How to use a hydraulic jack

For competent and non-traumatic lifting of loads, it is convenient to use a jack. How to use the hydraulic lifting device is described below (using the example of cars or trucks). First of all, you should find out whether the lifting capacity of the existing hydraulic device matches the weight of the car being lifted.

Another important parameter is the pick-up height. Please note that for low-slung cars (for example, Porsche and Lamborghini), you need to select a jack with a minimum lifting height of 65 mm. The purposes for which you intend to lift the car are also taken into account: to replace a wheel, a lower lifting height is sufficient than to repair a car.

The trunk of most vehicles has a special compartment for a jack. To access it in a passenger car, you just need to lift the tool compartment lid located in the luggage compartment.

How to install a hydraulic jack

When might you need a jack? Car enthusiasts take it with them so that they can repair a car that suddenly breaks down by lifting it. In most cases, the device becomes useful when you need to change a tire.

How to lift

Now let's figure out how to jack up a car if the device is successfully installed under the car body? First, make a few smooth movements of the jack handle up and down to raise the car a little. After this, you must check whether the device itself or the car is tilted to the side. When lifting the car using a rolling jack, remember that while lifting the plunger, the device must simultaneously gradually roll under the bottom of the car.

When you are sure that everything is firmly and level, lift the machine to the desired height. Since working with a machine that is on a jack is strictly not recommended, place the body on supports and remove the hydraulic device.

If you have a pneumohydraulic type of jack, in addition to the working fluid, it must also contain compressed air, the supply of which must be properly organized. In this case, additional equipment is used - a compressor. It is recommended to isolate the air suction valve from dust and small foreign bodies.

How to lower a hydraulic jack

The information below will show you how to lower a hydraulic jack. If all previous steps were carried out according to safety rules and the blocks were placed under the car, you should start from the first step and take a jack. Raise the hydraulic device to a height that will allow you to remove the safety chocks or other supports used to support a part of the machine.

To safely lower the jack piston after removing the stands, you must turn the bypass valve. This screw is easy to recognize: it has a round head with protruding shoulders (similar to a kind of crane), and the lifting lever has a corresponding socket at the end, designed for unscrewing it. When the screw is loosened, the device will lower without much effort.

A hydraulic jack's shut-off valve is a valve that, when closed, pumps oil into the piston. For any other hydraulic jacking mechanism, you need to find a shut-off valve to lower it. To return the jacking mechanism to its original state, you need to open this valve.

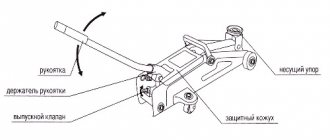

Rolling jack device

Which car jack is better?

The operating principle of a rolling hydraulic jack is based on a hydraulic drive. That is, the use of a working fluid (oil) that transmits force from the regulating body to the executive body. In this case, the regulating body is a handle with a system of gearboxes, valves and cylinders, in which the operator’s force is accumulated and transmitted to the executive body - the rod.

The system is based on the use of communicating chambers and shut-off valves. Based on the principle of hydraulic accumulators, they repeatedly enhance the initial movement, thanks to which the jack can lift loads of 2-3 tons or more (depending on the specific model). However, during operation it is necessary to monitor the serviceability of the shut-off valve and rubber sealing rings (gaskets). The normal operation of the jack, as well as the absence of oil leakage, depend on their integrity. But we will talk about this in the section on repairing hydraulic rolling jacks.

Jack design

The design also provides for the presence of additional devices that facilitate its operation and reliability. One of these is the locking dog, thanks to which the weight is held at the required height.

Safety precautions

When installing a jack-lift, using it and removing it from under the hood of a car, you should adhere to simple safety rules, and also take into account the nuances of using each specific type of lifting device.

For a car enthusiast who cares about the durability of his jack and proper repair (wheel replacement) of his car, it is important to monitor the safety of the hydraulic lifting device. To do this, it is enough to use the jack carefully, lifting the car not jerkily, but gradually. Also, do not allow the device to become dirty, which could lead to a decrease in the performance of the jack. Always keep the device clean before, during and after use.

Source

Ways to jack up a car correctly

Every driver who frequently travels not only on the highway, but also around the city, is familiar with the situation - a flat tire. Very lucky are those owners whose “four-wheeled” friends are equipped with a “spare wheel” and other tools for changing a wheel: the first place of which is a jack. After all, without it, even if you have a spare tire, you certainly won’t be able to replace it right on the road!

Recommendations for using a jack.

What is a jack

This is a unit that is used during scheduled repair work, as well as when unforeseen situations arise: getting out of a hole or mud, replacing a wheel, etc. Car owners who often have to drive off-road do not allow themselves to move without this assistant. And in general, it is recommended for absolutely everyone to carry a jack with them in order to get out of an unexpected unpleasant situation “unscathed” as quickly as possible. Otherwise, you will have to call a tow truck, whose services will not be cheap. Of course, the jack, as well as the spare tire, are helpers in solving many problems. BUT! Agree, if you don’t know how to use it, you will not only not achieve the desired results, but will damage your car even more (for example, by bending the sills, etc.). And in the worst case, improper lifting can threaten to cause certain (and not always minor) injuries to the car owner.

How does a rolling jack work?

The entire operation of the mechanism is based on the movement of a special handle. The rolling hydraulic jack itself is rolled under the car. After this, the working body is activated. The drive creates a certain pressure in the cylinder, due to which the car is lifted. The main work is done by the plunger and direct valve.

If you need to slightly reduce the pressure in the system, you can turn the knob. As a result, the check valve opens, which releases air from the system.

A vehicle or other device that was being lifted is lowered. There are also alternative models of mechanisms. In them, the relief check valve is located directly next to the handle. In order to relieve excess pressure, you simply need to install the handle on it, having first removed it from its place.

This is exactly how a hydraulic rolling jack works. Its design is simple and original. This is why such mechanisms are chosen.

Advantages and disadvantages

There are many different positive features of such a system. The main advantage is that the hydraulic rolling jack has a fairly low landing. This allows you to work even with low-slung vehicles. Therefore, they are used mainly in car services, where different clients may be present.

It is rational to use it in places where tire fitting is constantly carried out. Installing such a rolling jack under a car will take much less time than installing a vertical model.

Moreover, it operates on wheels, which makes the rolling process even easier. This is especially typical for large tire shops, where a large number of people work and there is a constant flow of customers.

The car service worker does not need to bend over again to roll the jack under the car or pull it out. All these manipulations are done using a comfortable and long handle.

Of course, such devices also have disadvantages. The specificity of working with them is such that you have to use an exclusively flat and even surface to lift loads. It is not possible to find one in all situations on the road.

They are convenient to use on a flat concrete floor in a car service center or garage, but not to be carried around in the trunk. This is probably why many motorists prefer vertical structures that can be installed anywhere without any problems. Don't forget about the dimensions of this equipment.

It can only be placed in a fairly spacious trunk. A small car is not made for it. Once again, it is worth emphasizing that such jacks are mainly created for professional car services and tire shops. Only here can they be fully used.

Jack installation

How effective, easy to use, and reliable your future jack will be must be determined before purchasing it! It is important, first of all, to pay attention to its maximum load capacity - this value should not be lower than the weight of the car. For example, if the weight of the TK is 800 kilograms, it is best to give preference to a device that can raise at least one tone.

Important! If your four-wheeled friend weighs more than the jack can lift, then we strongly recommend NOT using it. Such actions lead to overload, which ultimately leads to damage to the vehicle.

In addition, a car that falls off the supports can not only damage the car, but also harm your health (at a minimum, cause bodily injury).

How to properly install a jack.

First of all, the jack must be placed on a flat, hard surface. In no case should you jack it up on sand, gravel or crushed stone, as on this surface the jack will probably go a couple of centimeters below, or even to the side. Try driving on a flat tire to a hard surface, at a distance of 100-200 meters, and if you don’t drive fast, nothing will happen to your tires and wheel. If this is not possible, then place a board under the jack that will withstand the load of the car. If all of the above fails, it is better to call a mobile tire service, since your car will probably come off the jack and bend the stiffener and the paint layer of the car.

The jack must also be installed exactly perpendicular to the car. When changing the radius of the jack, it may bend under the pressure of the car, which will lead to the car falling. As you already understand, even at the initial stage you need to follow quite a few rules, since failure to comply with them can lead to unnecessary repair costs for both the car and the jack.

Tips from the professionals

Yes, of course, your main tasks are to choose the right place, as well as to install the jack efficiently (of proper quality). But! Do not be too confident in yourself; before performing these operations, carefully check the reliability of the jack, and also make sure how well your “four-wheeled” friend is fixed. Well, now you know that you shouldn’t be too careless with such “everyday” things as a jack. Yes, we wish that you don’t need it, but we nevertheless recommend that you always have it at hand in case “if something happens.”

Source

Review of popular models of hydraulic rolling jacks

We list several popular rolling jacks in our country. Both imported and domestic.

| Name | Minimum height, mm | Maximum height, mm | Load capacity, tons | Note |

| Nordberg N3203 | 133 | 465 | 3 | Distributed to domestic service stations |

| “Bison Master” | 135 | 385 | 2,1 | Missing rubber heel |

| “Matrix 510335” | 130 | 410 | 3 | Overload protection available |

| Ombra OHT203 | 192 | 533 | 3 | An original repair kit is included with purchase. |

| Airline AJ-3F-390P | 135 | 390 | 3 | Weight - 13 kg |

| "Stealth" | 100 | 350 | 2 | Weight - 12 kg |

| “Sorokin 3.520” | 125 | 300 | 2 | Weight - 6.5 kg |

| Biloxxi GTJ2004 | 130 | 336 | 2 | Good value for money |

| Forsage TH22501CB | 140 | 387 | 2,5 | There are three fixed levels at a height of 222, 285, 340 mm |

| “Ermak” | 135 | 385 | 2 | A very popular jack among car enthusiasts |

The choice must be made based on its technical characteristics. You should not buy a jack that is too cheap, but you should not overpay either. It is better to buy a mechanism from the middle price category. However, if you need it for professional work (for example, at a service station), then it is better to buy a professional rolling jack, the price of which will be slightly higher than that of conventional garage analogues.

Lifting a car with a jack, rules for installing a jack

The effectiveness and efficiency of the jack must be determined at the stage of purchasing this device.

An important indicator when choosing is the carrying capacity of the models under consideration. It is important that this value is not less than the total weight of the vehicle.

So, for a car that weighs 800 kilograms, it is advisable to place a device with a carrying capacity of 1 ton in the trunk.

However, you should not try to lift a larger vehicle with such a jack, since overloading will lead to breakdown of the lifting unit and, therefore, will cause damage to the vehicle.

Moreover, a car falling from its support can pose a significant threat to the health and life of a person who is close to it.

Rules for lifting a car on a jack and safety precautions:

Places for installing a jack

When removing and installing a wheel on a car, there is always a need to use a jack or other lifting mechanism, which can be equipped at a service station or tire shop. When installing a spare tire or changing wheels for the season, the motorist himself is often faced with the need to use a jack. When replacing a wheel yourself, you usually use a screw, hydraulic or rack jack, which is usually included in the set of necessary tools supplied with the car. In tire shops or service stations, hydraulic rolling or pneumatic jacks are usually used; specialized lifting stands and hydraulic mechanisms equipped with an automated control system are often found.

When using a jack in case of changing a wheel yourself, you must clearly determine the location for its installation. Usually, the places for installing the jack are marked in the illustration in the technical documentation for the vehicle, but in the absence of such documentation, you can determine them yourself without much difficulty.

For example, on most domestically produced cars, this place is a small area on the threshold, located in close proximity to the wheel and, as a rule, reinforced with a metal profile or plate. On foreign-made cars (Japanese, French, American, etc.), this place is marked with special recesses; in addition, on many foreign luxury cars (in Russia these are mainly German cars), the place for installing the jack is indicated by arrows or triangles and has a special rubber cushion that protects the threshold from possible damage.

In the case when the threshold of the car is rotten or deformed, as well as when it is necessary to lift two wheels at once (which is quite often used in tire shops when changing tires seasonally), it is permissible to install a jack under another load-bearing part of the body, which may be the lever support, the end part shock absorber struts, gearbox (on jeeps and gazelles), beam, load-bearing part of the bottom, etc.

When installing a jack under heavy cars such as Jeep, UAZ, Gazelle, as well as under some crossovers and station wagons (and sometimes sedans of some brands), you should carefully inspect the front and rear of the car under the bottom in order to detect a load-bearing support or beam , having a designated area for mating with the jack cup. In this case, two front or rear wheels will be lifted at once. In no case should a jack be installed under the sill on heavy vehicles, as this will inevitably lead to its deformation.

Rolling jack operating principle

A rolling jack is classified as a hydraulic jack, but has a slightly different design. Two pairs of wheels are installed on its body, made of metal. A lifting mechanism and a hydraulic cylinder are mounted in the holes located on it, which, when extended in the horizontal direction, lifts the platform. The device itself gradually lifts the car to the desired height, while it rolls under it.

The jack is set in motion by swinging the lever, and lowered by turning the valve screw. During the process of lowering the load, a tubular handle is mounted on the valve screw, and after that the partition fits into its groove. When the handle rotates around its axis, the screw itself rotates accordingly. In this case, the pressure in the working cylinder is released, and the load is lowered to the desired height.

In order for the jack to serve for a long time, it is necessary to monitor the presence of oil in it and the condition of the oil seal and valves.

There are rolling hydraulic jacks used for personal purposes for vehicles weighing up to 3000 kg. Most often, such a device, equipped with pedals necessary for preliminary lifting, is used in car services and tire stations. It can lift loads up to 4000 kg, doing the job quite quickly.

The jacks, which lift loads of up to 20 tons and are equipped with pre-lift pedals, as well as a sliding crossbar, are intended to serve heavy vehicles and special vehicles. This mechanism also has its drawbacks, which include its bulky size and heavy weight, which make it difficult to move it in a car. For its operation, a flat horizontal surface, such as asphalt or concrete, is required.

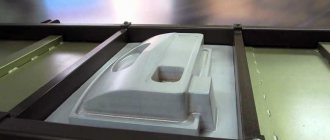

Installing a jack on a Hyundai Creta

But it happens that you lift the car not on a jack, but on a lift. Unfortunately, not all craftsmen install the lift legs correctly, which leads to bending of the thresholds. To prevent this from happening, it is recommended to install the paws in special places on the Hyundai Creta thresholds. These places are reinforced, which prevents them from bending when the car is lifted. The diagram below shows a schematic representation of the installation location of the jack on a Hyundai Creta:

That's all. I hope this article will be useful to you and, after reading it, you will correctly install the Hyundai Creta jack in place and not damage the sills when lifting the car. See you again on our website.

Where to put the jack on the Hyundai Creta?

When using a jack for the first time, many owners have a completely reasonable question: “Where to put the jack on the Hyundai Creta?” You won’t see standard jacks on the Creta, since they simply aren’t there. Or rather, they practically do not stand out.

But if you pay attention to the persistent part of the jack itself, you will immediately understand where to place the jack on the Hyundai Creta. On the thrust part of the jack there is a special groove for the threshold flange.

The photo below shows the places for the Hyundai Hreta jack:

To prevent the thresholds from bending due to the standard diamond jack, install the jack exactly as shown in the photo above. Otherwise, you may bend the sills when lifting the car.

Each type of jack has its own approach!

Above we have listed general rules that are important to follow when using all rolling jacks, but there are some features of using the equipment depending on the type of its drive. It can be hydraulic or pneumohydraulic . The first operates the lifting mechanism by creating oil pressure in the piston; the second, in addition to oil pressure, uses the force of compressed air to create the movement of the plunger and lift a heavy load. Hydraulic rolling jacks, as a rule, have a small load capacity, up to 3-4 tons, and those that operate on compressed air - up to 10 tons, which makes it possible to service freight vehicles with their help.

The algorithm for using a hydraulic rolling jack is as follows: first, tighten the bypass valve, then install the device under the car so that the hydraulic cylinder with the lifting platform fits exactly under the standard pick-up point, and begin to press the lever. For greater lifting speed, it is better to use the full stroke of the lever. Simultaneously with the lifting of the plunger, the jack rolls under the car, creating reliable support during lifting. After installing the safety stand, the jack can be removed. Upon completion of servicing the vehicle, the jack is rolled under the vehicle again, the hydraulic cylinder is again raised to the desired height when the user presses the handle, and the safety stand is removed. The load is lowered when the shut-off valve opens.

When working with a pneumatic-hydraulic jack , you need to organize a compressed air supply system from the compressor, ensure cleaning from dust, moisture and oil by integrating additional equipment into the system - a moisture separator, a device for draining condensate, and also using a lubricator. It is also very important to monitor the air pressure in the system. For example, the SOROKIN 3.650 jack has a permissible operating pressure of 7.5 - 8.5 atm. This means that the compressor air pressure parameter must be no less than this value. To do this, a pressure regulator must be installed at the outlet of the compressor. The jack is connected to the compressed air supply system with a hose, after which the air valve is opened by turning the flywheel on the handle - the lifting of the load begins. The valve closes when the desired lift height is reached. To lower the load, the handwheel that controls the opening/closing of the air valve must be turned counterclockwise to the minimum air supply position. Of course, the preparatory work before using such a jack requires a little more time compared to a hydraulic one, but you can lift heavier vehicles without much effort: buses, trucks, special equipment.