Sharpening machines in everyday life and industry

Every day, humanity uses cutting tools: scissors, knives, screwdrivers, axes, etc. Frequent use of any of these items becomes dull. The sharp edge of the metal blade quickly “sits”, which makes the tool unsuitable for use. And this is due not only to the mechanical impact that occurs during contact with other solid objects. The blade becomes dull even when not in use. Steel of any quality will corrode over time, which directly affects the sharpness of a thin edge. Therefore, such products need to be constantly sharpened.

Periodic sharpening of sharp metal tools is also necessary in production. The quality of any industrial operations depends on the readiness of the equipment for work. In manufacturing enterprises, tools are sharpened much more often, since in such conditions the load on the knives is higher.

A sharpening machine is a necessary device for solving industrial and household problems. A modern knife sharpening machine allows you to restore the sharpness of metal objects in a matter of seconds, while maintaining the geometry of the blade as much as possible.

The best knife sharpeners from AliExpress

Saim Fsda

Rating: 4.9

In first place is an electric sharpener, characterized by its versatility. The model is suitable not only for sharpening a variety of knives, but also for processing screwdrivers, scissors and other tools. The device has six grooves with different abrasives that provide sharpness to the blade. High power reduces processing time, allowing you to return the canvas to working condition in 1-2 minutes. For protection, the manufacturer has provided an automatic shutdown that is triggered during overheating. This protects the motor from failure. The body is made of high quality plastic. Users note that the device does not emit any foreign odors. Among most similar sharpeners, this model stands out due to its excellent results.

Advantages

- power – 60 W;

- ergonomic design.

Flaws

- relatively expensive - 4 thousand rubles.

Optimal blade angle

To use a knife effectively, it is important to sharpen the blade at a certain angle. During the sharpening process, the angle between the edges of the blade should be restored.

Each type of knife has its own recommended angle values:

- Knife for bread, vegetables and fruits – 15-20 degrees.

- A universal knife for different products – from 20 to 25 degrees.

- Travel knife – 25-30 degrees.

- Knife for cutting hard materials – 30-40 degrees.

You can sharpen knives at the recommended angle manually using abrasive stones and sharpening stones. But achieving the required blade angle in this case is quite difficult. To facilitate and speed up this process, special devices have been developed - knife sharpening machines. They are easy to use and have a simple design.

How to sharpen a blade

Household cutting accessories are made from special and powder grades of steel. The structure of their sharpening resembles the teeth of rodents: the further from the edge, the less hardness of the cutting layer.

Therefore, ideal manual sharpening of knives occurs according to the push-pull principle or the push-pull method (from English push-pull sharpening):

- The cutting blade is first pushed away from itself with a scraping motion, with a slight turn to the side.

- Further, without lifting the blade from the sharpener, the movement occurs towards itself, with a turn in the opposite direction.

- This continues until sharpening is complete, with a gradual weakening of the pressure.

This technique requires certain skills from the sharpener, as well as careful treatment of the blade itself. This method requires:

- Clearly maintain the tilt of the knife, gradually changing it depending on the curvature of the knife.

- The contact spot of the blade must coincide with the tangent line of the whetstone and be perpendicular to its longitudinal axis.

- The pressure on the surface must be changed smoothly.

It is difficult to carry out the process, observing all the rules when moving the blade in both directions, and an incorrect result renders the blade unusable. To relieve the sharpener from constantly monitoring the sharpening process, they came up with machines for sharpening knives.

What are knife sharpening machines?

This is an oversized electrical device with rapidly rotating abrasive discs. Compared to other sharpening devices, machines allow you to set the sharpening angle as accurately as possible and process the blade in a few seconds.

Such units are used in public catering establishments (restaurants and cafes), where there is a need for frequent sharpening of kitchen cutting tools. It is not practical to use machines for sharpening knives at home due to the high cost of these devices.

Modern electric sharpeners efficiently process blades with different types of edges. They can sharpen on one side or on both sides at the same time. Using the machine, it is possible to perform all stages of blade processing, from forming the optimal cut cut to polishing.

Typically, such devices have a function for selecting the operating mode. It allows you to set a gentle mode if you need to sharpen a thin blade from expensive material, or set more complex processing for hunting, tourist and pocket knives. There is no need to disassemble the machine. There is a control panel on the device body, with which you can select the necessary sharpening parameters.

An electric knife sharpening machine can be used both in the restaurant industry and for home purposes. In the first case, the use is completely justified. The high cost of the device pays off quickly.

Best Manual Knife Sharpeners

Profi Cook PC-MS 1090

Rating: 4.9

In first place in the rating category is a desktop manual sharpener with abrasive made from a diamond grinding stone. It will handle sharpening effectively and quickly; you just need to place the blade in the slot with the tip pointing down, swiping it towards you several times. The sharpening angle is optimal, prevents damage to the metal blade and prevents the formation of scratches. There are three slots for different stages: preliminary, fine and coarse sharpening. This approach allows you to process even very dull knives. The case has a laconic design and is made of stainless steel. It takes up very little space, so you can store the sharpener in a drawer where spoons, forks, and knives are stored, then the product will always be at hand.

Advantages

- ergonomic shape;

- acceptable cost - 1650 rub.

Flaws

- not found.

Advantages of electric sharpeners

Electric knife sharpening machine is very popular. It allows you to sharpen a blade of any length and thickness with high quality, accurately maintaining the desired angle. Modern electric machines automatically detect the inclination of the blade. The device perfectly sharpens knives with wavy blades.

Another advantage of this device is its versatility. This machine can be used for sharpening scissors, screwdrivers and other sharp tools. After grinding the blade looks like new.

Typically, electric machines consist of several abrasive discs located perpendicular to the blade and guide elements. Sharpening a knife on such a device is carried out in one motion. More complex models have several sets of discs with different grain sizes.

An important advantage of sharpening machines is their long service life. Basically, such devices are equipped with sharpening elements with ceramic or diamond coating. Even with everyday use, the need to replace such knives is extremely rare. Homemade knife sharpening machines may never be repaired.

The best electric knife sharpeners

Chef's Choice 120

Rating: 4.9

In first place is an American-made electric sharpener, suitable for sharpening regular and serrated (serrated) knives. It processes the blade in three stages: in the first stage, rough sharpening occurs with diamond-coated abrasive discs, forming the first bevel; on the second - with fine-grained abrasive, a second bevel is formed; on the third, even finer ceramic abrasives grind and polish the blade, creating a third final bevel that is sharp. The user can independently choose a combination of steps to obtain different results. The sharpener can also be used for processing folding, hunting, tourist, sports, fishing and other knives.

Advantages

- power – 75 W;

- instant sharpening;

- sharpening angle control – 20 degrees.

Flaws

- high cost - 16 thousand rubles.

KitchenIQ 50073

Rating: 4.8

The second position is occupied by an electric knife sharpening device, recognized as the best in terms of quality and price. The model is much cheaper than the leader in the category, but is not inferior in quality and practicality. The case with a metal insert looks massive, so initially it seems that the device will weigh a lot, but this is not the case. The sharpener is lightweight and has a neutral design. There are rubberized inserts on the bottom so that the device does not slip on the table surface. Only knives made of stainless, alloy or carbon steel can be sharpened. Geared tools may only be processed in the polishing slot. Simple and clear instructions included.

Advantages

- synthetic and ceramic abrasives;

- Suitable for sharpening knives of different sizes;

- sharpening angle adjustment;

- ergonomic handle.

Flaws

- low power – 6 W;

- relatively expensive - 4600 rub.

Universal sharpening tool

For sharpening European and Japanese products, there is a universal machine for sharpening knives and scissors with three stages of the process. The first one processes knives with a sharpening angle of up to 15 degrees, the second one – 15-20 degrees. The third uses composite discs that create a microscopic angle. This processing allows you to create a thin cutting edge.

This type of machine is suitable for sharpening kitchen, travel and pocket knives.

Rating of the best knife sharpeners

| Nomination | place | Name of product | price |

| Best Manual Knife Sharpeners | 1 | Profi Cook PC-MS 1090 | 1 750 ₽ |

| 2 | Rondell RD-323 | 891 ₽ | |

| 3 | Fiskars 120740 | 850 ₽ | |

| 4 | TimA TMK-001 | 590 ₽ | |

| The best electric knife sharpeners | 1 | Chef's Choice 120 | 15 590 ₽ |

| 2 | KitchenIQ 50073 | 3 671 ₽ | |

| 3 | Sititek Hozjajka 31M | 2 790 ₽ | |

| The best knife sharpeners from AliExpress | 1 | Saim Fsda | 4 870 ₽ |

| 2 | Ruixin PRO III | 1 350 ₽ | |

| 3 | NUOTEN ND-073 | 680 ₽ | |

| 4 | Findking MDQ001 | 270 ₽ | |

| 5 | Knife Sharpener | 150 ₽ |

DIY knife sharpening machine

If automatic sharpening devices are not affordable, and sharpening knives by hand is too time-consuming and ineffective, you can make a tool yourself. There are several options for homemade designs, the production of which requires very little time and effort.

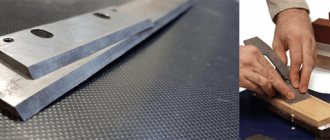

To create a tool you need:

- abrasive bars or stones;

- knife rest.

As discs that are used in machines and electric machines, you can use ready-made stones or make them yourself. To do this, you need to take small glass plates 5 mm thick and, using double-sided tape, stick sandpaper of different grain sizes onto their surfaces. When using such a device, it is not recommended to make quick movements so as not to overheat the blade.

Why do knives lose their sharpness?

Cutting products, no matter what their quality, become dull over time. This occurs due to the blades changing shape as a result of the loss of microscopic particles of the material from which the blade is made when interacting with the object being cut. In addition, under pressure, which is sometimes quite strong, the cutting edge is deformed as a result of deflection in any direction.

In addition, the cutting direction is not always maintained, which causes curvature of the very edge of the knife surface and makes it difficult to pass along the cut line. This is especially evident in blades made from low-grade raw materials.

Many people think that knives become dull much faster in hot water. This assumption is partly correct, although it is not decisive. Such tap liquid is saturated with salts and metals much more strongly than cold liquid, therefore their interaction with the cutting surface has a negative, although not decisive, effect.

Sharpener parts

No matter how many such devices are invented, they have the same common features. The main and constant parts of any sharpening tool are ;

- Abrasive component.

- The thrust part.

All sharpening components that are used at home and at work are presented in stores. Here are the main ones:

- Ceramic bars.

- A natural stone.

- Diamond sharpener.

- Japanese water devices.

The most popular and affordable abrasive is the ceramic stone, which is most common in retail outlets. Most often this is an ordinary boat for rough sharpening the blade. There are double-sided bars, which are preferable for household use. This is an inexpensive device, the replacement of which as it wears out will not bring large financial costs.

Grinding using diamond stones is more complex and expensive. In addition to the high price, such sharpeners quickly wear out the working part of the blade.

The best whetstones for sharpening are natural and Japanese stones. However, their price is very high and they are not produced in our country.

Homemade sharpening device

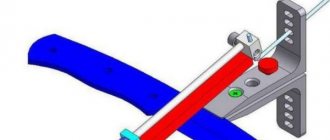

In order to make a knife sharpening machine with your own hands, the first thing you need to do is find a suitable drawing. There are many modifications for its production.

The easiest way

This option does not require special skill or the use of expensive components. To make it you will need:

- Wooden corners with a side of 20-30 centimeters: 2 pieces.

- Screws with nuts in the amount of 10 pieces.

- Protractor for precise angle setting.

- In addition, you will need a drill and drill bits.

To make it, you need to mark the corners and drill 3-4 holes at identical points. Place a block between them at the desired angle and secure with bolts.

To sharpen a knife or scissors, you simply need to run the blade along the surface of the block, holding it strictly vertically.