Methods for bending pipes and profiles

The process of bending pipes is present in many production operations: in the laying of oil and gas routes, heating mains, in the installation of water supply and sewerage networks, industrial ventilation and air conditioning systems.

Bent pipes serve as branches, connecting sections, bends and fences in the designs of various mechanisms and rigid metal structures. In all cases, pipe bending is carried out using pipe bending machines

. Each technology for changing the direction of the pipe has its own characteristics and indications that should be taken into account when choosing equipment.

BENDING STEEL OR PLASTIC PIPES: WAYS OF IMPLEMENTING THE PROCESS

By and large, there are only two ways to deform rolled pipe:

- cold pipe bending

- deformation of heated products

The first method - “cold” bending - is possible only if the deformed pipe is made of a sufficiently plastic material that can change its shape under the influence of external forces.

Therefore, “cold” bending is usually practiced when deforming relatively small metal pipes (with the exception of cast iron pipes).

True, bending stainless steel pipes (or any other pipes with increased annular

rigidity) forces us to use special machines in this process - pipe benders. Because with our own strength we can only bend very flexible pipes made of copper or aluminum.

However, “soft” plastic pipes cannot be bent using this method even on pipe benders. Indeed, despite the declared softness, plastic pipes either do not have sufficient ductility for this method of deformation, or they do not have ring rigidity sufficient to hold the product in a bent state (polyethylene products without a reinforcing frame).

An exception can be made only for combined materials based on polyethylene - bending of metal-plastic pipes is carried out only in a “cold” way. Inside such a pipe there is a reinforcing belt made of aluminum - during the deformation process it is this that is bent and it is this that holds the shape after bending.

Hot bending is possible in almost any case. Indeed, in a heated state, the plasticity of any material increases by an order of magnitude. For example, high-temperature bending of steel pipes (or products made of any other metal) is very simple: the pipe is simply heated at the point of deformation and bent by hand. That is, in this case, we will no longer need machines or mechanical pipe benders.

With plastic, in this case, problems arise again. Hot deformation is impossible in principle - polymer pipes lose their ring rigidity when heated above 250 degrees Celsius. That is, during the process of hot deformation, such a pipe will simply spread over the surface.

Well, now that we have become familiar with the methods of deformation, let's move from theory to practice and figure out how to bend pipes in a “cold” and “hot” way.

Despite the presence of connecting parts in the form of tees, elbows, etc., there is often a need to bend steel pipes. With a small radius of curvature and a large diameter of the pipe, bending is performed in a hot state on special bending machines. Cold bending of small diameters can be done manually.

Bending pipes with sand.

To ensure that the pipe does not wrinkle or bulge when bent, but maintains its normal cross-section at the bend site, it is filled with river sand (see article Bending pipes with sand. Mechanization of compaction of sand in pipes during bending. Plugs for pipes filled with sand. ). The sand must be dry, clean and not large (grain up to 2 ml in diameter). River sand ensures good movement of peppercorns during bending. Mountain sand is unsuitable for this, since it does not have the necessary mobility. Do not fill the pipe with wet sand, as the resulting steam can rupture it or squeeze out the plugs.

Wooden pipe plug.

The pipe with sand is closed with a wooden conical plug.

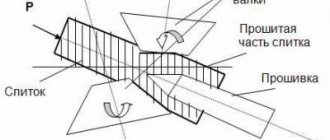

It is recommended to place a small layer of wet sand between the cork and the dry sand to compact the cork and reduce the fluidity of the dry sand around it. After this, the pipe is completely filled with sand and closed with a plug at the second end (Fig. 1, a); in mass production, a spring can be used to bend pipes (Fig. 1, b).

Types of machines for bending profile pipes

Based on the required bend angle, material and diameter of the pipe, bending can be done manually or using special equipment. There are also hot and cold bending, with and without filling the pipe cavity.

Here is a diagram, formulas and recommendations for calculating pipe bending parameters, following which is a guarantee of a good result

After the load is removed, a phenomenon called springing occurs, which is directly proportional to the elastic modulus of the material. The amount of possible deformation also depends on the bending method used and the geometry of the object.

Relatively recently appeared methods are bending pipes using industrial and high frequency currents and bending with tension. In the first case, a high-performance high-frequency installation is used, in which a pipe with a diameter of 95 - 300 mm is heated, bent and cooled.

It consists of two parts - a mechanical one in the form of a bending machine and an electrical one, which includes an electrical part and a high-frequency installation.

Flexible materials: Flexible hoses for faucets and toilets || Flexible eyeliner DN50

The pipe is deformed only in the heated area located in the inductor zone. The geometry changes to a given size under the influence of a deflecting roller. Using this method, you can obtain a bend with a small radius curvature.

Bending using the second method is carried out on bending and stretching machines, which include a rotary table. The pipe is subject to large tensile and bending forces. This is how steeply curved bends are obtained with a constant wall thickness along the entire circumference.

The method is used for bending large-diameter pipes used in the aviation, automotive, and shipbuilding industries, where high demands are placed on the pipeline. The advantage is the ability to bend pipes with a wall of 2 - 4 mm by 180⁰.

The OP pipe bending machine or pipe bender is designed for bending hydraulic pipes at an angle from 0 to 180°. The Italian manufacturer of pipe bending equipment, OP Srl, offers various types of pipe benders - manual, electrically controlled, service machines, industrial machines.

When choosing a pipe bending machine, first of all pay attention to the following parameters: maximum pipe diameter, wall thickness, bending angle. Knowing these parameters, you can choose the right machine for yourself.

There are two types of pipe bending machines

Portable equipment includes a manual pipe bending machine. It is lightweight and easy to install. A manual pipe bender is suitable for mobile workshops and service enterprises; it is optimal for bending pipes with a small wall thickness and copper pipes.

Stationary machines come with manual and electric drive. This equipment allows you to bend pipes with greater wall thickness and larger diameter. This section also presents machines for industrial use; using electronic control, you can set the required bending angle in advance, which will significantly save time during conveyor production.

Our company offers a wide range of pipe bending equipment for various purposes. The equipment is distinguished by high production characteristics, build quality, and durability in use. If you are planning to expand your production or open a full-fledged workshop for servicing flexible and rigid pipelines, we advise you to pay attention to the Italian brand O R.

When purchasing equipment, we offer free training and issue a certificate. Each machine comes with a one-year warranty.

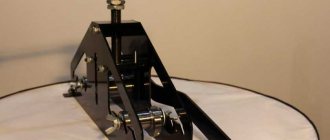

General form

Regardless of what consumables and mechanisms you have in your home workshop or garage, a do-it-yourself profile pipe bending machine can be made according to various design schemes. Having made even the simplest homemade pipe bender, in the future, if the need arises, you can improve its design by providing such equipment with a number of additional functions.

Design of a pipe bending machine (sectional view)

The main design elements of any machine used to bend pipes are:

- supporting frame, which is made of a powerful metal profile;

- three shafts rotating on separate axes (it is through such elements, which must be highly durable, that bending machines act on the profile pipe, deforming it to the required bending angle);

- a mechanism by which the working shafts are driven into rotation;

- chain connecting the elements of the drive mechanism.

Before making homemade bending equipment, it is advisable to prepare a drawing of it or find a ready-made one on the Internet. Moreover, there you can also find a video with detailed instructions explaining the process of manufacturing a device for bending profile pipes.

Pipe bender drawing

After the pipe bender drawing has been prepared, you can begin assembling the supporting frame. If you plan to use your pipe bending machine for large-diameter pipes, then it is better not to use welding to assemble its supporting frame: it will not be able to provide the equipment structure with the required reliability.

Pipe bender parts: bearings, shafts and chain drive

The shafts that are equipped with any bending machine for a profile pipe are cylinders with axes of rotation, made of high-strength steel. As mentioned above, three working shafts are installed on a pipe bending machine, with two of them fixed slightly above the surface of the work table, and the third above them.

Pipe bending radii depend on the distance at which the working surfaces of the lower shafts are located between each other. Thus, if, when creating your pipe bending machine, you immediately provide in its design the possibility of horizontal movement of the lower shafts and vertical movement of the upper one, you will be able to adjust the parameters of the bend being performed, as well as process pipes of various sizes.

U-shaped carriage welded from thick metal with a pressure shaft

To secure the bearings, “crescents” made of 4 mm metal are used

After all the working shafts of the pipe bending machine are installed on the frame, it is necessary to assemble a mechanism that will cause them to rotate. As such a mechanism, it is best to use a chain drive, the elements of which will be three sprockets and the chain itself, corresponding to them in its parameters.

Flexible materials: Flexible water line. Selection and installation of flexible liner

Two sprockets are installed on both lower shafts of the pipe bender for a profile pipe, and the third is fixed below, on one of the elements of the supporting frame. It is very important to be able to change the position of the lower sprocket, as this will allow you to tension the chain on the pipe bender. So that the drive mechanism of the machine can be easily controlled, a handle is fixed on one of the sprockets, which should be made not only durable, but also as convenient to use as possible.

The pipe bender is assembled and ready for testing

Upon completion of assembly of the machine, a test bend of the pipe should be performed on it. If you are satisfied with the test results, you can start using your equipment.

You can make a roll forming machine with your own hands using an even simpler design. If you choose a device of this type, you should keep in mind that in order to bend a profile pipe with your own hands on such a device, you will need serious physical effort.

Drawing of a small manual profile bender mounted on a mechanic's workbench (click to enlarge)

If bending equipment equipped with working shafts is used for rolling a profile pipe, during which it is bent, then the profile benders of the simplest design in question work on a different principle. On devices of this type, a profile pipe is bent along a radius, which must first be formed from rigidly fixed elements.

To make a device on which it will be possible to effectively bend a pipe along a radius, it is best to pour a concrete pad yourself and fix the metal pins on it as securely as possible.

- One end of the pipe is securely fixed.

- By physically influencing the second, loose end of the pipe, they begin to bend the product smoothly and accurately, bending its surface around the pins arranged in an arc.

- After the pipe has acquired the required configuration, its second end is also fixed and the product is left in this position for some time so that the metal gets used to the new state.

Since working with such a device requires significant physical effort, to make the task easier (especially when bending large-diameter pipes), the future bend site is preheated with a gas burner or over a fire. You can learn more about the rules of operation on such a device in the corresponding video.

Of course, such a device, which can be built in the yard of your home, has minimal efficiency and functionality. For example, it is quite difficult to bend stainless pipes or make complex bends with it. Nevertheless, it is quite possible to use it for simple bending work. Such work, for example, may be associated with laying a pipeline or making a frame for a home greenhouse.

The cold pipe bending method involves two bending options:

- Bending with a tool without a mandrel. This technology is used for bending large radius pipes (from 3D), workpieces with thick walls, and also in cases where high precision of work is not required. This method is outdated and has been used less and less in recent years.

- Bending a pipe with a mandrel tool. Depending on the type of pipe bending machine, the workpiece is bent in different planes in a certain way:

| Pipe bending by rolling method |

| Bending workpieces using the winding method |

| Pipe bending using drawing method |

| Bending using the rolling method (3-roller roll bending) |

| Pipe bending on 2 supports |

| Pipe bending by stretching method |

| Pipe bending with internal hydrostatic pressure |

| Bending through a die having a curved axis |

| Bending using copiers |

Portable pipe benders

- Lever pipe benders. Due to the large shoulder, it is possible to perform the necessary actions solely by human muscle effort. In products made of ductile metal, including stainless steel with a cross-section of up to 3/4 inch, they allow bending up to 180 o.

- Crossbow type pipe benders. The product is placed on two support points rotating around its own axes. A bending shoe connected to a moving rod applies force to that part of the pipe that is located between the supports. These easily portable pipe benders are capable of bending a stainless steel pipe with a diameter of up to 100 mm at an angle of up to 90°. The rod that creates pressure can be designed as:

- mechanical screw;

- hydraulic with manual drive;

- hydraulic with electric drive.

- Electric pipe benders. In them, pipe bending is carried out on replaceable bending segments of various radii. Here, using a rotary mandrel, the workpiece is bent at a certain angle.

maintaining pipe diameter during bending - photo

Metal pipes - steel, iron, copper, aluminum, go on sale and are used in a ready-made form, and do not require changing it, since a threaded or welded connection is used during installation. It is possible, although not advisable, to bend products made of soft metals - copper, aluminum alloys, and small sections with your own hands.

If we are talking about iron pipes with large wall thicknesses, then this kind of process should only be carried out in a factory setting.

Product classification

The pipeline, in addition to the material, cross-section, shape and wall thickness, differs in the production method. The latter is very important during the operation of the product.

- Welded - straight-seam or spiral-seam. They have a welded seam along the entire length, while the welded edges are characterized by different thicknesses. When bending, the cross-sectional shape and diameter of the product are extremely difficult to maintain.

- Seamless - produced by pressing, drawing, etc., and, in turn, are divided into two categories.

2.1. Hot rolled - characterized by low flexibility. The wall thickness is uneven, which is due to the manufacturing technology.

2.2. Cold rolled - least prone to deformation when bending. Therefore, despite the high cost when creating complex engineering systems, this category of products is used.

Deformation during bending

A change in the original shape of the pipeline is accompanied by the appearance of defects that affect subsequent operation.

- Ovalization - a round or oval pipe, when bent, loses its exact cross-sectional shape - it becomes flattened. The useful cross-sectional area does not change, but the distribution of water flows occurs differently, which creates an additional load in the plumbing or heating system.

- Formation of corrugations and kinks - the internal part of the pipeline is deformed, which forms a barrier to flowing water and provokes increased salt deposition.

- Thinning – the wall thickness changes, which leads to a loss of mechanical strength.

- Formation of elastic resistance - in this case, the bending radius changes, that is, the pipeline does not form a given structure.

Special equipment allows you to avoid the above problems.

Cold bending of pipes is performed using various devices.

In hot bending with filler, the pipe is annealed, marked, and then one end is closed with a wooden plug. To prevent collapse and cracks during bending, the pipe is filled with fine, dry sand. After filling with sand, the second end of the pipe is clogged with a plug, which should have holes for the release of gases formed when the pipe bends are heated.

The radius of curvature when bending pipes is taken to be at least three pipe diameters, and the length of the heated part depends on the bending angle and pipe diameter. Thin-walled pipes with a diameter of more than 30 mm are bent only in a heated state with fillers. After bending is completed, the plugs are knocked out and sand is poured out. Poor, loose filling of the pipe with sand, insufficient or uneven heating before bending lead to the formation of folds or tears.

The simplest device for bending pipes with a diameter of up to 10-15 mm in a free state is a plate with holes, in which pins are installed in appropriate places to serve as stops during bending.

Pipes of small diameters (up to 40 mm) with large radii of curvature are cold bent using simple hand tools with a fixed mandrel (Fig. 87). The bending mandrel is attached to the workbench on both sides with brackets. The bending pipe is inserted between the bending mandrel and the clamp, clamped and bent by hand along the groove-shaped recess of the bending mandrel.

Rice. 87. Devices for bending pipes in a cold state: 1 - plate, 2 - movable roller, 3 - handle, 4 - bracket,

5 - pipe, 6 - template roller, 7 - clamp

Bending of copper and brass pipes. Copper or brass pipes to be cold bent are filled with molten rosin. After bending, rosin is melted starting from the ends of the pipe to avoid rupture.

Copper pipes to be cold bent are annealed at 600-700 °C and cooled in water. The filler when bending copper pipes in a cold state is rosin, and in a heated state it is sand.

Flexible materials: Flexible polymer heat-insulated pipes. Flexible thermally insulated polymer pipes "Casaflex"

Brass pipes to be cold bent are annealed at 600-700 °C and cooled in air. The fillers are the same as when bending copper pipes.

Before bending, duralumin pipes are annealed at 350–400 °C and cooled in air.

Pipe bending into a ring is carried out on a three-roller bending machine without filler.

Pipes that are free from dents, bulges, and folds are considered to be properly bent.

When bending pipes, the following conditions must be observed:

- - carefully monitor the uniformity of pulling out the outer wall and seating the inner wall of the pipe;

- — take into account that the outer wall of the pipe is pulled out more easily than the inner wall fits;

- - bend the pipe smoothly, without jerking: the folds that appear are straightened with a hammer.

Flaring (rolling) of pipes involves expanding (rolling) the ends of pipes from the inside with a special tool (rolling). To do this, the rolling device is clamped in a bench vice. The pipe is inserted into a hole of the appropriate diameter, and then the end of the pipe is flared to the required size by striking a mandrel with a hammer.

The method of hot bending of pipes consists in preheating the area of the future bending of the part or the entire part, as necessary. This procedure is performed with gas or oil burners or in forges. Also, the workpiece can be heated on machines using high-frequency currents. This technology is very labor-intensive, so it is used when there are no units for cold bending of pipes.

The main feature of hot pipe bending is the use of a special filler. In the overwhelming majority, it is pure river sand of a certain fraction, without the inclusion of small or large particles, including without organic or inorganic impurities. The presence of foreign inclusions may cause them to burn to sand particles or the surface of the pipe. In addition, the sand should not be wet, otherwise, when the temperature rises, high steam pressure will occur in the pipe and its deformation.

Operating principle of hot pipe bending

- After pouring sand into the workpiece, the temperature rises to 900 degrees C and the pipe of the required radius is bent.

- Heating of the part occurs once without burning out, in order to prevent deterioration in quality.

- The choice of the size of the heated zone on the pipe depends on the bending angle, thickness and diameter size.

- After completing the procedure, remove the plugs, remove the filler and clean the workpiece.

The cold pipe bending method is a process of changing the radius of a pipe without heating at the bend.

The cold method is used to bend profiles and pipe blanks from:

- Copper.

- Aluminum.

- Become.

- Non-ferrous alloys.

- Gland.

This method is several times more productive and does not require the use of large amounts of energy resources and labor costs, which leads to a reduction in production costs.

In addition, cold pipe bending is performed by many types of pipe bending machines, including semi-automatic CNC machines, which has a positive effect on bending accuracy. This is especially important when performing complex spatial bending of pipes or bending fragile thin-walled parts. That is why this method has become much more widespread than hot bending technology.

When working with thin-walled or fragile pipes, it is recommended to use a mechanical stabilizer - a mandrel.

A mandrel is a special piece of equipment that is placed in the pipe cavity to regulate the pipe bending process. The use of a mandrel tool ensures the stability of the structure and avoids deformation of the workpiece, the appearance of folds, creases, and cracks.

Hot pipe bending method

This method is used if it is impossible to bend a pipe cold using a pipe bending device. Its labor intensity is much higher. In addition, filler is used for the workpiece. This can be pre-sifted and dried river sand without small particles and organic matter that burn to the walls of the pipe when heated. Otherwise, high pressure steam may form when the pipe is heated.

The bending process occurs when the workpiece is heated to approximately +900 °C. To obtain a high-quality product, it is necessary to prevent overburning of the workpiece. The size of the heated area depends on the bending radius and cross-section of the pipe. After bending is completed, the sand is removed from the cavity, after removing the plugs holding it. The product is then cleaned and washed.

What difficulties arise in the process of bending a profile pipe?

A flexible profile pipe means that it is partially or completely bent. As you know, corrugated pipes have a high degree of strength, so they can only be bent under pressure or when the section being bent is heated. During the process, two forces act on the part:

- compression - inside;

- extensions - outside.

It is precisely the opposite direction of these forces that makes the work difficult when rounding the pipe:

- In different places the corrugated pipe may react differently to bending, which will lead to loss of alignment, that is, individual sections of the workpiece will be located on different surfaces.

- The pipe is not always able to withstand the stretching process and may become wrinkled or burst. More often, such moments occur when bending is done incorrectly.

- The product may have folds that resemble corrugation.

- The degree of strength decreases when overheated, the structure is disrupted.

- The side walls are crushed - this happens when there is excessive pressure when the workpiece passes through the bending structure.

Features of the bending process

Each metal has its own characteristics; without taking them into account, it is impossible to give rolled metal a complex shape. The bent pipe is subject to radial and tangential forces.

The former deform the section, and the latter contribute to the appearance of folds. The main requirement for the final result is that the cross-section of the pipe should remain unchanged, and there should be no corrugations on the walls. Bending allows you to minimize the number of welds when laying pipelines with all kinds of bends.

Types of pipe benders used.

The modern tools market today offers manual pipe benders of various modifications:

- mechanical;

- hydraulic;

- electric.

Depending on the material and diameter of the pipes being laid, the type of pipe bender used is selected.

To bend small-diameter pipes made of soft metals, it is possible to use mechanical pipe benders, the operation of which is based on the principle of leverage using sufficiently large physical force. This modification of the tool is suitable for rare work with pipes and requires an error tolerance in the bending angle.

More convenient modifications of pipe benders include hydraulic tools. They can be used when working with pipes of sufficiently large thickness, achieving high operating speed and maintaining the accuracy of the bending angle. The main advantage of hydraulic tools is that the work does not require the use of physical force and is quite small in size, which ensures the mobility of the tool.

To bend large-diameter pipes, it is rational to use electro-hydraulic pipe bending machines, which consist of an oil block with hydraulic fluid, a pump and an electric motor, as well as templates according to which bending occurs at the required angle.

The operation of a hydraulic pipe bender is based on the use of pressure obtained as a result of the operation of the hydraulic cylinders of a hydraulic pump powered by electricity.

Thus, professional tools include pipe benders, whose work is based on the principles of hydraulics and are successfully used when laying various gas communications and water pipes, as well as when laying various protective pipes for expensive communication cables.

Bend using a pipe bender

If large-diameter corrugated pipes are used to make a greenhouse, then bending it by hand will be difficult. We suggest that you familiarize yourself with the instructions on how to make a standard pipe bender yourself; its design consists of a drive wheel (it moves along the edges, bending the pipe at the desired angle), a station, a conveyor and clamping elements.

The pipe bender is:

- Manual - designed for carrying out a small amount of work. The workpiece is placed in the conveyor and clamped with a roller. The wheel is rotated by a handle, eventually bending occurs.

- Electric - the equipment is recommended for thick corrugated pipes. The device runs on electricity, and the wheel rotates electrically, so you don’t have to waste your energy. The principle of operation is similar to the previous one, the profile is tucked into the conveyor, it bends as it passes through the pressure zone.

When using this device, the corners from the inside and outside of the pipe experience equal pressure, so the bend is of high quality and does not burst.

Types of roller pipe benders and principles of their operation

Equipment for bending pipes using a rolling method works like this. Three rollers are installed in the working cage of the machine (for more complex, spatial bending patterns, the number of rollers is increased). The bent pipe is passed into the gap between the rollers, the profile of which must correspond to the outer diameter of the pipe. The center-to-center distance between the supporting lower rocks is set depending on the length of the workpiece and the bending radius .

Roller pipe benders are produced:

- With a horizontal layout , if the tubular profile has small overall dimensions (up to Ø 60...80 mm);

- With a vertical layout - for profile pipes, as well as with a round cross-section, but with a large external diameter;

- With symmetrical and asymmetrical arrangement of support rollers . The asymmetrical layout allows for spatial bending of tubular workpieces.

The simplest, three-roll pipe bending installation consists of:

- Beds.

- Drive motor.

- V-belt transmission.

- Intermediate shaft with flywheel.

- Gearbox.

- Drive support roll assembly.

- Upper roller with a mechanism for its longitudinal adjustment.

- A counterweight that controls the tension of the workpiece during the bending process.

- Control panel.

The operational advantage of roller pipe benders is that they can be used to re-pass a semi-finished product to adjust the dimensional characteristics of the bending process.

To do this, the bent pipe can be passed again through the rollers, which have previously been reset to a new starting position. The need for a second pass appears when the spring rate of the pipe metal is unknown . In addition, the idle cycle for pipe benders of this type is much shorter, since removing the finished product and inserting a new workpiece into the gap between the rolls can be done by simply reversing the drive.

To carry out spatial bending, roller pipe benders are also equipped with spiral devices that allow you to change the vertical location of the pressure rollers during the bending process.

Due to the extreme simplicity of their kinematic scheme, roller pipe benders much cheaper than roller pipe . The low energy intensity of pipe bending processes explains the low values of working effort, and, as a result, the use of low-power electric motors . For pipes of small cross-section, such installations can even be manually driven . Therefore, pipe bending machines are often made by hand , in accordance with a certain range of tasks.