Making a carriage for a chainsaw with your own hands

Most home renovation and construction work requires the availability of the necessary materials.

Buying boards or timber of the right size is not a problem, but sometimes you need lumber of a certain size. Planks of one or another type of wood, non-standard thickness or width are often required. Finally, there are simply several logs from which to cut boards. It is possible to solve such problems; you only need a DIY chainsaw carriage. This simple device allows you to make a carriage, timber or boards of the required thickness from logs of any type. This device is especially valuable because it makes it possible to process non-standard logs - short, uneven or strongly curved. Let's take a closer look at this issue.

Design features of a homemade carriage

The carriage for a chainsaw is straight and even guides along which the tool is fed to the material being processed. To obtain a straight cut with the specified parameters, the saw is rigidly fixed on a movable platform, which, in fact, is called a carriage. The most common kit contents include:

- guides _ Their role is usually performed by rails, channels, I-beams. A good solution to the problem is to use a duralumin ladder;

- carriage , which is a type of cart that moves along guides. It has a grip or support platform for fixing the chainsaw. There are designs in which only the frame is rigidly fixed, and the engine itself only rests on a special stand;

- device for adjusting the thickness of lumber . Changes the lifting height of the cutting body of the chainsaw, which allows you to quickly and accurately set the desired sawing thickness;

- trolley feed motor . This element is not required, since large amounts of work are not performed on such devices. In addition, mechanized feeding requires the installation of limit switches and other control equipment. However, many users prefer to install a mechanism to obtain an even sawing pattern, which improves the quality of the boards.

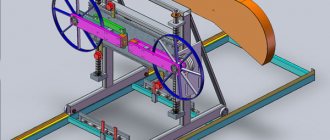

Figure 1 - Homemade carriage for a chainsaw

There are also simpler carriage designs, which consist of a rigidly fixed chainsaw and a bounding frame. The material is fed to a moving chain, and the frame calibrates the thickness of the resulting board. This type of carriage is rarely used, since it is extremely difficult to feed heavy logs manually, and the results obtained do not have a smooth and straight surface. The best option is to feed the tool onto a fixed log.

Important! When using this method, a lot of space is not required - the length of the carriage guides should only slightly exceed the size of the workpiece.

Pumping equipment: pump attachment for a chainsaw

The removable pump for a gasoline saw works on the same principle as a standard centrifugal pump. The structure of the structure is very simple, so there are no problems with installing the equipment and it does not require much time.

The pump is a turbine that is driven in two ways: using the drive sprocket shaft (directly) or from a pulley. A turbine usually has several blades. After the nozzle is installed, you need to connect two hoses to it. One of them will be a supply, and the second is intended to drain liquid. Hoses are not included and will have to be purchased separately.

The pump attachment for the chainsaw is simple and easy to use.

Using the “Pump” attachment on a chainsaw, you can perform the following tasks:

- drain a flooded basement or cellar;

- pump water from a well or well;

- fill the container with water for irrigation;

- move water from one place to another.

The pump can benefit not only owners of large and small farms. This device is also used in ship docks.

Like any other attachments for a gasoline saw, pumping equipment is produced by several companies, so the level of performance and other characteristics of devices from different companies may differ. Most models have a capacity of approximately 5 l/h.

The main advantages of a removable pump include its mobility. If desired, you can make this attachment yourself at home. This will require skills in working with a welding machine. On the other hand, factory-made pumps are made of plastic, which reduces their cost, and therefore such a device is much easier to buy than to create with your own hands. The average price is 3,000 rubles.

You can buy a pump attachment for a chainsaw for an average of 3 thousand rubles.

On a note! The performance of the removable pump depends on the size of the impeller. If it is expected that the pump will be used to perform large volumes of work, it is advisable to purchase a nozzle of appropriate dimensions.

Required Tools

To make a carriage with your own hands, you will need the following tools:

- grinder with cutting wheel for metal;

- electric drill or drilling machine with a set of metal drills;

- welding inverter with a set of electrodes;

- measuring instruments - tape measure, ruler, square;

- metal pipes of rectangular or square section;

- sheet metal 3-5 mm thick.

Figure 2 - DIY chainsaw carriage

Depending on the complexity of the carriage design, other materials may be required. The above list deliberately does not indicate the material for the guides, since the choice is determined by the capabilities of the owner. In addition, to feed the carriage you need specially shaped wheels, which are usually ordered from specialized workshops or purchased ready-made. Most often, the cart that moves freely along the guides is first made.

Features of the sawmill

Typically, wild logs are used for sawing using a sawmill. They have an irregular shape and uneven structure. Therefore, they are fixed in a static position, and the cutting is carried out by a carriage with a sawing tool. Otherwise, it will be very difficult to ensure an even cut. The exception is large industrial sawmills, where the saw is stationary and the logs are fed to the cutting element by a hydraulic press.

Important! Cutting a long log longitudinally is always carried out from the bottom of the trunk to its top. Otherwise, any saw will get stuck or break.

In general, a wood sawing machine consists of the following parts:

- The cutting element is a saw.

- The engine drives the cutting parts.

- Carriage for feeding the saw onto wood.

- Guides for the carriage.

- A carriage for fixing wood and a log feeding block.

- A frame that holds all parts together into a single structure.

Depending on the design features, some parts may be combined with each other. For example, a chainsaw, often used in homemade sawmills, combines a cutting part and a drive.

For large industrial logging sites, complex structures are used with tools and saws specially designed for this purpose. There is no need for such tricks in the household. As a rule, improvised materials are used that can cut an average log into bars.

Next, we will look at what available devices you can use to make a sawmill at home with your own hands.

How to do it yourself - step-by-step instructions

To make a carriage, you must perform the following steps:

- create a working drawing of the device , indicating all the necessary dimensions. Figure 3 – Drawing of the saw carriage

Based on it, a specification is drawn up for all materials, connections, and additional assembly elements. When creating a drawing of the carriage, the expected volume of work, the dimensions of the workpieces, the brand of chainsaw, as well as the capabilities and preferences of the owner are taken into account;

- All necessary materials and tools are prepared . Ready-made structural elements are purchased (if possible), the necessary devices and machines are sought;

- the manufacture of guides requires a flat platform on which to weld the base for the carriage. It consists of two guide strips connected to a workpiece support structure. Sections of timber, sleepers, and metal cross members can be used as a base. If you plan to make a portable version, you will have to think in advance about how to quickly assemble the base using threaded connections; Figure 4 – Guides on the chainsaw carriage

- The trolley consists of two pairs of wheels on axles, which are attached to a support frame through hubs. Sometimes they use ready-made wheels that rotate around their axis on a special platform. This option is quite acceptable, but it reduces the accuracy of movement of the cutting tool, which is why the boards can get a wavy surface. It is necessary to take into account that a massive trolley will ensure greater accuracy and safety of sawing;

- The tool locking mechanism is usually combined with a size adjustment device. There are two options - with a stationary chainsaw and a moving limiter, or with a movable platform on which the tool is fixed. The second option is much more effective, but technically more difficult. As a rule, they use parts from a mechanical jack, to the upper part of which a platform for attaching a chainsaw is welded, and the lower part is rigidly fixed to the trolley. It is necessary to install vertical guides that provide sufficient rigidity and reduce the load on the lifting mechanism during operation;

- The control and measuring rod with divisions allows you to adjust the lifting height of the saw. The easiest way is to weld a vertical bar to the cart, and a pointer on the saw platform. Subsequently, you can attach a ruler to the bar, having previously calibrated its position using a test cut. The device is simple, but very useful and greatly simplifies the work process;

- The chainsaw feed mechanism is usually an electric motor with a reduction gear. It is installed so that it is possible to move the cutting element in both directions. Considering that connecting the power supply is not always possible or advisable, a manual feed mechanism is usually used. The simplest option is a handle installed on the cart in such a place as to eliminate the possibility of injury if the chain breaks or other situations. This option is convenient because the operation of the chainsaw has to be constantly adjusted by increasing or decreasing the fuel supply.

The described option is not the only possible design. Other methods of feeding tools, attaching chainsaws or logs may be used. The choice of the optimal technique is the prerogative of the owner.

Devices for longitudinal sawing of logs (mini sawmills)

Device for vertical cutting of logs

. The simplest is the device for vertical sawing of logs, shown below.

It consists of an adapter (1), attached to the tire at its base, and a guide (2), which determines the straightness of the adapter's movement. The guide is installed on the board (3), which in turn is attached to the log being cut.

The main purpose of this device for a chainsaw is to ensure the straight movement of the bar. With its help, you can not only dissolve a log into two or four parts (quarters) or cut a beam out of it, but also saw it into boards or beams. However, in the latter case, you will have to rearrange the board with the guide each time, and it will not be possible to achieve great accuracy when sawing. The unfixed end of the tire may move to the side, as a result of which constancy of the parameters and complete parallelism of the sides of the beams or boards are unlikely to be achieved.

Device for horizontal cutting

. Using the device shown in the photo below, logs are cut in a horizontal plane. Compared to a device for vertical cutting, it has increased functionality and accuracy, allowing you to cut boards or beams of the same thickness.

A device attached to the tire in two places. beginning and end. has a frame structure that ensures the rigidity of the device. The mounting location (1) can move along the tire. A device for longitudinal cutting of logs with a chainsaw. This allows you to set the required cutting width (according to the diameter of the log). within the length of the tire. A carriage for longitudinal cutting is a device for cutting boards with a chainsaw. The guides (2) can be installed at any distance from the tire, thereby ensuring the required thickness of the cut beams or boards. The first horizontal cut is carried out using a guide frame (3) mounted on the log and serving as a base surface for the guides (2). Carriage for longitudinal cutting of logs, how to evenly cut a log lengthwise with a chainsaw, longitudinal cutting of a log with a shtil ms230 chainsaw!. For subsequent cuts, the flat surface (4) obtained in the previous pass is used as the base surface. During operation, to avoid pinching the saw, wedges are inserted into the cut to prevent the cut from narrowing.

If it is necessary to cut logs whose diameter exceeds the length of a standard bar, a more complex device is used, which uses a long bar. In this case, the saw’s native lubrication system does not provide high-quality lubrication of the entire chain, so it becomes necessary to install an additional system consisting of a tank and a hose that supplies lubricant to the end of the bar. To ensure oil supply by gravity, the tank is placed on a rack above the tire.

Types of lumber

In order to effectively use a carriage, you need to know the techniques for making a particular type of lumber. The following varieties exist:

Using a chainsaw for longitudinal cutting

Let's consider the technology for manufacturing these lumber using a carriage:

The carriage is made by sequentially cutting off opposite sides. First, cut off the top of the slab until a flat, even surface is obtained. Then the log is turned over, laid on a flat cut surface, and the operation is repeated on the opposite side.

The beam is made by sequentially removing the slab. First they make a carriage, then remove the slab from the sides in a similar way

It is important to ensure that the sides are perpendicular to each other.

An unedged board is made from an unsanded log (with the bark not removed). The most convenient way is to remove the slab, lay the log on the resulting flat surface and sequentially cut the boards to the required thickness

After each pass, the saw is lowered by the thickness of the board plus the thickness of the chain cut.

To make an edged board, first make a carriage, then cut off a slab from one of the sides and lay the resulting three-edged beam on the middle face. After this, the boards are cut sequentially, the side surfaces of which will be parallel, and the width of all boards will be the same.

Figure 5 - Types of lumber

If you have certain experience and skills, you can cut grooves, quarters and other longitudinal relief shapes. To do this, you need to position the workpiece taking into account the reach of the saw frame and the depth of the chain insertion into the material. Such work is quite complex and requires precision and sufficient width of the support area.

Safety precautions

A chainsaw is a dangerous tool that requires caution and attention. The use of additional devices significantly increases the risk, since when sawing the cutting tool is not visible, which lulls the vigilance of an inexperienced worker. It is necessary to ensure complete safety when moving the carriage; install all handles at a sufficient distance from the moving chain. In addition, you must comply with all standard safety requirements when working with a chainsaw:

- work only with a working chainsaw;

- Do not refuel while the tool is operating;

- refuel the chainsaw outdoors or in a ventilated area;

- do not smoke while refueling and working;

- carry the chainsaw only after it has come to a complete stop in the case;

- Start a stalled chainsaw only after removing it from the cut;

- monitor the actions of assistants so as not to accidentally injure them;

- use personal protective equipment - glasses, gloves, headphones.

The requirements are simple, but allow you to maintain the health and ability to work for yourself and your assistants.

A DIY chainsaw carriage significantly expands the capabilities of the tool. It becomes possible to produce different types of lumber, and the accuracy and precision of work increases. However, at the same time, the danger of using the tool increases. All homemade carriages and other devices pose a risk, so people without the proper experience and skills are not recommended to undertake the manufacture of such devices.

You must correctly assess your capabilities and level of knowledge, the degree of danger and responsibility of such work. If the user has sufficient training and experience, the process of making a carriage will not take much time and will allow him to obtain a useful and convenient device.

Device for sawing boards with a chainsaw

A homemade device for sawing logs into boards with a chainsaw, a detailed description of the manufacture of the device with dimensions and photos.

Hi all! I would like to show you a homemade device for sawing boards, which is installed on a chainsaw or electric saw. I made this homemade product for my electric saw, and used it to saw boards. I was satisfied, the method really works, but of course you will need to customize everything for yourself.

I will describe how I made it, and anyone interested can familiarize themselves with and improve this design.

Goats for sawing firewood with a chainsaw - the correct manufacturing algorithm

Nowadays you can find a large number of all kinds of goats, which greatly facilitate the preparation of wood for the winter. However, you can make such a device for sawing logs with a chainsaw yourself.

First, draw up a drawing of further work. In it, indicate the dimensions of the elements and their location in the future structure.

After this, prepare the necessary materials. For production you will need:

- Bars;

- Pillars made of strong wood;

- Metallic profile.

After this, you can proceed directly to assembling the goat. At the same time, take into account your height, otherwise sawing logs on the manufactured device will be inconvenient. In most cases, for comfortable work you will need a goat with a height of 120–150 cm.

When making a structure, be sure to take care of personal safety. To do this, make the device as strong and stable as possible on the ground surface.

';document.body.appendChild(d);document.pnctLoadStarted=(new%20Date()).getTime();document.pnctCnclLoad=function(){document.pnctLoadStarted=0;pl=document.getElementById('pnctPreloader' );if(pl)pl.parentNode.removeChild(pl)};document.getElementById('pnctCancelBtn').addEventListener('click',function(e){e.preventDefault();document.pnctCnclLoad()}); setTimeout(function(){var%20st=document.pnctLoadStarted;if(st>0&&((new%20Date()).getTime()-st>=14000)){document.pnctCnclLoad();alert('%3C %3F%3DYii%3A%3At%28%22uniprogy%22%2C+%22Unfortunately%2C+the+image+search+is+not+available.%22%29%3F%3E')}},15000);var %20e=document.createElement('script');e.setAttribute('type','text/javascript');e.setAttribute('charset','UTF-8′);e.setAttribute('src', '//postila.ru/post.js?ver=1&m=b&rnd='+Math.random()*99999999);document.body.appendChild(e)})());”>

Materials used:

- Profile pipes - 20 x 40 mm and 20 x 20 mm.

- Tubes with a diameter of 32 mm and 25 mm.

- Strip 40 x 20 x 4 mm, for clamping the busbar, 2 pieces.

- Rods and handle with rubber.

- Bolts with nuts, washers and locknuts.

The following photo shows the dimensions of the parts.

I leveled all the elements and welded them by welding; I took the dimensions arbitrarily at my discretion and adjusted them to fit my saw. Be sure to make a handle to guide sawing and pushing.

All saws are different in size and bar length, and therefore modifications can be made to the design for your specific saw, which will need to be taken into account.

I was forced to cut the boards myself, why? When you live in a rural area, you need boards for your needs; the thing is in great demand. There will always be something to nail, make, replace, put together. Where can I get boards for my needs? Tell me you can just buy it. Yes, you can, but it’s not always profitable, and you’ll also have to pay for delivery. And if you need a little, let’s say just a few boards, 2-3 pieces in total, nail down some small things. After all, no one will sell you a few pieces of boards if you don’t live in the city.

Now, I’ll tell you how I sawed. To begin with, I secured the log on a simple workbench using clamps.

The upper part of the log was leveled with an ax, then additionally processed with an electric planer so that the surface was even. I did this by eye, but used a ruler for a more or less even surface.

And then, I simply placed a saw with an attachment from the end of the log, with a pre-set size for the thickness of the board, and sawed. That's all!

Some people make special guides for straight cutting, along which the saw with the attachment moves, but I sawed straight along the log and it seemed to work. Although special guides simplify the sawing process, you will also have to do a lot of them.

And in this simple way, I sawed myself about 50 boards, ranging from 1.4 to 1.8 meters in length. I chose logs of this length for reasons of making it easier to carry and carry alone, by hand.

Small clarification! Chainsaw chain, sharpened for longitudinal sawing at an angle of approximately 10 degrees. Of course it doesn’t cut quickly, but it can be cut. The speed of sawing depends on the power of the saw and the sharpness of the sharpened chain. The more powerful the saw, the faster the sawing process. If the chain becomes dull, it will cut slowly and fine dust will fly out. I also removed the chain’s tooth stopper a little so that it would bite into the wood better. I did it by eye and removed about a millimeter.

Homemade author: Vadim Vasiliev.

Mechanized sharpening on a machine

In addition, each tool model has its own tooth pitch, the value of which for household and semi-professional models is associated with the power of the chainsaw and the torque that the drive develops. For example, for rip sawing, the pitch is taken smaller (for example, 0.325 inches). In this case, work productivity will decrease, but the required force will be significantly lower.

When purchasing a chainsaw, it is advisable to acquire a special template (see Fig. 3), with which you can easily set the optimal values of the tooth angles. It is used to control the values of the rear angles of the upper and end blades, as well as the front edge angle (it is indicated in the manufacturer’s instructions and can vary within 65...80°).

It is especially important to use a template to estimate the clearance angle of the upper blade. This chainsaw chain sharpening angle is otherwise very difficult to determine, and yet it must be maintained within fairly limited limits - from 50 to 60°

The sharpening angle of the chainsaw chain can be changed, depending on what work will be done. As the hardness of the wood increases, its value should decrease. In general, the optimal angle value is 10...12° for longitudinal cutting, and 25...30° for cross cutting.

Figure 3 – Appearance of a template for sharpening chainsaw teeth

Sharpening can be done manually using a round file with a working diameter of 4...5.5 mm, or on a machine

In the first case, it is extremely important to correctly position the tool relative to the tooth being sharpened. The upper edge of the working part of the file is located approximately a fifth above the upper edge of the tooth

The tool is positioned perpendicular to the chain axis, and at an angle of 25...30° to the upper edge of the tooth

Additionally: Chainsaw attachments will help you do everything!

Sharpening on a machine is much more convenient and does not require highly qualified performers. Technical characteristics of the partner 350 chainsaw. The partner 350 s is considered the most common saw from the “partner” series. This model is used for longitudinal and cross cutting of wood. Such machines are electrically driven and equipped with special grinding wheels.

For a household workshop, it is worth purchasing compact units that do not take up much storage space and are suitable for quick and high-quality sharpening of chainsaw chains from different manufacturers. Such units should operate from a stationary power supply with a voltage of 220 V, have low power consumption (up to 100 W) and be easy to install on the circuit.

When choosing a machine, you need to pay attention to the following technological characteristics:

- Possibility of processing teeth with different thicknesses of the upper edge and different chain pitches;

- The ability to adjust the sharpening angle, within the limits specified earlier;

- Availability of replaceable grinding discs;

- Constant value of the cutting width.

Optionally, the machines can also be equipped with a miniature electric light bulb, which illuminates the working area, as well as a hydraulic booster, which facilitates sharpening.

Safety of work is ensured by a folding safety shield.

Types of log cutting

Before you start cutting the workpiece, you need to decide how to get a high-quality final product with the least amount of waste. The wood is uneven in quality; the lower part of the trunk produces the most valuable lumber. When sawing logs, you can obtain the following types of lumber:

- timber - lumber, more than 10 cm thick and wide. The most common type is four-edged timber, square in cross-section. Used as a building material and in furniture production;

- board - lumber, up to 10 cm thick and twice as wide as the thickness. Boards are obtained from logs or beams and are used in construction and in the furniture industry.

Advantages of cutting logs with a chainsaw

The saw and ax, as woodworking tools, have long faded into the background, giving way to more productive gas and electric saws. The chainsaw operates using a two-stroke gasoline engine; the working tool is a sharpened chain. Main advantages:

- high productivity, which significantly facilitates human work;

- mobility, it is easy to move it from place to place, load it into a car, it is not tied to an energy source;

- can be used in conditions of high humidity and even during rain;

- the ability to use various types of attachments to perform different tasks;

- ease of use;

- financial accessibility in comparison with specialized woodworking machines.

Therefore, not only experienced professionals prefer this tool, but also farm owners successfully use a chainsaw to solve everyday problems in the garden and on construction sites. When constructing auxiliary structures, it may be necessary to cut logs. It is very easy to saw the workpiece into boards in a workshop, but it can also be done at home.

Useful features of the “Drill” attachment on a chainsaw

The "Bur" attachment is used in fish farms. It has a simple design, is quite easy to use and is used to supply air to frozen bodies of water. The combination of a gasoline saw and this attachment has repeatedly proven its success and efficiency in practice.

The "Drill" attachment is used for drilling holes in the ground or in ice.

The ice auger is lightweight and compact in size, which has made it so popular among ice fishing enthusiasts. At the same time, the nozzle is characterized by high productivity.

The MB-2 Ice drill is recognized as one of the best removable devices in this category. This attachment operates through a reduction gearbox, which reduces the rotational speed of the shaft to 150 rpm. You can find analogues of this device on sale, but this particular model requires a minimum of installation time. It takes about 5-10 minutes to connect the attachment to the chainsaw.

In addition, the “Bur” attachment is suitable for drilling wells in the ground. The diameter of the holes reaches 35-40 cm. Such a device can greatly facilitate construction and installation work. Depending on the functionality, the price of a nozzle for drilling ice or soil can range from 2,500 to 5,500 rubles.

Tools for sawing logs

Choosing the right tool for sawing a workpiece depends on many criteria. These include:

- workload,

- dimensions of workpieces for cutting,

- quality and quantity of the required lumber.

To cut a large number of blanks and get a large amount of high-quality lumber, it is best to use a sawmill. This is a machine for processing wood, the working tools of which are various saws. Designed for longitudinal cutting of logs up to 6 meters long and 20-80 cm in diameter.

Large woodworking enterprises with large production volumes use specialized lines for cutting wood. On the line, you can saw logs of different sizes, thereby obtaining lumber of a precisely specified size with high-quality processed surfaces. The lines are characterized by high productivity.

To obtain a small amount of lumber for the needs of a small farm from logs 2-3 meters long and 30-50 cm in diameter, you can use a chainsaw. You need to know that sharpening chains for rip cuts is different from sharpening chains for cross cuts.

For longitudinal sawing with your own hands, you can make a wooden stop - a leading ruler, which will allow you to saw the log evenly. The stop consists of two wooden boards, one of which is fixed perpendicularly in the middle of the other. The device is screwed to the workpiece with self-tapping screws so that the top edge of the vertically located board is below the top edge of the log. The difference between the top edge of the log and the top edge of the board determines the thickness of the sawn slab.

Types of working attachments

If necessary, the workpiece can be cut into boards with a chainsaw using special attachments. The chainsaw frame is attached to the tool and is designed to ensure straight-line movement when cutting the workpiece horizontally. The structure consists of:

- a guide frame moving along the surface, parallel to which it is necessary to cut the wood;

- a vertical stand on which the mechanism for adjusting the thickness of the product is mounted;

- thickness adjustment mechanism, consisting of adjustment handles and a screw that fixes the desired size;

The ability to set the exact size and correct cutting of the log allows you to get boards of the same thickness and reduce the amount of waste. To cut wood for the first time, you need a guide frame or a flat, straight board. Alternatively, create a level base surface using an axe, power plane and level. For subsequent cuts, the base surface is the flat side of the board obtained in the previous approach.

The carriage for a chainsaw is a type of frame. It is attached to the saw and has additional rollers or wheels that allow the attachment to move around the workpiece more easily. At the same time, resting against the workpiece, the wheels give the rip saw stability, allowing you to evenly cut the log into boards.

This kind of chainsaw attachment for longitudinal sawing allows you to cut a log with your own hands without much labor and financial expenditure. Varieties of the carriage are mini sawmills and portable sawmills.

Characteristics of the “Wood splitter” attachment for a chainsaw

It is very difficult to split thick logs and stumps using an ordinary ax. This process is long and laborious. To make this task easier, it is enough to purchase and install a “Wood Splitter” attachment on the saw. It has a cone-shaped, pointed shape, due to which the wood splits during the screwing process.

Such attachments are most often universal and suitable for different models of chainsaws. According to reviews from users on the network, the “Wood Splitter” greatly simplifies the process of splitting stumps and logs, saving time and effort. To confirm this, you can consider the possibilities of the Partner chainsaw attachment.

The Wood Splitter attachment is universal and fits most models of chainsaws.

This wood splitter copes with logs with a diameter of 40 cm (although more powerful models of attachments can be found on sale). It is suitable for splitting material directly on the ground, so it can be used for splitting long firewood, old boards, and slabs. The average cost of such a nozzle is 6,300 rubles.

On a note! It is not recommended to use a removable angle grinder and other accessories as an attachment on a Champion chainsaw, the power of which does not exceed 2 kW. This requirement also applies to other companies that produce low-power models of this tool.

Chainsaw cutting technology

Before you cut a log into boards at home, you need to cut it correctly in order to get the maximum number of high-quality boards with a minimum amount of waste. Rational use of raw materials is achieved by using special cutting schemes. Markings are applied to the tree that correspond to the intended purpose and the type of lumber planned.

Before starting work, it is necessary to carefully secure the workpiece in order to achieve a high quality surface of the boards. The cutting of logs is most often carried out horizontally. The advantage of horizontal cutting is that less effort is required to hold the chain saw suspended. You can cut the workpiece along the chainsaw using devices for longitudinal sawing - a wooden stop - a device made by yourself.

When using a rip saw attachment, you must carefully secure it to the body of the chainsaw. Before starting work, you need to take care of creating a base surface, parallel to which the chainsaw will be cut.

It is necessary to insert wedges into the longitudinal cut to avoid pinching the chainsaw blade with the sawed edge of the board. The saw should move smoothly and should not be pressed with force. It is better to saw a log with two people, since additional hands are needed to move and secure the workpiece in order to insert the wedges into the cut.

Knowing all these subtleties and features, it is not difficult to cut a beam or log into boards yourself.

Safety rules during work

Before you start sawing a workpiece with a chainsaw, you need to take measures to ensure that it is safe to work:

- make sure that the nozzle is mounted on the chainsaw according to the attached drawing;

- be sure to know the types of chainsaw problems and how to fix them;

- carefully prepare the workplace and securely fasten the workpiece;

- when working, be sure to wear special clothing, glasses to protect your eyes from small sawdust, headphones to protect against noise, and a respirator to protect your respiratory system;

- the chainsaw starts on the ground, the chain brake must be unlocked before starting work;

- Be sure to have a first aid kit on hand;

Knowledge and strict adherence to safety rules will allow you to cut the workpiece with a chainsaw without harm to health and obtain high-quality lumber.

Why it is not recommended to connect attachments to a chainsaw

Using nozzles has certain disadvantages. This is primarily due to operational and technical characteristics. Chainsaws have a given load level; they are designed to operate in certain modes. For this reason, some tool owners are against the use of additional devices. This mainly applies to attachments for the Shtil, Husqvarna and other prestigious professional models.

The fact is that connecting the grinder attachment to a Partner or Husqvarna chainsaw does not go without leaving a trace. When using such devices, the tool engine operates at maximum speed. And this is done over a long period of time. In some cases, the saw does not have enough torque. As a result, the period between repairs is reduced, and internal parts wear out much faster.

On a note! According to research, attachments such as “Wood splitter”, “Winch”, “Corroder” and “Compressor” do not harm the technical condition of a gasoline saw.

The most unsafe types of attachments for chainsaws:

- "Bulgarian";

- "Mower";

- "Boat motor";

- "Boer".

When connecting the attachments, the chainsaw engine will operate at maximum speed.

If sanding equipment is used, the air intake filters on the tool become too clogged. The use of attachments such as “Pump” and “Boat Motor” requires long-term operation of the engine at high speeds, which is also not good for the chainsaw.

These disadvantages are fully or partially compensated for by the high wear resistance of modern chainsaws. The negative impact of the grinder attachment on the Husqvarna chainsaw can be reduced by using heat-resistant branded motor oil. It will protect the engine from premature wear.

Homemade sawmill from a chainsaw: production and video

Since ancient times, wood has been the most popular building material. And if earlier rather primitive tools were used for its processing, today the latest modern technology is used. For example, in order to cut wood and process it to the required size, builders resort to the help of a sawmill. Unfortunately, such a tool is not cheap and therefore not available to everyone. Home craftsmen found a way out of this situation by making a sawmill from a chainsaw with their own hands. Tips for its design, drawings and video instructions can be found on numerous Internet sites, as well as in our article.

About the capabilities of a chainsaw

A compact and powerful engine, an unpretentious gasoline engine, a sealed system for supplying gasoline, a membrane-type carburetor (see how to set it up here) - all this provides a wide range of work performed by a chainsaw.

The output shaft of the tool allows you to attach any type of attachment. Another advantage of this tool is the ability to use it anywhere, thanks to its offline mode.

The design of the chainsaw is so successful that the possibility of breakdown when using it is practically eliminated (especially with proper running-in).

To choose your own chainsaws, read our rating of the best chainsaws. In this article of ours you will find tips on choosing a chainsaw.

You might also be interested in an article about what kind of chainsaws the manufacturer Shtil produces.

Types and features of chainsaw sawmills

Construction markets offer a large selection of sawmills, which are based on a chainsaw. Fixed in a trolley with rollers, the unit can be manually moved along a pre-laid rail track. A powerful chainsaw or band saw can be used to harvest wood.

The chain unit is used for cutting round timber. Its design includes a saw chain, after operation of which a large amount of sawdust remains. This is the main disadvantage of this type of sawmill.

Band chainsaws are capable of sawing logs of fairly large diameters. When working on such a sawmill, you should keep in mind that sawdust scatters over a large area around it, so you need to be careful. A flexible air duct connected to the chip ejector will help cope with this problem.

For domestic conditions, large sawmills are most often not required, so the optimal solution would be to manufacture a functional homemade mini-machine. Such a unit will be small in size, and therefore can be easily moved if necessary.

Most often, the main element of such a device is a chainsaw , which can be purchased at a specialized store or use a Ural brand unit.

Do-it-yourself sawmill from a chainsaw: video instructions and drawings

Having the drawings available and having studied the video instructions, it is quite simple to independently make a structure for processing logs, boards and slats. Before starting work, you must select a suitable location. You can install a sawmill using a chainsaw in an old barn, garage, hangar, or even just under a shed. If the room for the unit is closed, then you should take care of the hood.

Chainsaw sawmill - option No. 1

To make the structure, in addition to a chainsaw, you will need:

- two channels 8 meters long and 140-180 millimeters high;

- two rails;

- corners 50x100 mm and 40x40 mm;

- 25 cm sections of water pipe as ties;

- steel plate 4-6 cm thick and 60 cm long;

- movable hoses;

- pipes with a diameter of 35-40 mm.

Making your own sawmill should begin with assembling the base from rails and 50x100 mm corners turned upside down. They must be installed strictly parallel to the floor, so you need to use a building level.

Next, the following work is performed:

- Along the length of the base, according to the drawing, holes are drilled in increments of 1-1.5 meters and with a diameter of 14-16 mm.

- Then, according to the number of holes, ties are taken and connected with bolts.

- Stands are made from metal squares and the base is placed on them. The distance between the outer posts and the base should be about 100 cm.

- To make the structure more rigid, braces between the posts can be welded.

After the base is completed and installed, you need to make a movable cart with your own hands. To do this, 40x40 mm

corner is welded to the bottom of the steel plate Two corners are welded on top of the plate, to which a chainsaw is attached. At the last stage of the work on making a homemade sawmill, it is necessary to make a structure for fixing the logs. To do this, movable hoses and pipes should be positioned at the required height and secured.

The first version of a homemade sawmill using a chainsaw is ready. There is another way to make a wood processing unit with your own hands. The tools and drawing for it will need the same, however, the design itself is more refined.

Do-it-yourself sawmill from a chainsaw - option No. 2

The structure consists of four main components:

- Driven saws.

- A mechanism for regulating the thickness of the board being produced.

- A mechanism for moving the saw part of the structure.

- Devices for fixing logs.

Since a chainsaw with a working engine and cutting teeth is already available, you will only need to make both mechanisms and a device for fixing logs with your own hands.

Mechanism for adjusting the thickness of the boards.

Logs are sawed by raising or lowering the base, which must be welded to the plate using four nuts with bent edges. At the top of this device it is necessary to install lock nuts , which must be tightened after the unit is adjusted to the desired thickness of the material being processed.

Mechanism for moving the saw.

The saw in the structure moves along the frame along guide angles, the distance between which should be 50 cm. 20 mm rollers or bearings must be welded The lower roller should keep the sawmill from lifting, and the upper one should rest on the guide angle.

Device for fixing logs.

On such a unit, logs are fastened using two ridges - a stationary one and one moving by means of a screw. After the material to be processed has been installed, the moving comb is secured with screws in a stationary state. Now you can safely begin to operate a homemade sawmill made from a chainsaw.

Some useful tips

A sawmill is an impressively sized unit that is quite dangerous to operate , so before you start assembling it, you should carefully consider the place where it will be used.

It should be well lit, ventilated and have free space. The nearby warehouse for finished boards will greatly facilitate the process of processing the material. For a sawmill with an electric motor, you should very carefully install the necessary switches and automatic machines, as well as install the wiring.

Since the most dangerous elements of the unit are all its cutting and moving parts, when assembling the structure they should be given special attention.

Before starting to operate the assembled equipment, it is necessary to check all fastenings and components, as well as the stability of the structure.

Operating instructions for a homemade chainsaw sawmill

After the structure has been assembled and tested, it must be tested in wood. To do this you need:

- Using a vice, clamp the log onto the base.

- Install markings on the runners and sawmill.

- Smoothly start the unit and slowly begin to drive it towards the log. In this case, the chainsaw bar must be located exactly in the center of the cut marking.

Jerky movements when cutting should not be made, as this can lead to the tire stopping.

It should be borne in mind that it is necessary to work in personal protective equipment , which includes mittens, a robe, sleeves and goggles. In addition, you should worry about protection for the moving frame in advance. It can be made from acrylic or transparent plastic. Such guards can protect against saw chain and chips.

A sawmill assembled with your own hands from a chainsaw will allow you to produce high-quality lumber with a cut of the correct shape. Therefore, if you often have to work with lumber, then such homemade equipment, made on the basis of the attached drawings and videos, will become an indispensable thing on the farm.