Wood is the most popular material, gifted to humanity by nature itself. Furniture is made from it, houses are built, and even dishes are made. But in order to use wood as a construction or finishing material, special machines are required for its processing.

wood material It is for this purpose that band sawing machines (sawmills) exist.

Band sawmills

This type of sawing machines allows you to obtain building material from round wood in the form of boards and timber of various cross-sections and sizes with minimal waste. The board may not be edged, the edges of the board have a curved line, or edged (the edges form a straight line). The beam can be of square or rectangular cross-section.

The modern tool market today offers a variety of woodworking machines manufactured by domestic and foreign manufacturers. Among them are a large number of machines designed specifically for longitudinal cutting of round wood.

One of these is the band model of the Taiga sawmill , which is today the most popular among entrepreneurs producing lumber for construction, the furniture industry and other production areas.

Band sawmill "Taiga"

- According to reviews from users of the sawmill, this model of sawing machine pays for itself in a short period of time, which averages about 3 months. And the warranty when purchasing from the manufacturer is one year.

- Naturally, by purchasing such equipment, an entrepreneur is practically making an effective investment of his funds, which in a short period of time will bring him a good profit.

- In addition, at this time there are a large number of dealers throughout the country who sell woodworking machines from the manufacturer. Thanks to this, repairing the sawmill will not pose any difficulties. It will be possible to freely purchase from dealers for replacement almost any part for the machine, including even entire technical units.

- The Taiga band sawing machine is one of the equipment that has the best price-quality ratio. This is a reliable, high-performance machine that produces high-quality multi-purpose products, which, with a small financial investment, can bring consistently good profits. Naturally, this is beneficial for any large or small enterprise.

- In addition, the Taiga machine can operate not only from electricity, but also from an autonomous source with a gasoline engine. Thanks to this, it can be installed far from populated areas directly on the site where deforestation is taking place.

- Having small dimensions and easy to disassemble, the equipment can easily be transported at a time by a Gazelle car.

Peculiarities

- Today, Taiga model machines practically occupy a leading position in the woodworking equipment market. The list of this line of equipment is quite large and practically occupies the first two places in its technological chain.

- Sawmills driven by an electric motor, based on their power, the presence or absence of lifting carriages, as well as the diameter of the sawn logs and other additional components, such as an electronic ruler, are divided into 5 modifications.

- Band sawmills driven by gasoline engines are divided into three models according to their power, the size of the saw blades and the diameter of the sawn logs.

- All electric and gasoline sawmills manufactured by domestic manufacturers have certificates confirming that they comply with certain Russian GOSTs and are manufactured in compliance with the Technical Specifications, which are developed specifically for serial production at industrial enterprises.

Sawing at home

Purchasing sawmills for use at home is unprofitable both from an economic point of view, the price is quite high, and from a practical point of view. For these purposes, a regular chainsaw is quite suitable.

However, you can also use an electric one, but a gasoline one is much more powerful and does not require electricity, which is very useful when carrying out work far from civilization. Despite the labor-intensive nature of this process, if you have certain skills, the labor costs can be justified.

Do-it-yourself frame-nozzle for cutting logs

All work related to cutting requires special equipment:

- a device that secures the log in a stationary state;

- a frame-attachment designed for a chainsaw - if it is necessary to obtain boards of different thicknesses, they are fixed to the tool bar, but in such a way as to be able to adjust the distance remaining between the attachment and the chain;

- ruler-guide. It can be successfully replaced with a metal profile or a regular board of the required length, the main thing is that it is smooth and rigid.

Tip: for a chainsaw you need to purchase a special chain that allows you to make longitudinal cuts. Its distinctive feature is the special sharpening angle of the teeth.

Process

The operating instructions will be as follows:

- Free the logs from bark and branches. The less waste there is, the more finished material there will be.

- Determine the cutting pattern that will be most optimal. Why inspect the log for possible defects.

In the photo - cutting logs

- Carry out cutting in the direction from east to west or vice versa. This is due to the fact that obtaining high-quality material is only possible if the density of the boards is the same across the entire width. Please note that the density of a tree trunk on the north side is much higher than on the south.

- Remove the slabs located opposite each other.

- Saw the double-edged timber formed as a result of this operation into lumber.

- Remove the edges from the resulting unedged wood board.

Advice: if any defects are detected in the log, for example, a false core, it can be rotated by 90 and 180˚ as with circular sawing.

Distinctive properties

"Taiga T-1"

This sawmill model has small dimensions and is driven by an electric motor. Used for cutting round logs, as well as large timber into boards.

Has a reliable metal frame. When cutting there is no vibration of the saws (waves). Sawing small diameter logs. It has a low price and low power consumption. Small overall dimensions allow it to be transported even in a minibus.

"Taiga T-2"

This is an almost inexpensive machine with a power of only 7.5 kW . Its metal frame has a large margin of safety, which is designed for fairly long-term use. The productivity of the model depends on the type of product being processed, and can be approximately 5-10 cubic meters. per shift.

It can be additionally equipped with an electronic ruler of the Micron - 4 type, with the help of which complete automation of the control of almost all production operations is carried out.

Using Micron - 4 helps the operator accurately, without errors, create a sawing map, mathematically calculate and make corrections for the thickness of the cut. In this case, all calculations are stored by an electronic ruler, which has 8 memory cells.

"Taiga T-2B"

Based on its technical properties and performance, this model can be considered unique equipment. It is equipped with an economical drive from a four-stroke gasoline engine with a power of 10 kW (13 l/hp). When fully loaded, the engine consumes only about 1.5 liters of AI-92 gasoline.

To warm up the engine before the expected load, idling is provided, thereby extending its service life.

The structure of the sawmill consists of a standard Taiga sawmill frame, but it has mounts for installing an electric motor instead of a gasoline engine .

The T-2B machine can work in field conditions directly on a felled forest plot, where, naturally, there cannot be a power line.

Depending on the diameter of the logs being cut, Taiga-2B can cut about 10 cubic meters per shift.

"Taiga T-2M"

This model of band sawmill has a fairly powerful 11 kW electric motor, which makes it possible to saw large logs with dense wood .

Its design has a fairly large margin of safety, therefore it is designed for long-term, multi-shift work with a capacity of up to 10 cubic meters/m. in one shift.

On this sawmill , as on the T-2 model, an electronic ruler of the Micron - 4 type can be installed, which automates many work processes.

"Taiga T-3"

The T-3 sawmill is designed for multi-shift work with wood of any density. Power

its electric motor is 11 kW, has a reinforced design of the sawing carriage, due to which the diameters of the sawing pulleys are increased to 60 cm, which increases the service life of the band blades several times.

The design of this model is designed for fairly high loads, with minimally fast settings . This allows you to carry out work without long breaks to adjust the equipment.

The productivity of the T-3 model is about 12 cubic meters when cutting large round timber. in one shift.

The function of moving the sawmill along the processed log can be separately configured and additionally equipped with a multifunctional electronic ruler of the Micron - 4 type to automate the work process.

How to cut a log crosswise

If you plan to saw the trunk crosswise and then cut the logs into boards, this is not practical. Usually a log intended for preparing firewood is sawn crosswise.

Logs sawn crosswise are often used to make garden benches and tables. Garden paths decorated with sawn wood look beautiful. In this case, they are cut into discs 10-15 cm thick.

- Place the log on strong, stable trestles 60-80 cm high.

- If you plan to remove the tree bark, do it before cutting.

- Make a shallow cut that will serve as a guide groove.

- Rotate the log 90º so that the saw bar fits in the groove.

- When cutting logs into logs, first make notches with an ax.

- Cut the log. Further processing of the material depends on its area of application.

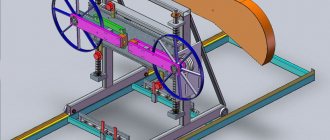

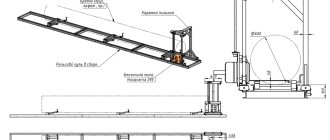

Design of Taiga belt models

The base for the sawmill can be a concrete platform or thick wooden beams laid on a flat area of dense soil. Rails are laid on the beams or prepared platform, which are rigidly fastened to each other. They also have a system for fastening the processed logs.

The rails can be extended with an additional section, making it possible to cut logs whose length can exceed 8 meters.

The sawmill frame can have a mechanical or electric drive for vertical movement and move along rails using support rollers in manual mode. The saw cut is removed manually by one or two auxiliary workers.

The sawing mechanism moves along a vertical plane using a double-row chain transmission simultaneously with the lowering/raising drive gearbox, and is controlled by a metric scale located on the frame. Thanks to this, the sawing mechanism is precisely adjusted in height and firmly fixed to the sawmill frame.

On the T-1 series sawmill, the sawing mechanism is moved manually by rotating the gearbox with a special handle. And on other machines, the vertical movement of the sawing mechanism is carried out by an automatic switch, but if there is a need to adjust the saw height, it is done using a manual closer.

The sawing mechanism is equipped with two balanced rollers (driver and driven) on which the cutting saw is fixed. The drive roller is driven by a belt drive from an electric motor pulley. The driven roller is attached to the tension system and rotates from the movement of the belt web.

The speed of movement of the band saw can increase with increasing diameter of the pulley, which can have a maximum value of 520-600 mm. At the same time, the quality of the cut surface of the log improves and the service life of the cutting blade increases.

After installing the band saw, its tension is carried out with a special wrench with a dynamometer. Tension control is carried out using a scale located on the dynamometer sensor mounted on the tension wrench.

Constant tension and prevention of vibration of the saw blade is carried out by calming rollers of the sawing mechanism. To prevent the saw blade from becoming pinched in the cut of the log, which can be caused by wood resin accumulated on the blade, the sawing machine is equipped with a special lubrication system. The system has a lubricant flow regulator, which simultaneously cools the cutting blade.

All moving and rotating parts of the sawmill are protected by a protective metal casing, and the machine is controlled through the sawmill keypad, which is installed on the sawing frame.

Purpose and consumer groups

- Band sawmills T-1 and T-2, whose power is 7.5 kW, are most often used on construction sites for private construction. In this case, the building material obtained with their help has a fairly low cost, plus some waste remains in the form of slabs and sawdust, which are always useful in construction. At the same time, the construction team practically does not depend on the delivery time of the material, and the customer can always control the quality of the received material. The average cost of these sawmills is approximately 136 thousand rubles.

- Sawmills T-2M and T-3 are more powerful models for producing high-quality lumber. They have an almost perfect combination of price and quality. Their cost on the market is from 150 thousand rubles.

- The T-4 model freely saws almost any hard tree species with a diameter of more than 105 cm. At the same time, the lowest cost of this sawmill is about 238 thousand rubles.