presented in the diagram.

A visual technology for working on a lathe for hand-made metal is presented in the video.

Features of lathe care

Caring for the mechanism is an essential condition for its long-term, trouble-free operation. Several rules must be followed:

- All waste that falls on the working surface of the device during operation must be removed in a timely manner.

- To ensure even distribution of oil along the guides, you need to move the carriage 7-8 times back and forth.

- All connections need to be tightened periodically, since constant vibration during operation gradually weakens them.

- It is important to ensure that the belt tension is always uniform - either too tight or too loose a tension is unacceptable.

- All moving parts are periodically lubricated with ordinary machine oil. In this case, the bearings are lubricated especially carefully - they experience special friction during operation.

NOTE. Lubricant should not get on the drive belts, since in this case friction is greatly reduced, the belt slides along the surface of the pulley, as a result of which the tension weakens.

Professional metal lathes

If you need a professional tool for large volumes of complex work, you should understand what types of metal lathes exist.

Machine diagram

The schematic diagram of the device is shown in the figure.

Types of machines

Depending on their purpose and features of the device, there are several types of metal lathes:

- Universal ones are designed to perform basic metal work:

- drilling;

- milling;

- turning.

This is the most popular type of device - with their help you can process parts outside and inside, work with flat, conical and cylindrical surfaces. You can carry out complex work on cutting precise threads, processing the ends of parts and drilling holes of almost any diameter.

- Pipe cutting devices are designed for various types of processing of pipes and their connections. They are mainly used in the mining industry and geological exploration.

- Computer numerical control (CNC) lathes are a separate class of modern machine tools that are used in almost all large industrial facilities. Using electronic settings, you can achieve high cutting accuracy and manufacture parts of any degree of complexity. Moreover, all processes are fully automated, which eliminates the human factor.

Depending on the location of the bed, there are the following types of machines:

- Sloping (at angles from 30 to 60 degrees). In this case, all the chips are poured down a chute into a special waste container, making the production process fully automated.

- With a horizontal frame - these devices are equipped with a mandatory casing that prevents waste from scattering during operation.

Types of work on a lathe

Depending on the characteristics of the workpiece feed, as well as on the specific type of metalworking, the following types of work on a lathe are distinguished:

- Turning with manual or automatic feed.

- Cone turning.

- Thread cutting.

- Drilling holes.

Turning with manual or automatic feed

In this case, it is important to set the top of the cutting part so that it is slightly below the axis with the workpiece. If this cannot be done, then it is better to install another tool or grind the part.

Often, when carrying out such work, the tailstock is not needed - then it can simply be removed

NOTE. If it is not possible to ensure reliable fixation of the workpiece in the chuck, you can use a steady rest.

Many models provide the ability to automatically feed the workpiece. In this case, the cutting part should be located to the right of the workpiece.

While working, it is better to always keep your left hand free so that you can immediately press the emergency shutdown if the workpiece strays from the desired direction.

Taper turning

The sequence of actions is as follows:

- The part is secured with a spindle and tailstock.

- If possible. then the speed of the mechanism is adjusted on the machine. It is selected depending on the softness of the material, which can be determined in advance from the reference book. If this is not possible, it can be established experimentally.

- Next comes roughing, followed by finishing.

- If it is necessary to make a so-called Morse cone, it is necessary to shift the centers so that the cone is located at the desired angle, as shown in the figure.

Features of the technology for turning a cone on a universal machine are shown in the video.

Threading

On lathes you can make internal or external threads on a workpiece. Threads are applied to both cylindrical and conical products. There are three types of profiles:

- at right angles;

- at an acute angle;

- trapezoidal.

Technologically, the process is performed using a sharp tip of the cutter. The cutter is attached to the support and moves with it, leaving marks on the metal product at a certain interval.

Cutters can be either solid or prefabricated with fasteners. Cutters with soldered plates are also manufactured - they are especially durable, since the plates are made of durable alloys (brass).

Drilling holes

For proper drilling, it is important to prepare the end of the workpiece especially well. It is trimmed to ensure that the surface is as smooth as possible. You also need to make a slight recess at the end so that the work can be done exactly in the intended place. The recess can be made using a drill or cutter.

The size of the holes is adjusted by installing the appropriate drill. If the hole is made smaller, you can drill it out - that is, obtain a larger hole using a wider drill.

Machining on lathes, diagrams and drawings

Briefly about the control system, we can say that if knowledge and skills in engineering radio modeling allow, you can always make a simple screw-cutting lathe or lathe-milling machine with numerical control. CNC lathes allow you to automate the same type of work and they are needed if the master has to make a large number of identical workpieces according to a template.

For the most part, desktop machines are designed to perform one-time work, so the use of complex programming systems is hardly justified on machines with a low degree of accuracy.