Introduction

The crisis forces us to look at old processes with new eyes. Somewhere sawmills are closing, and somewhere, on the contrary, they decide to open a sawmill. As a rule, private owners have recently opened sawmills; their costs are lower and efficiency is higher. Here you don’t need a business plan for a sawmill, but if it comes in handy, come here!

Sometimes the word “open” is too strong. They simply set up a sawmill for use at home, for example to build a house, or, in extreme cases, to cut a log for a neighbor. This is the case we are considering.

When opening your own sawmill, there are several options on how best to do this:

- Buy inexpensive equipment;

- Do it yourself.

Again, to build a house and get 3 - 5 cubic meters of boards, buying a sawmill for 50 - 150 thousand is just some kind of waste. After all, our boards will cost several times less: 18 - 30 thousand rubles.

There is a way out, make a sawmill from a chainsaw. This will not take you much time if you have hands that grow from the right place. In addition, it will serve you faithfully for a long time, because having your own sawmill is a fairly profitable business today.

My services:

I offer a range of services for starting up equipment, sourcing and selling your equipment. I will help you calculate a business plan for sawmill production. More details about my services can be found in the “SERVICES” section.

I also have an excellent book on sawmilling. It is designed for large sawmills, but will also be useful for private owners in small sawmills. More details about it in the “MY BOOKS” section.

Good luck and see you again, Andrey Noak was with you!

When it is necessary to process a large number of boards and wood, it is best to use a self-made sawmill. Many people believe that it is best to purchase a ready-made unit, but making it yourself will not be difficult. The main thing is to decide what the volume of work ahead will be, as well as the wood, after which you need to choose the type of sawmill to successfully complete the task.

When assembling the unit with your own hands, special attention should be paid to safety issues , because such a device is considered a high-risk object. The manufacture of various types of sawmills is presented further in the video.

What do we need?

- Welding machine, electrodes;

- Lumber, posts, screws, nails;

- Chainsaw, electric saw or just an electric motor;

- Extended tires with chains, if you cut wood with large diameters, more on that below;

- Material for making the case, preferably a corner, as it is quite resistant to vibrations;

- Rollers and guides;

- Cord, clothesline or cable for moving the saw while sawing;

- Roller bearings.

What material should I choose to make the case? Metal is certainly considered generally accepted. It withstands the weight of logs well and is resistant to changes in humidity.

Another cheaper and more economical option for using wood can be considered as a material. With high-quality fastening with screws and self-tapping screws, the wood will easily withstand the load from thin wood.

What needs to be provided?

Before making, you need to pay attention to the following things:

- The diameter of the logs being cut, if there are large diameters, then you need a more powerful saw, a longer bar with chain;

- Loading heavy logs for sawing, for this it is necessary to provide some kind of mechanism, or they can be rolled up either by additional jacks or, ideally, by a loader;

- The log must be fixed so that it does not play during sawing and the boards are even;

- The chainsaw guide and sled should not play, so they need to be strengthened;

- The more powerful the saw, the easier production will be. Therefore, when purchasing a saw, you need to take the most powerful one;

- Using electricity as an energy source allows you to save a lot;

- Do not forget that the chain must be for longitudinal sawing, this will significantly increase the speed of the process. Experts recommend using a 3*8 chain.

- It is advisable to buy a carbide chain. This is what he is doing today. Conventional circuits fail quite quickly;

- The length of the logs to be cut must take into account the maximum and minimum. So that the longest ones fit in, and the shortest ones don’t fall between the guides;

- Calculate in such a way that the saw does not vibrate or play on the guides during operation;

- The power of the saw, in some cases you want it to be both more powerful and more economical. In this case, folk craftsmen do the following. Instead of a chainsaw, an electric motor is installed, and the tire is left for sawing, see photo below;

- The height of the sawmill. It is necessary to provide in such a way that the back does not hurt to bend over and the logs do not need to be lifted high. If the wood is not heavy, it is better to make it higher. If the forest is heavy, you can go lower.

- Sawing of wood can be carried out either by the upper part of the tire or by the lower part. When sawing with the lower part, sawdust flies towards the chainsaw and clogs it. The upper part throws out sawdust from the chainsaw, this allows you to increase both the service life of the saw and the downtime during sawing;

- During the sawing process, the chain very often stretches on the saw and needs tensioning. Therefore, when installing the saw, it is necessary to provide access to the chain tension and secure the saw with access to the mechanism;

- When sawing, it is better to fix the position of the chainsaw handle, this simplifies the process;

- The cable, clothesline or lace should not drag, since the sawing process should be uniform over time.

Step-by-step manufacturing process

So, our process will go as follows:

- We draw drawings based on the materials you have;

- Making the frame. To do this, we weld a corner or pipe into a frame;

- Making sleds. It can be made from a wooden board with the area of movement of the slide covered with a stainless sheet or galvanized. The second option is from the corner where the rollers will roll. The third option is from rails. Options are presented as the load on the sawmill increases;

The sled is made of 50 mm boards. The board is galvanized for less abrasion. A profile (square) pipe without a fourth wall rides on the slide.

- The next step is the mechanism for adjusting the thickness of the board. There are two options here. The first is like in the Logosol sawmill, the log is raised, and the cutting part is motionless. This option is more suitable for sawing small logs, so as not to bend over and hurt your back, and to make sawing faster. To use this method, ordinary mechanical jacks are well suited; you need to ensure that their lifting height is as high as possible. The second option is when the log is motionless, and the saw lowers and rises along the ruler. Which option you will implement needs to be thought out at the stage of creating drawings;

- Chainsaw mount. Checking the structure for strength. Elimination of backlashes;

- Making a mechanism for uniform advancement of a saw from a cable, clothesline or lace:

- Commissioning and modification.

Homemade band sawmill

Let’s make a reservation right away – making a band sawmill yourself is very difficult.

It’s not so much about the components, extensive turning and welding work, the need to sharpen and route the saw in a special way, but about the well-functioning performance of the entire complex. It is necessary to ensure loading and stability of movement of up to 300 kg of one log, adjustment of cutting thickness, and most importantly, safety precautions. But if the availability of free wood wins, we make a band sawmill with our own hands.

Let us explain the principle of tape cutting with an example: take two spools of thread, stretch a threaded thin tape between them. By forcibly rotating the tape, we cut the log, the distance between the tapes is the maximum size of the beam. Band saws are convenient for cutting boards.

We start with choosing a production area or premises - at least 3x6 m, verified. The second most important thing is the metal wheels of the cart and band saw, this must be found or purchased. Order the frame of the belt mechanism with wheels, or it is better to buy a ready-made one. Self-production requires skills and a lot of high-precision tooling.

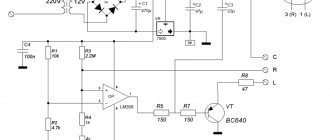

View 1 : 1 - stand; 2 - roller; 3 - plate; 4 - screw; 5 - chain; 6 — guide lug; 7 — movable comb; 8 - screw; 9 - fixed comb; 10 - remote control. Type 2 : 1 - pulley for starting the engine (if a three-phase motor is connected to a single-phase network); 2 - engine; 3 - pulley; 4 - shaft; 5 — housing with bearing; 6 - base; 7 - flywheel; 8 - finger; 9 — connecting rod; 10 - saw; 11 — M14x2 screw; 12 — roller; 13 — guide angle; 14 - stand; 15 — steering wheel; 16 — bushing; 17 — asterisk; 18 — nut M14x2; 19 — lock nut; 20 is an asterisk.

We install guides - any strong, flat metal: I-beam, channel, corner, under them, after 0.5 m, supports or anchors for stability. The distance between the guides is the diameter of the largest log with a margin of about 0.7 m. Maintaining the geometry, we weld everything together. We attach wheels, a belt mechanism frame, and an electric motor through a pulley to the cart.

Consider a mechanism for changing the horizontal movement of the saw relative to the log. Moving the cart relative to the fixed log, we cut off a horizontal layer of wood - we make boards.

Homemade sawmill is a great alternative

There are a large number of different sawmills based on chainsaws on the World Wide Web and, as a rule, they have a similar basis. What they all have in common is a movable cutting element, which is fixed in the trolley. The trolley moves along pre-laid rails.

The cutting part, for example, from the Druzhba chainsaw, due to its excellent performance characteristics, can effectively cope with the task of sawing round timber. If large volumes of work are planned, you can install an even more powerful Ural chain saw.

Advantages of domestic chainsaws - one of the few Soviet brands that have gained worldwide fame and recognition. Back in 1958, at the EXPO World Exhibition, the saw received a “Gold Medal”.

And, although there is an opinion among buyers that this model has long been obsolete, the Druzhba-4 unit is still relevant for use as the main cutting part of a home sawmill due to the fact that:

- Body parts are made of high quality aluminum alloy;

- The model is characterized by high performance;

- Availability of mechanical chain brake;

- Exceptional engine reliability.

The Ural chainsaw inherited reliability and quality from the legendary Druzhba. Modern models of the Perm plant are in stable demand among buyers.

- Household saws have a simplified design (easy to use without proper experience);

- The Ural chainsaw has a higher power rating (5 horsepower, while the Druzhba has only 4);

- Easy to repair.

Homemade equipment

A homemade tire sawmill is a unit that cuts wood with a chain attached to a tire. Therefore, in many sources such an installation is called a homemade chain sawmill.

The sawing process occurs as a result of engine operation. The engine itself can be either gasoline (diesel) or electric. The main positive factor of installing a chainsaw on a frame is that the saw can be removed at any time and used for its original purpose.

Sketches and drawings

In order for a home sawing unit to work without failures, it must be assembled using only high-quality, understandable drawings. This is necessary primarily from a safety point of view, so that in the future the installed equipment does not cause any problems during operation and does not pose a threat to the health of the owner.

It’s easy to find drawings and dimensions on the Internet, then print or draw them. It is important that the sawmill assembly plan contains the main elements:

- Rails;

- Base fixing plan;

- A mobile structure and a chainsaw attached to it.

In addition, it is imperative to provide clamps for logs. When assembling the sawmill, it is necessary to constantly monitor the levels, and upon completion of installation, check the stability of all equipment.

The nuances of installing a sawmill

There are usually no difficulties with choosing a location for a sawmill. Here everything is at the discretion of the owner, depending on the goals and objectives assigned to the homemade equipment. It is not necessary to use an empty barn or garage for a sawmill; perhaps it is quite enough to build a simple shed somewhere in the utility yard.

Installation of the base can be carried out on a prepared concrete floor, but in any case, fastening elements will be required: anchor bolts, foundation reinforcement, welding, etc. Then rails are laid along the base, which are installed using side fastenings.

Movable element of a homemade sawmill

The moving element is a regular frame, which must move along the rail route forward and in the opposite direction. Typically the element should be on rollers that are attached to the frame. The roller system itself must be secured to the skids.

The moving element also serves as a supporting part on which the chainsaw is mounted. There are also special clamping parts - fasteners that hold the chainsaw on itself. There are many mounting options: from clamps to homemade clamps. Alternatively, look for fasteners in specialized hardware stores or on the market.

Trial run of the sawmill

When a homemade sawmill from a chainsaw has already been constructed, it is necessary to carry out a test run. First you need to carefully study the design and make sure it is ready for work. Then install the workpiece (log), check it on the clamps and make sure it is strong. Next, you need to secure the chainsaw to the moving element with fasteners. It must be checked in advance for serviceability and readiness for work.

Then you should carry out a test run of a homemade sawmill. You need to start the chainsaw and slowly, carefully bring it to the log, gently pushing the frame. Do not make sudden jerks so that the saw bar does not get stuck in the cut. The main thing is to do everything slowly and follow safety precautions.

The most primitive sawmill

There are situations when it is necessary to cut a small number of boards from a log, and the owner has no other tool other than a low-power chainsaw, for example a Stihl MS 180.

To begin with, if the tree is thicker than the length of the tire, you need to saw off the slab. To make the cut more or less even, you need to make a corner from 2 boards and use it as a guide.

By pressing the cover to which the tire is attached to the board, it will not be difficult to make an even cut. Then you can reconfigure the manufactured guide to a vertical cut and fix it with self-tapping screws.

Note! To make cutting as easy and efficient as possible, it is necessary to sharpen the chain so that the sharpening angle is in the region of 10 - 15° instead of 30°, which is used for a conventional cross-cut.

Depending on the height of fixation of the guide from the top of the log, you can obtain boards of the required thickness. It can be difficult for one person to correctly set and fix the guide, so it is better to use a support.

Then, when two slabs have been sawed off and removed from the workpiece, subsequent cuts will produce quite good boards. Considering that the saw is not a professional one, you need to periodically let the tool cool down.

Results

A chainsaw is a universal tool that, if you have the skill and talent, can be used not only for its intended purpose, but also to build your own effective structure in the form of a home sawmill. And as a result, save a decent amount on building materials.

Homemade circular sawmill

Disc sawmills have received the greatest handicraft use due to their versatility and ease of manufacture. We will make a circular sawmill with our own hands. The most important thing is that we will need a circular saw - a disc larger than 500 mm (the larger the better). The propulsion device is usually an electric motor through a pulley that increases the speed.

1 — main sleeper (steel pipe 80x80x3, 5 pcs); 2 — lining (steel sheet, 40x10x1.22 pcs.); 3 — guide blade (steel channel No. 8, L1750, 4 pcs.); 4 - trolley (telpher carriage); 5 — bottom bracket (steel channel No. 18, 2 pcs); 6 - plate - base (stylish sheet s5); 7 — M20 bolt) (4 pcs.); 8 — Grover washer (4 pcs.); 9 — nut M20 (4 pcs.); 10 — three-phase asynchronous electric motor (220 V, 5 kW, 930 rpm); 11 — upper bracket (steel angle 45×45); 12 — circular saw blade; 13 — protective casing (steel sheet s2); 14 — steel pin (8 pcs.); 15 — circular saw hub (St5); 16 — thrust handle (water and gas pipe 3/4″); 17 — cut-off slab; 18 — thrust gusset (steel sheet s5); 19 — comb (steel angle 45×45, L400); 20 - log; 21 — M30 bolt; 22- split washer; 23 — retaining washer (steel sheet sЗ); 24 — thrust crossbar (steel angle 45×45); 25 — shortened sleeper (steel pipe 80x40x3, 6 pcs.); 26 — overlay for lengthening the blade (steel sheet 250x180x10, 2 pcs.).

Advantages of homemade equipment

Factory-made gas sawmills are distinguished by their reliability, ease of operation and versatility of use. Unfortunately, they come at a high cost, which is often unaffordable for most homeowners. At the same time, you can make a functional sawmill with your own hands, and the costs of implementing such equipment will be minimal.

It is possible to select the desired modification of woodworking equipment, which in its functionality will fully meet the requirements of the homeowner. These can be either simple options that only involve cutting logs, or multifunctional installations that can not only provide high-quality even cutting, but also subsequent processing of lumber.

Tire sawmill

We need to start by understanding what and how much we will cut. If you need to cut 100 - 200 rafters for a house being built from free logs, then 400 boards, it is better to use a hand-held professional chainsaw. Let's make a homemade sawmill from a chainsaw, an inexpensive, simple and effective method.

drawing of a simple sawmill using a chainsaw (download full drawing)

You will need any smooth metal profile, welding and a grinder. We start with the maximum length of the log - practically about 4 m. For this length you need to find a channel or I-beam, you can weld it from pieces with reinforcement - the main thing is that the resulting profile is even. We are starting to make our autonomous sawmill based on a chainsaw.

The design is a powerful profile at a working height - above the waist, along which a fixed chainsaw moves in a cart.

The height is determined by ergonomics; a prolonged knee-elbow position is not useful. A log is placed parallel to the main profile on a support frame, a running chainsaw moves along the log and makes the necessary trimming.

A few more details about the features. The main element is the main profile, which ensures the geometrically correct dimensions of the lumber, must be sufficiently strong and rigid, if the channel is at least 200. The profile rests on 3 or more supports connected to the support frame on which the log rests.

If you decide to make a chain sawmill with your own hands, be sure to look at the LOGOSOL sawmills. Drawings and documentation can be downloaded from the website and used as the basis for your homemade project.

The main errors during sawing are formed when the trolley with the chainsaw oscillates, so the trolley moves along the profile using at least four rigidly pressed metal wheels; it is necessary to provide a manual drive. The simplest is a well crank with a drive wheel along the main profile.

To install a heavy log, slopes are usually installed along which it is convenient to push the log successively from side to side onto the support frame, wedging it on the frame.

The most difficult thing is the adjustment mechanism for the thickness of the product. The simplest method is to install screw or any rigidly fixed jacks along the edges of a support frame movable in a vertical plane. We adjust the jacks - we adjust the thickness of the product. An example of the construction of a mobile tire sawmill based on a chainsaw can be seen in the photo.

Cutting wood can be done by one person: holding the chainsaw handle and adjusting the gas, we feed with the other hand.

Conclusion

A few thoughts on the feasibility of making a sawmill. Tested by time and practice - self-production makes sense with free materials. If you calculate the labor costs and materials, and the possible benefits, you will understand for yourself. The worst thing about making it yourself is that few people pay attention to safety precautions. This moment definitely needs to be thought through! Trouble-free operation and high-quality wood.

Do-it-yourself band sawmill using a chainsaw

In addition to the classic method of cutting logs using the sawing element of a chainsaw, there is another mechanism. The motor is used only as a drive, and the workpiece is cut with a band saw.

Band sawmills have long been used in sawmills. Their advantage is a high quality cut (compared to a chainsaw) and a smaller cutting thickness. On a thick log, wood savings can reach 10 cm in thickness. And this is a couple of full boards. Therefore, homemade workers often use this particular design.

Read also: Mtz decoding in electrical

The principle of operation is the same as on a chainsaw sawmill with a movable carriage mounted on stationary rails. Only two automobile wheels are added, one of which is supplied with a chain or belt drive from the power plant. The band saw is pulled between the wheels and the autonomous cutting device is ready.

All presented designs have undergone many years of testing in home and commercial sawmills.

Watch the video: do-it-yourself sawmill using a chainsaw. For home use, if you really need to cut a log into planks, the most suitable option is a frame made of square pipes and a not-so-powerful Partner chainsaw.

Hello dear readers and blog subscribers, Andrey Noak is in touch! Today I will tell you how to make a sawmill from a chainsaw with your own hands with drawings and photos.

Operating principle, advantages and disadvantages

The operating principle of a sawmill made from a portable chainsaw is very simple. The saw is firmly attached to any surface, and then boards, beams or logs are “driven” through it. In this case, instead of a sawmill disk, a chainsaw chain acts.

Here are the main advantages of this homemade design:

- Possibility to mount anywhere. A sawmill from a chainsaw can be assembled absolutely anywhere: at a construction site, on a personal plot, or even at a logging site in the field.

- Easy to assemble. For installation, you only need a chainsaw and materials that are on hand.

And the main drawback is that the device’s power is not very high. When cutting long boards from a thick log, it can work unstably and get stuck.

Depending on the ability to move, homemade chainsaw sawmills are divided into two types:

The stationary device is a structure made of metal or wooden slats on which the saw is fixed. It has guides along which the logs move. The saw is motionless during operation.

Drawings of a sawmill using a chainsaw photo

Before studying the manufacturing process of the device in question, it is recommended to first make a drawing or diagram. To do this, you will need to initially decide what type of device you need - mobile or portable, as well as home or stationary. Below are several types of sawmill manufacturing schemes that are easy to make at home.

This is the simplest option for making a mobile machine for making boards of different thicknesses.

If the first drawing of a chainsaw sawmill involves the sawyer moving the tool itself along the workpiece, then the second option is more versatile and practical. The tool is mounted on a movable frame, and the workpiece is placed on a flat surface. After this, the required thickness of future boards or beams is set, which is done by raising up or lowering down a tool fixed on threaded slots.

The third option for a sawmill with a chainsaw as a cutting tool is a stationary machine. Making it is much more difficult than the first two, but it greatly simplifies the master’s work. All that is needed from the master cutting at the sawmill is to push the workpiece towards the rotating chain of the chainsaw. Using levers, the required thickness for the boards, which are obtained from the sawn log, is set.

How to make

Let's take a closer look at how to make your own sawmill from a regular chainsaw using the example of a stationary structure.

What you need

For work you will need the following materials:

- Chainsaw.

- Welding machine.

- Square metal pipes.

Manufacturing process

To manufacture the device you will have to perform the following steps:

- Assemble the base of the future sawmill from pipes and angles. There is no need to install the structure immediately. First you need to fold it and check how smoothly all the elements are connected. They do this using a level. Only after this the pipes are connected to each other by welding.

- When the base rectangle is assembled, for greater structural strength it must be strengthened with at least two ties. They can be made from the same metal pipes. The ties are fastened transversely at an equal distance from each other. The best mounting option is bolted.

- Then thinner pipes or metal profiles are welded on top of the pipes from which the base of the structure is assembled. They will serve as guides for the logs being cut and will not allow them to fall off the sawmill. Transverse guides are also welded. Ideally, they should rotate - this will ensure smoother movement of the log and minimize the effort that needs to be applied during operation of the device.

- After the base is completely ready, it is installed on racks. Steel squares are best suited for their role. They are welded in the corners of the base. For greater structural strength, braces can be welded between the posts.

- Afterwards, the trolley for the cutting part is assembled. It is a rectangle of metal pipes supported by two longitudinal steel strips. Between these strips and the walls of the rectangle, two slopes are installed so that the structure is stable. Rollers are placed under the strips, which will ensure the movement of the cutting part along the base. Then another pipe is welded to one of the strips, connecting it to the rectangle on top. This is the attachment point for the saw.

- When the cart is ready, secure the saw. This can be done in a variety of ways. The most common method is to secure the saw body using clamps or metal ties. It is quite reliable and does not cause irreversible damage to the device. If necessary, additional transverse strips are welded to the trolley from the same pipes from which the remaining parts of the structure were made.

Other types of construction

Homemade sawmill made of wood

In general, making a chainsaw sawmill from wood is no fundamentally different from installing a device from a metal profile or pipes. The difference is that wood is used instead. The main advantages of this design are simplicity and speed of assembly, lower cost of materials, and no need for a welding machine.

As for the service life of a wooden sawmill, it is quite high provided that it is protected from rain and other precipitation.

Mobile

To make a mobile sawmill, only a rectangular attachment-limiter is assembled from a metal profile. It is fixed to the chainsaw plate where the chain is attached. The attachment is lowered onto a firmly fixed log and the saw is passed along it. As a result, the board is cut off.

The main advantage of a mobile chainsaw sawmill is that it can be taken anywhere and can be quickly assembled and disassembled.

But it also has one very significant drawback - since it must be constantly held in your hands while working, it is very easy to make a mistake and end up with an uneven board with different thicknesses in different places.

Sawmill from a grinder or circular saw

To make a sawmill, you can use not only a chainsaw, but also a grinder. The device is assembled in exactly the same way. The only difference is that at the end of the base, a grinder with an appropriate attachment or a hand-held circular saw is attached in the center.

The result of making your own sawmill from a chainsaw

If you set a goal to build a mini sawmill for your home, then you need to start first by making a homemade diagram. Based on the diagram, you can begin to implement the idea into reality. Making a mobile machine for sawing boards is not difficult, and every craftsman can handle it. To do this, you need to have on hand the necessary tools in the form of a grinder, a drill and a welding machine, consumables in the form of fasteners, handles and screws, rollers, as well as the main parts - angles, channels, tubes.

Then it's a matter of time and skill. When working at a sawmill, you need to take into account the following: in the design of a chainsaw it is better to use chains made of carbide materials with pobedite or diamond coating on the teeth. This will extend the life of the chains and also eliminate excess stress on the tool when the teeth on conventional chains become dull. It is not recommended to cut logs at low temperatures, since frozen workpieces will dull the teeth of gas-powered tools even faster. Having a chainsaw on your household, you should not limit yourself to its basic functionality, since this tool is capable of performing a lot of useful work, replacing such expensive equipment as a sawmill. What other capabilities does a chainsaw have that can be expanded using special attachments? You can read it in the material.

Owner reviews

Owners of sawmills made from chainsaws note the high efficiency, low cost and ease of installation of the structure. Most reviews about this device are positive.

They talk about the advantages of such an improvised sawmill. Thus, the famous video blogger Maxim Egorov assembled a sawmill from a chainsaw right in the forest. To do this, he used several boards and two roughly processed pine logs. Using the device, he managed to obtain boards in the required quantity, which were intended for the construction of a forest house. Maxim noted the simplicity and efficiency of the design, as well as the ability to quickly transform it back into a chainsaw.

Another video blogger, Mark Didenko, also assembled a similar design. True, he did not use boards for this, but a metal profile. In order for the cart to move smoothly along the base, he attached a gear drive to it, which is driven by rotating the handle. Didenko was also pleased with the assembled device. He noted the low cost of materials as its main advantage - according to the blogger, they cost only 10,000 rubles (not taking into account the cost of the chainsaw itself).

But the author of the blog “Lumberjack” is more critical of the device. He agrees that it can be assembled quickly and cheaply and even tells how he used a homemade one to build his parents' house.

But the blogger also points out two important aspects:

- The saw constantly operates at maximum load, which can lead to engine breakdowns or burnout of the electric motor.

- When using a homemade sawmill there is a very high risk of injury.