GOST-9467-75, E6013 and other standards, quality certificates, passport

All ESAB welding materials undergo strict quality control. This is confirmed not only by certificates of the National Welding Control Agency, Maritime and River Registers, but also by reviews of the welders themselves.

Certificates:

- NAKS (National Agency for Control and Welding)

- ABS - American Bureau of Shipbuilding Standards

- BV – French Bureau of Standardization in the field of shipbuilding Bureau Veritas SA, Paris

- DnV – Norwegian shipbuilding standardization company Det Norske Veritas, Oslo

- DS – Danish Standard Certificering A/S, Denmark

- GL – German Marine Insurance Association Lloyd's Register, Hamburg

- PRS – Polish Register of Shipping, Gdansk

- PPP – Russian River Register

- RS – Russian Maritime Register of Shipping

- Sepros – Certificate in the Ukr SEPRO system, Ukraine

- SS – Singapore Standard, Singapore

- UDT – Office of Technical Inspection, Warsaw, Poland

- U – German building requirements

- VdTUV – Association of Technical Inspection Agencies, Berlin, Germany

Welding electrodes ESAB OK 46.00. Photo by ESAB

Approvals:

- ABS 2

- BV 2

- DB 10.039.05

- DNV 2

- DS EN 499 E 38 0 RC 11

- GL 2

- LR 2

- PRS 2

- RS 2

- Sepros UNA 485154

- SS EN 499 E 38 0 RC 11

- UDT EN 499

- Ü 10.039/1

- VdTÜV 00623

Standards:

- SFA/AWS – E6013

- EN – E 38 0 RC 11

- ISO – E 38 0 RC 11 / E 43 3 R 11

Specifications:

- TU 1272-024-55224353-2006

- TU 1272-137-53304740-2007

- TU 1272-137-53304720-2009

OKVED-2, E7016, GOST, NAKS and other certificates, standards

The standardization system provides a certain guarantee that the buyer will purchase high-quality and safe products and create the necessary working conditions at the manufacturer.

The All-Russian Classifier of Types of Economic Activities (OKVED) divides it into codes. The correct choice of codes allows government agencies to organize control over any type of activity and, based on the information collected, introduce regulations to regulate it. Taxes, insurance deductions - everything is calculated according to the OKVED code. It is used in conjunction with the OKPD code (all-Russian classifier of products by type of economic activity). OK brand consumables have the following codes for this classification:

- OKPD category - 25.93.15.120 Coated electrodes;

- OKVED category - 25.93.1 Production of wire and spring products.

Technical characteristics and purpose of the electrodes comply with standards, technical specifications and other regulatory documents . On the Russian market there are OK consumables manufactured by both Russian and foreign enterprises. All of them must comply with Russian GOST standards for coated electrodes used for manual welding and surfacing of various steels and alloys (GOST 9466-75, GOST 946-75, GOST 10051-75, GOST 10052-75, GOST R ISO 3580-2009, GOST R ISO 3581-2009, GOST R ISO 2560-2009).

ESAB electrodes manufactured overseas are manufactured to European, British and American standards. The most popular is the American standard AWS (American Welding Society). AWS requirements are in many ways similar to GOST requirements .

Welding electrode "OK 74.70".

Therefore, most brands of OK consumables from ESAB have easily won a place in the sun on the Russian welding materials market. So, for example, an OK 53.70 electrode, which according to the AWS standard has the designation E7016, where E means it belongs to coated electrodes for manual arc welding, the number 70 indicates the tensile strength value in pounds per square meter. inch divided by 1000, number 1 determines the possibility of welding in all spatial positions, number 6 determines the main type of electrode coating and the possibility of welding on both alternating and direct currents.

Electrodes are not subject to mandatory certification . However, in order to compete for the buyer, having a NAKS certificate (national welding control agency), quality certificates of professional societies such as VNIIGAZ (OJSC Gazprom), the American Bureau of Standardization in the field of shipbuilding (ABS), the British Lloyd's Register of Shipping (LR) and others will be a significant advantage .

Explanation of markings, designations of welding rods

ESAB OK 46 electrodes have fairly simple markings. First of all, these are products of an internationally renowned company. The ESAB industrial plant has over 110 years of experience in the manufacture and development of welding consumables. The abbreviation OK used in international markings is nothing more than the initials of the founder of the manufacturing company, Oscar Kjellberg. 46, or 46 00 - the maximum load that a seam resulting from the use of these electrodes can experience.

Description of consumables for welding, photo

Electrode packages OK 46.00

A unique electrode in its class, with excellent welding and technological characteristics, designed for welding structures made of low-carbon and low-alloy steels with a yield strength of up to 380 MPa in all spatial positions on direct current of any polarity and alternating current.

The electrode is characterized by relatively low sensitivity to rust, primer, zinc coatings, etc. contamination of the surface of products, ease of slag separation and the formation of a smooth surface of the weld bead with a smooth transition to the base metal.

Due to the ease of both first and repeated ignitions, the electrode is indispensable for welding with short seams, tack welding and welding with periodic arc breaks. Unlike most rutile electrodes, thanks to the ability to weld in the “vertical downhill” position, combined with significantly lower threshold values of the minimum current at which the arc burns stably, OK 46.00 allows you to weld thin-walled products. Low open circuit voltage and stable arcing at extremely low currents allow the use of these electrodes for welding from household sources.

What are they intended for, what can be cooked, what metals and steels, areas of application

Welding electrodes OK 46.00 are recommended for MMA welding of carbon marine and structural steels . They are ideal for both tack welding and root and short welds. Considering the reduced heat input, these welding electrodes are widely used when welding wide gaps, including during installation . In addition, ESAB OK 46.00 electrodes are widely used when welding galvanized sheets.

Comparison with MP-3 and other brands

There are hundreds of manufacturers operating in the welding materials market. Each has its own technology for producing coated electrodes. However, the range of materials used is very limited, as a result of which they produce products with similar characteristics.

Electrodes OK 68.81. Photo by ESAB

In the article “OK 46 Electrodes: Analogues,” consumables with similar characteristics are available with the same rutile coating as OK 46.00. The article names the following as close analogues of this popular brand of electrodes: MR-3, OZS-4, OZS-12, ANO-21.

Peculiarities

A distinctive positive feature of OK 46 electrodes is the ability to easily ignite, including when re-igniting. They can be used for welding galvanized (galvanized) products. The low heat input of the electrodes allows them to be used for welding wide gaps, and their insensitivity to surfaces with rust and dirt ensures their high manufacturability.

Due to their high quality indicators, electrodes have found wide application in various branches of industrial production, where the use of effective welding materials is necessary . Minimal spattering and ease of slag removal give the seam a good aesthetic appearance. Despite the universal use of electrodes, they provide good seam properties and are ideal for short and root seams, as well as for tack welds. The ability to use electrodes in all positions in space makes them indispensable when working in confined spaces.

Characteristics of OK 46 electrodes

ESAB OK 46.00 electrodes are distinguished by good welding performance. They have a dense coating and maintain a stable arc during operation, which helps protect the weld pool from interaction with atmospheric chemical elements. The electrodes ignite equally well under normal conditions, at low current, and when re-igniting the arc when part of the rod has already been used.

OK 46 electrodes are “democratic” in terms of placement of the weld in space: horizontal, vertical or ceiling in the hands of a specialist turn out equally well. They are capable of welding even on painted surfaces or in very narrow spaces. They are excellent for applying installation tacks, forming cosmetic or root seams. The product has proven itself to be excellent in cases where periodic arc breaks are inevitable.

The most important features of OK 46 electrodes:

- used in welding galvanized metal with other types of galvanic coatings;

- perfectly connects thin-walled workpieces;

- easy to set on fire both at the beginning of work and again;

- due to low heat input, they are an excellent tool for filling wide gaps;

- can be used to form a vertical seam in the top-to-bottom direction;

- low sensitivity to edge contamination, which reduces the requirements for preliminary surface preparation.

The manufacturer recommends fusing the metal in small sections. If it is necessary to apply a long suture, break it into several sections.

Advantages and disadvantages

Welding electrodes OK 46.00 are universal electrodes and have a number of advantages that facilitate their use in different welding modes:

- provide good formation of the welding seam and easy initial and re-ignition of the welding arc;

- create a reduced heat input compared to other welding electrodes;

- insensitive to contamination of the welded surface and rust on it;

- it is possible to apply a seam in a vertical position in the direction of descent;

- excellent quality of both consumables and the resulting connection;

- ease of use;

- low splashing;

- low slag formation;

- suitable for beginners.

OK 46 has only two disadvantages: high price and frequent counterfeits. But we do not consider these disadvantages significant. After all, the price is not much higher than analogues, and the final quality of the seams is much better. Well, to avoid counterfeits, you need to buy electrodes from certified representatives or in large stores.

Available operating and welding modes

The correct operating conditions are created by observing the selection of rods depending on the direction of the seam in space. A wide range of parameters helps in this search along with tables and graphs. The device does not require much voltage and connects to your home network.

We recommend reading Characteristics of OZS-12 electrodes

Users note the disadvantages of consumables:

- high prices;

- workpieces with thick walls are poorly cooked;

- The coating quickly absorbs moisture.

These shortcomings do not spoil the overall impression of the universal electrodes.

Technical characteristics: type, which group they belong to, constant or variable, and others

- OK 46.00 welding electrodes allow welding on alternating (with an open circuit voltage on the transformer of at least 50 V) and direct (any polarity) current in any spatial position.

- electrode coating: rutile-cellulose;

- welding steel wire Sv08 and Sv08A is used as the rod material;

- welding wire diameter 2; 2.5; 3; 4 and 5 mm;

- type – E46;

- consumption coefficient of electrodes with a diameter of 3 mm. g/Ah – 8.5;

- consumption of electrodes per 1 kg of deposited metal, kg – 1.7;

- surfacing productivity (for diameter 4.0 mm), kg/h. – 1.4;

- flow coefficient group – 4.

Types of electrodes

OK 46 have analogues in the form of E46, SEOK-46. They support arc burning and operate with alternating and direct current in any spatial position. Hot metal spatters moderately. Dimensions vary between 300-450 mm.

A replacement can be OZS-12, ANO-4, MP-3 with rutile coating.

Many indicators are the same, but there is a difference:

- They only need straight polarity;

- individual fragments of the slag crust are difficult to remove;

- the seam surface appears concave.

Analogues are recommended for welding T-bars and pipe structures.

In terms of seam quality, electrodes coated with cellulose and rutile are close to OK 46 00 - SZSM 46 and SE-46, in which the number indicates the tensile strength of the seam in kg/mm². Before use, it is recommended to calcinate the rods in order to eliminate lack of penetration.

The procedure takes place at a temperature of 300°C for at least an hour. Masters do not advise doing this more than 3 times to avoid destruction of the coating.

OK 46 is also produced by a company located in Penza. In the manufacture of electrodes, the same materials are used as the original. Externally, the products are no different. Practice has shown that the coating on an analogue rod holds up worse, the arc burning is less stable, but the seam is the same.

We recommend reading Characteristics of LB 52U electrodes

Craftsmen replace ESAB OK 46 with the following brands: OZS 6, ANO with indices 6, 23 and 29 M. With their help, welding quality cannot be achieved, but the cost of materials is much lower.

Analogues are not very high quality.

Diameter, length, weight of rod and pack, quantity, how many pieces in a package, tables

Information from the manufacturer's website:

| Amps | IN | Melting time per electrode at 90%, sec. | Electrode diameter x length, mm. | kg deposited metal/kg electrodes | Number of electrodes per kilogram of deposited metal | Coeff. surfacing, kg/hour |

| 30-60 | 26 | 36 | 1.6 x 300 | 0.63 | 263 | 0.38 |

| 50-70 | 25 | 38 | 2.0 x 300 | 0.60 | 172 | 0.55 |

| 60-100 | 22 | 50 | 2.5 x 350 | 0.65 | 86 | 0.80 |

| 70-140 | 32 | 46 | 3.0 x 350 | 0.51 | 77 | 1.0 |

| 80-150 | 22 | 57 | 3.2 x 350 | 0.65 | 53 | 1.30 |

| 80-150 | 22 | 63 | 3.2 x 450 | 0.64 | 43 | 1.33 |

| 100-200 | 26 | 64 | 4.0 x 400 | 0.60 | 33 | 1.69 |

| 100-200 | 23 | 76 | 4.0 x 450 | 0.58 | 33 | 1.94 |

| 150-290 | 24 | 87 | 5.0 x 350 | 0.60 | 24 | 2.30 |

| 150-290 | 30 | 71 | 5.0 x 400 | 0.56 | 22 | 2.2 |

| 150-290 | 24 | 114 | 5.0 x 450 | 0.60 | 31 | 2.30 |

Welding parameters, information from suppliers' websites:

1)

| Diameter, mm | Length, mm | Welding current, A | Arc voltage, V | Weight (kg) of deposited metal / weight (kg) of electrodes | Number of electrodes / mass of deposited metal ( pcs/1 kg) | Weight (kg) of deposited metal / arc operating time (hour) | Combustion time, sec/electrode |

| 1.6 | 300 | 30-60 | 20 | 0.63 | 263 | 0.38 | 36 |

| 2.0 | 300 | 50-70 | 21 | 0.60 | 172 | 0.55 | 38 |

| 2.5 | 350 | 60-100 | 22 | 0.65 | 86.0 | 0.8 | 50 |

| 3.2 | 350 | 80-150 | 22 | 0.65 | 53.0 | 1.3 | 57 |

| 4.0 | 450 | 100-200 | 22 | 0.60 | 39.0 | 1.6 | 65 |

| 5.0 | 450 | 150-290 | 24 | 0.60 | 24.0 | 2.3 | 87 |

| 5.0 | 450 | 170-220 | 24 | 0.60 | 31.0 | 2.3 | 114 |

2)

| Diameter, mm/Current, A | Lower | Vertical | Ceiling | Length, mm | Number of electrodes in 1 kg, pcs. |

| 2,0 | 40…80 | 40…60 | 50…70 | 300 | 50 |

| 2,5 | 60…110 | 60…90 | 60…110 | 350 | 45 |

| 3,0 | 80…160 | 80…140 | 80…180 | 350 | 39 |

| 4,0 | 110…210 | 110…200 | 90…220 | 450 | 19 |

| 5,0 | 150…300 | 150…280 | 150…270 | 350 | 13 |

Chemical composition of the deposited metal

Packaging of electrodes ESAB-SVEL OK 46.00

For reliable storage, OK 46.00 electrodes are packaged in a pack of micro-corrugated cardboard, sealed in plastic film. The pack is yellow in accordance with ESAB standards. The number of ESAB electrodes in packages and packs is given in the following table:

| Diameter of electrodes, mm | Electrode length, mm | Weight of a pack of electrodes, kg | Pallet weight, kg | Number of packs on a pallet, pcs. |

| 1.6 | 300 | 24,0 | 1848 | 77 |

| 2.0 | 300 | 2,0 | 640 | 320 |

| 2.5 | 300 | 5,3 | 954 | 180 |

| 3.2 | 350 | 5,3 | 954 | 180 |

| 3.2 | 350 | 2,5 | 900 | 360 |

| 4.0 | 450 | 6,6 | 950,4 | 144 |

| 5.0 | 450 | 6,6 | 950,4 | 144 |

How to choose by diameter: 1.6; 2; 2.5; 3; 4 and 5 mm.

| 1.6-2 mm. | Suitable for working with carbon steel. In case of cracks in the seams, they can be easily cleaned. They are not afraid of large overheating. Not suitable for pipeline work. |

| 2.5 mm | Suitable for working with carbon steel and stainless steel. Used for surfacing metal, with low consumption. Moderate sensitivity to rust and severe sensitivity to dirt. It is better not to use it for DC welding. |

| 3 mm | They are distinguished by increased viscosity. Suitable for working on pipelines and various metal structures. |

| 4 mm | This diameter allows you to perform work of increased complexity. Consumption when surfacing metal is within normal limits. Often used for work on pipelines. Not for use with AC voltage. Sensitive to rust. Impact strength approximately 77 J. |

| 5 mm | Excellent for metal surfacing. Not suitable for short arc welding. Maximum tilt angle 75 degrees. Moderate consumption. |

How to cook cast iron, instructions

Cast iron. Welding should begin with deposition of the first cladding layers in the groove. Further, it is possible to continue welding with OK 46.00 electrodes.

The cladding layers are fused with special electrodes of the TsCh-4 brand. In order to reduce material costs, it is possible to use a homemade copper-iron electrode. It is made from a cheap steel electrode (for example: UONI 13/45, ANO-4, etc.). To do this, a spiral of copper wire (note: you cannot use brass wire - when heated, toxic zinc and its oxide will be actively released into the air) with a diameter of 1.5...2 mm. The amount of copper wire should be calculated in such a way that the mass of copper is 4...5 times greater than the mass of the steel rod. It is allowed not to wind copper wire, but to use it as a filler rod. The resulting seam will be of acceptable quality.

Manufacturers/brands: ESAB, LEZ, Penzaelectrod (PE), Goodel and others, where they are produced

The production of electrodes of the OK 46.00 brand is carried out by the Swedish concern ESAB. Many companies produce analogues of Swedish products, for example:

- GOODEL-OK 46 – for welding critical structures made of carbon and low-alloy steels with a tensile strength of at least 490 MPa. Used for tack welds, short and root seams, and when welding wide gaps. Manufacturer: GOODEL plant, Shadrinsk.

- LEZ 46.00 are intended for manual arc welding of ordinary critical structures made of carbon steel, when increased demands are placed on the formation of seams in various spatial positions. Manufacturer: Losinoostrovsky Electrode Plant, Moscow.

- PE OK 46.00 – rutile electrodes are intended for manual arc welding of structures made of carbon steel (with carbon content up to 0.22%) in all spatial positions. Manufacturer: Penzaelectrod, Penza.

- SZSM-46.00 are intended for welding carbon and low-alloy structural steels of the pearlitic class with a minimum yield strength of no more than 360 MPa. Manufacturer: Sudislavsky Welding Materials Plant, Kostroma Region.

E46A, technical specifications

E46A provide a weld with increased ductility and toughness due to a decrease in the proportion of sulfur and phosphorus in the rod (S and P in the range of 0.04–0.045%). Designed to operate under variable loads, including dynamic and low temperatures. Low-alloy steels with a carbon content of up to 2%, such as 15HSND, 14G2, are welded. Heat loads above 2000 are not desirable.

Analogs similar in weld quality: OMNIA-46, OK 48.00, OK Femax 38.95, Pipeweld 6010. Type E46A includes the following brands:

- With cellulose-rutile coating – SE-46-00, SZSM 46.00;

- With the main coating of the rod and the creation of an alkaline environment in the weld pool (neutralization of hydrogen against cracking) - ANO-8, UONI-13/45A, UONI-13/55K;

- With the inclusion of iron powder VN48U and ITS-1.

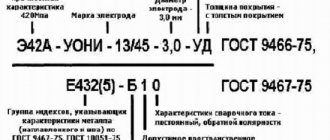

The decoding of the alphanumeric indication informs about the basic technical data in accordance with GOST 9467-75:

- E – electrode with external coating for manual electric arc welding;

- 46 – value of temporary tensile strength in kg per mm2;

- A – ductility and impact strength are designed for variable loads.

Welding process requirements include holding a short arc as a measure to eliminate porosity and lack of fusion . Calcination of electrodes for an hour at 3000 C before use.

Preference is given to direct current of reverse polarity. The requirements for surface cleanliness, especially regarding scale and rust, are high. Increasing the concentration of iron powder in the coating reduces the carbon content of the surfacing and the tendency to cracking.